Patents

Literature

56results about How to "Good ball" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High titanium type petroleum oil pressing crack propping agent and production method thereof

InactiveCN1730422AReduce manufacturing costImprove low efficiencySolid waste managementClaywaresSurface finishingAluminium

The invention provides a high-titanium type petroleum fracturing propping agent, whose chemical constituents comprise (by weight ratio) 5-45% of high-titanium blast furnace slag, 10-30% of high-alumina brick, 17-77% of bauxite, and 4-8% of composite agglutinant, its preparation process comprises the following steps, (1) grinding the raw material, making mother balls with an atomizing granulation system, charging the mother balls into a sugar-coating machine, squeezing and dressing so as to obtain blank pellets, (2) drying the blank pellets through a drying system, loading into high temperature kiln for agglutination, (3) cooling down and carrying out surface polishing through high speed rotation in a friction tube, (4) elevating the temperature to 80-100 deg. C, carrying out surface treatment with acid-resisting organics, finally cold-setting.

Owner:攀枝花环业冶金渣开发有限责任公司

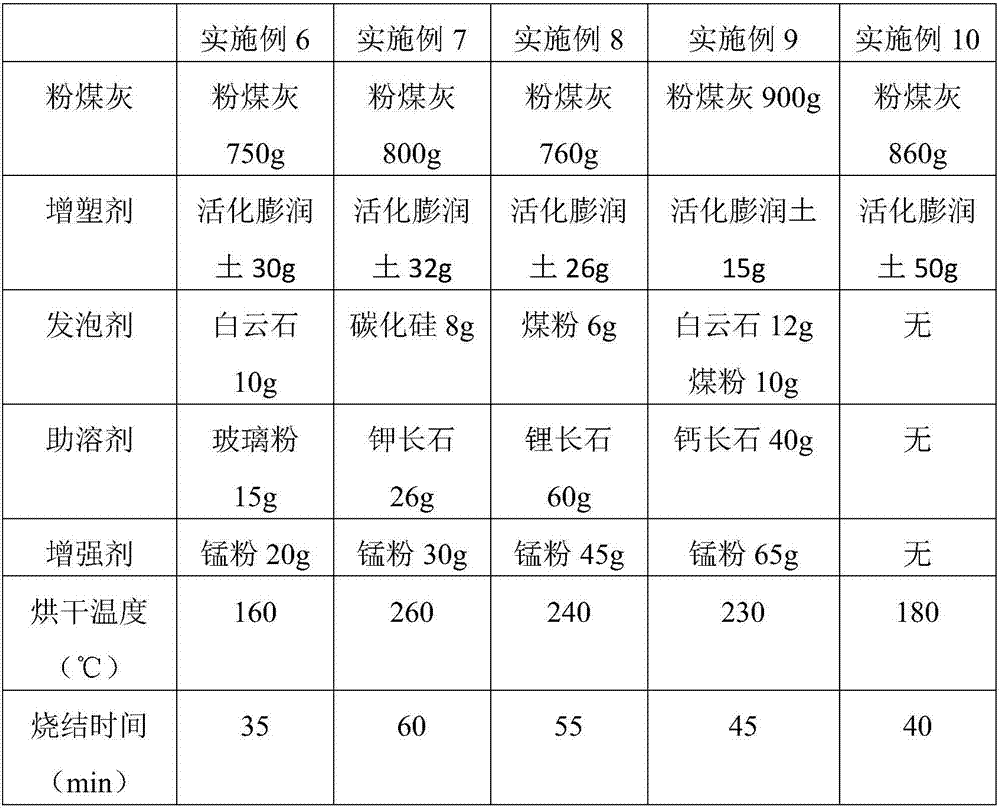

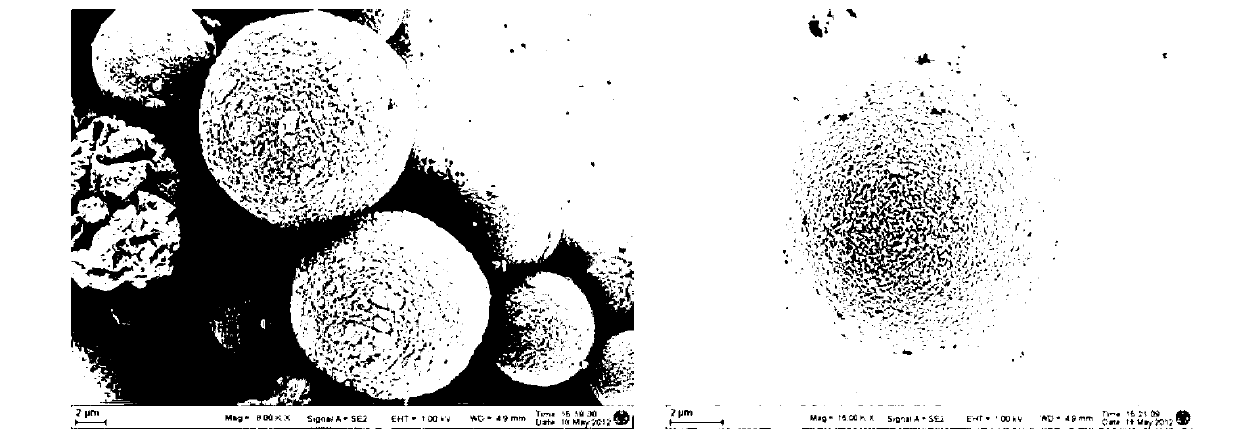

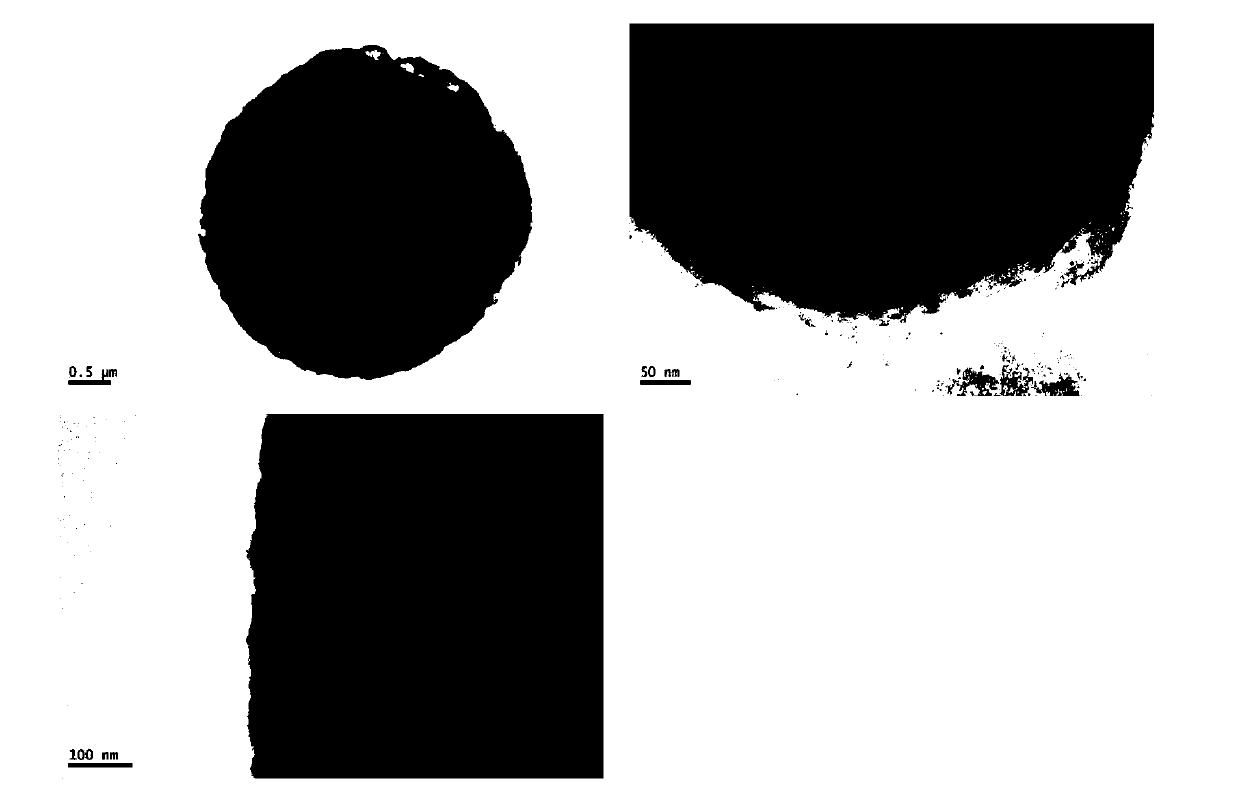

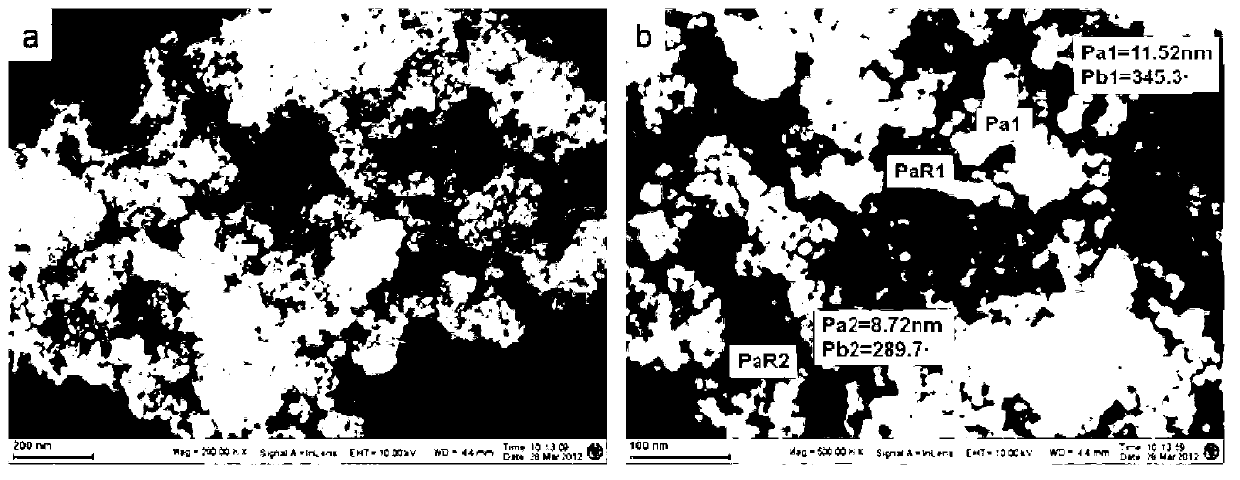

Light high-strength high mixing amount coal ash ceramsite and preparation method thereof

InactiveCN107417150AHigh granulation rateHigh strengthCeramicwareClaywaresPolymer scienceFoaming agent

The invention provides light high-strength high mixing amount coal ash ceramsite and a preparation method thereof. The ceramsite comprises the following components in parts by mass: 70-95 parts of coal ash, 1-5 parts of a plasticizer, 0-5 parts of a foaming agent, 0-10 parts of a fluxing agent and 0-10 parts of a reinforcing agent. The coal ash ceramsite provided by the invention is light in weight and high in strength, the density grade is as high as 600-900kg / m<3>, the cylinder pressure intensity is as high as 7-15MPa, the water absorption rate is as low as 3-5%, and damage is not easily caused; the coal ash ceramsite can be used for preparing lightweight aggregate high-performance concrete, building wall plates, bridges and pipelines; the coal ash ceramsite is relatively lowly required in Lightweight Aggregates and Its Testing Methods Part I: Lightweight Aggregates, the strength requirement of high-strength ceramsite of which the density range is 600-900kg / m<3> is 4-6.5MPa, and the water absorption rate is generally less than 20%.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD +1

Film-coated modified propping agent, and preparation method and application thereof

The invention discloses a film-coated modified propping agent, and a preparation method and an application thereof. The film-coated modified propping agent is composed of a matrix and a resin layer uniformly coated out of the matrix, wherein the matrix is Hobq quartz sand; the resin layer is 1-10 wt% based on that of the matrix; and the resin layer comprises a resin binder and a curing agent, wherein the resin binder is bisphenol A epoxy resin, polyurethane resin or a combination thereof, the curing agent is an aliphatic polyamine curing agent an oralicyclic amine curing agent, and the usage amount of the curing agent is 10-50 wt% based on that of the resin layer. The preparation method of the film-coated modified propping agent is that the resin layer is coated on the outer surface of the matrix. The film-coated modified propping agent can be applied in fields of fracturing exploitation of oil and gas wells, is helpful to increase sand ratio and reduce usage amount of fracturing liquid, can effectively prevent backflow phenomenon, alleviates insertion of the propping agent, increases crack diversion capability, prolongs fracturing validity period, is helpful to increase oil output, reduces water yield and has significant meaning for solving the exploitation of low permeability oil field.

