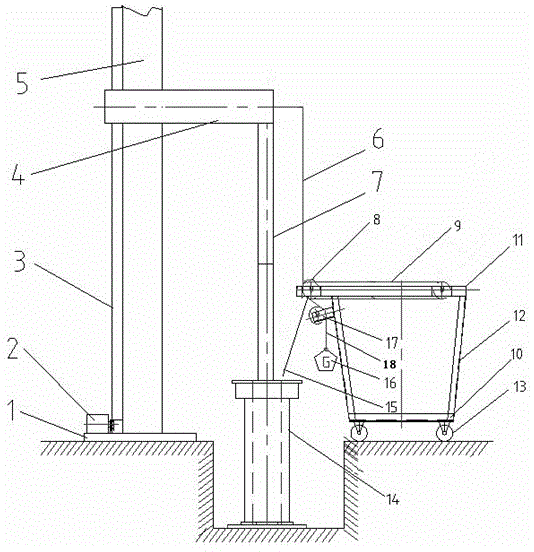

Patents

Literature

44results about How to "Improve smelting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

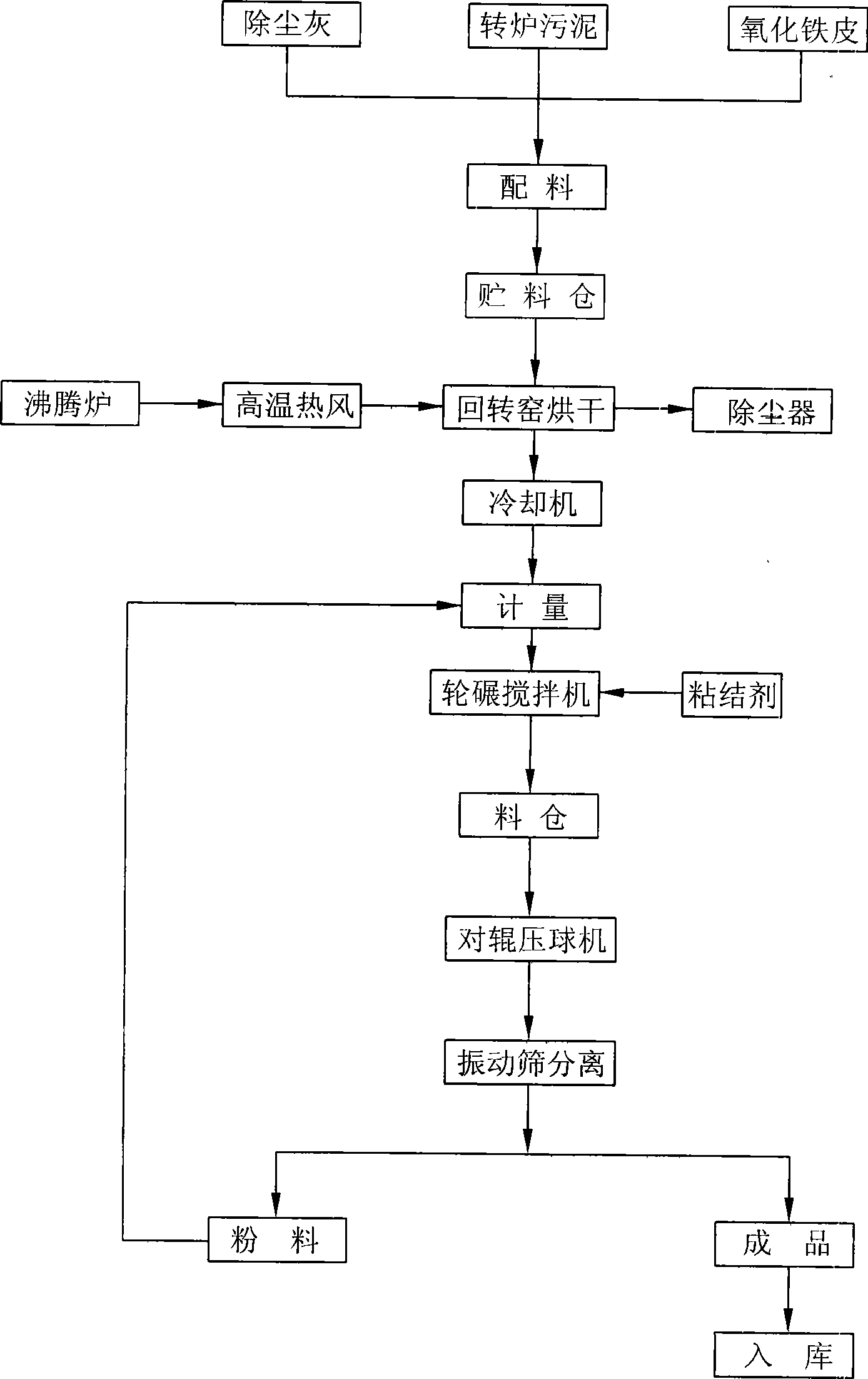

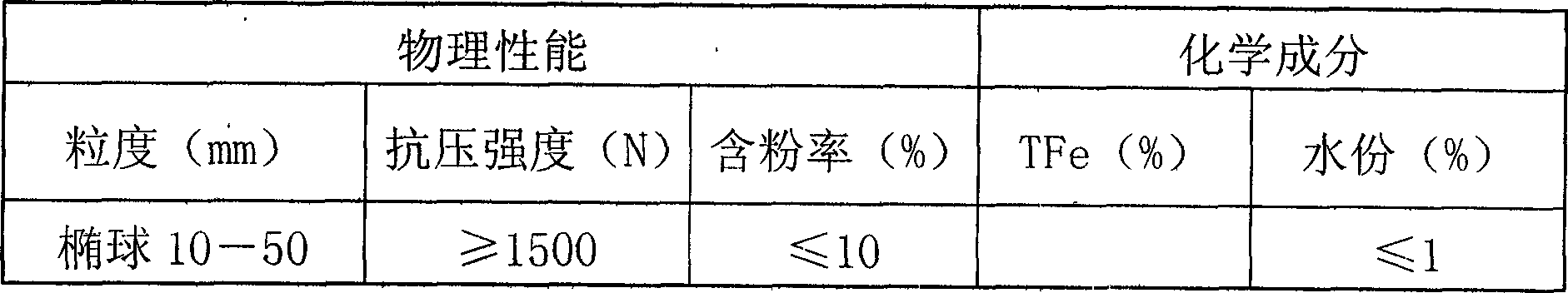

Method for utilizing iron containing metallurgical dust

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

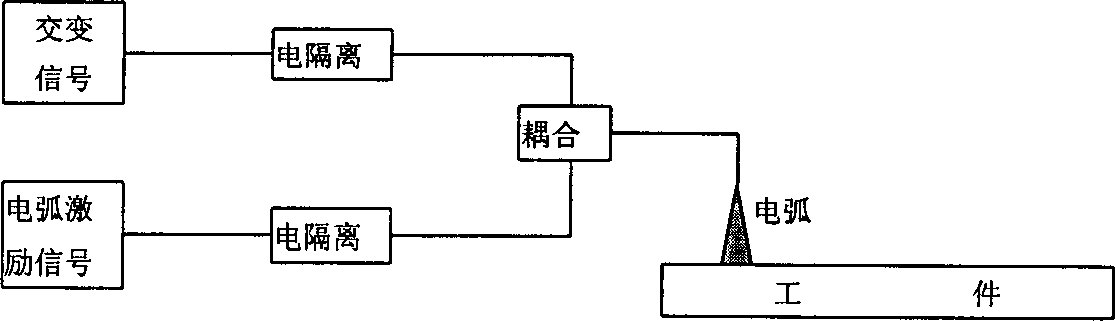

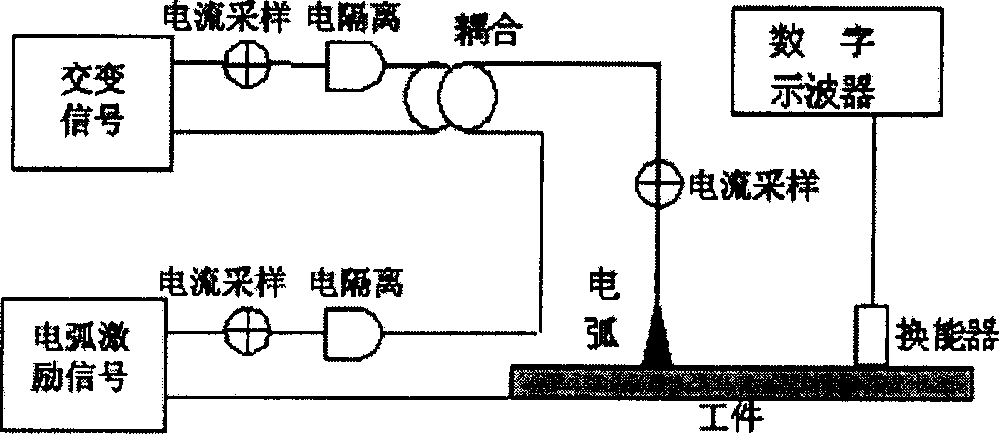

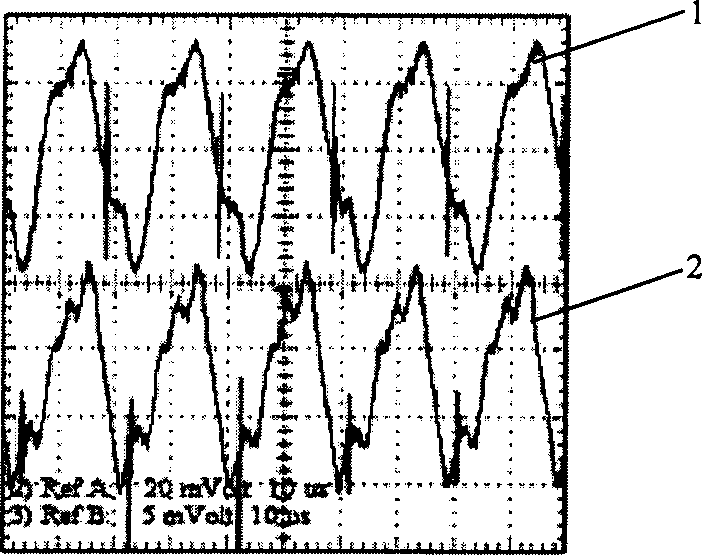

Electric arc method for exciting ultrasonic waves

InactiveCN1355081AControllable wide-spectrum frequency response characteristicsControllable flexibilityArc welding apparatusNon-electric welding apparatusElectricityUltrasound

A method for using electric arc to excite ultrasonic wave includes such steps as electrically isolating alternating signals for guaranteeing safety of circuit, electrically isolating the are exciting signal of electrode for preventing signal interference, coupling the ultrasonic signals with arc exciting signals to obtain arc-ultrasonic exciting signals, and exciting electric arc for arc welding or smelting while modulating the electric arc by the said alternating signals in electric arc to excite ultrasonic waves, so improving the welding effect.

Owner:TSINGHUA UNIV

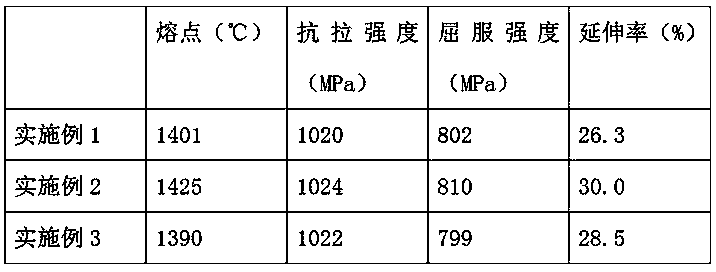

Cobalt-based high-temperature alloy wire and preparation method thereof

InactiveCN110983113ADecreased high temperature strengthImprove high temperature strengthDouble phaseOxidation resistant

The invention provides a cobalt-based high-temperature alloy wire which is prepared from the following chemical components in percent by mass: 0.06-0.12% of C, less than or equal to 0.3% of Si, 1-1.8%of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 19.2-20% of Cr, 9.5-10.5% of Ni, 14.2-15.5% of W, less than or equal to 2.8% of Fe, less than or equal to 0.4% of other impurities and the balance Co. By adding 19.2-20% of Cr, the cobalt-based high-temperature alloy wire has excellent corrosion resistance, and a condition that high-temperature strength is decreased as aresult of a double phase area as the content of Cr is too high to promote generation of an epsilon-Co phase and a sigma phase is avoided. Elements such as massive Co, 14.2-15.5% of W and 19.2-20% ofCr and the like in the cobalt-based alloy can reduce stacking fault energy, so that the high-temperature strength of the alloy is improved. The content of W is controlled at 19.2-20%, so that it is ensured that a condition of prominent work hardening of the alloy, difficulty in cold processing and poor stability as the too high W content is avoided. As the cobalt-based high-temperature alloy wirecontains 9.5-10.5% of Ni, the tissue stability of the alloy is improved favorably, and precipitation of a Co7W6 phase is reduced. By adding 1.1-1.8% of Mn, the oxidation resistance of a Ni-Cr alloy isimproved effectively.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

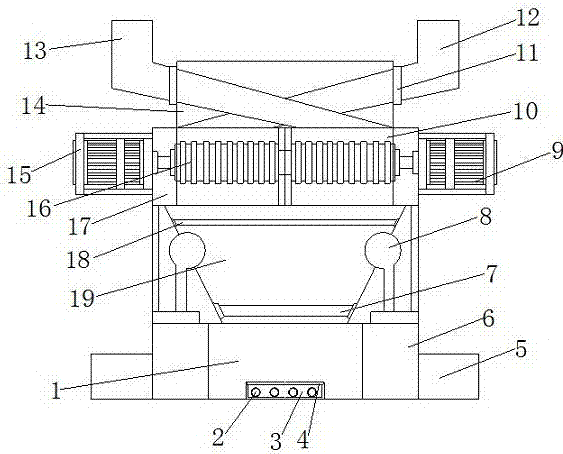

Crushing smelter with better smelting effect

ActiveCN106871644AEasy to reinforcePromote meltingCharge treatment typeFurnace typesCombustorEngineering

The invention discloses a crushing smelter with a better smelting effect. The crushing smelter comprises a smelter body, discharging holes are formed in the obverse side of the smelter body, and burning cavities are formed in the two sides of the smelter body. Burning devices are connected to the outer sides of the burning cavities, a discharging cavity is connected to the top of the smelter body, and a crushing cavity is connected to the top of the discharging cavity. A crushing idler wheel is arranged in an inner cavity body of the crushing cavity and connected with a rotary motor arranged outside the crushing cavity through a wheel shaft, a feeding cavity is connected to the top of the crushing cavity, and a left feeding pipe and a right feeding pipe which are connected with the top of the crushing cavity are installed on an inner cavity of the feeding cavity in a staggered mode. The crushing smelter with the better smelting effect is provided with the crushing cavity and the crushing idler wheel on the whole so that input large metal waste materials can be crushed and pressed, and the large metal waste materials are changed into small metal waste materials, so that smelting operation is convenient to conduct, and the metal waste materials are quickly and conveniently smelted.

