A kind of preparation method of modified titanium concentrate

An ilmenite concentrate and modification technology, which is applied in the field of preparation of modified ilmenite concentrate, can solve the problems of increased binder ratio, increased pelletizing cost, poor pelletizing effect, etc., and achieves increased reactivity and smelting time. The effect of shortening and good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

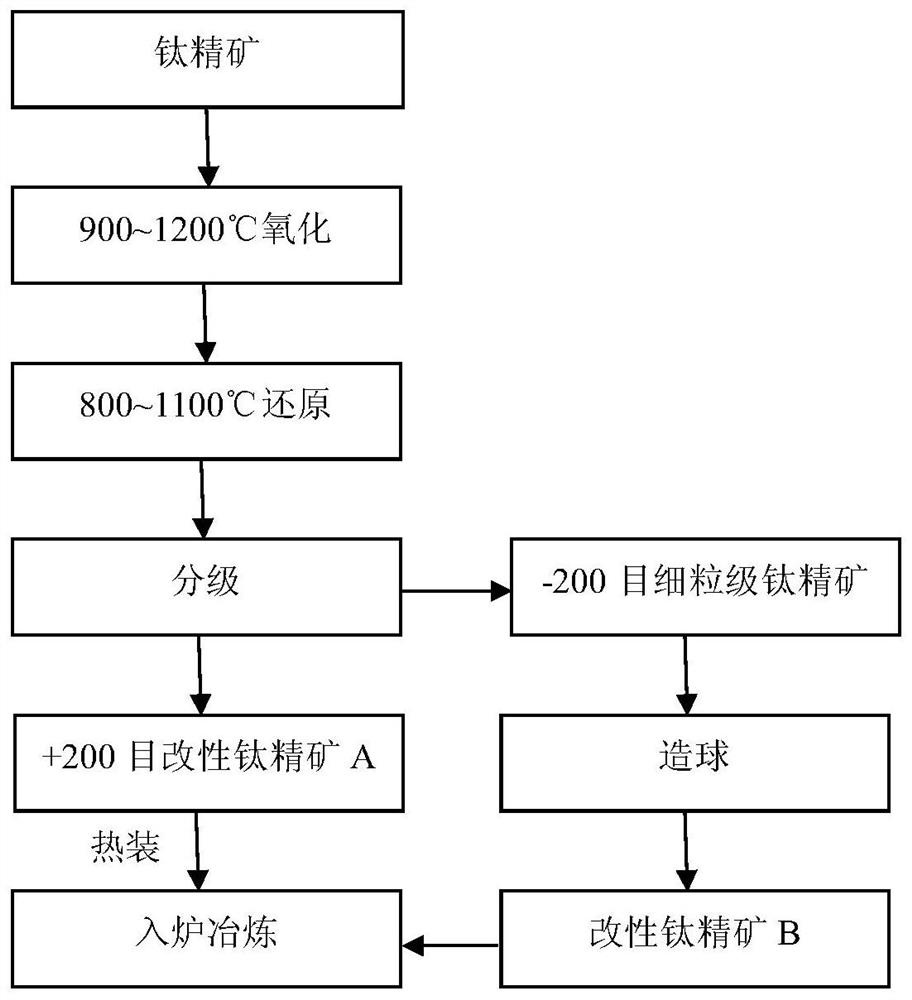

[0024] Concretely, a kind of preparation method of modified titanium concentrate, the method comprises the following steps:

[0025] a. Oxidation: Oxidize the titanium concentrate, control the oxidation rate of the titanium concentrate to not less than 90%, and obtain the oxidized titanium concentrate;

[0026] b. Reduction: enter the oxidized titanium concentrate into the reduction process, control the oxidation rate of the titanium concentrate at 30% to 50%, and obtain the reduced titanium concentrate;

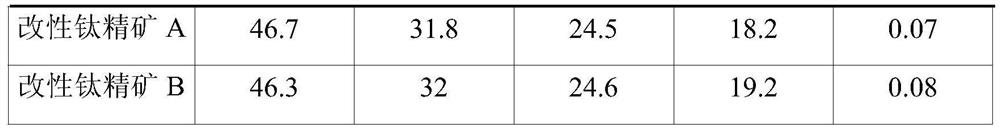

[0027] c. Classification: classify the reduced ilmenite concentrate to obtain a coarse-grained ilmenite concentrate with a particle size of +200 mesh ≥ 90%, and a fine-grained ilmenite concentrate with a particle size of -200 mesh ≥ 90%. The coarse-grained titanium concentrate is modified titanium concentrate A;

[0028] d. Pelletizing: pelletize the fine-grained titanium concentrate, and control the particle size of the pellets to 10-20mm to obtain modified titanium concen...

Embodiment 1

[0055] In this embodiment, the PTK10 titanium concentrate produced by Panzhihua Iron and Steel Co., Ltd. is used as the initial titanium concentrate, and the preparation method of the modified titanium concentrate is as follows:

[0056] a. Oxidation: Use a fluidized device to oxidize titanium concentrate, use gas as the main heat source, and use air as the oxidation atmosphere. The flow rate of the oxidation atmosphere is 0.2m / s, the oxidation temperature is about 1100°C, and the oxidation time is 2h. After oxidation, the oxidation rate of titanium concentrate is controlled above 95%;

[0057] b. Reduction: directly hot charge the oxidized titanium concentrate into the fluidized reduction equipment, use carbon monoxide as the reducing gas, the flow rate of the reducing gas is 0.18m / s, the reduction temperature is 950°C, the reduction time is 2h, the reduced titanium concentrate The ore oxidation rate is controlled at about 40%;

[0058] c. Classification: Classify the reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com