Owner:亿利沙材料科技有限责任公司

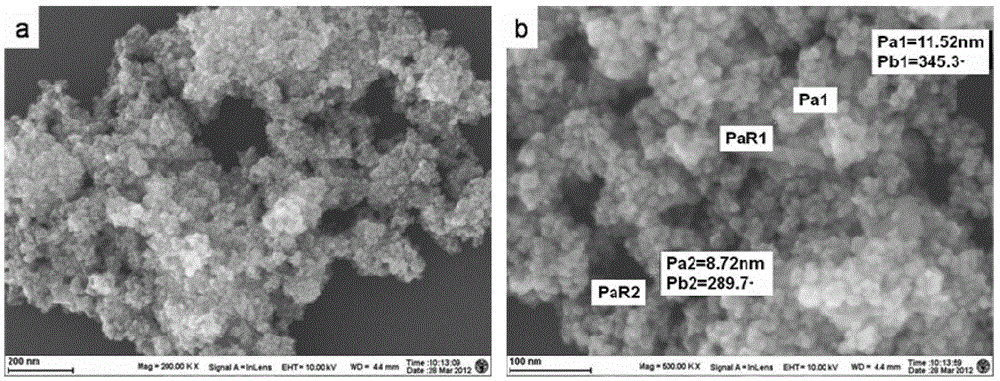

Preparation method of porous magnetic polystyrene microspheres

ActiveCN102964539AEasy to shapeEvenly distributedOrganic/organic-metallic materials magnetismCross-linkBenzoyl peroxide

The invention discloses a preparation method of porous magnetic polystyrene microspheres. The method comprises steps of: (1) adding dry Fe3O4 magnetic nanoparticles into an aqueous ethanol solution, treating with ultrasonic, adding vinyltriethoxysilane, transferring into a reactor together, stirring under a constant temperature and a nitrogen atmosphere for aging, and then washing, drying under vacuum and grinding the obtained product into powder; (2) mixing the powder obtained in the step (1) and benzoyl peroxide, and then adding into styrene containing a pore forming agent and a cross-linking agent for the ultrasonic treating; (3) dissolving polyvinylpyrrolidone and sodium dodecyl sulfate into water by using the ultrasonic; and (4) adding the liquid obtained in the step (2) into the liquid obtained in the step (3), treating with the ultrasonic, pouring the obtained mixture into a reactor, heating for condensation reflux to obtain a suspension liquid, separating with magnet, washing with ethanol, re-separating with the magnet, re-washing with pure water, drying under vacuum and grinding to obtain claybank powdery product, extracting with a soxhlet way, and drying under vacuum to obtain the finish product.

Owner:NANJING FORESTRY UNIV

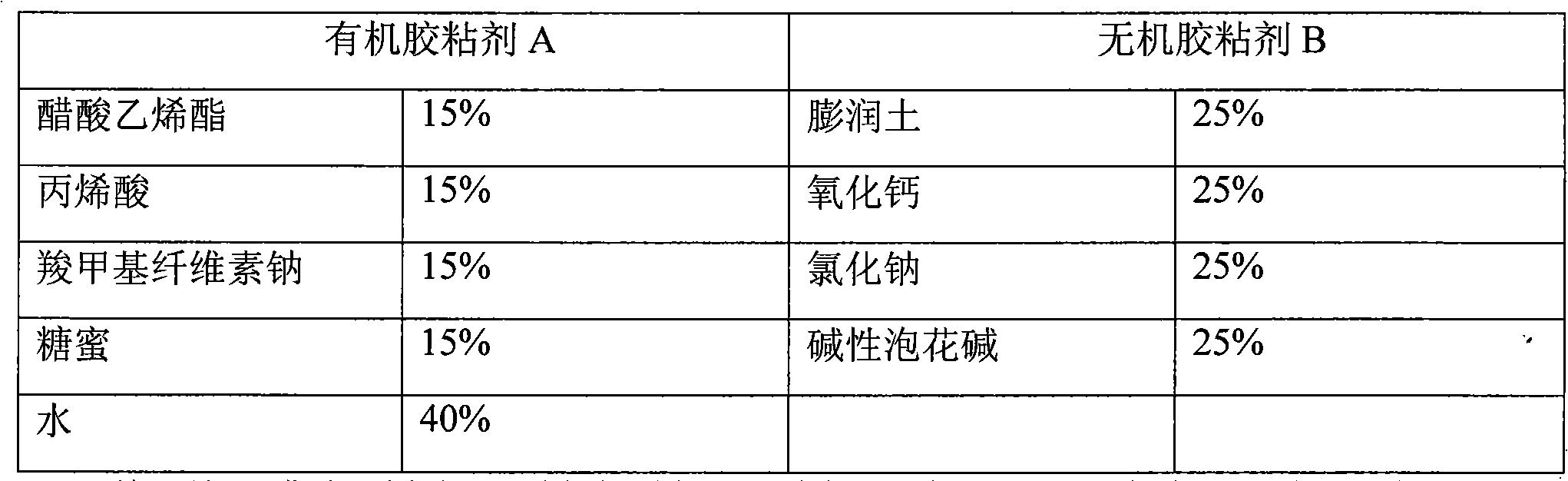

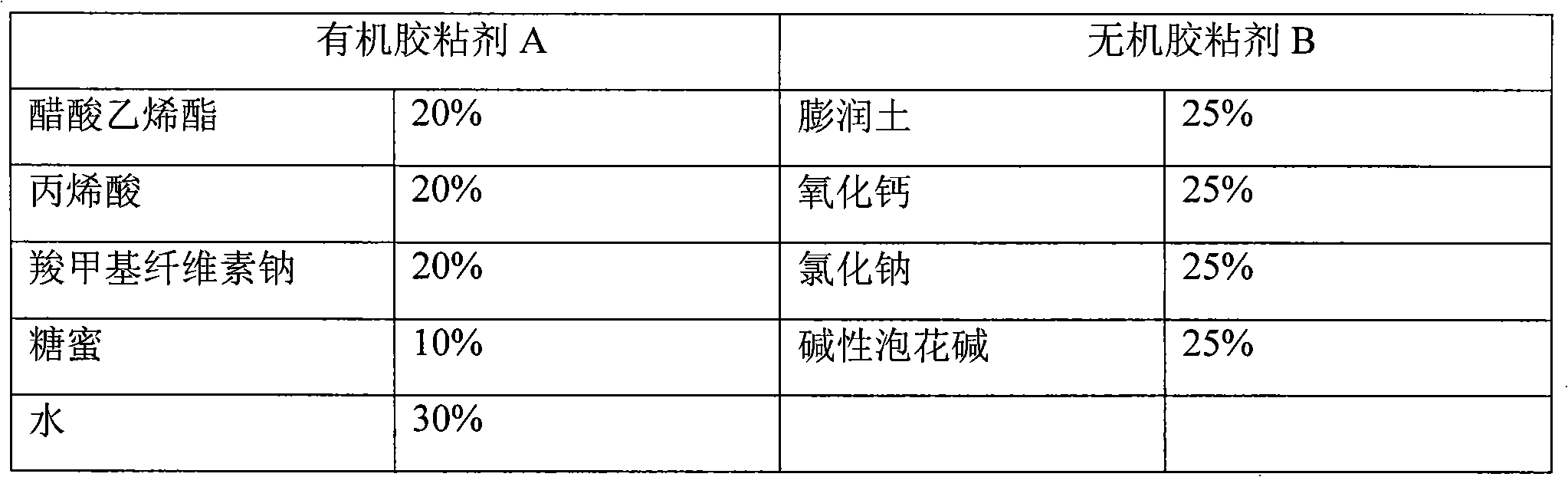

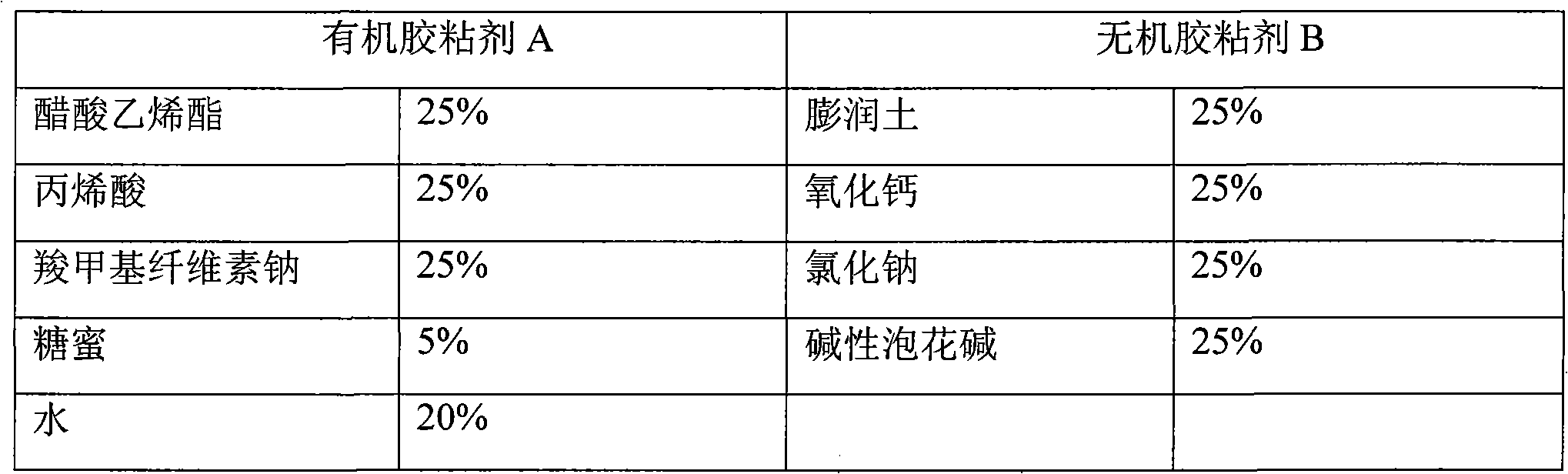

Method for preparing cold-bonded pellets from iron containing sludge by compound adhesive

InactiveCN101775489AReduce the amount of non-ferrous materialsReduce pollutionCelluloseSodium Bentonite

The invention relates to a method for preparing cold-bonded pellets from sludge containing iron by an compound adhesive, belonging to the technical field of adhesives for metallurgical ironmaking. The method of the invention comprises the following concrete steps: adopting the compound adhesive of an inorganic adhesive and an organic adhesive, wherein the organic adhesive in the compound adhesive comprises the following raw materials: vinyl acetate, acroleic acid, sodium cellulose glycolate, polyvinyl alcohol, polyisobutylene, molasses and coal tar; and the inorganic adhesive comprises the following raw materials: bentonite, calcium oxide, basic sodium silicate, sodium chloride, talcum powder and light calcium carbonate. When the organic adhesive and the inorganic adhesive in the adhesive are prepared, the components are proportioned and controlled strictly in a proper order, so that the defects of one adhesive singly used can be avoided, and the compound adhesive has good caking property on the iron containing sludge. The method of the invention recycles iron from iron containing sludge and changes waste into resources, thereby reducing pollution of storage and transport on the environment, and saving the energy consumption in the sintering and high furnace production.