Owner:XINGHUA SANQIANG MACHINERY MFG CO LTD

Method for producing low phosphorus steel or extra-low phosphorus steel by using limestone slagging-single slagging method

ActiveCN107574281AEasy to masterImprove smelting performanceManufacturing convertersProcess efficiency improvementSteelmakingAlkalinity

The invention provides a method for producing low phosphorus steel or extra-low phosphorus steel by using a limestone slagging-single slagging method, and belongs to the technical field of steelmaking. The method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging comprises the steps that when slagging is conducted by using limestone, the oxygen consumption range of ton steel is controlled in 40-65 cubic meters, and the total adding amount of ton steel, the limestone and dolomite is 40-100 kg; the dolomite is about 1 / 4-1 / 5, accordingto converter capacity, the oxygen supplying intensity is controlled at 2-5 cubic meter / cent.ton steel, the alkalinity of final slag is controlled at 3. 0-6. 0, and the oxygen lance position is controlled within about 50% range of the decarbonization gun position; the furnace atmosphere is adjusted, the molten slag temperature is controlled between 1450-1630 DEG C, the adding batch of the limestone is controlled at 2-20 times, the eight of each batch of limestone is 30-0.5 kg / ton steel, and molten iron can be efficiently dephosphorized; and the single slagging method can produce low phosphorussteel or extra-low phosphorus steel. According to the method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging, the goal of dephosphorization can be achieved by easy operating, resources and energy can also be reduced, and workers easily master the method for producing low phosphorus steel or extra-low phosphorus steel by using the limestone slagging-single slagging.

Owner:UNIV OF SCI & TECH BEIJING

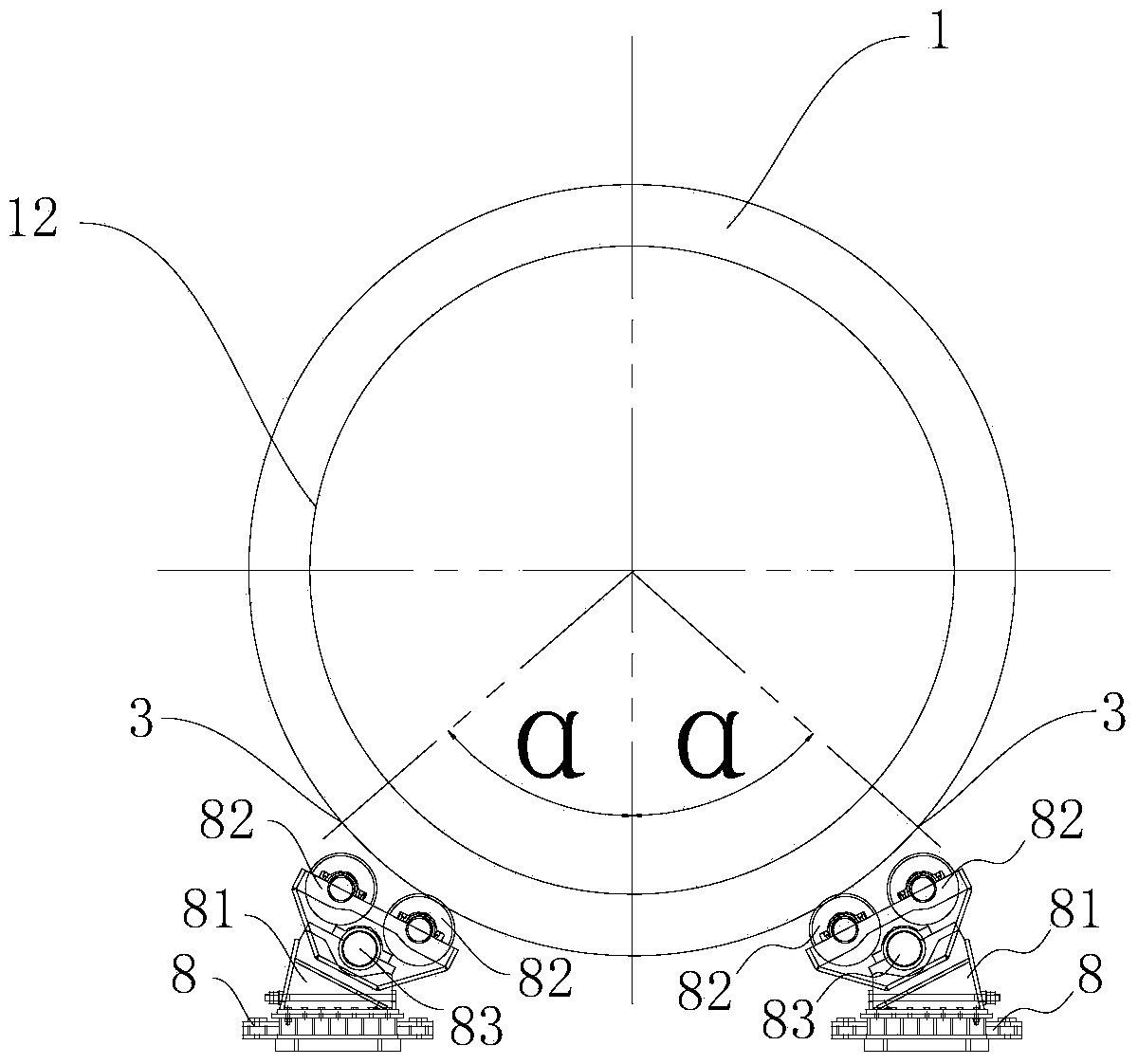

Bottom blowing or side blowing metallurgical furnace for treating scrap copper

InactiveCN103468971AImprove convenienceRapid responseProcess efficiency improvementScrapHeating efficiency

The invention discloses a bottom blowing or side blowing metallurgical furnace for treating scrap copper, which comprises bearings, a horizontal cylindrical furnace body, bottom blowing or side blowing spray guns, a burner and a driving part, wherein the horizontal cylindrical furnace body can be supported on the bearings in a 360-degree rotation manner; feed ports, a copper outlet and a slag hole are formed in the side face of the horizontal cylindrical furnace body, respectively; the horizontal cylindrical furnace body is provided with a smoke outlet and a nozzle port; and reductant-oxidant injection ports and air bricks are formed and arranged at the bottom or the side part of the horizontal cylindrical furnace body. The bottom blowing or side blowing spray guns are used for injecting oxygen-containing gas and natural gas, oil or powdered coal into the horizontal cylindrical furnace body, and inserted into the reductant-oxidant injection ports. A burner is mounted at the nozzle port. The driving part is connected with the horizontal cylindrical furnace body to drive the horizontal cylindrical furnace body to rotate. The bottom blowing or side blowing metallurgical furnace for treating the scrap copper is simple in structure, good in environmental protection property and high in heat efficiency.

Owner:CHINA ENFI ENGINEERING CORPORATION

Smelting furnace of non-ferrous metals oxygen side blow fused bath

The invention discloses a nonferrous metal oxygen side-blown molten pool smelting furnace and relates to extraction of a nonferrous metal. The invention provides a nonferrous metal oxygen side-blown molten pool smelting furnace applicable to smelting of copper, nickel and other nonferrous metal minerals. The technical proposal of the invention is that a nonferrous metal oxygen side-blown molten pool smelting furnace includes a furnace crucible, a water jacket, a feed opening, a smoke vent and an air opening; one furnace bottom is high and the other is low; an inclined surface is arranged between the high and the low furnace bottoms; a partition wall is arranged in a siphon well out of the wall on the front end of the furnace for separating the siphon well into a slag siphon well and a metal siphon well; a channel is arranged between the partition wall and the furnace bottoms for communicating the two siphon wells; the upper end of the slag siphon well is provided with a slag tap; the upper end of the metal siphon well is provided with a metal liquid discharge opening. The invention is used for smelting the nonferrous metal.

