High-grade vanadium-titanium pellet and preparation method of high-grade vanadium-titanium pellet

A high-grade pelletizing technology, applied in the field of steelmaking, can solve the problems of high cost and low smelting performance of vanadium-titanium pellets, and achieve the effect of reducing ironmaking cost and improving smelting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023]The present application also provides the preparation method of high-quality vanadium titanium balls, including the following steps:

[0024]Mixing high-grade vanadium titanium iron concentrate, steel slag powder, dust removal ash and bentonite to obtain a mixture;

[0025]The mixture was sequentially carried out, dry, preheated, and calcined to give high-grade vanadium balls.

[0026]During the above process, the process of high-quality vanadium titanium iron concentrate, steel slag powder, dust removal ash, and bentonite, the application is not particularly limited, as long as mixing uniform, in the specific embodiment, the cylindrical mixer can be used Mix well.

[0027]After mixing, the mixture was sequentially carborn, dried, preheated, and calcined to give high-grade vanadium balls. In the above process, the ball after the ball after the ball is h.2The content of O is 5 to 10% by weight, and the particle size is 5 to 20 mm. The dried temperature is from 100 to 200 ° C, the time is f...

Embodiment

[0035]Step 1: The mass ratio of vanadium titanium concentrate in the ball mining is controlled at 80 ~ 90% by weight, steel slag powder 5.0.0% by weight, blast furnace dusting ash: 5 ~ 10% by weight, bentonite: 0 ~ 3 wt%, pellets The alkalinity is controlled from 0.6 to 1.2;

[0036]Step 2: Mixing the ball: Mix the above materials into the cylindrical mixer by matching the cylinder mixture, to the garden pots, the particle size is 8 ~ 20mm;

[0037]Step 3: Drying, preheating and calcination: The drying system is a blast drying, drying temperature 180 ° C, drying time 4 min; drying the ball, preheating, preheating temperature 800 ° C, time 12 min; preheating the ball after oxidation The calcination temperature was 1250 ° C, and the calcination time was 20 min.

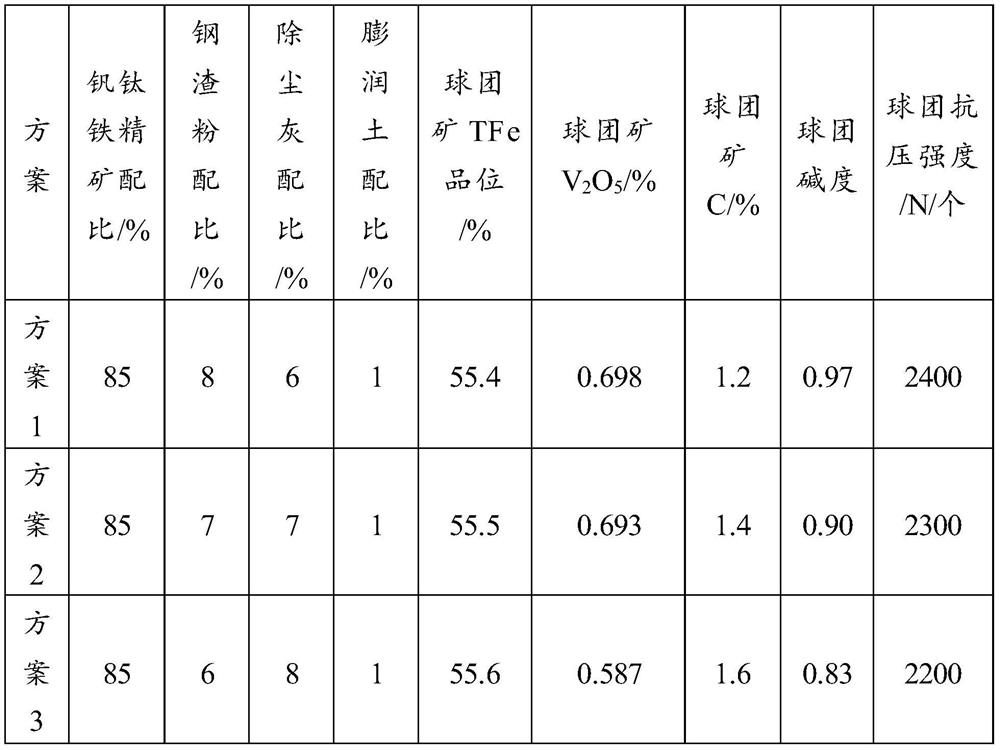

[0038]According to the above, the following three programs were prepared by the following three programs: Solution 1: 85 wt% vanadium iron concentrate + 8WT% steel slag powder + 6 wt% Dust removal ash + 1 wt% bentonite; Solution 2: 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com