Owner:TONGJI UNIV

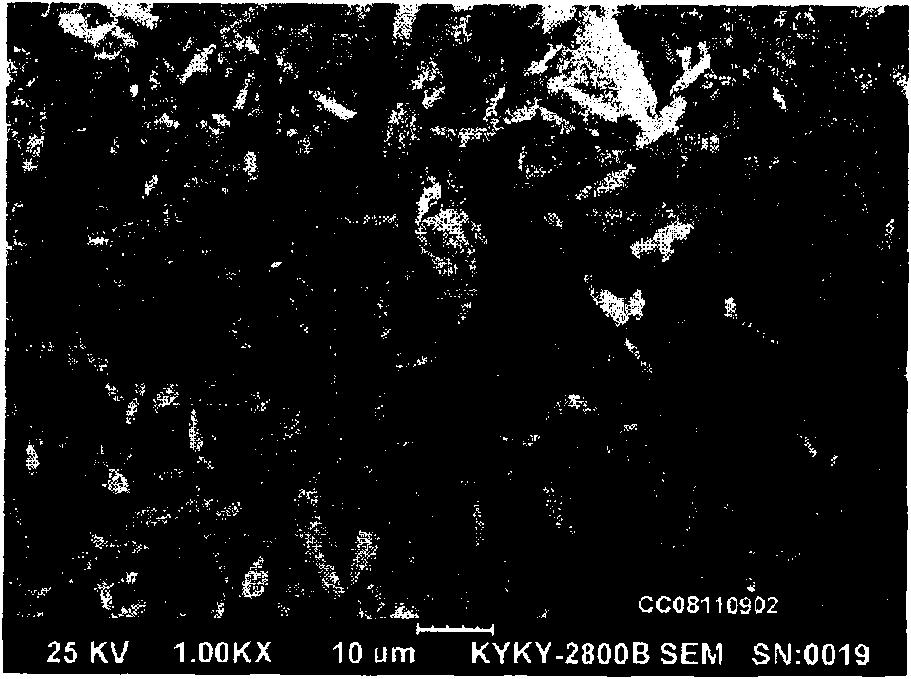

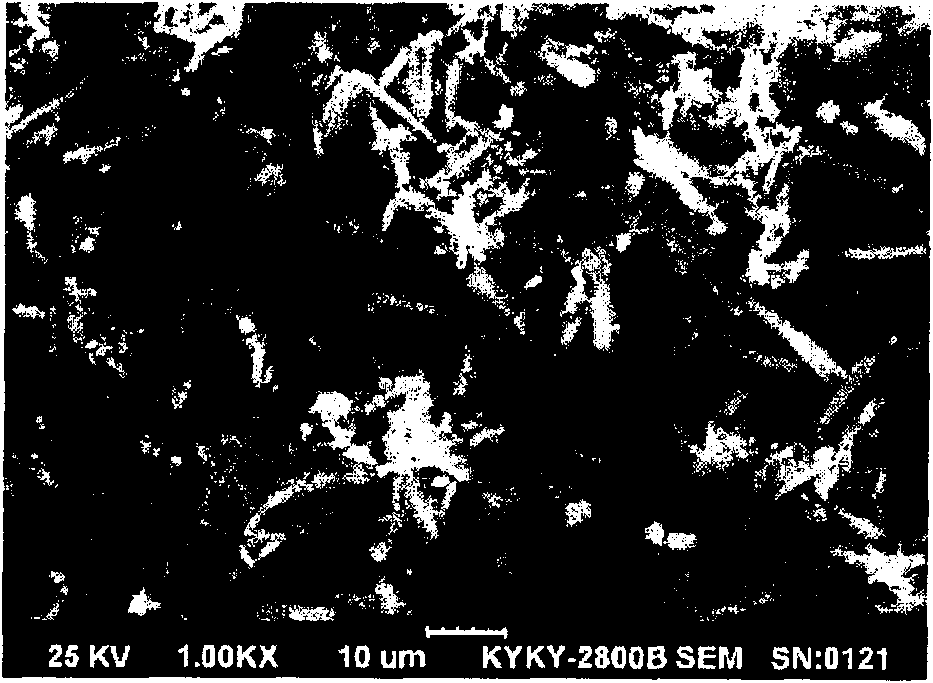

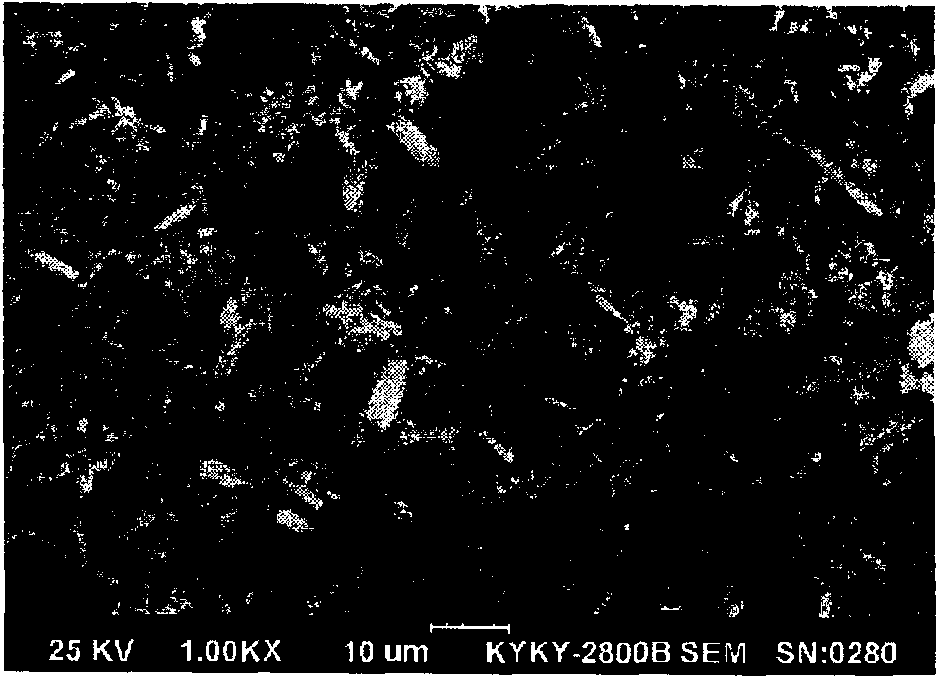

Raw material mixing ratio and preparation method of red mud ceramsite

InactiveCN109665813AGood ballSolve the use problemCeramic materials productionCeramicwareSodium BentoniteSludge

The invention discloses a raw material mixing ratio and preparation method of red mud ceramsite. The red mud ceramsite is prepared from the following raw materials by weight percent: 15 to 75 percentof red mud, 10 to 65 percent of building waste or sludge or bauxite or coal ash or coal gangue or clay or binder, 1 to 20 percent of water, 5 to 35 percent of crushed glass or SiO2, 5 to 25 percent ofcement and 10 to 45 percent of foaming agent or gas forming agent or expansion agent or other additives (comprising bentonite, NaNO3 powder, starch and metal powder such as aluminum, zinc, calcium carbide, magnesium and the like). The binder, the gas forming agent and the foaming agent comprise all types available in the market at present. The production process comprises the steps of treating raw materials, pelletizing, granulating, layering screening, baking by a temperature box, calcining raw ceramsite, and cooling. The ceramsite prepared in the invention meets the national and relevant industrial safety requirements and indexes and has excellent acoustic performance and is high in high temperature resistance, high pressure resistance and strength. In addition, a great amount of solidwaste is adopted, so that the environmental protection significance is outstanding. Production equipment utilizes bio-fuel, thereby saving the energy compared with a conventional calcining productionmethod.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Fluorescent microsphere and preparation method and application thereof

ActiveCN104046350AWith fluorescent whitening effectGood ballMicroballoon preparationLuminescent compositionsColored whiteBright-white

The invention relates to a fluorescent microsphere and its preparation method. Particle size of the fluorescent microsphere is within the range of 0.1-10 micrometer. The fluorescent microsphere has good sphericity and narrow particle size distribution and also has fluorescent brightening groups. The fluorescent brightening groups are uniformly or randomly distributed in a polysiloxane microsphere or on the surface of the polysiloxane microsphere such that the polysiloxane microsphere has a fluorescent brightening effect, has high light fastness, has excellent heat resistance and high chemical stability, can absorb ultraviolet rays to prevent aging of a product, is especially suitable for an originally yellowish product, endows a product with bright white appearance, can make a colored product more dazzlingly beautiful when used in the colored product, and can enhance brightness of a product when used in a black product. The invention, on the other hand, provides a preparation method of the above fluorescent microsphere and a prepared photodiffusion material.

Owner:GUANGZHOU SHINE POLYMER TECH

Linseed oil microcapsules capable of quickly forming films to timely repair scratches and preparation method thereof

InactiveCN103897471AGood lookingUniform and controllable particle sizeCoatingsMicroballoon preparationSolventEmulsion

The invention relates to linseed oil microcapsules capable of quickly forming films to timely repair scratches and a preparation method thereof. According to the microcapsules, linseed oil is used as capsule cores, gelatin is used as a wall material, the capsules are spherical, the average capsule diameter is 20 microns, the capsule walls are uniform, and the surfaces of the microcapsules are smooth. The preparation method comprises the steps of preparing gelatin emulsion and linseed oil emulsion respectively, dripping the linseed oil emulsion into the gelatin emulsion while stirring, and emulsifying the two phases together; adding glacial acetic acid to adjust the pH value of the solution to 4.8, adding an aqueous solution of anhydrous sodium sulfate, and cooling to 20 DEG C to wrap the capsule walls compactly; dripping formaldehyde while stirring, curing capsule films to obtain a solution, and performing freeze drying on the solution to obtain white linseed oil microcapsule solid powder. The gelatin and the linseed oil are emulsified respectively and then emulsified together, so that the linseed oil microcapsules are good in shape, easy in capsule diameter control and stable in solvents such as water, dimethyl benzene and the like; after the microcapsules are added into a coating, the light scattering is weak, and the appearance of the coating is not affected; the linseed oil flowing out after the microcapsules are broken can quickly form the films in oxygen to timely repair the scratches.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +2

Ultralow-density ceramsite proppant prepared from silica and preparation method of ceramsite proppant

The invention relates to an ultralow-density ceramsite proppant prepared from silica and a preparation method of the ceramsite proppant. The ceramsite proppant consists of the following raw materials in parts by weight: 60-80 parts of silica, 5-30 parts of low-aluminum and high-iron bauxite, 1-7 parts of limestone, 1-6 parts of talcum and 1-7 parts of forsterite powder. The preparation method comprises the following steps: breaking and intermediately crushing the raw materials, proportioning the raw materials in proportion, grinding the raw materials by virtue of a wet-process ball mill, removing large particles by virtue of a sieve of 80-110 mesh, and spray-drying so as to obtain a powdery material; forcedly balling the powdery material, drying the material until water content is less than 5wt%, and sieving by virtue of 18-30 mesh so as to obtain a half-finished product; and calcining the half-finished product to obtain a product, cooling the product to room temperature and sieving the product by virtue of 20-40 mesh so as to obtain a finished product with proper grain size, wherein the grain size of the broken raw materials is less than 0.056mm. The ceramsite proppant disclosed by the invention is low in apparent density, high in strength, low in turbidity, relatively low in acid solubility, and the ceramsite proppant is excellent in roundness and sphericity; and the preparation method is simple and is easy to operate.