Owner:新乡县中联金铅有限公司

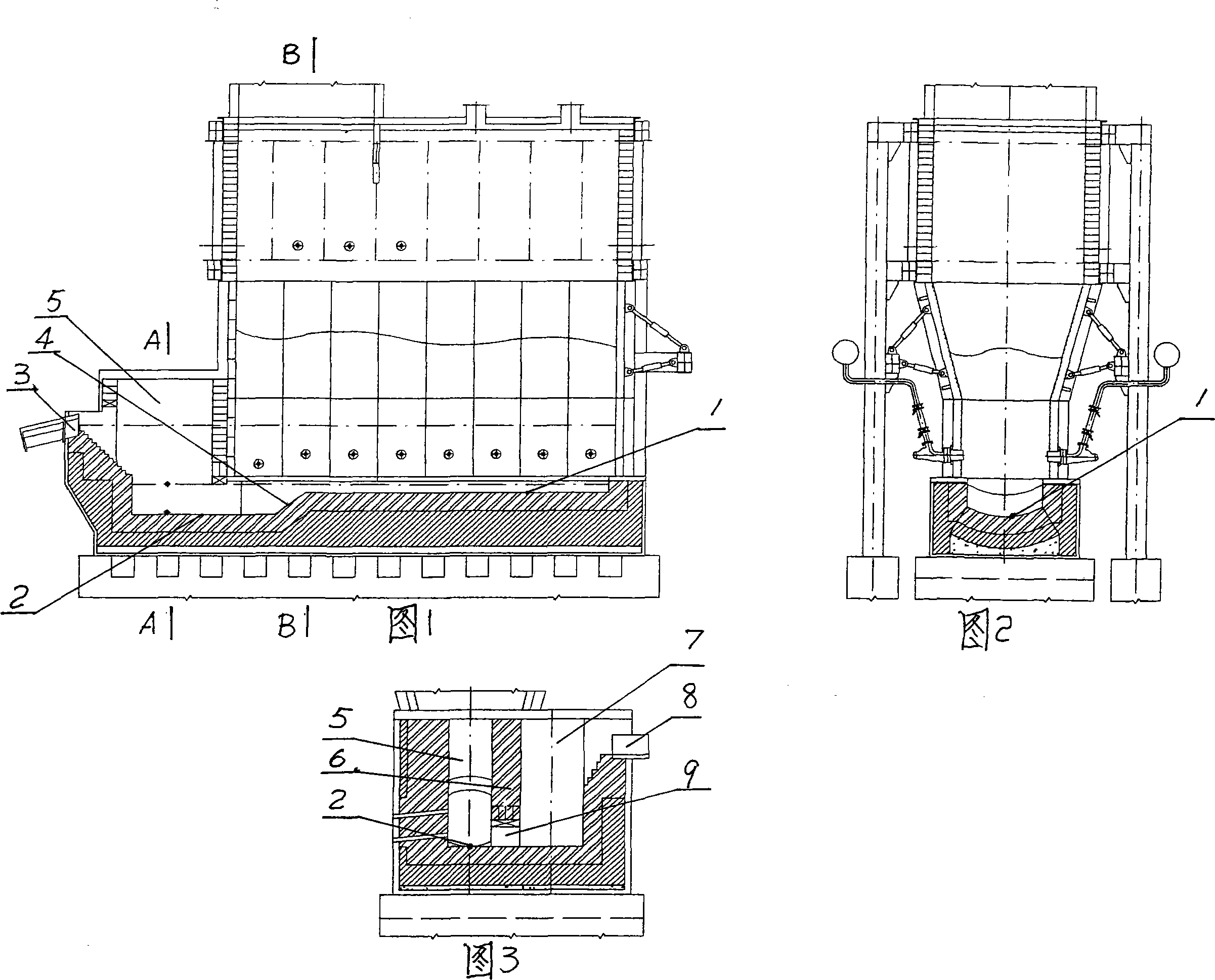

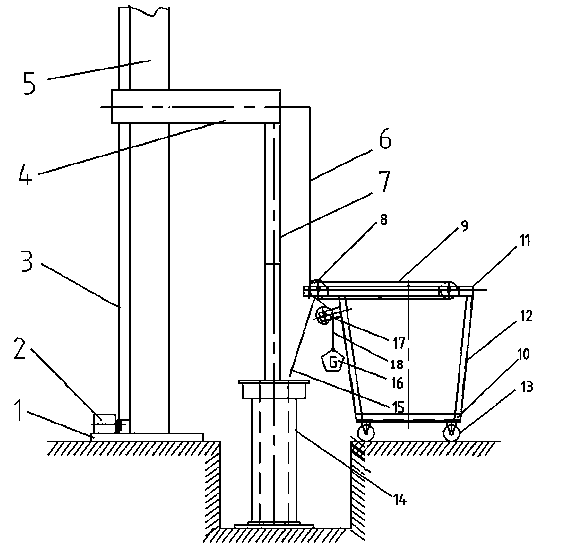

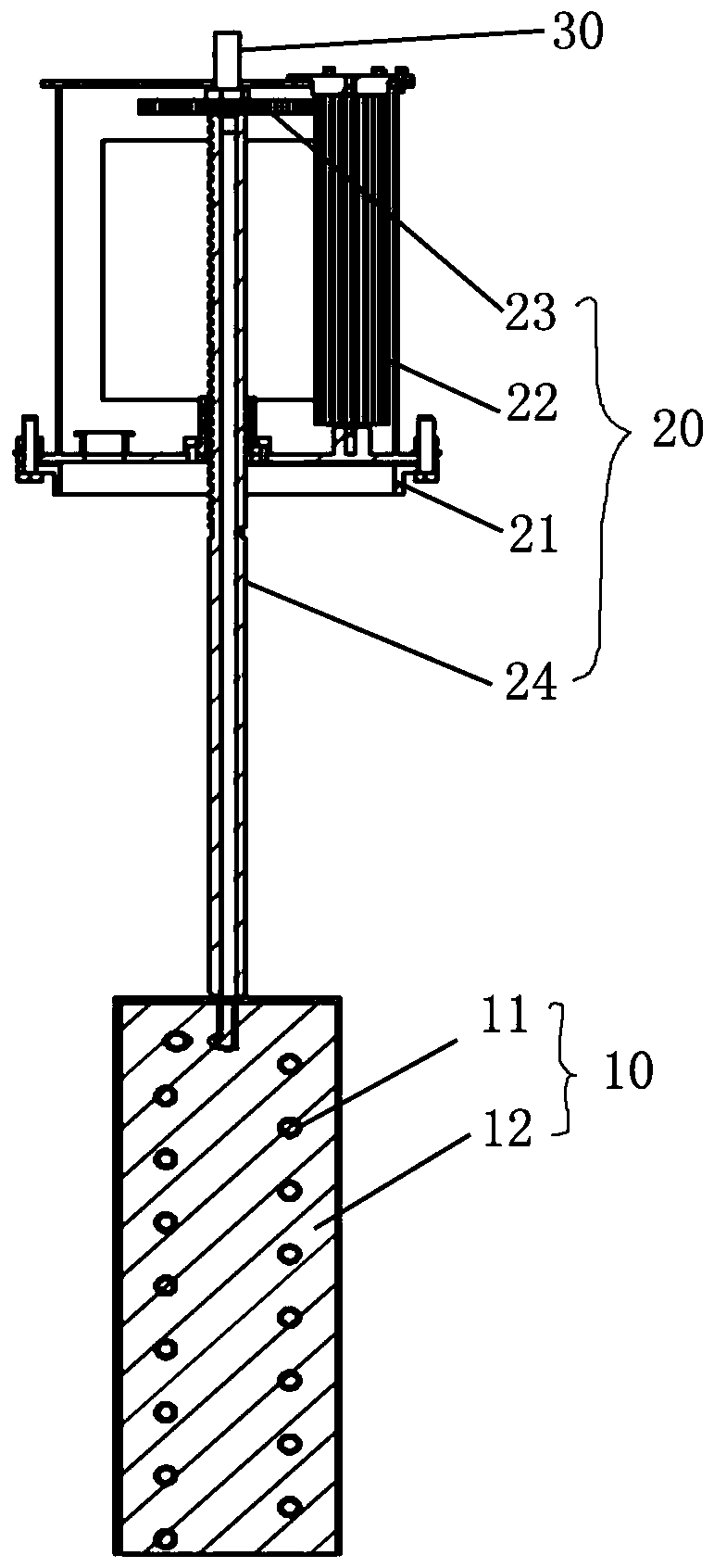

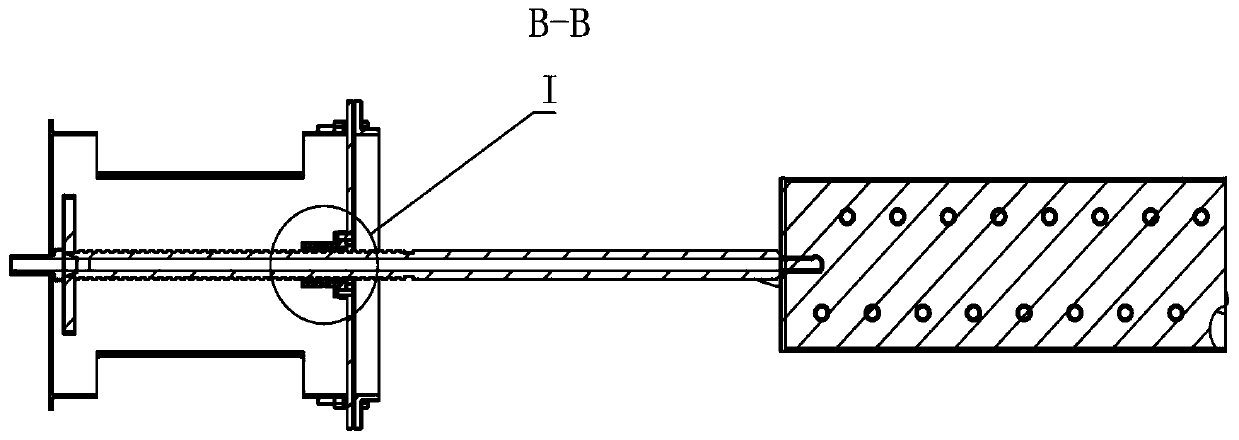

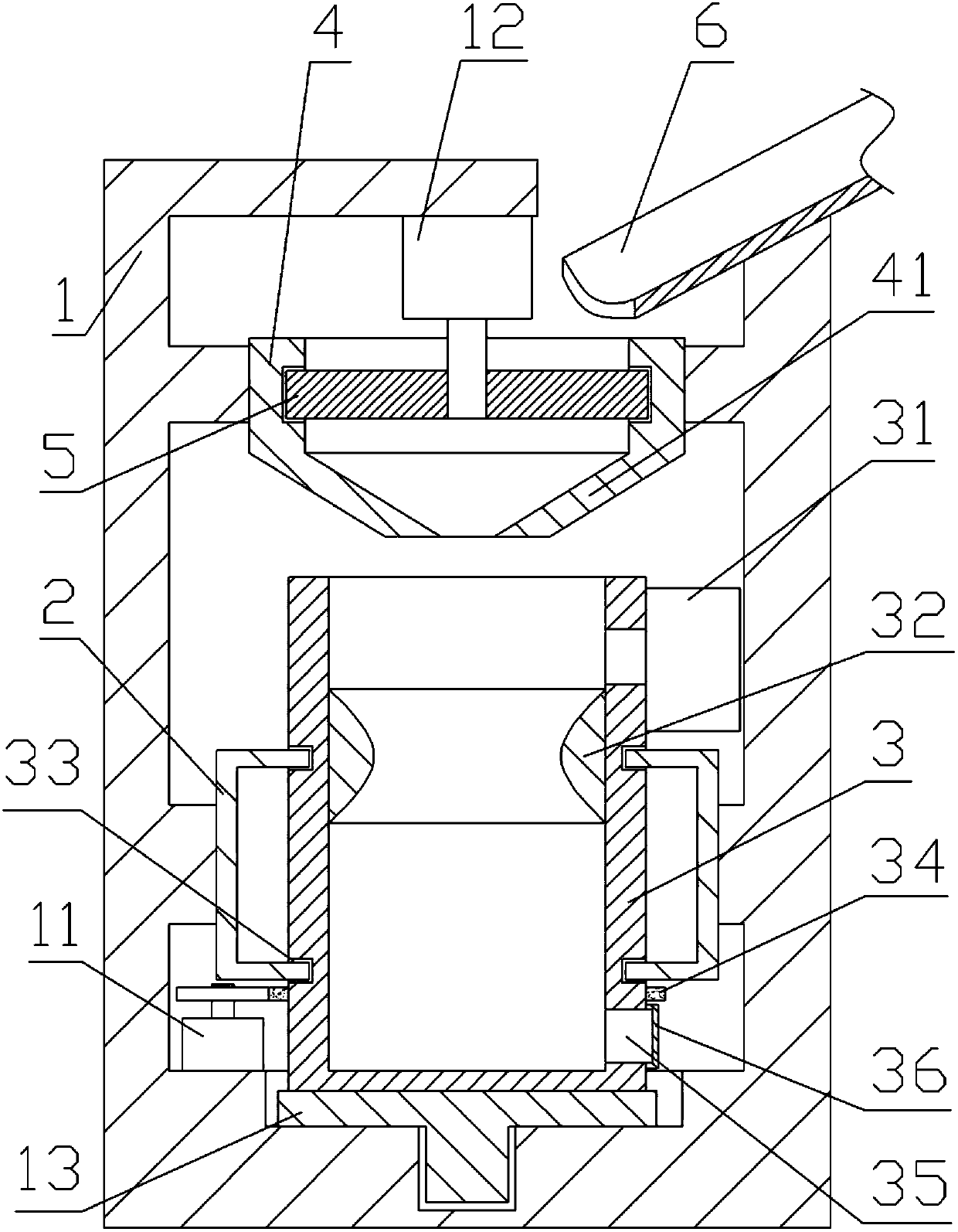

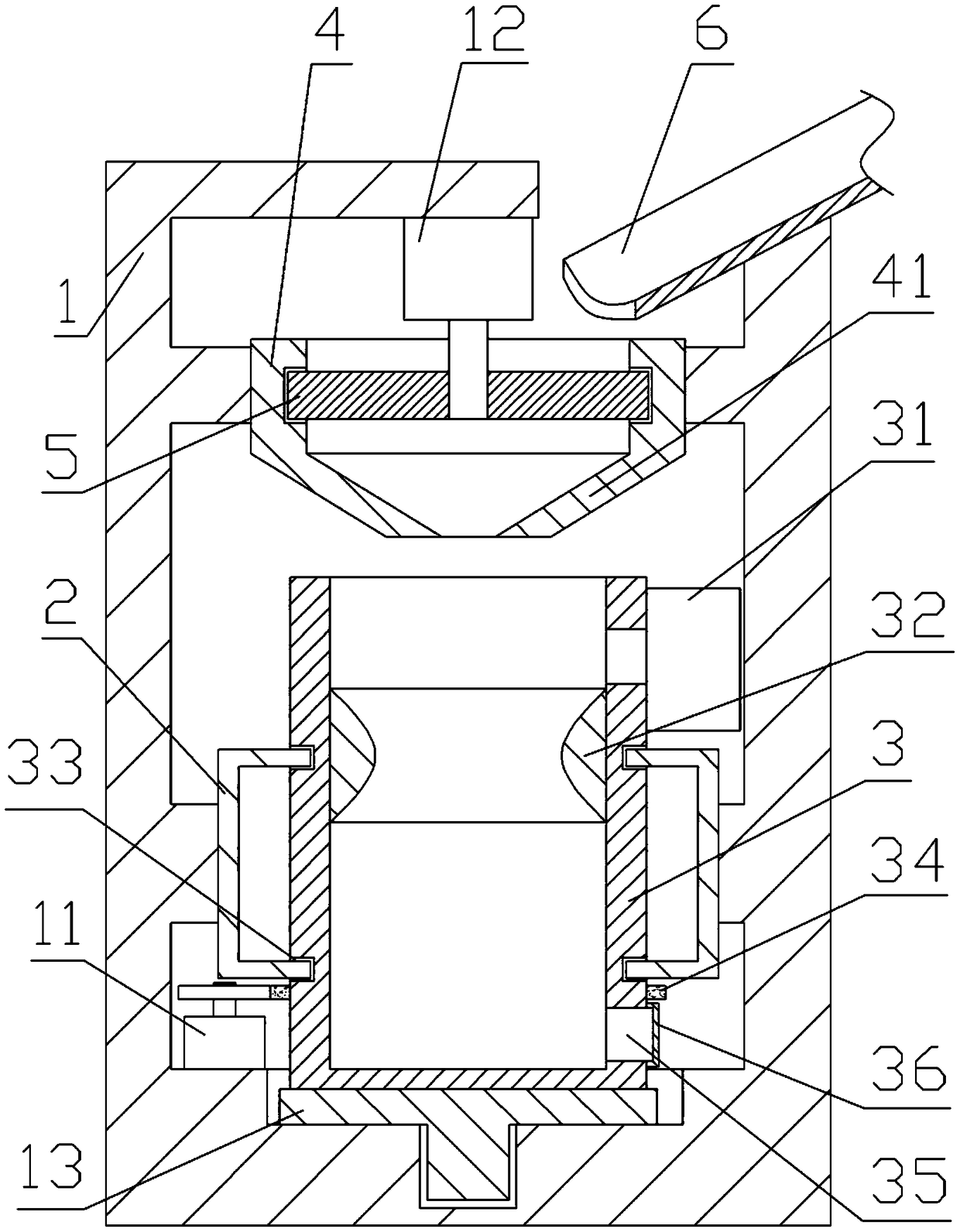

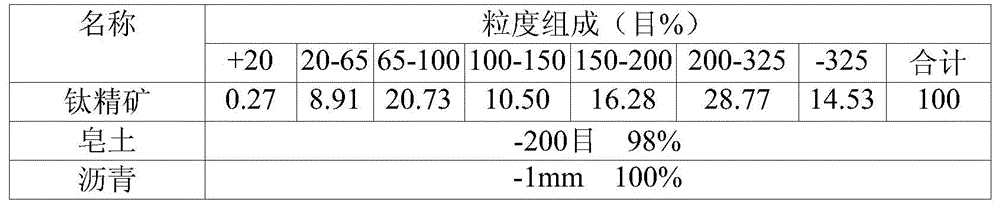

Metal electroslag remelting and smelting equipment

The invention discloses metal electroslag remelting and smelting equipment comprising a crystallizer and an upright post, wherein the whole crystallizer is furnace-shaped and is located in a crystallizer mounting groove; and the upright post is located at one side of the crystallizer mounting groove, a horizontal cantilever is arranged above the upright post and is provided with an electrode dead against the crystallizer by virtue of an electrode holder, and the electrode downwards extends to enter the crystallizer. The metal electroslag remelting and smelting equipment is characterized by also comprising an automatic auxiliary material feeding device located at the side of the crystallizer, wherein the automatic auxiliary material feeding device comprises a discharging part structure and a power control part structure. The metal electroslag remelting and smelting equipment has the advantages that the structure is simple, auxiliary materials can be automatically fed during smelting, the auxiliary material feeding control process is stable and reliable, and the smelting effect is good.

Owner:宝武特冶航研科技有限公司

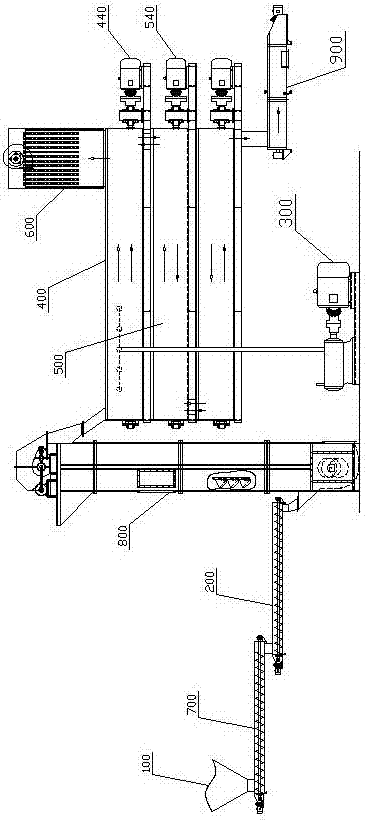

Quick lime hydrator

The invention provides a quick lime hydrator, which belongs to the technical field of slaked lime preparation equipment. In order to solve the problem of mixing nonuniformity caused by inappropriate mixing ratio of quick lime and water in an existing quick lime hydrator, the hydrator comprises a stock bin for placing the quick lime, a metering screw conveyer for conveying the quick lime and accomplishing metering work, a metering water pump connected with an external water source, a primary spiral stirrer and a secondary spiral stirrer for mixing the quick lime and the water, and a dust collection device for absorbing dust and water vapor generated during hydration reaction of the quick lime and the water, wherein the metering screw conveyer is communicated with the stock bin; the primary spiral stirrer and the secondary spiral stirrer are arranged up and down in parallel; the primary spiral stirrer is respectively communicated with the metering screw conveyer and the secondary spiral stirrer; the water spray end of the metering water pump stretches into the primary spiral stirrer and relatively gets close to the metering screw conveyer; the metering water pump starts to spray water when the quick lime enters the primary spiral stirrer; the dust collection device is communicated with the primary spiral stirrer.

