Quick lime hydrator

A quicklime and digester technology is applied in the field of dry powder calcium hydroxide production equipment, which can solve the problems of poor working environment, harm to the health of workers, unfavorable pelletizing, etc., so as to improve smelting performance, reduce dust removal burden, and speed up dust removal. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

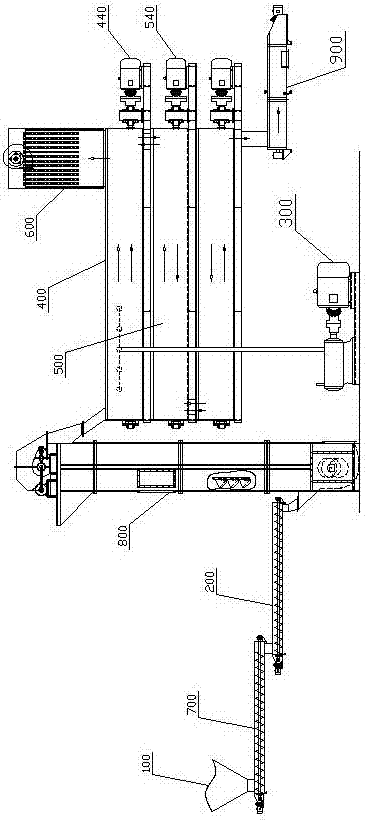

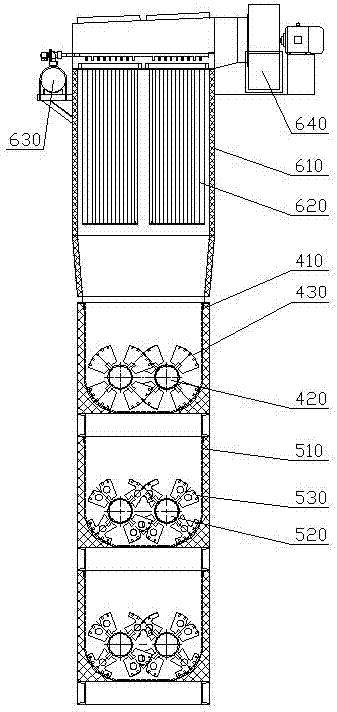

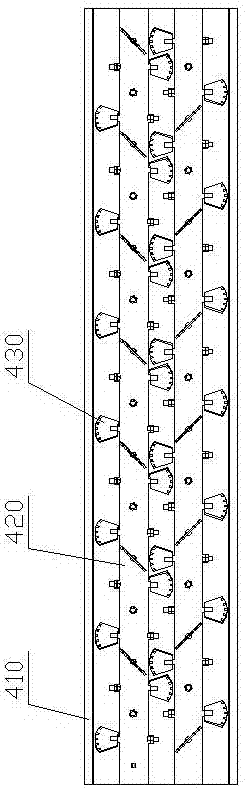

[0057] Attached below Figure 1-12 , a quicklime digester of the present invention is described in detail below.

[0058] as attached figure 1 Shown, a kind of quicklime digester of the present invention, this digester comprises

[0059] A silo 100 for placing quicklime;

[0060] The metering screw conveyor 200 for conveying quicklime and completing the metering work. The metering screw conveyor 200 is placed horizontally, and the left feeding end of the metering screw conveyor 200 is connected upward to the outlet of the silo 100;

[0061] A metering water pump 300 connected to an external water source;

[0062] The first-stage screw mixer 400 and the second-stage screw mixer 500 are used for mixing quicklime and water. The first-stage screw mixer 400 and the second-stage screw mixer 500 are arranged in parallel up and down. The left feeding end of the first-stage screw mixer 400 is connected to the metering screw conveyor. The right discharge end of 200, the right discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com