Owner:ZIBO JIAFENG MINING

Spherical cobalt oxalate powder and production method thereof

ActiveCN101570478AHigh purityQuality improvementCarboxylic acid salt preparationCobalt saltWater soluble

The invention relates to a spherical cobalt oxalate powder and a production method thereof. The average Riley sphericity value of the cobalt oxalate powder is above 0.9, the average grain diameter of the cobalt oxalate powder is 0.5-20mum, and the spherical cobalt oxalate powder is prepared by the liquid phase deposition of potassium oxalate and water soluble cobalt salt in a solution with the pH value over 1.5-8. The spherical cobalt oxalate powder prepared by the producing method has fewer impurities and better appearance, and can be prepared by a simple and efficient production method.

Owner:GEM CO LTD

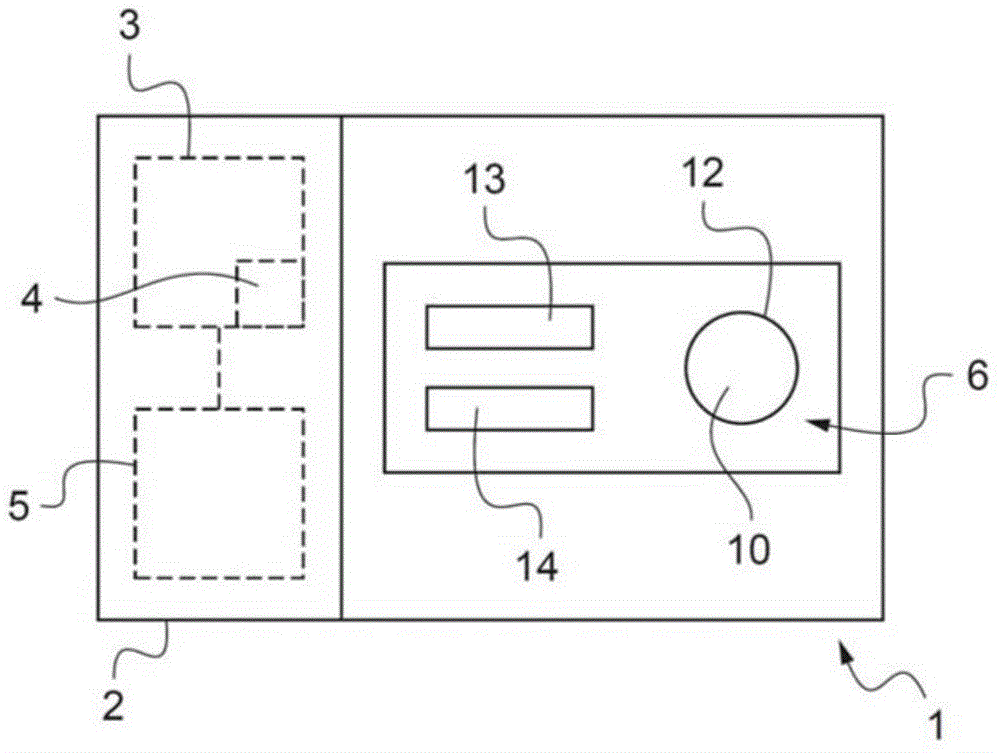

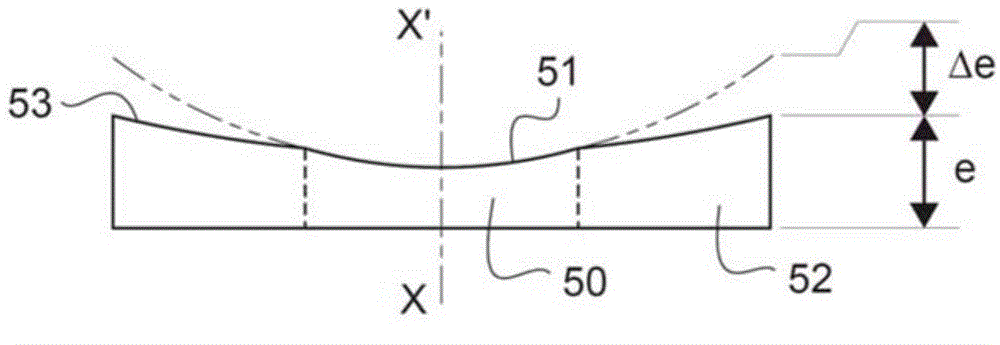

Ophthalmic lens and process for manufacturing such a lens

InactiveCN104950470AGood ballImprove optical qualitySpectales/gogglesAdditive manufacturing apparatusVoxelRefractive index

Owner:ESSILOR INT CIE GEN DOPTIQUE

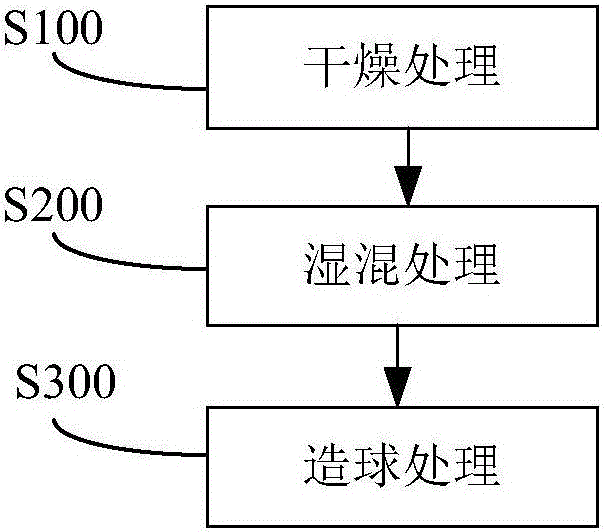

Method and system for preparing red mud pellets

The invention discloses a method and a system for preparing red mud pellets. The method for preparing the red mud pellets comprises the following steps: drying red mud and calcium oxalate so as to obtain dried material and flue gas; performing wet-mixing treatment on the dried material with a reducing agent and a binder so as to obtain wet-mixed material; and carrying out pellet making treatment on the wet-mixed material so as to obtain the red mud pellets. The calcium oxalate is added into the red mud and then dried, the calcium oxalate is dried and heated to decompose to generate CO gas and CaCO3, wherein CO gas can destroy the stable pore passages in the red mud, so that the pore diameter is increased and the surface area is reduced; meanwhile, the capillary water in the red mud pores is reduced, and furthermore pelletizing is facilitated; moreover, the prepared pellet is large in porosity, and the pelletizing rate and the pelletizing efficiency are remarkably improved; CaCO3 obtained by decomposition of the calcium oxalate can be used as a reducing agent in a pellet reduction process, and the addition of the calcium-based reducing agent in the reduction process is omitted.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

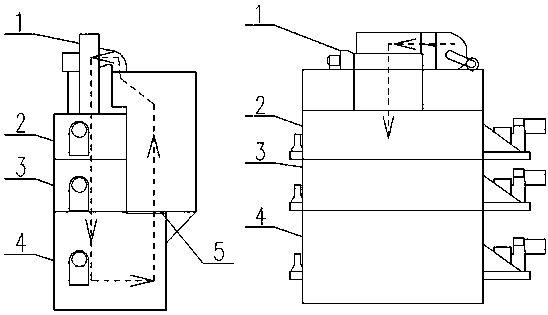

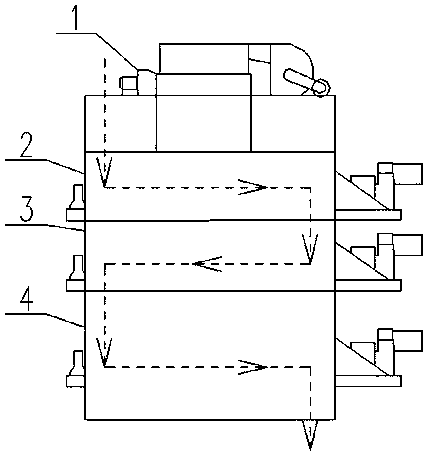

Quicklime hydration method

ActiveCN109608061APromote digestionProlong digestion timeProcess efficiency improvementCalcium hydroxidePropeller

The invention relates to the technical field of quicklime hydration, in particular to a quicklime hydration method. The method comprises the steps that a traditional spiral propeller is transformed into a flat-blade paddle stirring rod, quicklime is squeezed and pushed to pass through three hydration chambers by means of the accumulation of the quicklime under the action of the gravity, the hydration time is prolonged, and the hydration degree of the quicklime in the hydration chambers is greatly increased; the temperature in the hydration chambers is controlled to be 100-120 DEG C through a gas circulation system and condensing equipment, thereby not only ensuring the quick hydration of the quicklime, but also avoiding the damage of a high-temperature environment to the equipment, and also ensuring that the quicklime and calcium hydroxide have moderate viscidity during hydration, so that pelletizing is facilitated, the gas permeability during sintering is good, and the yield and quality of sintered ore are greatly improved; clogging of the hydration chambers caused by excessively sticky raw materials is also overcome.

Owner:南京鲁兴科技有限公司

In-situ generated proppant for hydraulic fracturing

PendingCN112111265AImprove mining efficiencyGood ballFluid removalDrilling compositionPhenol formaldehyde resinSolid particle

The invention discloses an in-situ generated proppant for hydraulic fracturing. When a feed solution of the proppant and a fracturing fluid are injected into an artificial fracture together, small liquid beads formed by the feed solution of the proppant in the pumping process are dispersed in the fracturing fluid, the small liquid beads are carried into the artificial fracture by the fracturing fluid, and the small liquid beads undergo a curing reaction in the fracture to form the spherical granular proppant. The feed solution of the proppant comprises the following components: curable resin,a diluent, a curing agent and a pH regulator, wherein the curable resin is one or a mixture of at least two selected from thermoplastic phenolic resin, thermoplastic urea resin and melamine-formaldehyde resin. A phase interface stabilizer is added into the fracturing fluid. The feed solution beads of the proppant are gradually cured in fracture to form solid particles with good sphericity and highstrength, the effects of supporting artificial fracture and maintaining a high flow guide channel are achieved, and the exploitation efficiency of oil and gas fields is improved.