Owner:肥城汇立机械有限公司

Method for remelting and smelting metal electro slag

The invention discloses a method for remelting and smelting metal electro slag. The electro slags are placed into a crystallizer, an electrode is inserted from an upper position, then the electrode is energized to enable the electrode, the electro slags and short net guide wires in the crystallizer to be switched on to form a current loop, and during the energizing, joule heat is discharged by the electrode and a slag pool, metal slag in the slag pool are molten, the molten metal is converged into a liquid state to flow through the slag pool to fall into the crystallizer to form a metal molten pool, and then the metal molten pool is solidified to form steel ingots; at the same time, during the smelting, auxiliary materials using aluminum particles as the main bodies are added, and the deoxygenation is carried out. The method is characterized in that during the smelting, the electrode is firstly inserted into the upper positions of the electro slags, the electro slags start to melt to fall into the crystallizer to form the metal molten pool, the electrode is controlled to slowly move downwards to be smelted, and the auxiliary materials are continuously and uniformly fed in a linkage control manner when the electrode move downwards. The method has the advantages of low cost, easy implement, automatic feeding of the auxiliary materials during smelting, stable and reliable feeding control process of the auxiliary materials, good smelting effect and the like.

Owner:宝武特冶航研科技有限公司

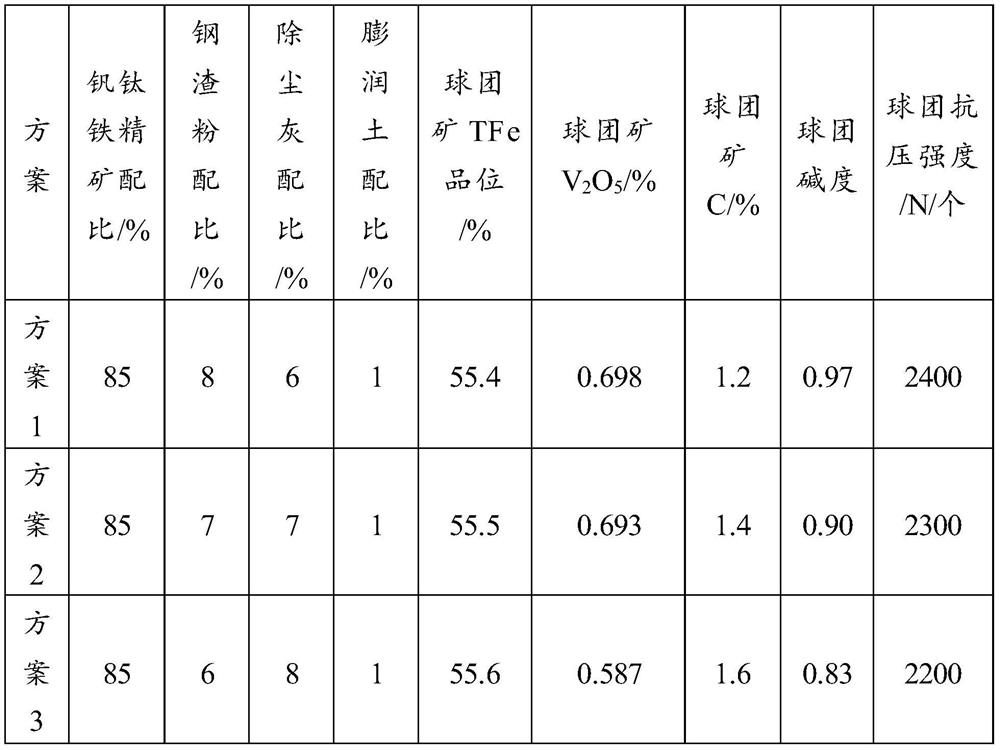

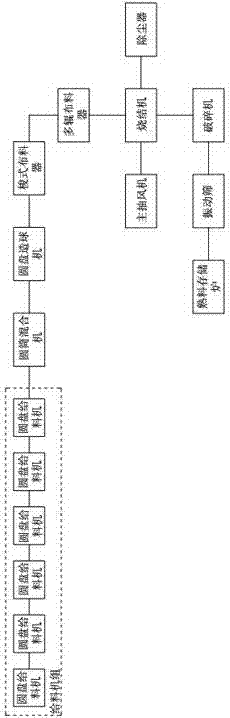

High-grade vanadium-titanium pellet and preparation method of high-grade vanadium-titanium pellet

The invention provides a high-grade vanadium-titanium pellet. The high-grade vanadium-titanium pellet is prepared from a high-grade vanadium-titanium-iron concentrate, steel slag powder, fly ash and bentonite. The invention further provides a preparation method of the high-grade vanadium-titanium pellet. According to the high-grade vanadium-titanium pellet, iron and carbon in iron-making fly ash and iron, CaO and V2O5 in steelmaking steel slag are utilized, reasonable utilization of secondary resources is achieved, a positive effect is achieved on reduction of an iron-making production cost, and actual production results show that the vanadium-titanium pellet contains 57%-60% of TFe, 8%-12% of TiO2 and 0.6%-0.9% of V2O5, and a roasted pellet compressive strength reaches 2,000-2,500 N / pellet.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

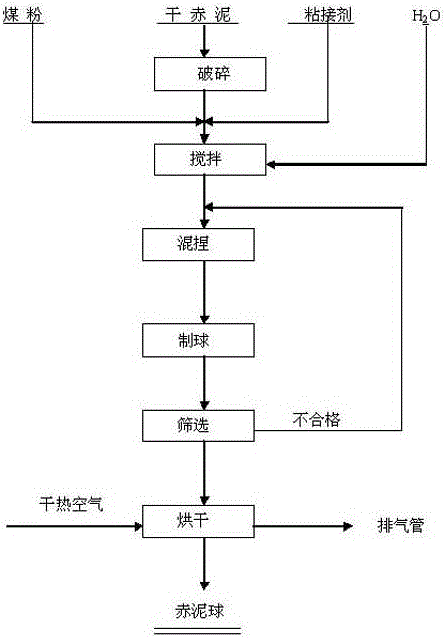

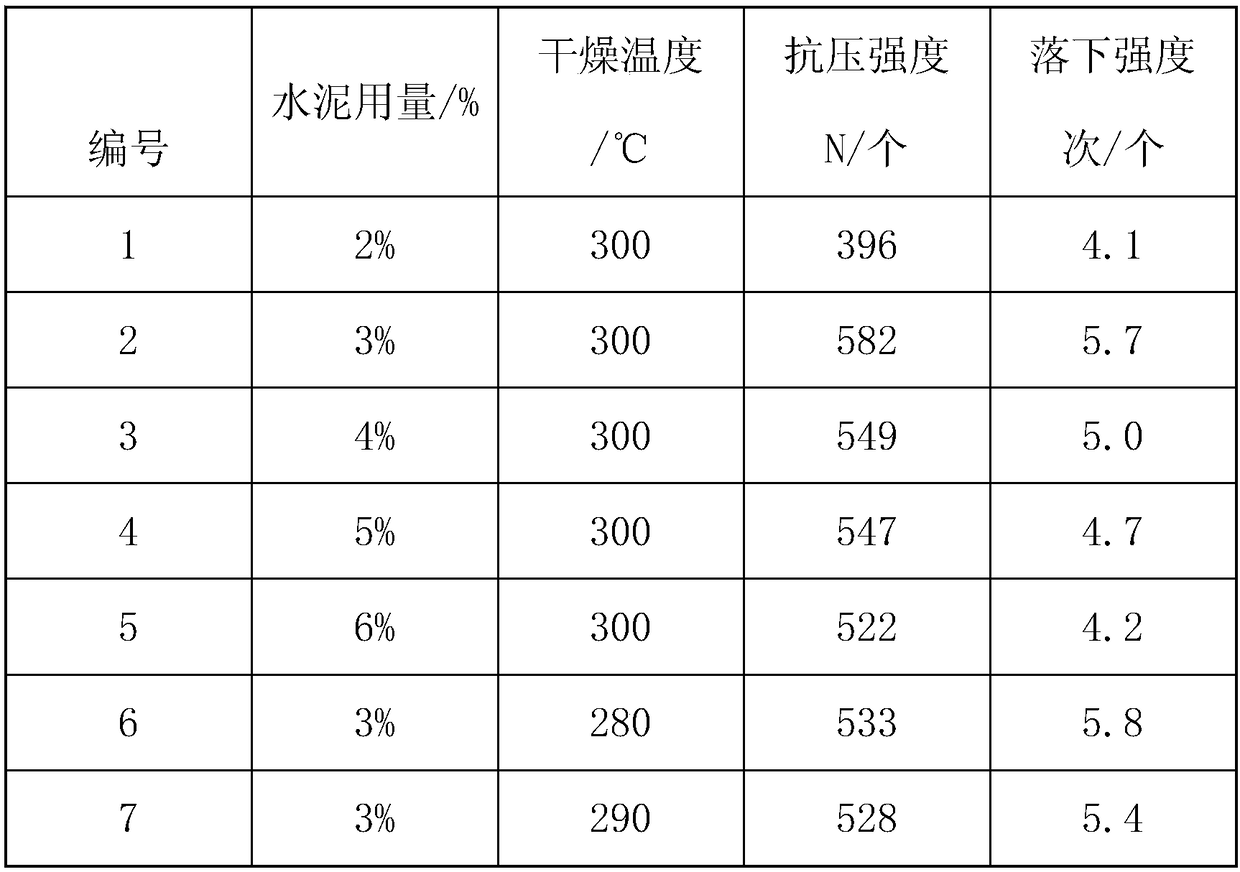

A kind of red mud pellet and preparation method thereof

The invention provides red mud pellets and a preparation method thereof. The red mud pellets are prepared from the following raw materials in parts by weight: 80-120 parts of red mud, 3-10 parts of coal powder, 0.2-1 part of organic adhesive or 5-20 parts of inorganic adhesive, and 15-20 parts of water. The preparation method comprises the following steps: crushing the red mud, adding the coal powder and adhesive, gradually adding water in the stirring process, uniformly mixing, kneading in a kneading machine, extruding into pellets through pair rollers, and finally, drying the red mud pellets. The method has the advantages of simple technique and feasible operation, implements comprehensive utilization of red mud, reduces the associated cost of red mud stacking, and eliminates the influence and accident potential on the environment due to red mud stacking.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Red mud pellets and preparation method thereof

The invention provides red mud pellets and a preparation method thereof. The red mud pellets are prepared from the following raw materials in parts by weight: 80-120 parts of red mud, 3-10 parts of coal powder, 0.2-1 part of organic adhesive or 5-20 parts of inorganic adhesive, and 15-20 parts of water. The preparation method comprises the following steps: crushing the red mud, adding the coal powder and adhesive, gradually adding water in the stirring process, uniformly mixing, kneading in a kneading machine, extruding into pellets through pair rollers, and finally, drying the red mud pellets. The method has the advantages of simple technique and feasible operation, implements comprehensive utilization of red mud, reduces the associated cost of red mud stacking, and eliminates the influence and accident potential on the environment due to red mud stacking.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

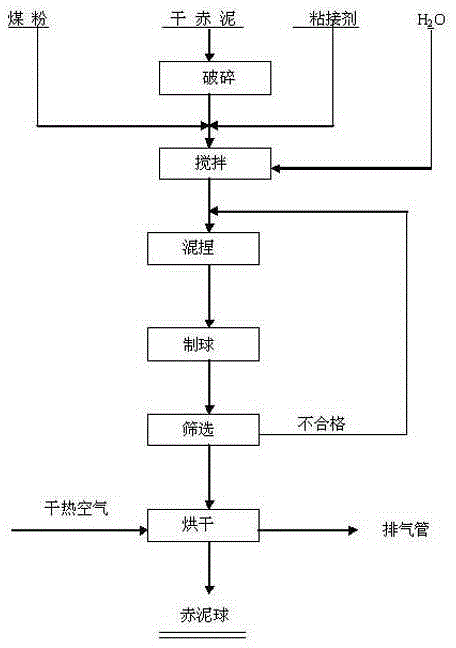

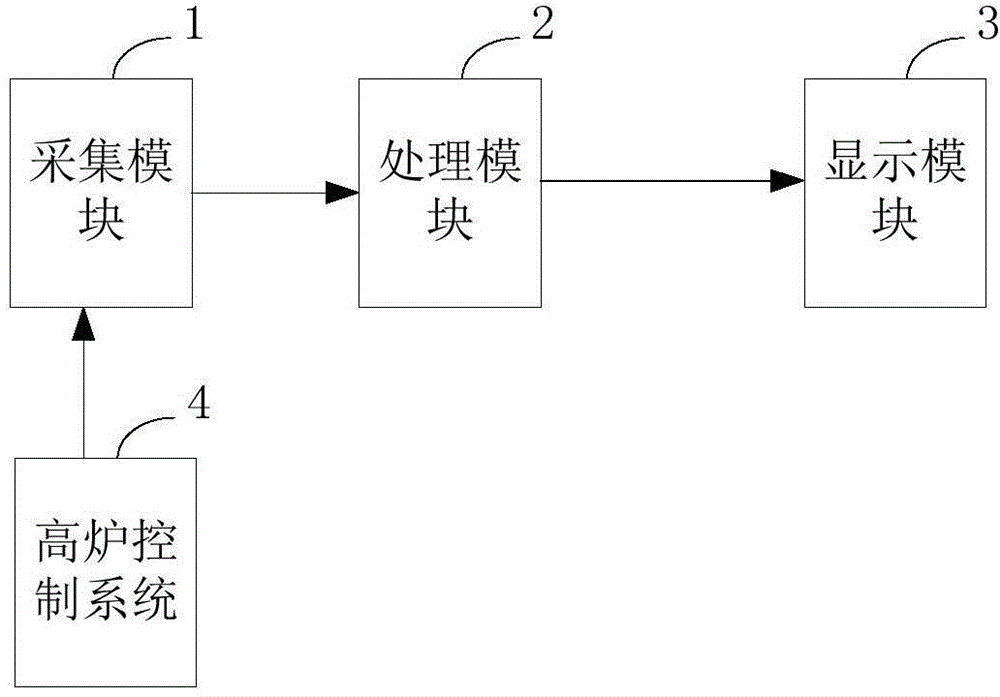

System for tracking data in blast furnace

InactiveCN104898626AEasy to monitor in real timeGood for mastering smelting conditionsProgramme total factory controlControl systemLayer thickness

The invention provides a system for tracking data in a blast furnace. The system includes an acquisition module suitable for acquiring furnace burden data to be tracked in a database in a blast furnace control system; a processing module suitable for calculating burden batch position and burden layer thickness according to charging parameter sub information and system parameter information so as to generate a burden batch position information mirror image in the blast furnace, and calculating time for burden batch to arrive at a tuyere in the blast furnace so as to generate a core parameter tendency chart according to the time for the burden batch to arrive at the tuyere in the blast furnace and core parameter sub information; and a display module suitable for displaying correlated information of the burden batch position information, the core parameter tendency chart and burden batch parameter information when searching content is one or a plurality of kinds of information selected from the burden batch position information, the core parameter tendency chart and burden batch parameter information. According to the system, the furnace burden data in the blast furnace is tracked; the mirror image is generated according to the furnace burden data; the burden batch position information, the core parameter tendency chart and burden batch parameter information are correlated to each other; and when the data in the blast furnace are searched or observed, combination display can be realized, and the efficiency of real-time tracking and observation of the furnace burden data can be improved.

