Gas protecting system of metal powder laser quick forming machine

A gas protection system and metal powder technology, applied in the field of gas protection systems, can solve the problems that equipment safety and personal safety cannot be ensured, oxygen content cannot be stably controlled, and oxygen content is high, so as to ensure equipment and personal safety and save consumption. The effect of low volume and air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

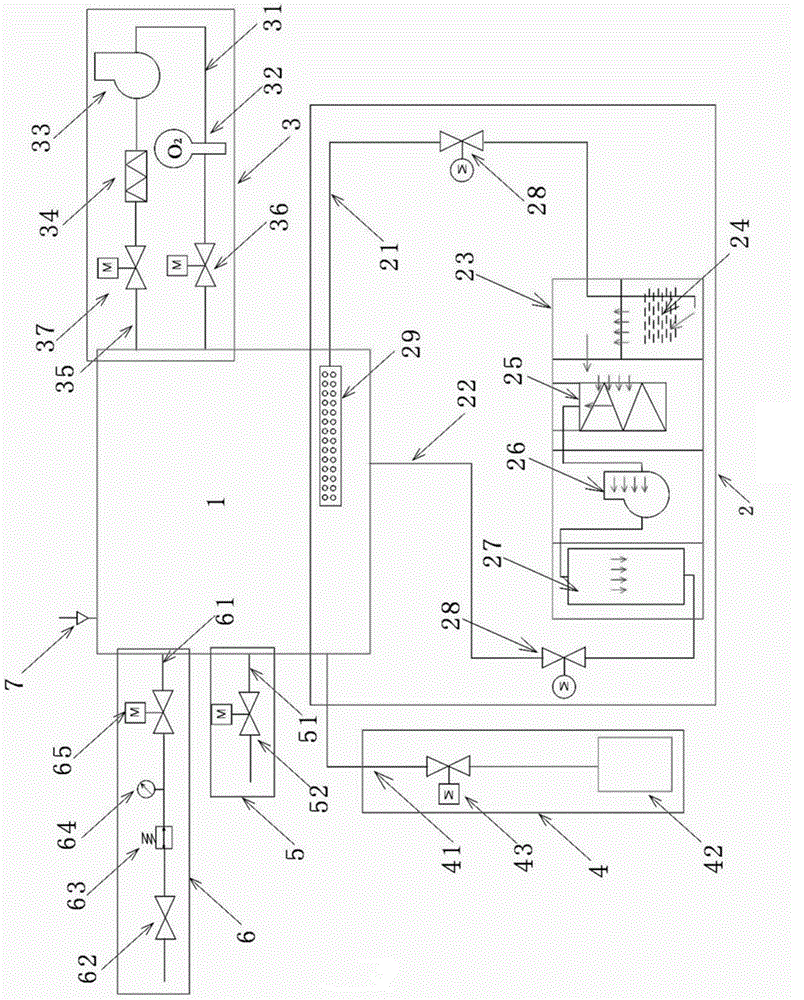

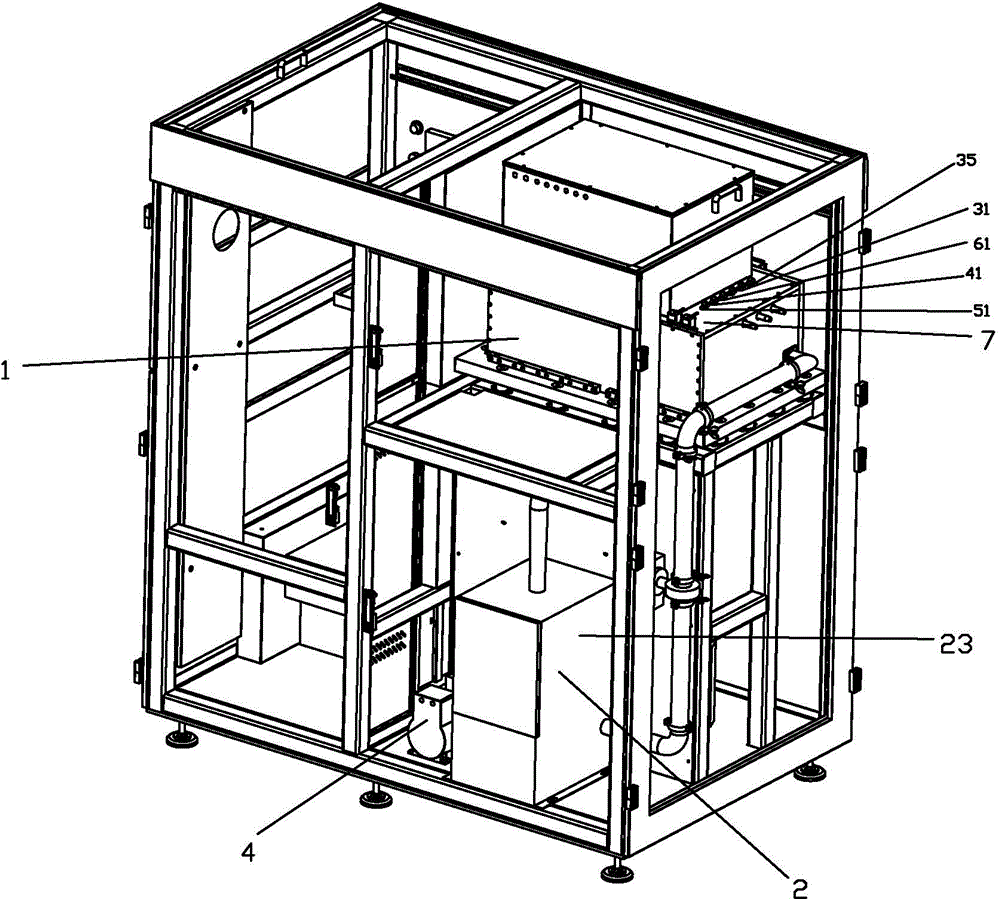

[0030] A gas protection system for a metal powder laser rapid prototyping machine, the metal powder laser rapid prototyping machine includes a sealed molding chamber 1, and the gas protection system includes a gas protection system that is connected to the sealed molding chamber 1 and protects the gas in the sealed molding chamber. The gas circulation purification mechanism 2 that performs circulation filtration and purification; the gas circulation purification mechanism 2 includes an explosion-proof dust removal purifier 23 that is connected to the sealed molding warehouse 1 through an inlet pipe 21 and an outlet pipe 22 to form a gas circulation purification, and an explosion-proof dust removal purifier 23 A water filter device 24, a filter core device 25, a circulating fan device 26, and a dryer 27 are arranged in sequence from the entrance to the exit; the air inlet pipe 21 and the air outlet pipe 22 are respectively provided with an electric valve switch 28. The air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com