Owner:四川省帕提科斯能源科技有限公司

High titanium type petroleum oil pressing crack propping agent and production method thereof

InactiveCN1325423CEnvironmentally friendlyReduce manufacturing costSolid waste managementClaywaresSpray GranulationSlag

Owner:PANZHIHUA HUANYE METALLURGICAL SLAG DEV CO LTD

Tectorial membrane proppant as well as preparation method and application thereof

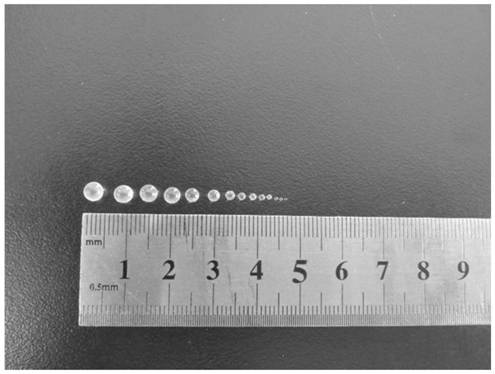

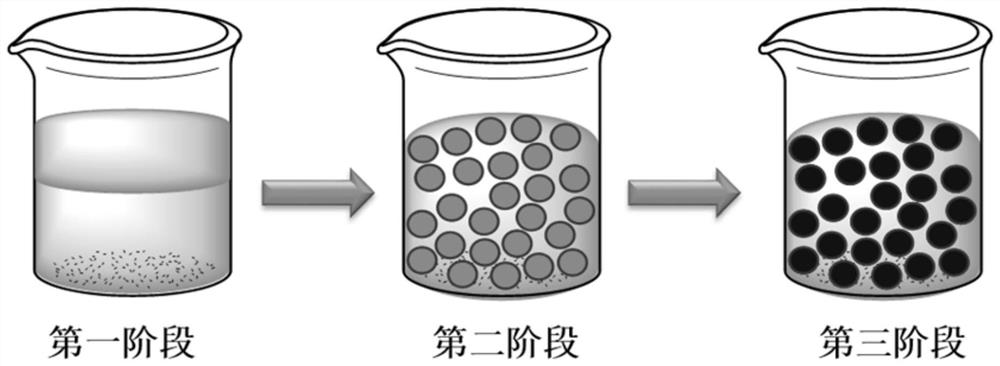

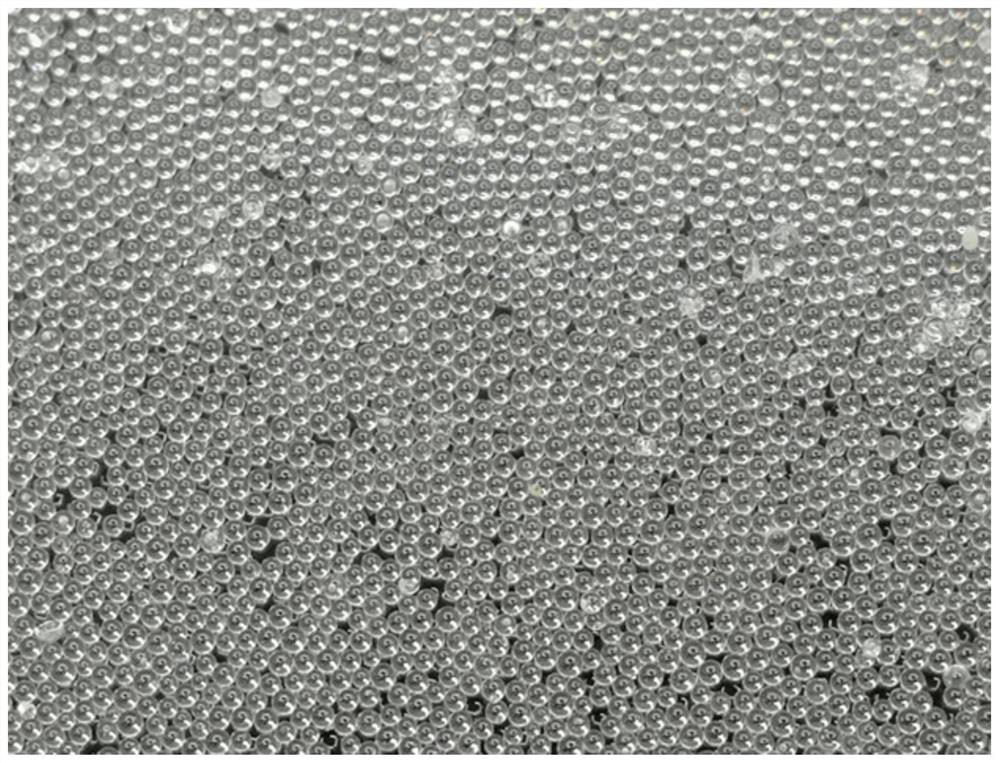

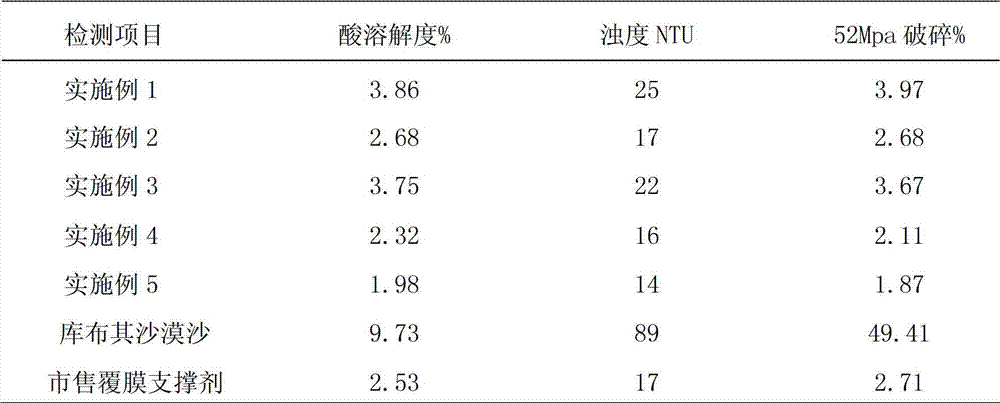

The invention discloses a tectorial membrane proppant as well as a preparation method and the application thereof. The tectorial membrane proppant is characterized by consisting of the following components in part by weight: 150 to 250 parts of Kubuqi desert sand, 2 to 20 parts of resin binder and curing agent and 5 to 50 parts of water, wherein the using amount of the curing agent is 10 to 50 percent of the weight of the resin binder and the curing agent; the resin is waterborne epoxy bisphenol A resin; and the curing agent is waterborne epoxy fatty amine curing agent. The tectorial membrane proppant is prepared by stirring the components uniformly, completely curing, dispersing uniformly and sieving. The tectorial membrane proppant is applied to the field of fracturing exploitation of petroleum and natural gas oil. The invention has the characteristics that the production process is simple; the product has low relative density, high strength, low breakage rate and high roundness, sphericity and chemical inertness; and pollution in the preparation process is avoided. The invention is widely applied to fracturing of oil field and gas field, so that the using amount of fracturing liquid is reduced, the flow guide ability of crack is improved, the fracturing useful life is prolonged, the oil yield is facilitated, and important significance of solving problem about exploitation of low-permeability oil field is achieved.

Owner:亿利沙材料科技有限责任公司

Preparation method of porous magnetic polystyrene microspheres

ActiveCN102964539BEasy to shapeEvenly distributedOrganic/organic-metallic materials magnetismCross-linkBenzoyl peroxide

The invention discloses a preparation method of porous magnetic polystyrene microspheres. The method comprises steps of: (1) adding dry Fe3O4 magnetic nanoparticles into an aqueous ethanol solution, treating with ultrasonic, adding vinyltriethoxysilane, transferring into a reactor together, stirring under a constant temperature and a nitrogen atmosphere for aging, and then washing, drying under vacuum and grinding the obtained product into powder; (2) mixing the powder obtained in the step (1) and benzoyl peroxide, and then adding into styrene containing a pore forming agent and a cross-linking agent for the ultrasonic treating; (3) dissolving polyvinylpyrrolidone and sodium dodecyl sulfate into water by using the ultrasonic; and (4) adding the liquid obtained in the step (2) into the liquid obtained in the step (3), treating with the ultrasonic, pouring the obtained mixture into a reactor, heating for condensation reflux to obtain a suspension liquid, separating with magnet, washing with ethanol, re-separating with the magnet, re-washing with pure water, drying under vacuum and grinding to obtain claybank powdery product, extracting with a soxhlet way, and drying under vacuum to obtain the finish product.

Owner:NANJING FORESTRY UNIV

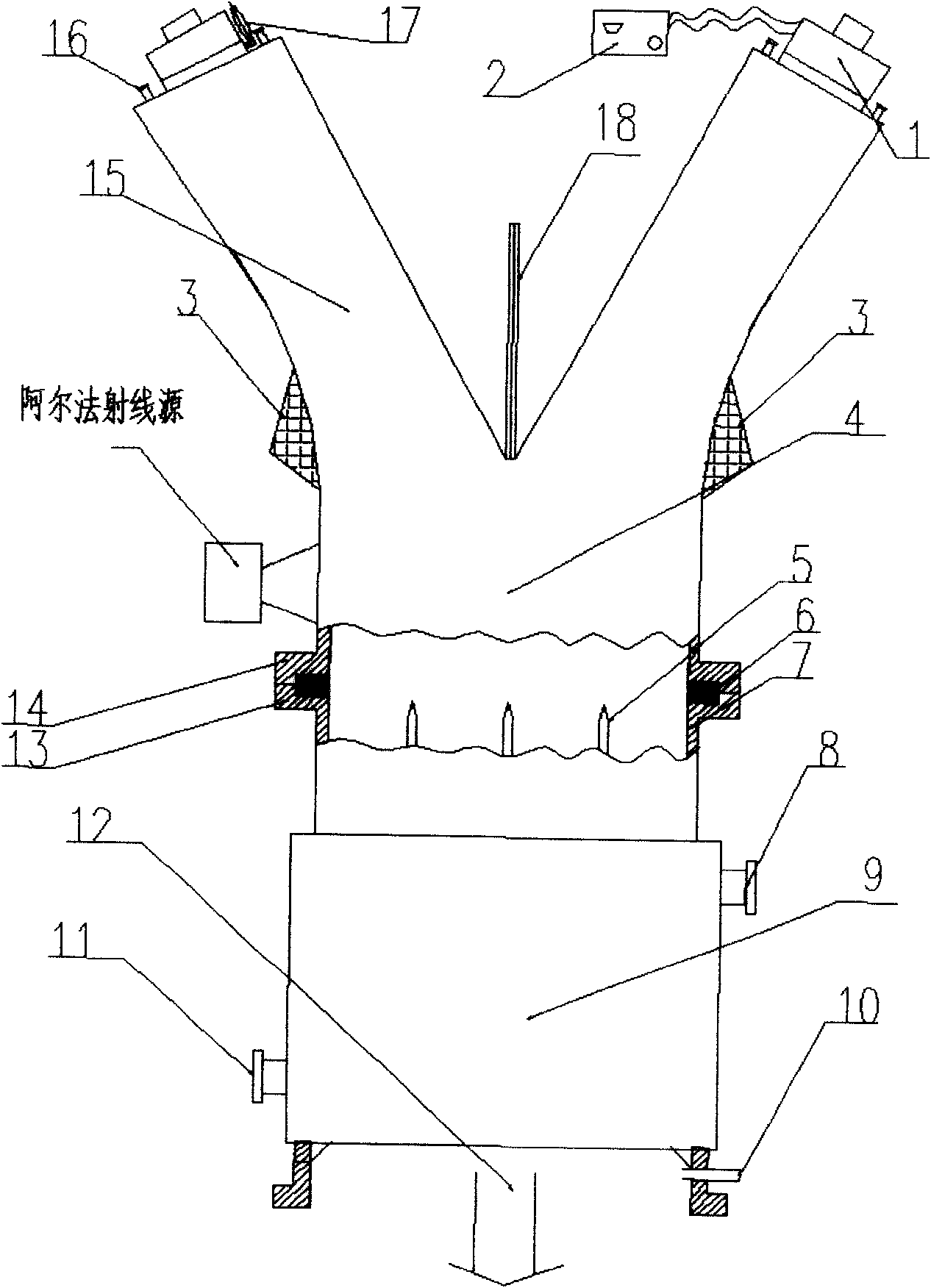

Process and device for preparing nano-powder by utilizing ultrasonic static electricity

InactiveCN101623616AGood monodispersityReduce reunionGranulation by liquid drop formationChemical/physical/physico-chemical nozzle-type rreactorsEngineeringPollution

The invention provides a process and a device for preparing nano-powder by utilizing ultrasonic static electricity. The process and the device combine the advantages of ultrasonic atomization and static atomization and skillfully overcome the disadvantages of the two. The process mainly comprises the following steps that: raw material is heated to be in a liquid state through a heating furnace, degassed through a degassing device and then conveyed to an atomizer through a pipeline; the raw material in the atomizer is first precharged via a precharging device and then is guided into a nozzle of a piezoelectric-type ultrasonic atomization system through a flow-guiding pipe in order to be atomized; the obtained material is accelerated through a primary acceleration-ring group, enters an inductive charging ring, and is charged and atomized again; the atomized raw material is accelerated through a secondary acceleration-ring group, joined and mixed through a Y-shaped pipe; mixed compounded fog drops are irradiated with an alpha ray source to remove surface charge; the charge-removed fog drops pass through a flow-guiding device (a resistance-wire heating pipe is arranged in the flow-guiding device to perform corresponding thermal decomposition on the fog drops needing thermal decomposition), enter a condenser, are condensed into solid powder; and the solid power leaves the atomizer and then enters a collection device in order to be collected. Therefore, the nano-powder with product stability, high performance, narrow particle distribution, uniform particle distribution, good monodispersity, little agglomeration, high purity and good sphericity can be prepared by utilizing equipment which is simple, low in cost, free from pollution, easy to control and suitable for large-scale continuous industrial production.