Owner:CISDI ENG CO LTD

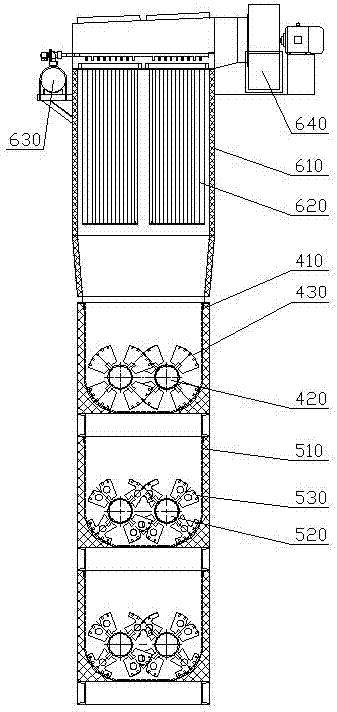

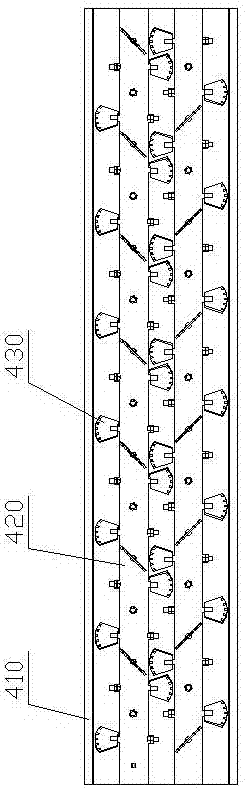

High-speed mixing equipment for metallurgical powder of engine rotating part

ActiveCN111330479AWell mixedUniform particle sizeTransportation and packagingRotary stirring mixersEngineeringMechanical engineering

The invention discloses high-speed mixing equipment for metallurgical powder of an engine rotating part. The equipment comprises a mixing box and a discharging mechanism, the discharging mechanism ismounted below the mixing box, three groups of loading cavities are formed in the mixing box, a plurality of mixing cavities are formed in each loading cavity from top to bottom, a mixing mechanism isinstalled in each mixing cavity, a fourth rotating shaft is rotatably installed on the upper part in each mixing cavity, a plurality of second mixing rods and a plurality of third rotating shafts areinstalled outside the fourth rotating shafts, the third rotating shafts are rotatably installed outside the second mixing rods, and a plurality of cutting knives are connected to the exteriors of thethird rotating shafts in a staggered mode; second rotating shafts drives a plurality of external crushing cutters to cut falling raw materials, and the extruded raw materials are cut and crushed, so that one particle contains a variety of different raw materials, and the variety of raw materials are mixed more uniformly. And the influence of inconsistent particle sizes and inconsistent weights ofthe various raw materials on mixing is reduced.

Owner:广东华于科技股份有限公司

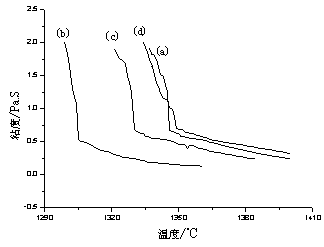

Process for preparing compound slag agent by silicon-manganese alloy fly ash

The invention discloses a process for preparing a compound slag agent by silicon-manganese alloy fly ash. The process comprises the following steps: (1) adding 0.5-6% of a binder and 0.5-5% of an additive by mass percent into silicon-manganese alloy fly ash, then adding CaO to regulate the binary basicity to be 1-3.5, and performing uniform mixing to obtain a product A; (2) adding water into the product A for pelletizing to obtain a product B; (3) placing the product B at normal temperature for drying for at least 24 h, and then performing drying for 2-4 h at 250-300 DEG C to obtain the compound slag agent. The obtained compound slag agent has the advantages of high strength, low melting point and appropriate viscosity, and has the characteristics that the recovery rate and the added valueof fly ash can be improved.

