Method for preparing through-type composite strip embedded with silver copper

A technology of clad strip, silver clad copper, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of limited service life of mold hot pressing device, unsuitable for mass manufacturing, and high requirements for manufacturing equipment capacity, Achieve the effect of enhancing bonding firmness, facilitating automated processing, and requiring less manufacturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

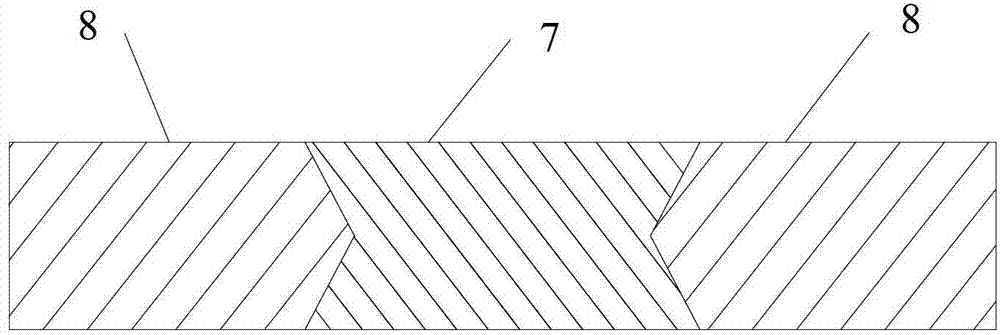

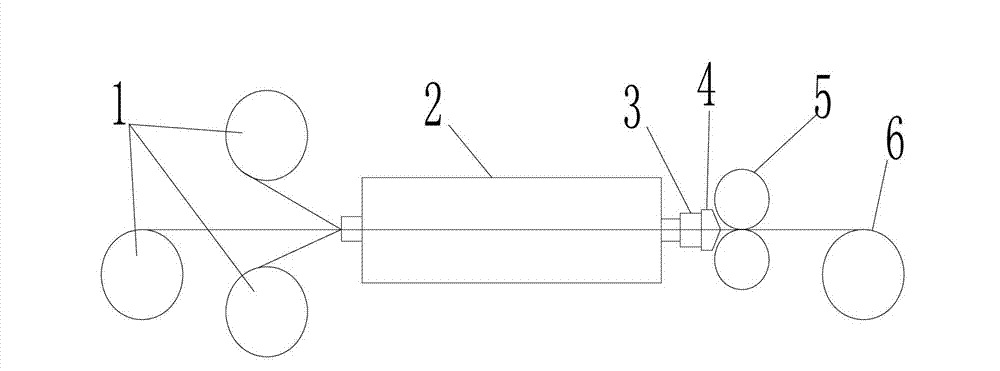

[0035] Example 1 A method for preparing a silver-clad copper composite strip alternately. The silver ingot is extruded into a special-shaped silver strip and the surface of the purchased special-shaped copper strip is cleaned. The two sides of a silver strip are centered inwardly. The depth is 3mm, and the angle It is a concave angle of 118°, with a total width of 30mm and a thickness of 10mm. The two copper strips are convex 3mm in the center on one side, with a convex angle of 118°, a total width of 25mm, and a thickness of 10mm. A silver strip and two copper strips form a composite billet. Remove oil and impurities from the surface of the silver strip and copper strip, acidify the material, grind and dry the material to obtain a clean composite billet, the concentration of sulfuric acid is 15%, the grinding material is a steel wire wheel, the diameter of the steel wire is ¢0.1mm, and the cleaning speed is 2.5m / min. Put the cleaned material on the unloading machine of the...

Embodiment 2

[0036] Embodiment 2 A preparation method of two silver-clad copper composite strips in phases. The silver ingots are extruded into special-shaped silver strips and the surface of the purchased special-shaped copper strips is cleaned. The two sides of the two silver strips are centered inwardly. mm, with a concave angle of 104°, a total width of 15mm, and a thickness of 9mm. The two copper strips have a convex angle of 3.5mm in the center on one side and a convex angle of 104°, with a total width of 20mm and a thickness of 9mm. One copper strip has a convex angle of 3.5mm in the center on both sides and a convex angle of 104°, with a total width of 15mm. Thickness 9mm. Two silver strips and three copper strips form a composite billet. Remove oil and impurities from the surface of the silver strip and copper strip, acidify the material, grind and dry the material to obtain a clean composite billet, the concentration of sulfuric acid is 13%, the grinding material is a steel wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com