Owner:李洋

Low-density petroleum fracturing propping agent and preparation method thereof

ActiveCN110628411ALow densityHigh strengthFluid removalDrilling compositionSodium BentoniteResource utilization

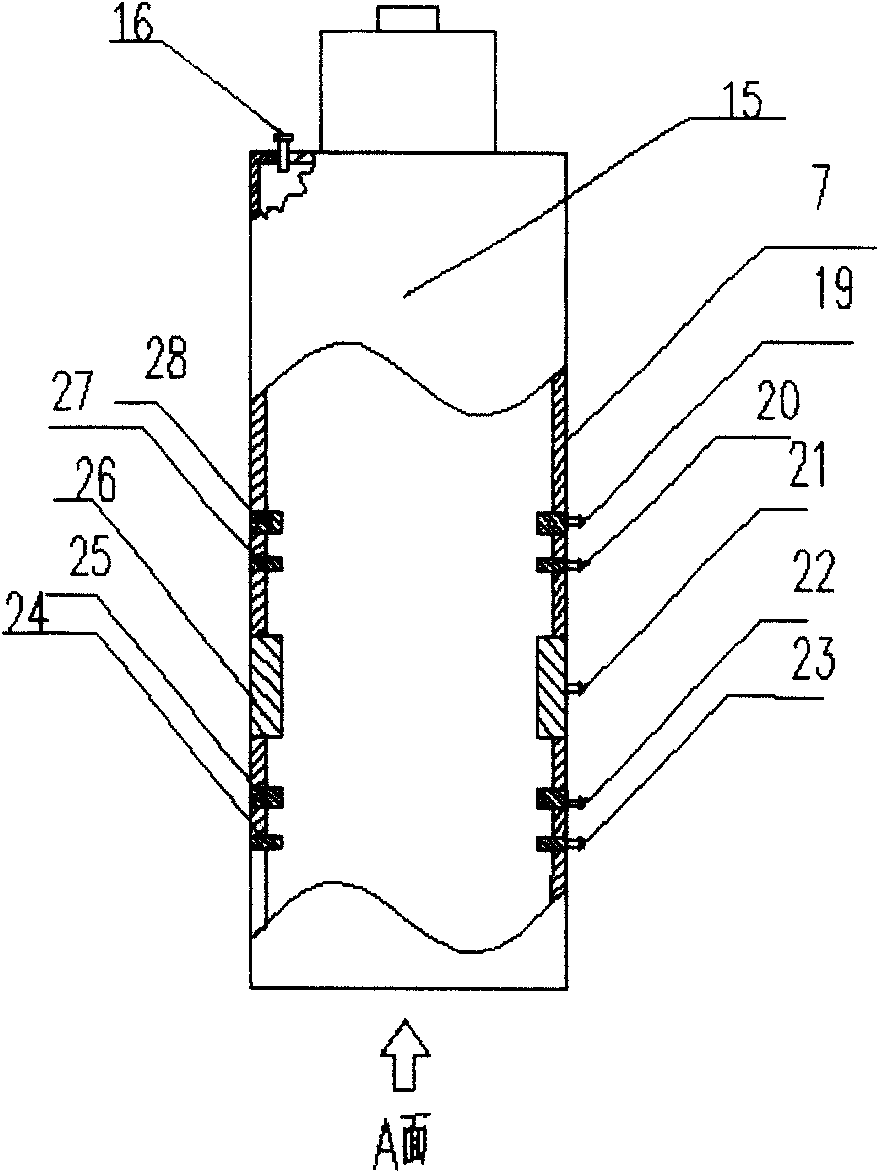

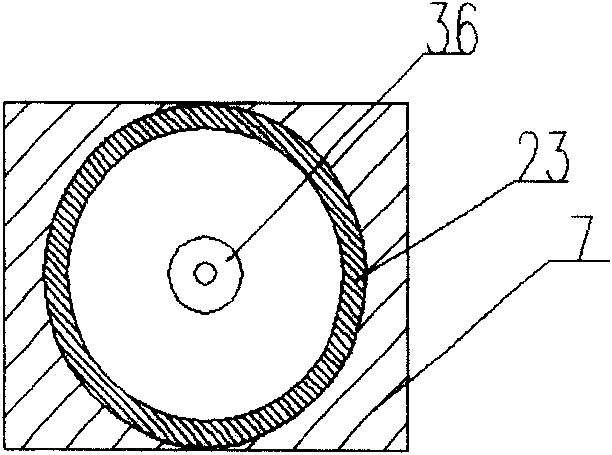

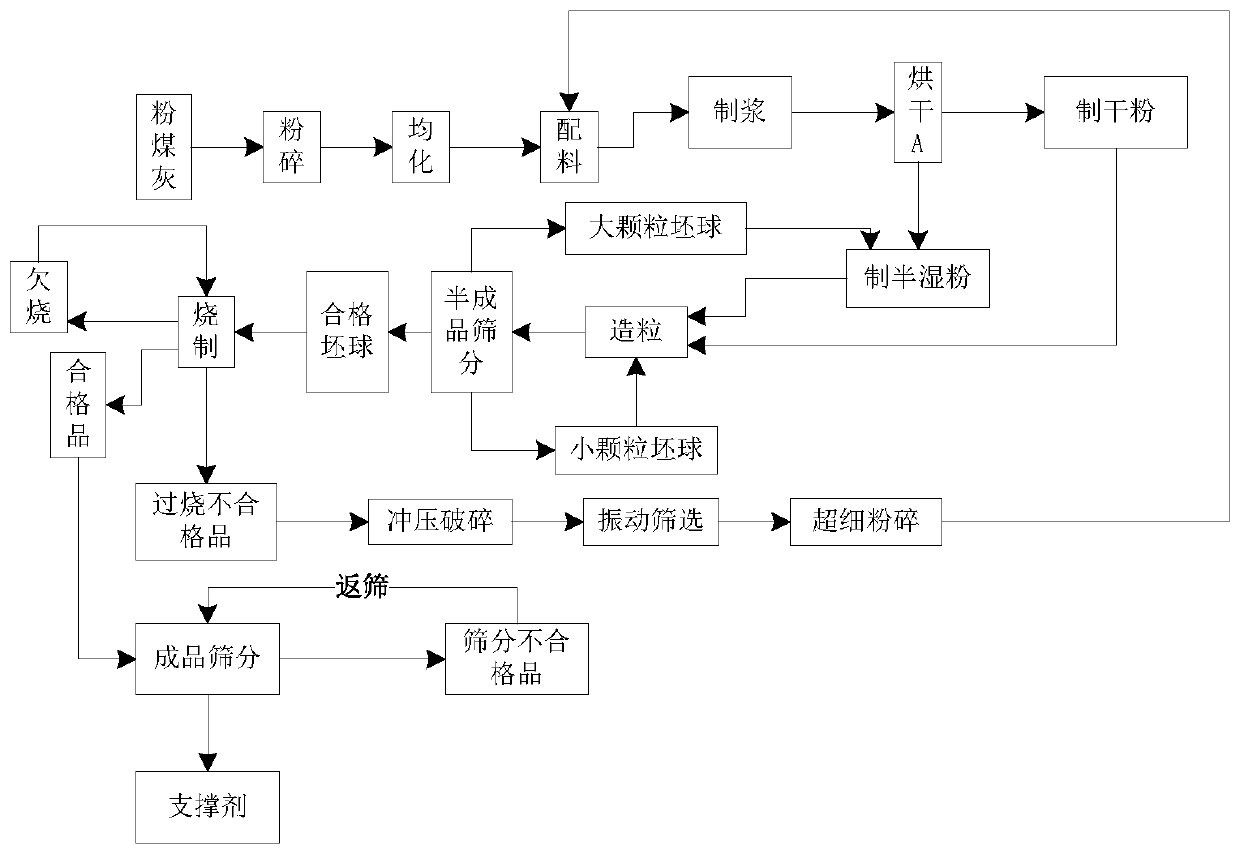

The invention discloses a low-density petroleum fracturing propping agent and a preparation method thereof, belonging to the technical field of petroleum fracturing propping agents. The low-density petroleum fracturing propping agent is prepared from light-burned bauxite, bentonite, light-burned magnesium powder, manganese powder, overburned recycled powder, silica fume and low-alumina fly ash. The invention further discloses a preparation method of the low-density petroleum fracturing propping agent. The method comprises the steps of burdening, slurrying, homogenizing, drying, granulating andscreening. According to the invention, overburnt blank balls are crushed and then used as the overburnt recycled powder, so the problem of raw material wasting is reduced, the density of the petroleum fracturing propping agent is reduced, the stability and strength of the petroleum fracturing propping agent are improved, resource utilization is achieved, and large-scale production of the petroleum fracturing propping agent is facilitated.

Owner:DATANG TONGZHOU TECH

A film-coated modified proppant and its preparation method and application

Owner:亿利沙材料科技有限责任公司

Low-energy-consumption preparation method of pitch-based spherical active carbon

The invention discloses a low-energy-consumption preparation method of pitch-based spherical active carbon, belonging to the technical field of spherical active carbon. The preparation method comprises the main steps of: mixing benzoyl peroxide, divinylbenzene, styrene, diethylbenzene and pitch powder with a softening point of 240-280 DEG C and the grain size of 150-200 meshes; and suspending in a polyvinyl alcohol dispersion liquid to form balls, curing the balls by using a hydrothermal method to form original carbon balls, calcining original carbon balls in a segmental manner and activating to obtain the pitch-based spherical active carbon. The low-energy-consumption preparation method of the pitch-based spherical active carbon, disclosed by the invention, has the advantages and benefits of fast curing speed, low needed temperature, low energy consumption and saved production time as the benzoyl peroxide, divinylbenzene and styrene are adopted as curing agents for curing the pitch. The pitch-based spherical active carbon prepared by the method has the specific surface area of 650-1200 sq.m. / g and the grain size of 300-800 microns and has good sphericity.