Owner:GUIZHOU UNIV

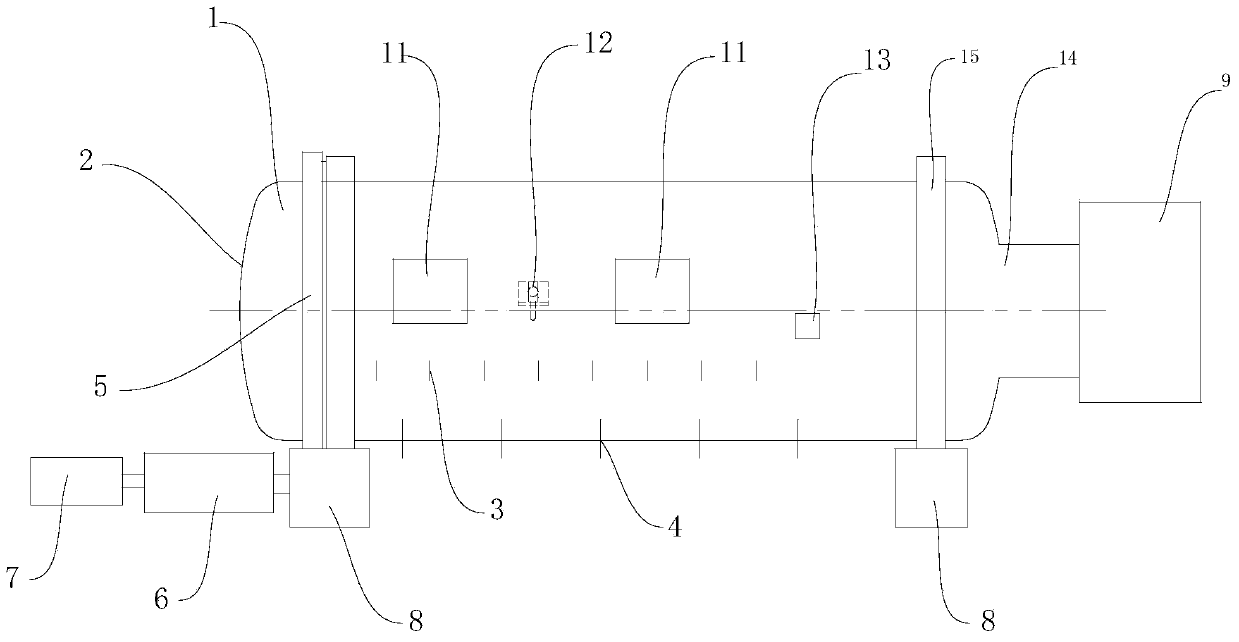

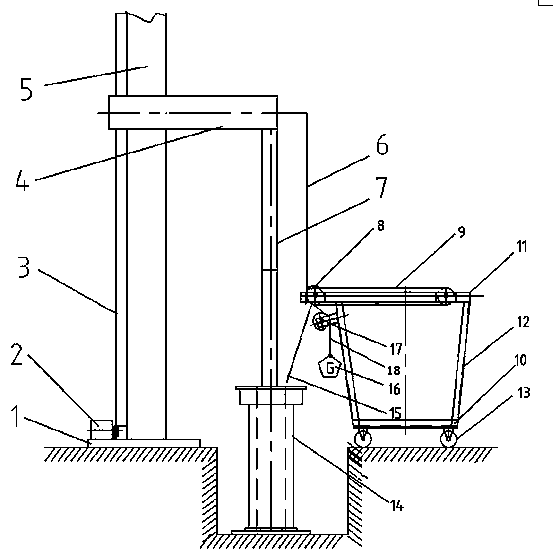

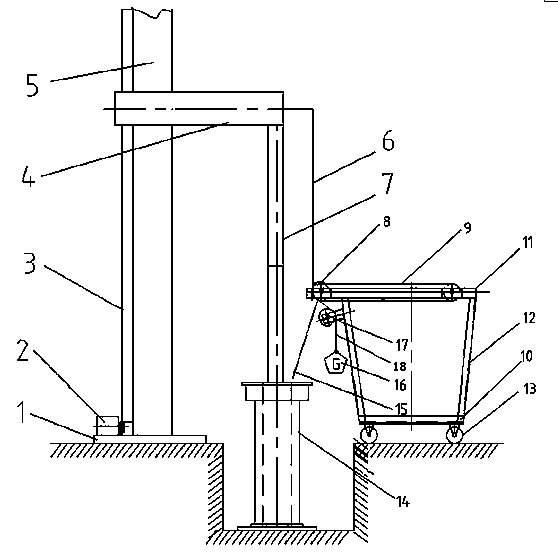

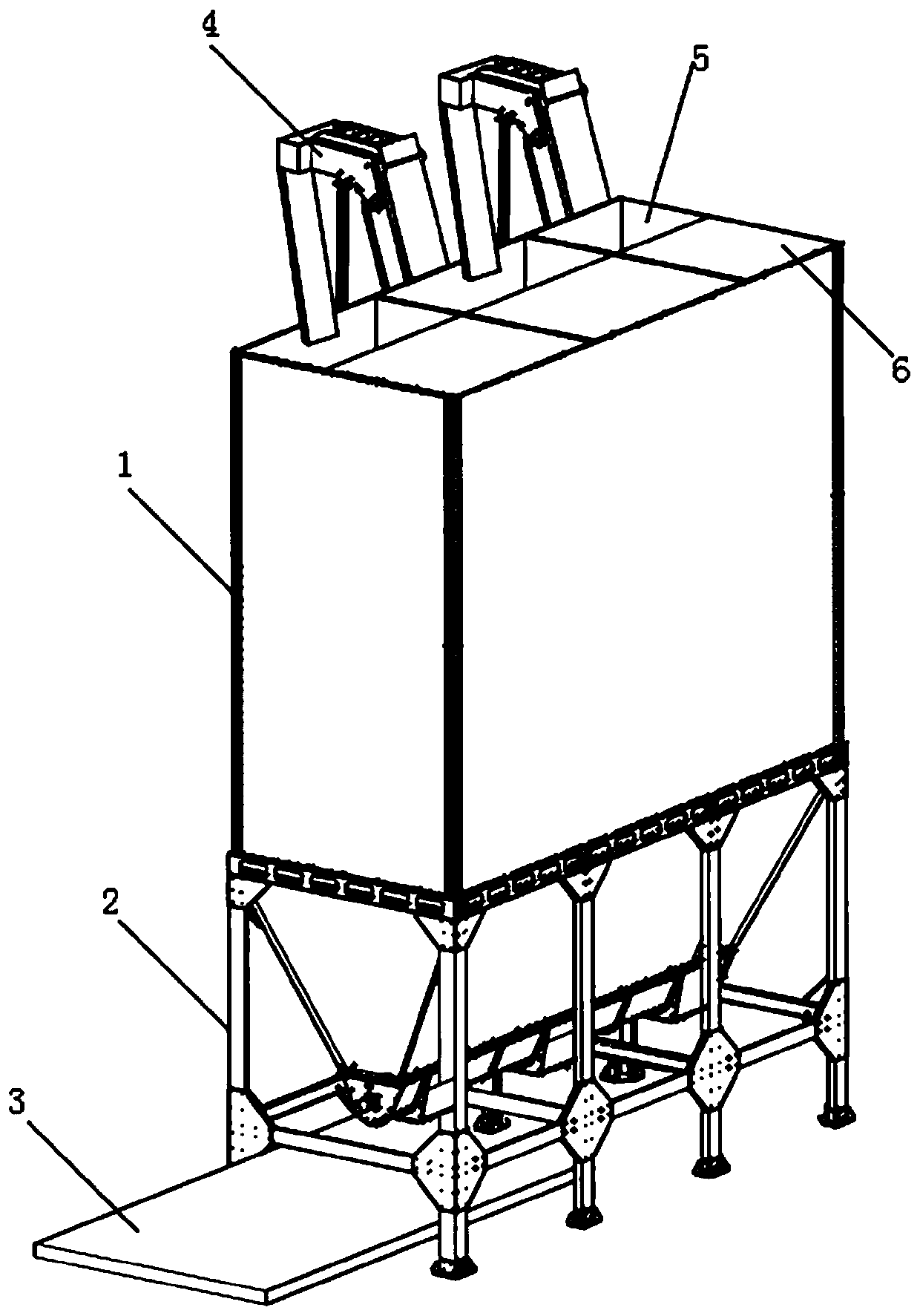

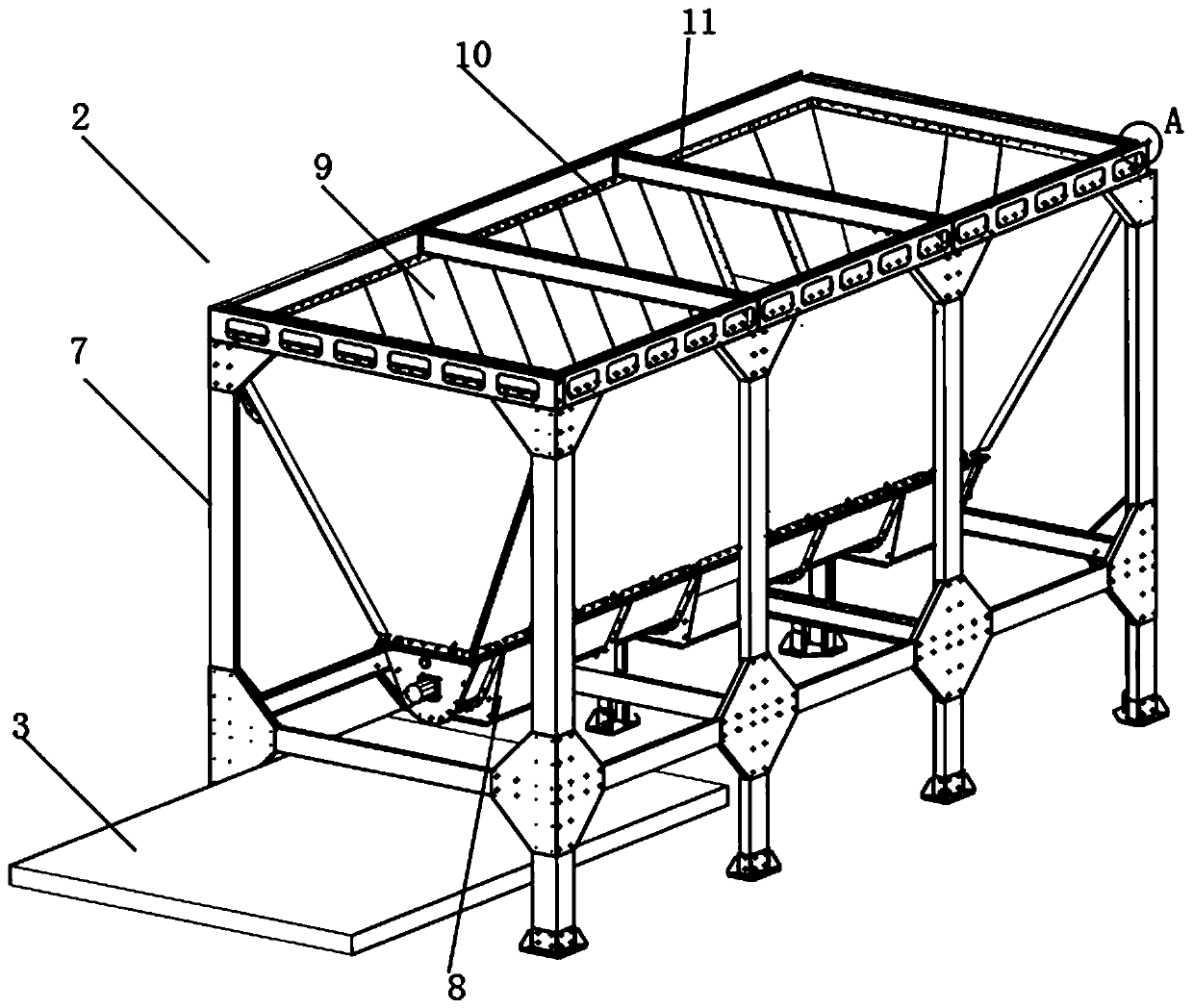

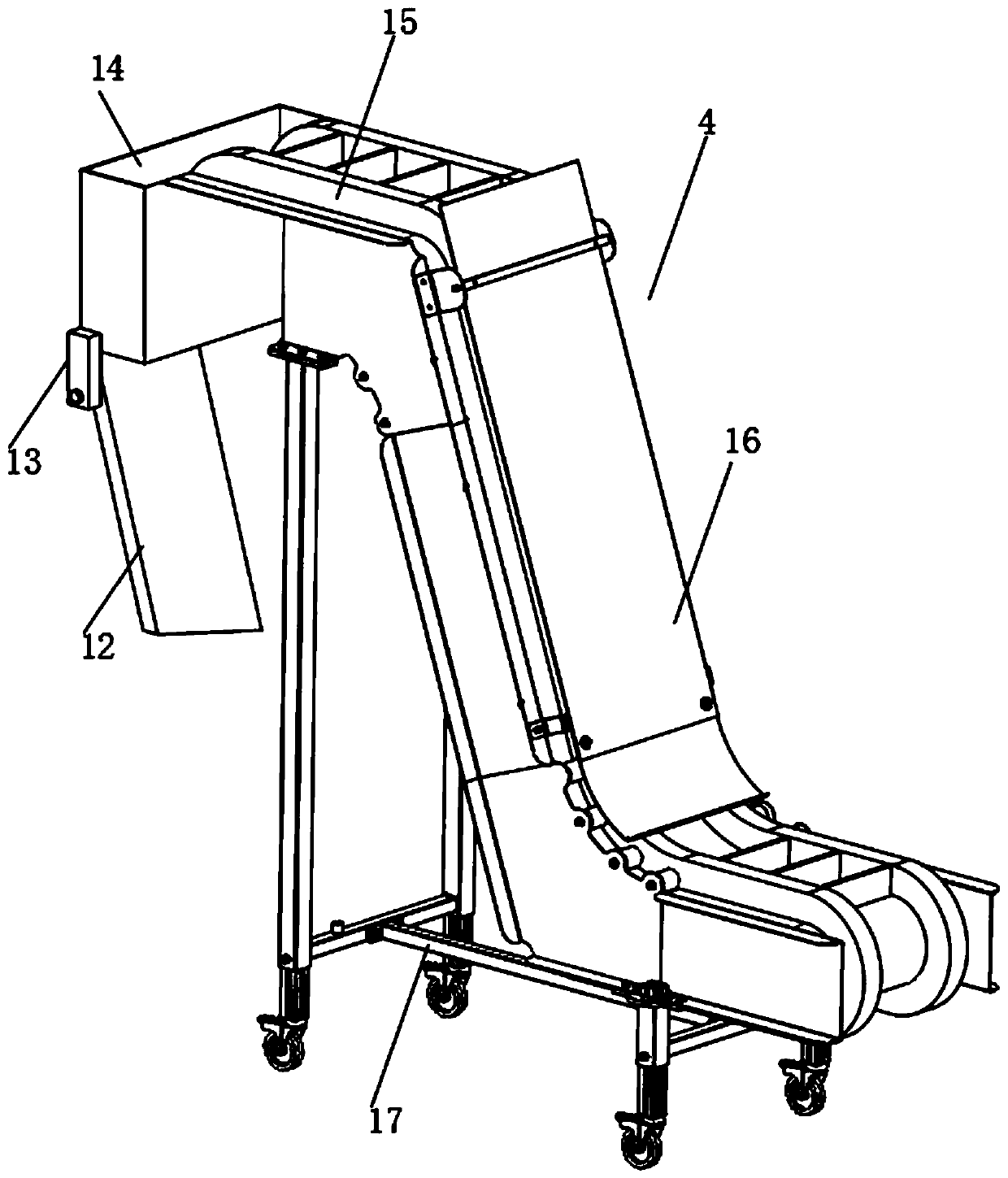

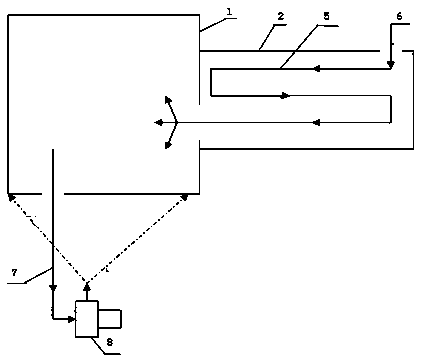

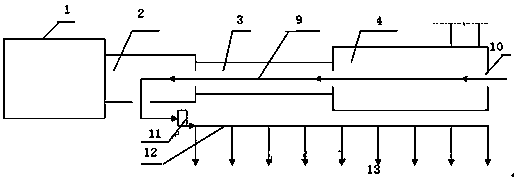

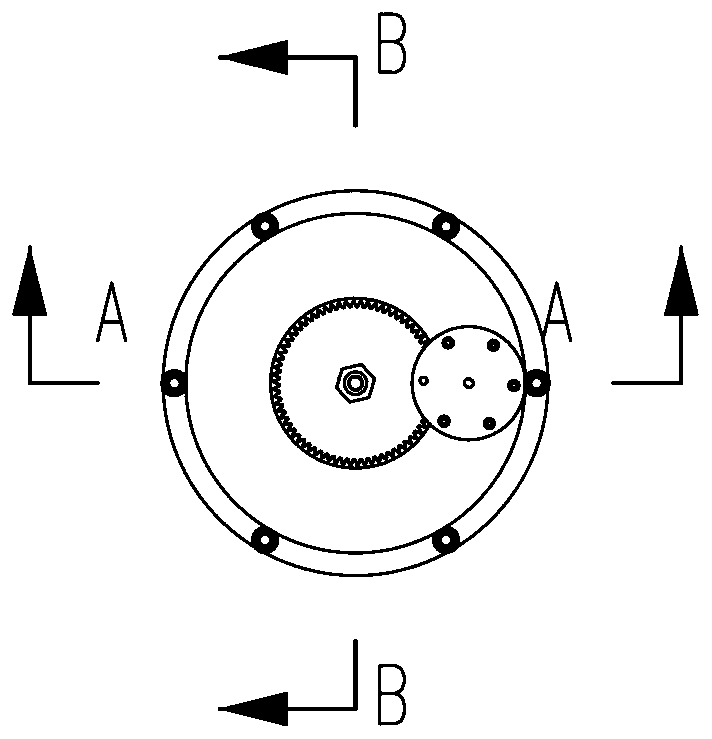

Automatic feeding device for auxiliary materials for electroslag smelting

The invention discloses an automatic feeding device for auxiliary materials for electroslag smelting. The automatic feeding device is characterized by comprising a discharging part structure and a power control part structure, wherein the discharging part structure comprises a rack arranged at the side of a crystallizer, the upper end of the rack is provided with a pair of belt pulleys along the horizontal direction, the belt pulleys are annularly sleeved by a conveying belt, one end of the conveying belt is located above the crystallizer, and the other end of the conveying belt is far away from the crystallizer; and the power control part structure comprises a horizontal cantilever lifting mechanism and a linkage control mechanism, wherein the linkage control mechanism is connected between a horizontal cantilever and the discharging part structure and is used for realizing linkage control on the discharge of the discharging part structure by virtue of the lifting of the horizontal cantilever. The automatic feeding device has the advantages that the structure is simple, the auxiliary materials can be automatically fed during smelting, the auxiliary material feeding control process is stable and reliable, and the smelting effect is good.

Owner:宝武特冶航研科技有限公司

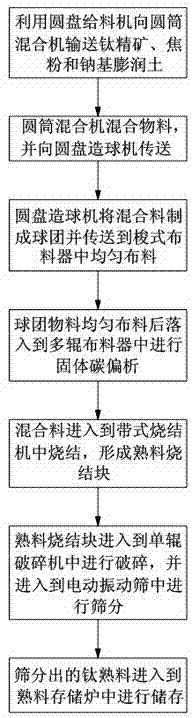

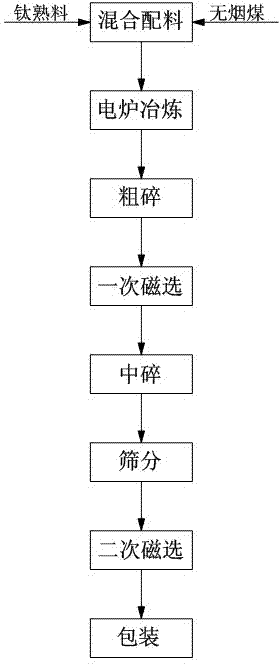

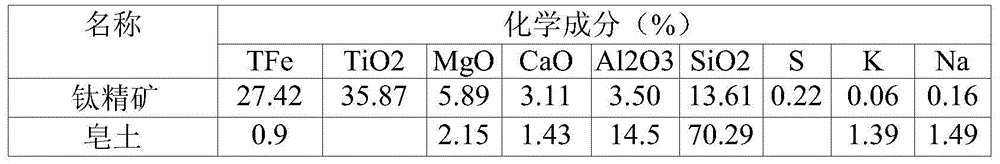

Titanium clinker for smelting high-titanium slag

The invention discloses titanium clinker for smelting high-titanium slag, which is used for solving the problems of high energy consumption and environmental pollution when raw materials are adopted for producing the high-titanium slag according to a high-titanium slag smelting process. The titanium clinker disclosed by the invention comprises the following substances in percentage by weight: 60%-80% of titanium concentrate, 10%-30% of coke powder and 5%-15% of bentonite. Through the scheme, by adopting the titanium clinker disclosed by the invention for producing the high-titanium slag, the purposes of reducing electric energy and coal consumption and saving operation cost can be achieved; furthermore, the smelting time of the whole high-titanium slag process can be further shortened, so that the titanium clinker disclosed by the invention is suitable for popularization and application.

Owner:成都天禄源商贸有限公司 +2

Method for reducing coal consumption by comprehensively and circularly utilizing waste heat of Webster furnace

ActiveCN103411438ASolve the icingImprove efficiencyCombustion processReverberatory furnacePhysical chemistryEngineering

Owner:HEZHANG LINGXUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Top-blowing powder spraying method for electric furnace smelting

InactiveCN111471824AProcedural powderImprove smelting effectProcess efficiency improvementElectric furnaceElectric furnacesEngineering

The invention provides a top-blowing powder spraying method for electric furnace smelting. The method comprises the following steps that air powder is blown into a furnace by adopting one or more thantwo top-blowing powder spraying systems which are uniformly distributed on a furnace cover; one or more than two top-blowing powder spraying systems can be controlled independently or in a linkage manner; and when any top-blowing powder spraying system is controlled, the method can drive a lifting mechanism through a driving unit in any top-blowing powder spraying system so as to drive a spiral spraying pipe of a lifting spiral spraying gun to rotate and lift, and therefore air powder is sprayed into the furnace at a constant spiral lift angle, wherein the system comprises a liftable spiral spray gun, a lifting mechanism, a driving unit, a stretchable rotary joint and a gas powder supply device. According to the method, multi-point powder spraying can be achieved, each top-blowing powderspraying system can operate independently and can also operate in a linkage mode, and the smelting effect of the electric furnace can be improved; the blowing angle can be kept unchanged for a long time; and the equipment is light in weight and low in furnace top mounting height limit requirement.

Owner:成都亿兆晶创科技有限公司

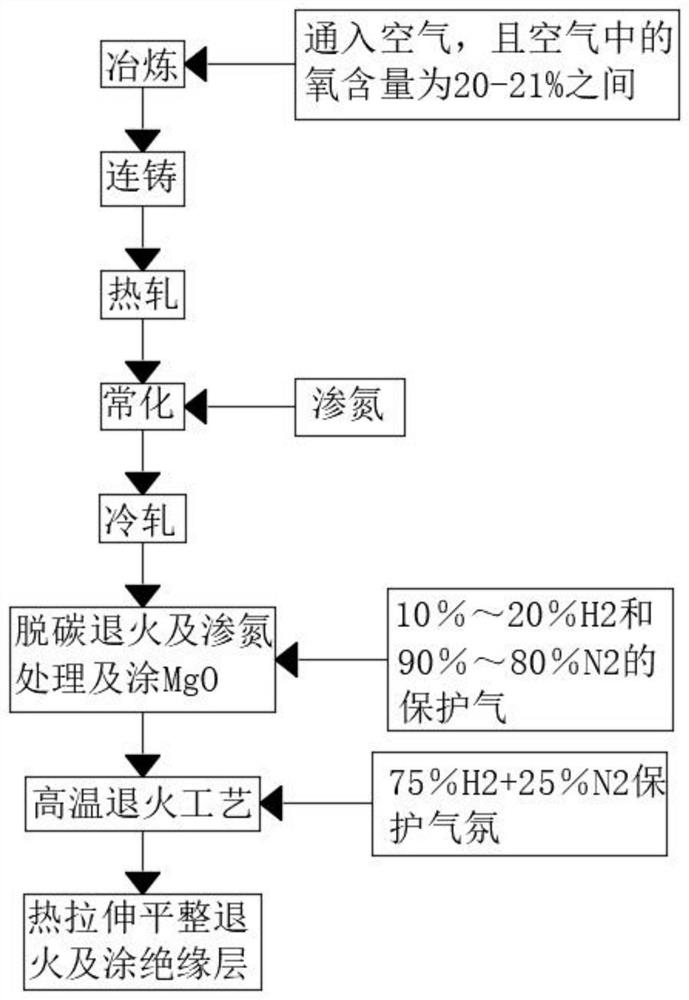

Atmosphere control process of high-magnetic-induction oriented silicon steel with excellent magnetism

PendingCN112626447AImprove the accuracy of atmosphere controlReduce FeO contentSolid state diffusion coatingHeat treatment process controlSmelting processNitrogen gas

The invention relates to the technical field of oriented silicon steel, and discloses an atmosphere control process of high-magnetic-induction oriented silicon steel with excellent magnetism. The atmosphere control process comprises the following steps of 1, smelting, specifically, smelting in a converter and RH refining to obtain molten steel, introducing air in the smelting process, and setting the total air inflow to be 100-300Nl / min and the oxygen content in the introduced air to be 20-21%. According to the atmosphere control process of the high-magnetic-induction oriented silicon steel with the excellent magnetism, the content of oxygen and the content of nitrogen in a certain proportion are added in different processes, the atmosphere control precision of each stage is effectively improved, therefore the obtained final high-magnetic-induction oriented silicon steel is excellent, the influence of air pressure, flow and other factors on the magnetic effect of the final high-magnetic-induction oriented silicon steel is avoided, the FeO content in the slag is reduced, the steel recovery rate is increased, the service life of a furnace lining is prolonged, the effect of reducing the production cost is achieved, accurate atmosphere control is conducted, the smelting effect is better in the smelting process of the high-magnetic-induction oriented silicon steel, and the magnetism of the smelted high-magnetic-induction oriented silicon steel is more excellent.

