Method for producing ore briquettes from fine ores with pitch as adhesive, ore briquettes and application of ore briquettes

A technology of binder and fine ore, which is applied in the field of powder ore to produce pellets, can solve the problems of non-reduction, smoke pollution, etc., and achieve the effects of convenient management, low capital investment, and high pellet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

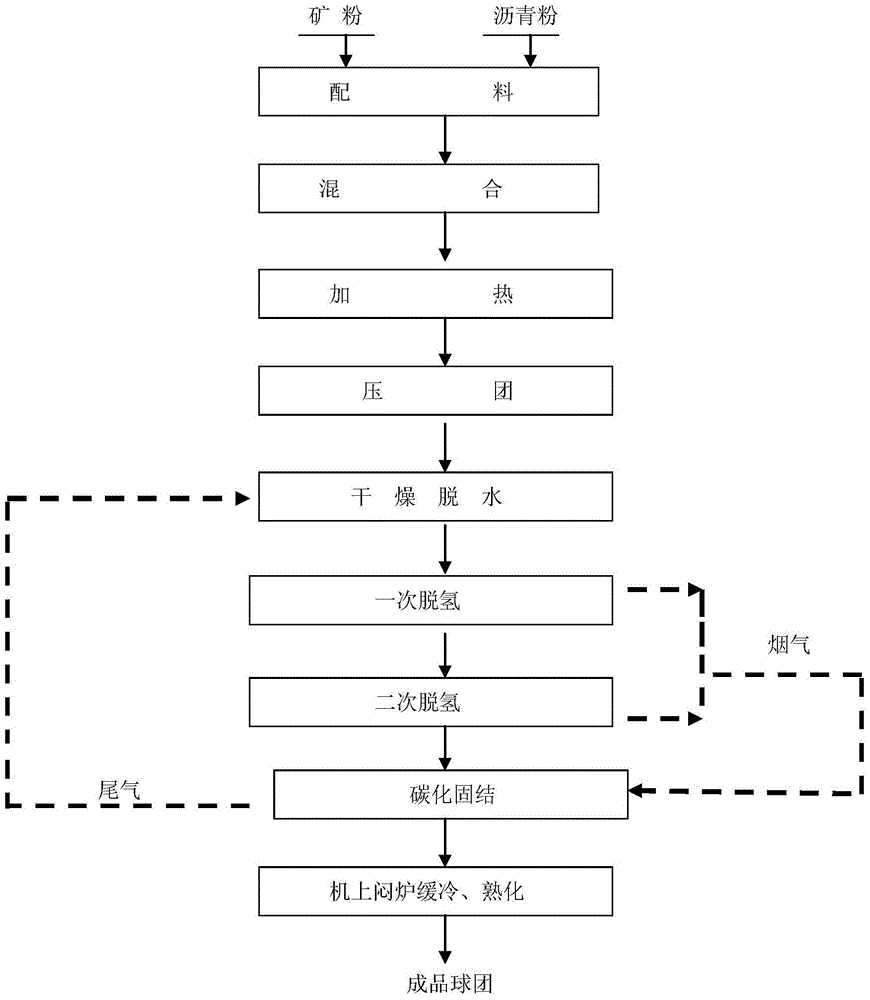

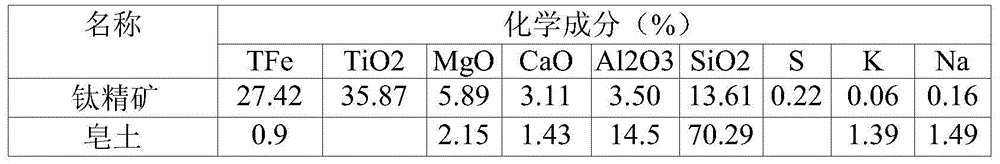

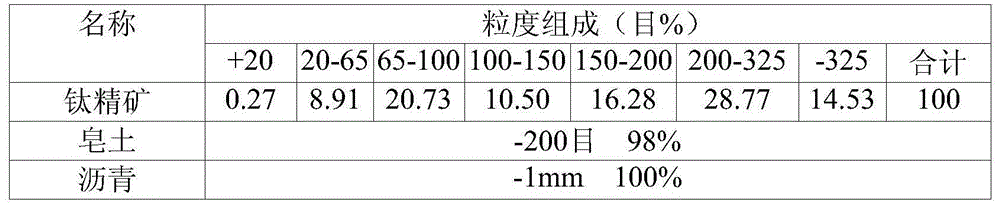

[0038] A kind of method of the present invention is that the fine ore that takes bitumen as binding agent is produced agglomerate, comprises the following steps:

[0039] 1) Mix 89.0wt% titanium concentrate, 3.0wt% bentonite, and 8.0wt% asphalt according to the weight of the ingredients on a dry basis, and add water to the batch. The mixing time is 10 minutes, so that the water content of the mixture is 7.5%. . It is measured that the raw ball falls 1.7 times / 0.5m, and the compression resistance is 2.5Kg / piece.

[0040] 2) Put the dough in a drying oven for drying and dehydration: start from room temperature (25°C) to 160°C for 20 minutes, then keep warm at 160°C for 10 minutes. The air gas premixed flameless burner is used for heating, the primary air is input according to the air consumption coefficient n=1.45, and the secondary air is input into the combustion chamber so that the total air consumption coefficient n=7.25. The volume composition of the heating medium in the...

Embodiment 2

[0046] A kind of method of the present invention is that the fine ore that takes bitumen as binding agent is produced agglomerate, comprises the following steps:

[0047] 1) Mix 90.5wt% titanium concentrate, 3.0wt% bentonite, and 6.5wt% asphalt according to the weight of the ingredients on a dry basis, mix them with water for 10 minutes, and make the water content of the mixture 7.5% ( The actual measurement is 7.3%), and it is measured that the raw mass falls 1.8 times / 0.5m, and the compression resistance is 2.4Kg / piece.

[0048] 2) Put the dough in a drying oven for drying and dehydration: start from room temperature (25°C) to 160°C for 20 minutes, then keep warm at 160°C for 10 minutes. The air gas premixed flameless burner is used for heating, the primary air is input according to the air consumption coefficient n=1.53, and the secondary air is input into the combustion chamber so that the total air consumption coefficient n=7.10. The volume composition of the heating med...

Embodiment 3

[0054] A kind of method of the present invention is that the fine ore that takes bitumen as binding agent is produced agglomerate, comprises the following steps:

[0055] 1) Mix 92wt% titanium concentrate, 3.0wt% bentonite, and 5wt% asphalt according to the weight of the ingredients on a dry basis, and mix them with water for 10 minutes to make the water content of the mixture 7.5%. The raw ball falls 1.8 times / 0.5m, and the compression resistance is 2.3Kg / piece.

[0056] 2) Put the dough in a drying oven for drying and dehydration: start from room temperature (25°C) to 160°C for 20 minutes, then keep warm at 160°C for 10 minutes. The air gas premixed flameless burner is used for heating, the primary air is input according to the air consumption coefficient n=1.50, and the secondary air is input into the combustion chamber so that the total air consumption coefficient n=7.15. The volume composition of the heating medium in the furnace is: 1.88% CO 2 , 2.06%H 2 O, 78.19% N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com