Owner:TIANJIN UNIV

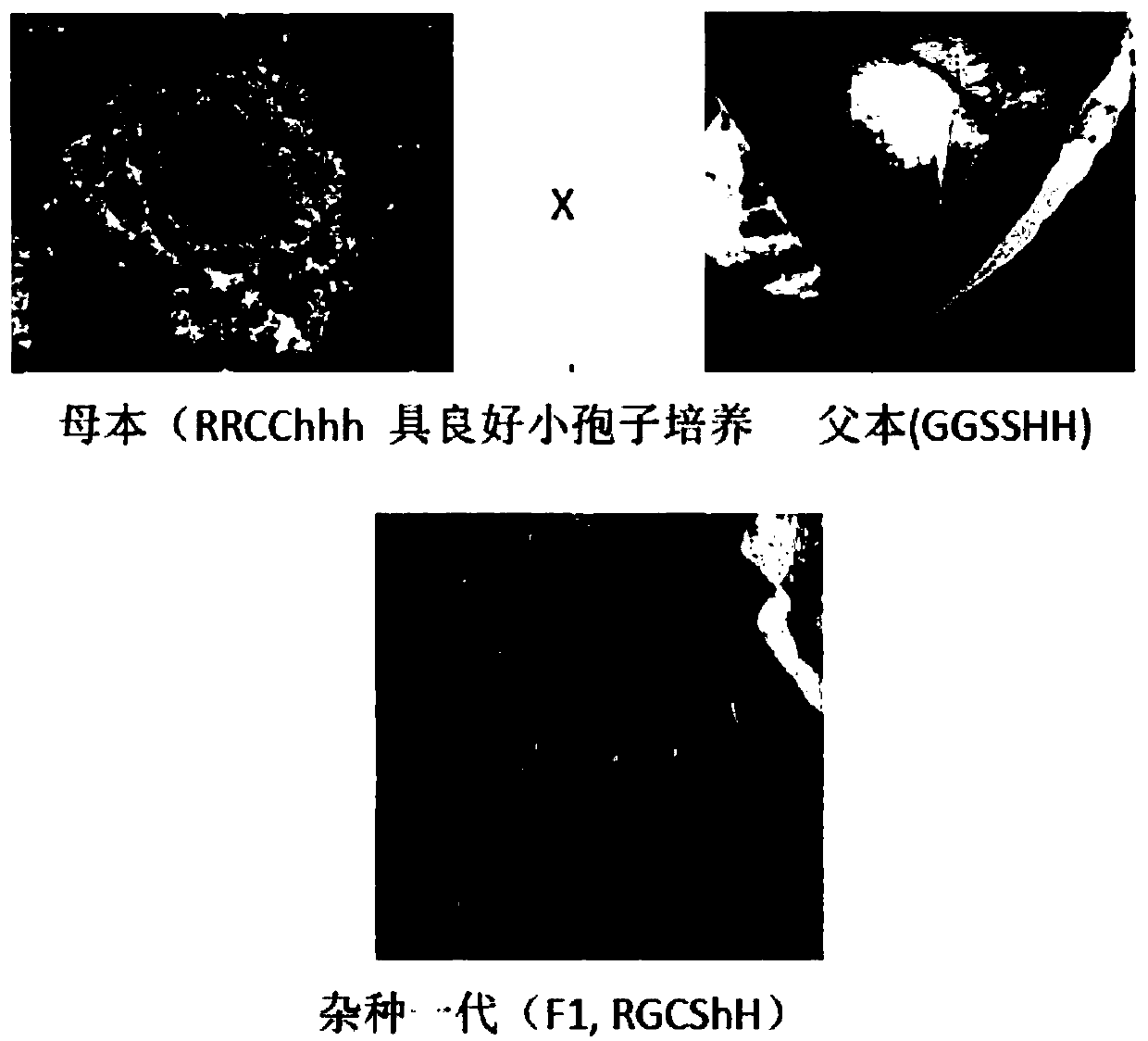

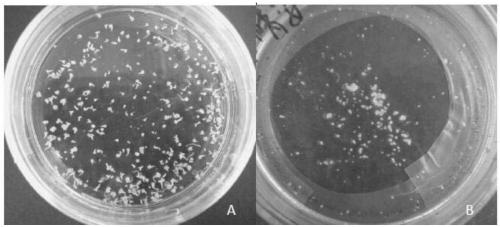

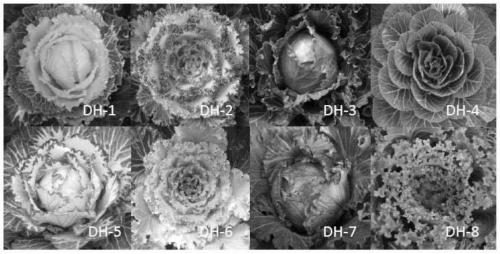

Cultivation method of novel germplasm of colorized brassica oleracea L.var.capitata

PendingCN109662025AStrong ornamentalImprove cold resistancePlant genotype modificationPlant cellsGermplasmGenotype

The invention belongs to the technical field of genetic breeding of plants, and specifically relates to a cultivation method of a novel germplasm of colorized brassica oleracea L.var.capitata. The cultivation method is characterized in that parents of the cultivation method comprise brassica oleracea L.var.capitata and ornamental kale; the male parent is the brassica oleracea L.var.capitata, and the female parent is the ornamental kale; or, the female parent is the brassica oleracea L.var.capitata, and the male parent is the ornamental kale; the ornamental kale is b.oleracea L.var.acephala DC.; and more preferably, the genotype of the male parent is GGSSHH, and the genotype of the female parent is RRCChh; or, the genotype of the male parent is RRSShh, and the genotype of the female parentis GGSSHH. According to the invention, when the breeding germplasm is selected, the b.oleracea L.var.acephala DC. with strong ornamental property and cold-resistant property is selected, and the brassica oleracea L.var.capitata with sweet and soft mouth feel, and good balling property and ball shape and suitable for uncooked eating is selected as a parent material, so that the cultivated colorizedbrassica oleracea L.var.capitata has the characteristics that the color variety is rich; the color is bright; the ornamental property is strong; the cold-resistant property is strong; the eating quality is good; the mouth feel is sweet and crisp; the colorized brassica oleracea L.var.capitata is suitable for uncooked eating; and the balling property is relatively good.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES +1