Owner:海安华诚新材料有限公司

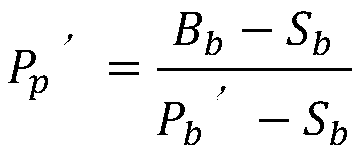

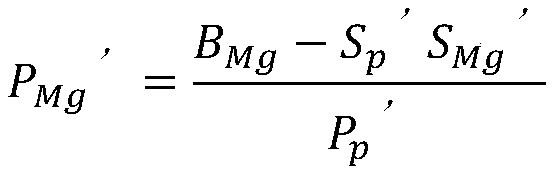

MgO optimal distribution method for iron-containing furnace charge of blast furnace

ActiveCN110982971ALarge span of soft melting zoneImprove smelting performanceSteel manufacturing process aspectsForecastingMaterials scienceBlast furnace

The invention relates to an MgO optimal distribution method for iron-containing furnace charge of a blast furnace. The method comprises the following steps: S1, determining that the MgO content SMg' of optimized sintered ore is less than or equal to 1.8% and the binary alkalinity (CaO / SiO2) Sb' is greater than or equal to 1.8; S2, determining that the MgO content of optimized pellets is 1.5%-2.0%and the binary alkalinity is less than or equal to 0.4, namely, PMg' is greater than or equal to 1.5% and less than or equal to 2.0%, Pb' is less than or equal to 0.4, and the charging proportion Pp'is less than or equal to 30%; S3, according to the binary alkalinity requirement Bb of the blast furnace comprehensive furnace charge and the binary alkalinity constraint condition of each iron-containing furnace charge, determining the charging proportion Pp' of the optimized pellets; S4, determining the MgO content PMg' of optimized pellets and the MgO content SMg' of optimized sintered ore according to the MgO content requirement BMg of blast furnace comprehensive furnace charge, the optimized iron-containing furnace charge proportions and the optimized iron-containing furnace charge MgO constraint conditions. The method has the advantages that the reduction degree of the comprehensive furnace charge is effectively improved, the soft melting temperature is reduced, the interval is narrowed, and the smelting performance is improved.

Owner:ANSTEEL GRP MINING CO LTD

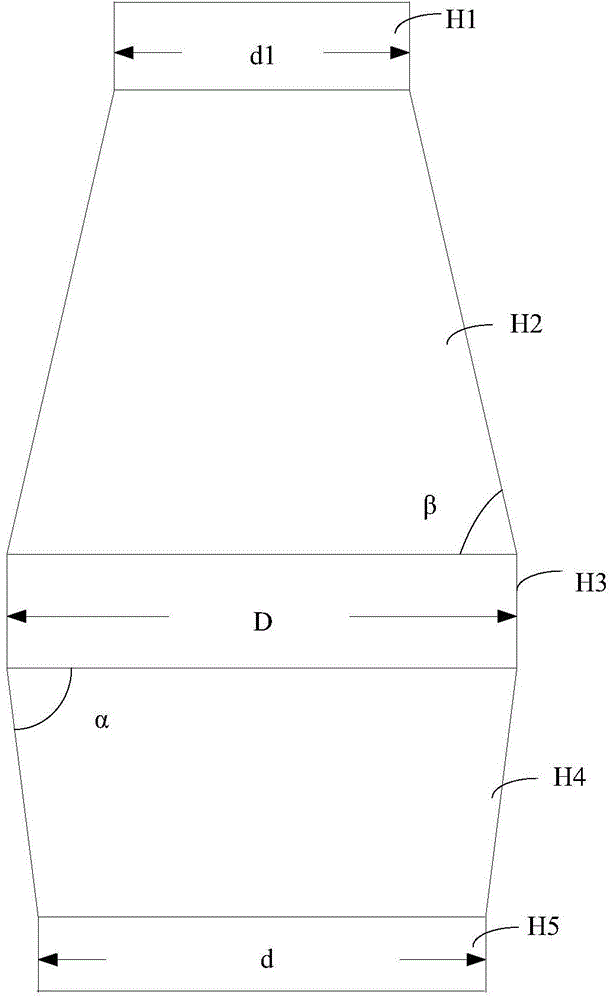

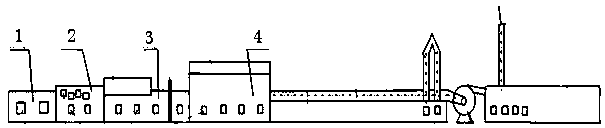

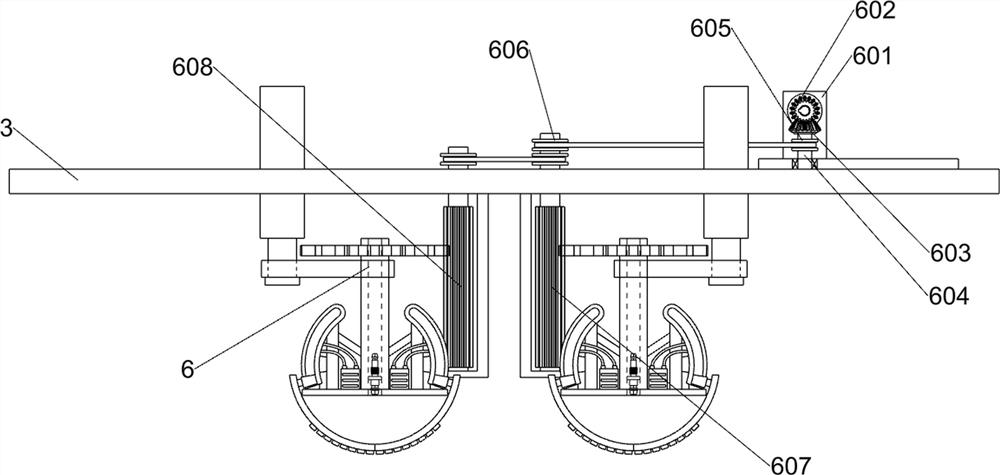

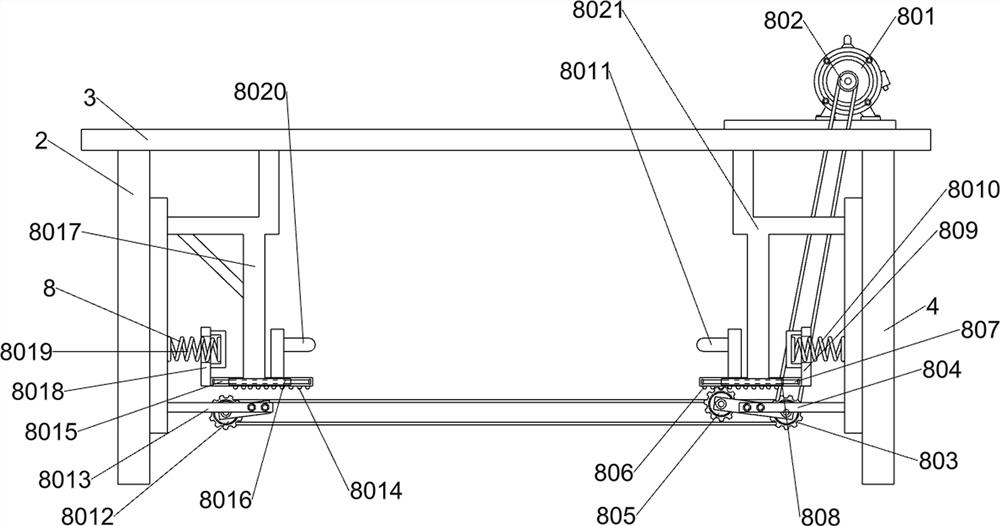

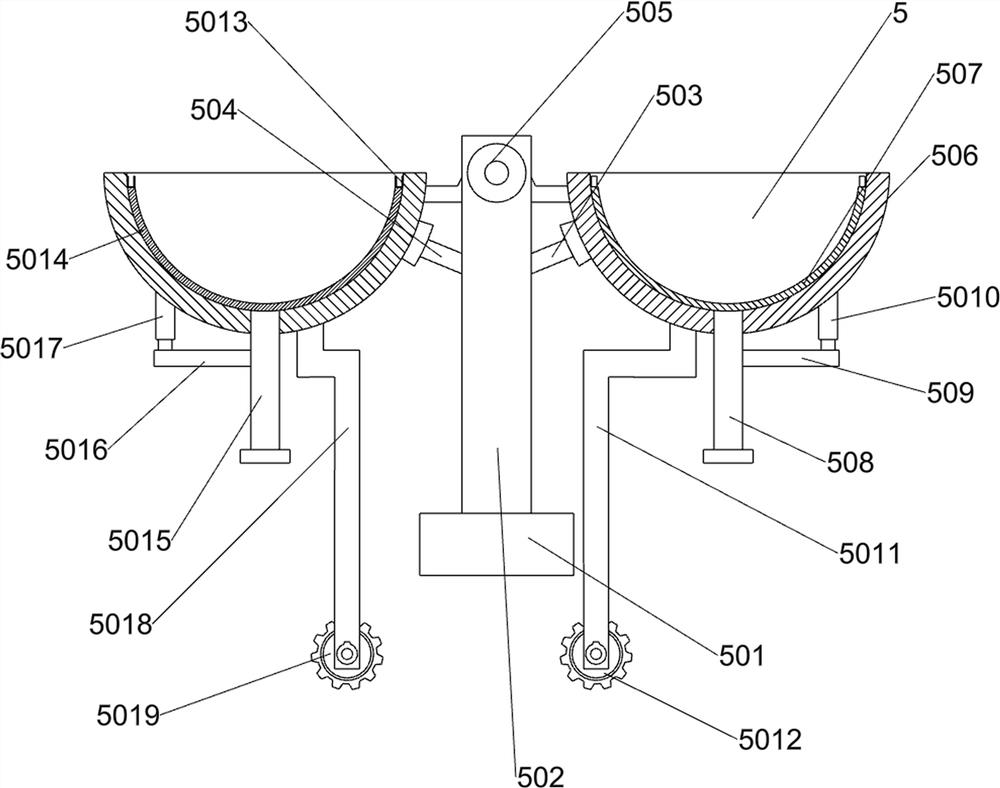

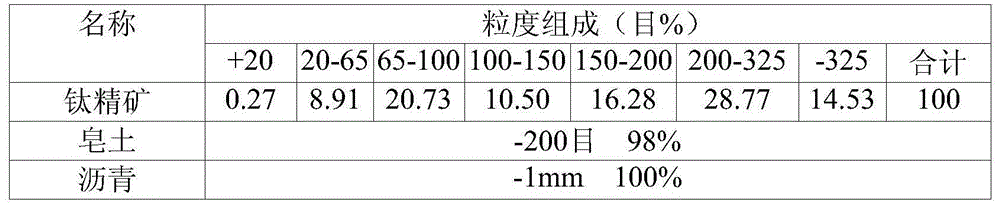

Laterite briquetting device for wrapped nickel alloy

ActiveCN112410550AConvenient smeltingNot easy to disperseProcess efficiency improvementCompression moldingMetallurgy

The invention relates to the field of nickel alloys, and particularly relates to a laterite briquetting device for a wrapped nickel alloy. The invention aims to provide the laterite briquetting devicefor the wrapped nickel alloy. According to the technical scheme, the laterite briquetting device for the wrapped nickel alloy comprises a balling system, a compression molding system, a trimming andleveling system, an extrusion control system, a third mounting side plate, an operation control screen, a long-distance electric sliding column and the like, and the upper part of a working machine bottom plate is welded with a first mounting side plate. According to the laterite briquetting device for the wrapped nickel alloy, the briquetting treatment of the nickel alloy smelting raw material laterite is realized, the laterite is used for preparing two solid hemispherical outer shells, then the two hemispherical outer shells are continuously filled with the laterite, a binder is added, so that the two hemispheres are combined into a complete laterite pellet, the outer surface of the laterite pellet is not prone to scattering, and the effect of smelting the laterite pellet in the later period is facilitated.

Owner:崇义县高坌长飞矿业有限公司华山页岩矿

Smelting method

ActiveCN107937718AReduce volumeIncrease surface areaProcess efficiency improvementSlagElectric machinery

The invention relates to the field of metallurgy, and particularly discloses a smelting method. A smelting furnace which can carry out smelting quickly is used for conducting smelting. The smelting furnace comprises a rack, a cutting mechanism and a smelting mechanism. The cutting mechanism comprises a cutter, a cutting motor and an outer cylinder, wherein the cutting motor can drive the cutter torotate. The smelting mechanism comprises a smelting furnace body, a stepping motor and a burning cylinder, wherein the burning cylinder is located on the periphery of the smelting furnace body, and the stepping motor can drive the smelting furnace body to rotate. The smelting furnace body is fixedly provided with a collection tank, the smelting furnace body is internally and fixedly provided witha slag blocking ring, the middle portion of the slag blocking ring protrudes towards the center of the smelting furnace body, and the lower portion of the smelting furnace body is provided with a slag outlet. The smelting method comprises the first step of material mixing, the second step of pre-heating, the third step of smelting, the fourth step of discharging and the fifth step of cleaning. Bymeans of the scheme, metal in ores can be rapidly reduced.

Owner:重庆琅博宛冶金材料有限公司

a method of smelting

Owner:重庆琅博宛冶金材料有限公司

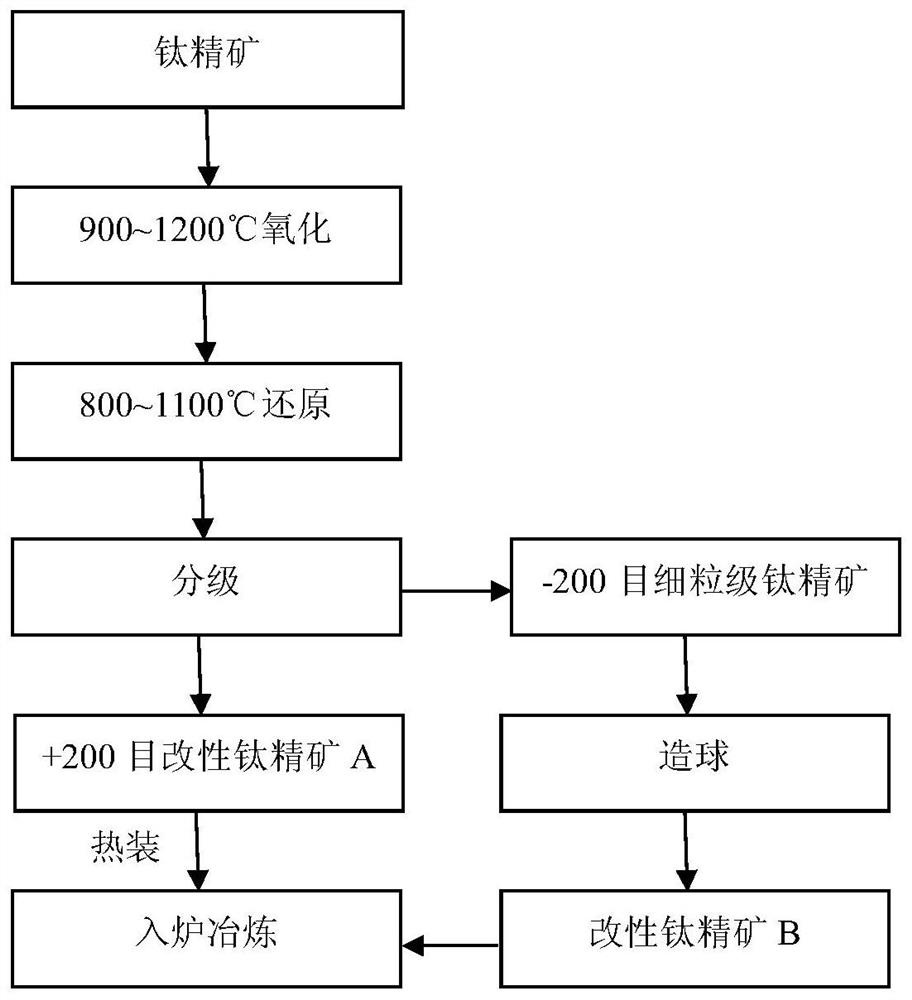

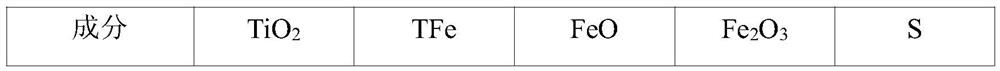

A kind of preparation method of modified titanium concentrate

The invention discloses a preparation method of modified titanium concentrates, and belongs to the technical field of titanium slag smelting. The preparation method of the modified titanium concentrates comprises the following steps: (a) oxidation: the oxidation rate of titanium concentrates is controlled to be not lower than 90%; (b) reduction: the oxidation rate of the reduced titanium concentrates is controlled within 30-50%; (c) classification: thick-particle titanium concentrates with particle sizes of +200 meshes not less than 90% and fine-particle titanium concentrates with particle sizes of -200 meshes not less than 90% are obtained; and the thick-particle titanium concentrates are modified titanium concentrates A; and (d) granulation: the fine-particle titanium concentrates are granulated; the particle sizes of pellets are controlled within 10-20 mm; modified titanium concentrates B are obtained; and the modified titanium concentrates are ones of the modified titanium concentrates A and the modified titanium concentrates B. The modified titanium concentrates are used as titanium slag smelting raw materials, so that the smelting electric consumption and the smelting time can be effectively reduced, meanwhile, the granulation conditions are improved, reasonable utilization of the fine-particle titanium concentrates is realized, the energy saving and cost reducing effectsare obvious, and excellent home and abroad popularization and application prospect is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

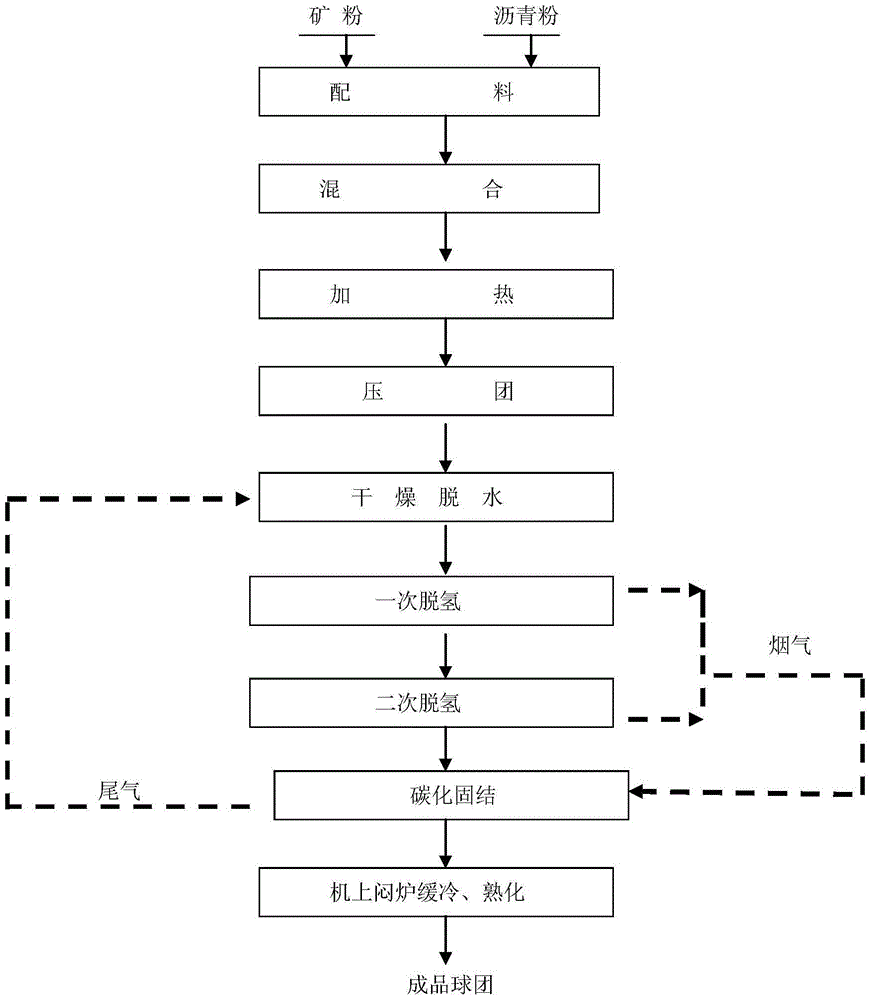

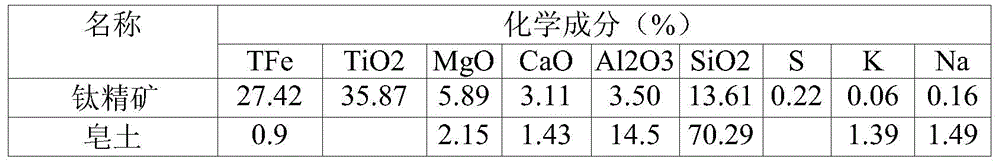

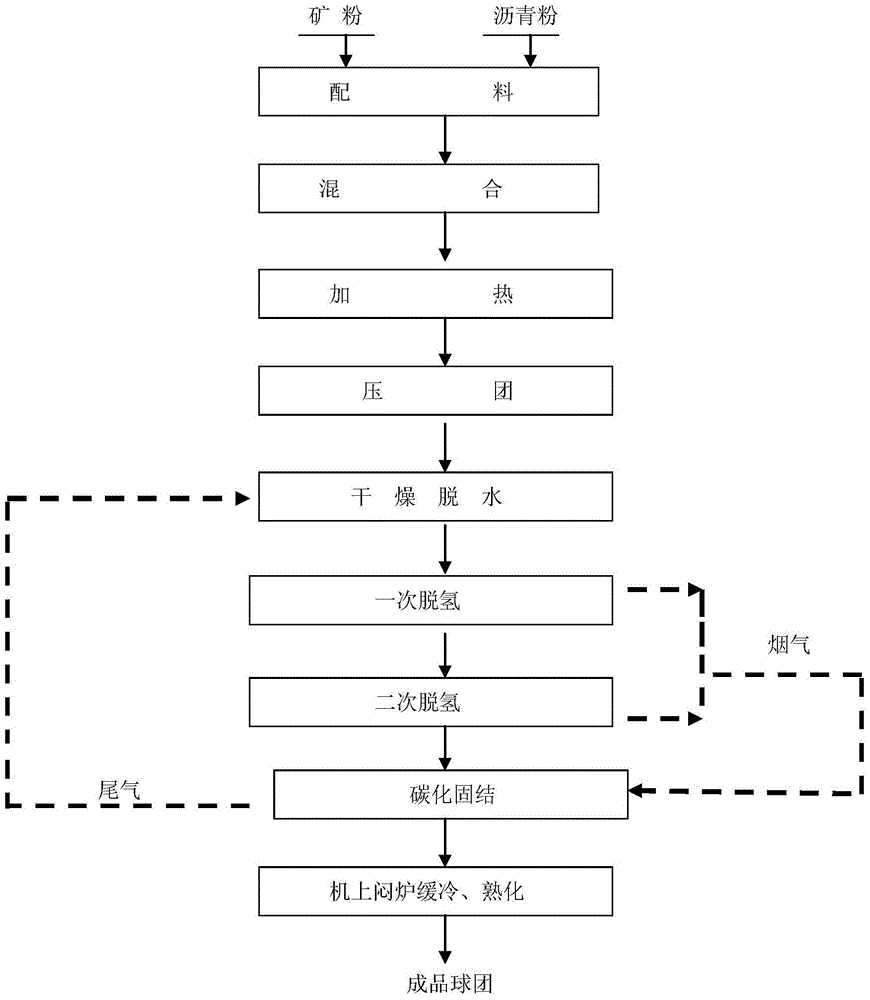

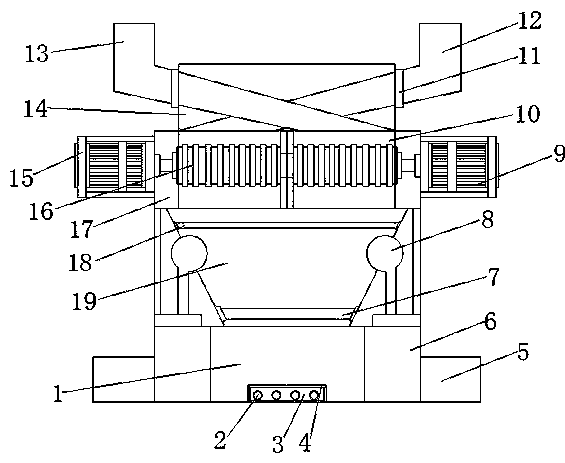

Method for producing agglomerates from fine ore with bitumen as binder, the agglomerates and its application

The invention discloses a method for producing ore briquettes from fine ores with pitch as an adhesive. The method comprises the following steps: 1) preparing raw ore briquettes from the fine ores as the raw material and by taking the pitch as the adhesive; 2) drying and dehydrating the raw ore briquettes; 3) orderly performing primary dehydrogenation and secondary dehydrogenation on the dried and hydrated raw ore briquettes, wherein the primary dehydrogenation is performed in a strong oxidative medium, while the secondary dehydrogenation is performed in a weakly oxidative or neutral medium; and 4) performing carbonization consolidation on the ore briquettes after the treatment in the step 3), and slowly cooling the ore briquettes obtained after carbonization consolidation in a sealed furnace until the temperature is below 300 DEG C, thereby obtaining the finished product ore briquettes. The ore briquettes prepared by use of the process can be applied to blast furnace smelting, electric arc smelting, vertical furnace smelting, rotary kiln smelting and bottom converter smelting. According to the method, due to the primary dehydrogenation, the secondary dehydrogenation and the carbonization consolidation in the process, the prepared ore briquettes are thoroughly dehydrogenated without oxidation; and the finished briquettes contain no tar and other toxic and harmful compounds, and are safe and environment-friendly.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

An automatic feeding device for electroslag smelting auxiliary materials

ActiveCN104313341BImplement auto-joinDosing control process is stable and reliableCantileverPower control

The invention discloses an automatic feeding device for auxiliary materials for electroslag smelting. The automatic feeding device is characterized by comprising a discharging part structure and a power control part structure, wherein the discharging part structure comprises a rack arranged at the side of a crystallizer, the upper end of the rack is provided with a pair of belt pulleys along the horizontal direction, the belt pulleys are annularly sleeved by a conveying belt, one end of the conveying belt is located above the crystallizer, and the other end of the conveying belt is far away from the crystallizer; and the power control part structure comprises a horizontal cantilever lifting mechanism and a linkage control mechanism, wherein the linkage control mechanism is connected between a horizontal cantilever and the discharging part structure and is used for realizing linkage control on the discharge of the discharging part structure by virtue of the lifting of the horizontal cantilever. The automatic feeding device has the advantages that the structure is simple, the auxiliary materials can be automatically fed during smelting, the auxiliary material feeding control process is stable and reliable, and the smelting effect is good.

Owner:宝武特冶航研科技有限公司

Method for producing ore briquettes from fine ores with pitch as adhesive, ore briquettes and application of ore briquettes

The invention discloses a method for producing ore briquettes from fine ores with pitch as an adhesive. The method comprises the following steps: 1) preparing raw ore briquettes from the fine ores as the raw material and by taking the pitch as the adhesive; 2) drying and dehydrating the raw ore briquettes; 3) orderly performing primary dehydrogenation and secondary dehydrogenation on the dried and hydrated raw ore briquettes, wherein the primary dehydrogenation is performed in a strong oxidative medium, while the secondary dehydrogenation is performed in a weakly oxidative or neutral medium; and 4) performing carbonization consolidation on the ore briquettes after the treatment in the step 3), and slowly cooling the ore briquettes obtained after carbonization consolidation in a sealed furnace until the temperature is below 300 DEG C, thereby obtaining the finished product ore briquettes. The ore briquettes prepared by use of the process can be applied to blast furnace smelting, electric arc smelting, vertical furnace smelting, rotary kiln smelting and bottom converter smelting. According to the method, due to the primary dehydrogenation, the secondary dehydrogenation and the carbonization consolidation in the process, the prepared ore briquettes are thoroughly dehydrogenated without oxidation; and the finished briquettes contain no tar and other toxic and harmful compounds, and are safe and environment-friendly.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

A crushing furnace with better smelting effect

ActiveCN106871644BEasy to reinforcePromote meltingCharge treatment typeFurnace typesEngineeringIdler-wheel

Owner:XINGHUA SANQIANG MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com