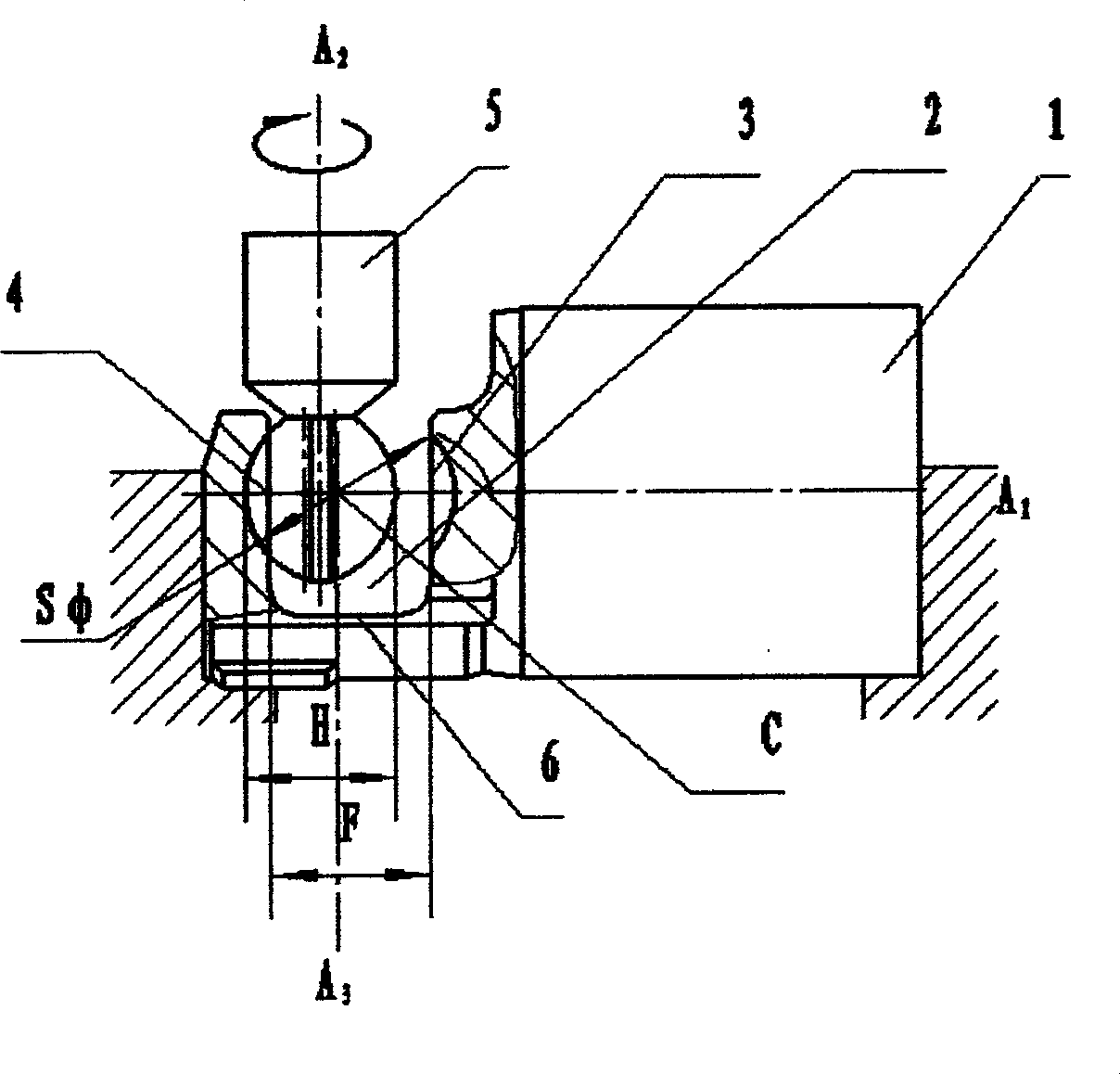

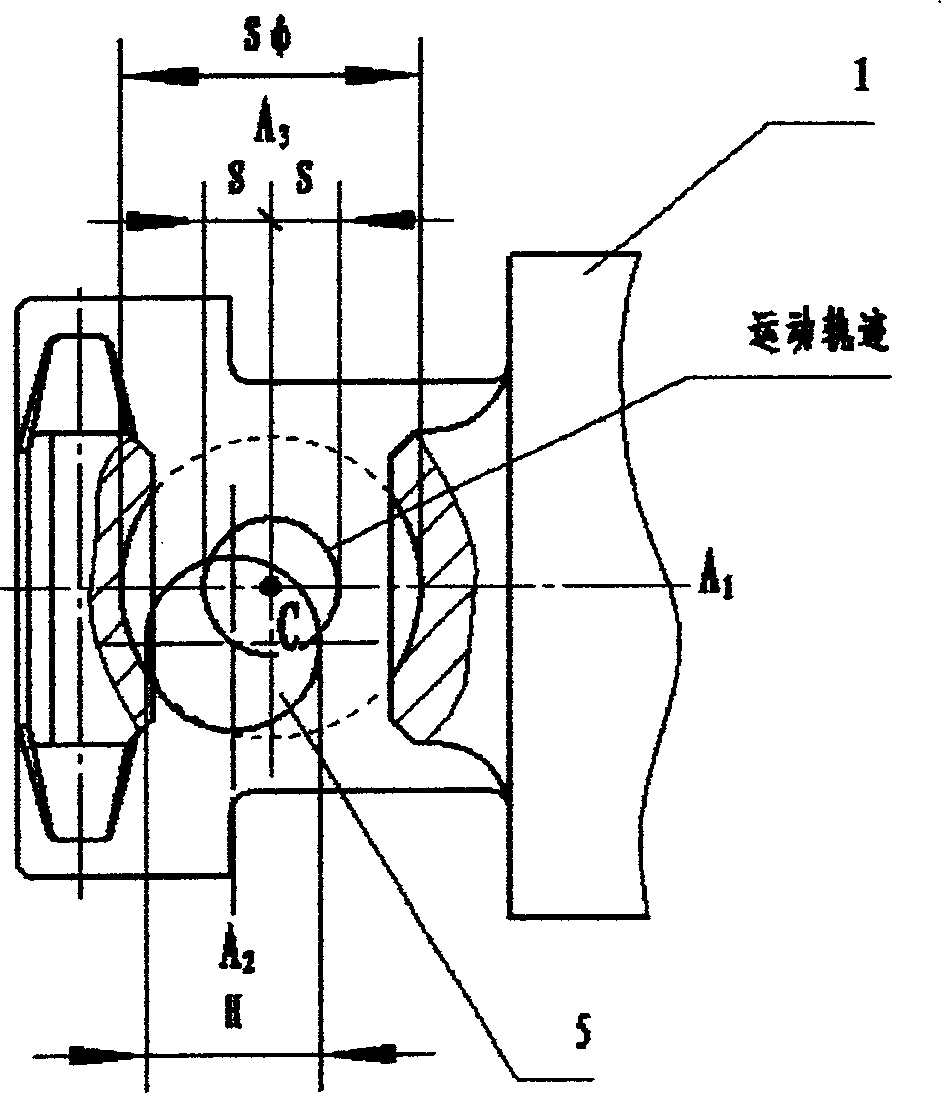

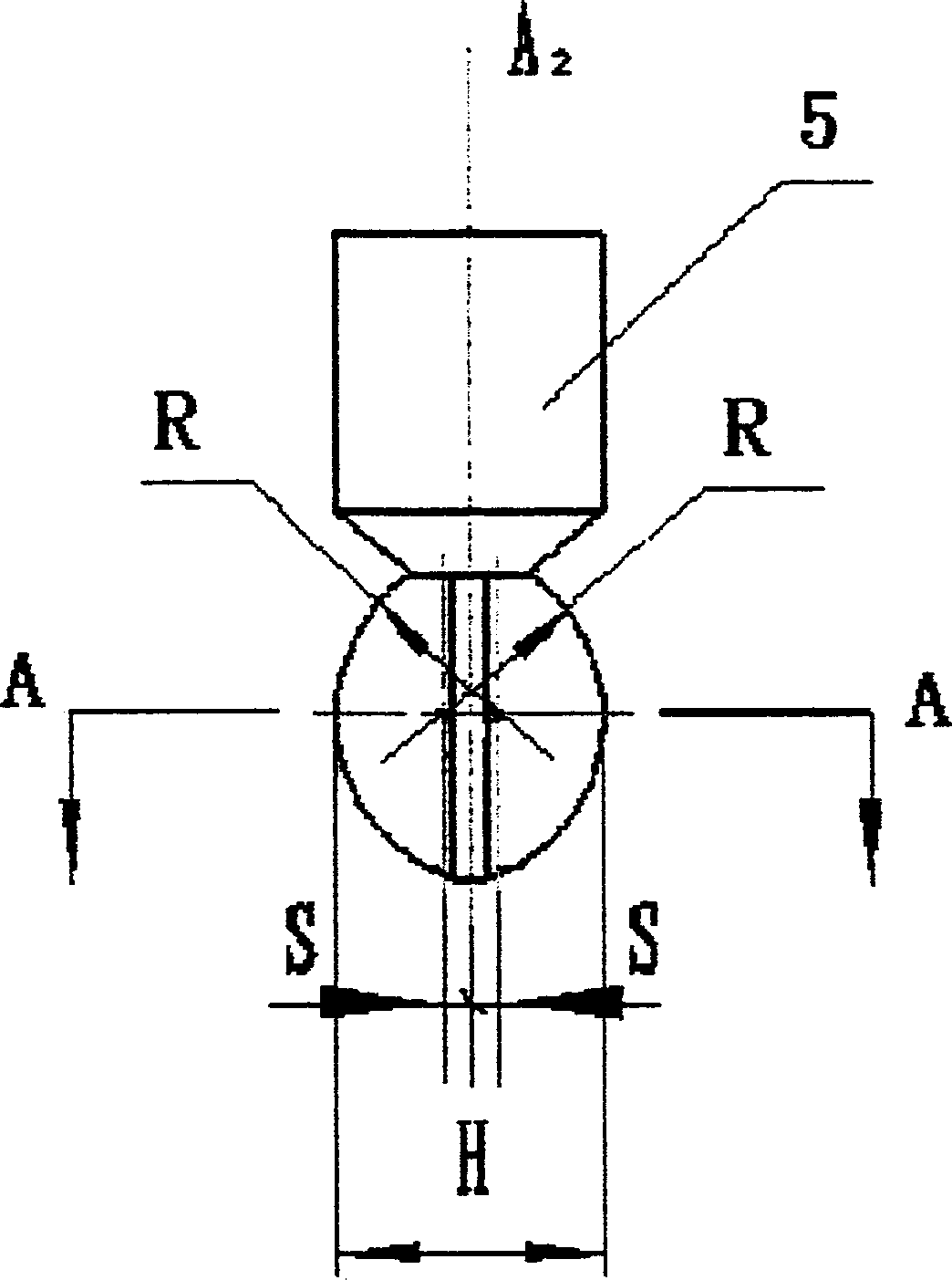

Method for manufacturing pistons of compressor

A method for machining a slippe slot on a piston used for compressor of air conditioner features that the piston and cutting tool are relatively moving and one of them is doing a circumferential movement relatively to another on a single plane around a circle center which is a predefined point on a ball body with the cutting tool is rotating around its central line.

Owner:ZHEJIANG YIFENG MACHINERY

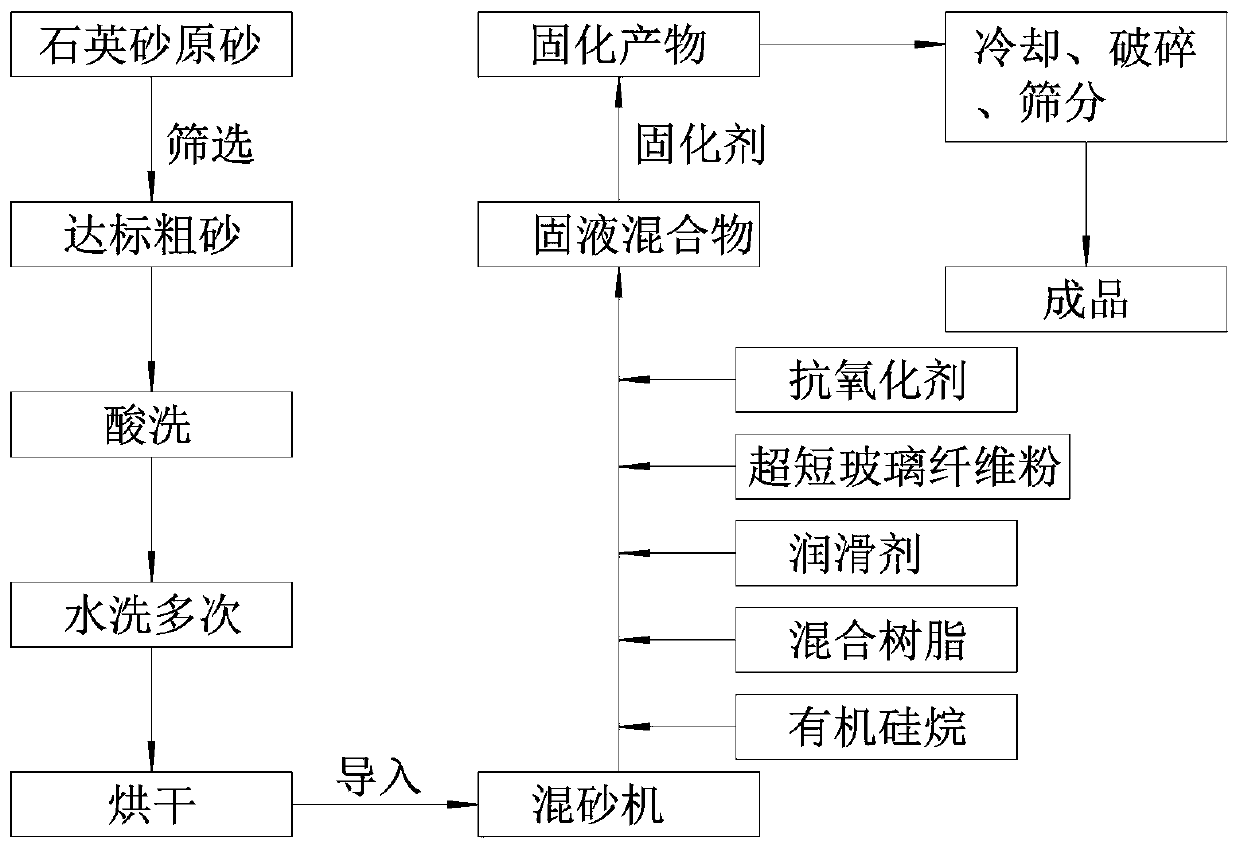

High-strength coated quartz sand, and preparation technology and preparation device thereof

InactiveCN109852369AImprove the bonding strength of the interfaceHigh strengthFluid removalChemical treatmentAlkali free

The invention relates to a high-strength coated quartz sand, and a preparation technology and a preparation device thereof. The high-strength coated quartz sand comprises, by weight, 70-120 parts of quartz sands, 10-50 parts of mixed resin, 10-15 parts of ultra-short glass fiber powder, 5-10 parts of a curing agent, 1-10 parts of organosilane and 0.5-1 part of a lubricant. The quartz sands are chemically treated during preparation to change the surface roughness, and a coupling agent is added to enhance the interfacial bonding strength between a coating layer and the quartz sands through chemical bonds; a plurality of resins are combined in proportion, and are combined with the alkali-free ultra-short glass fiber powder to further enhance the strength of the resin, so the strength of the coated sand is enhanced; the lubricant can avoid the adhesion between sand bodies in order to keep particles from sticking to each other; and the raw materials are easy to obtain and are cheap, the technology is simple, and the prepared coated sand has good sphericity and high strength, and is easy to promote and use.

Owner:河南祥盛陶粒有限公司

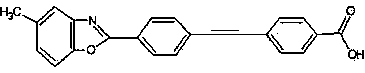

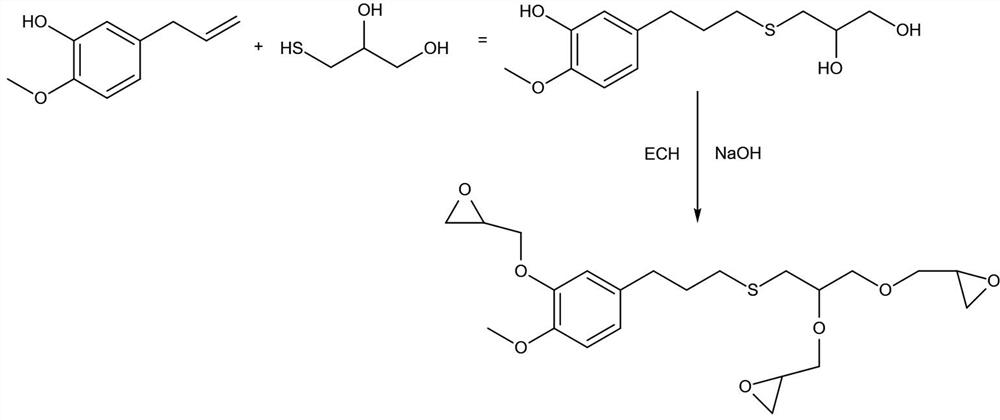

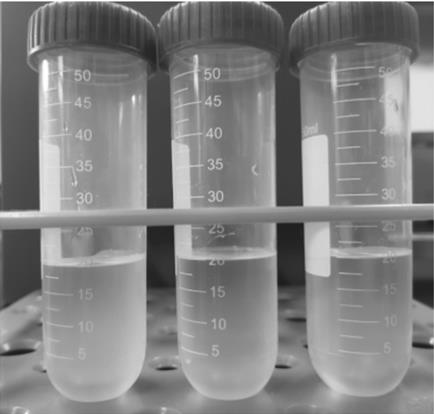

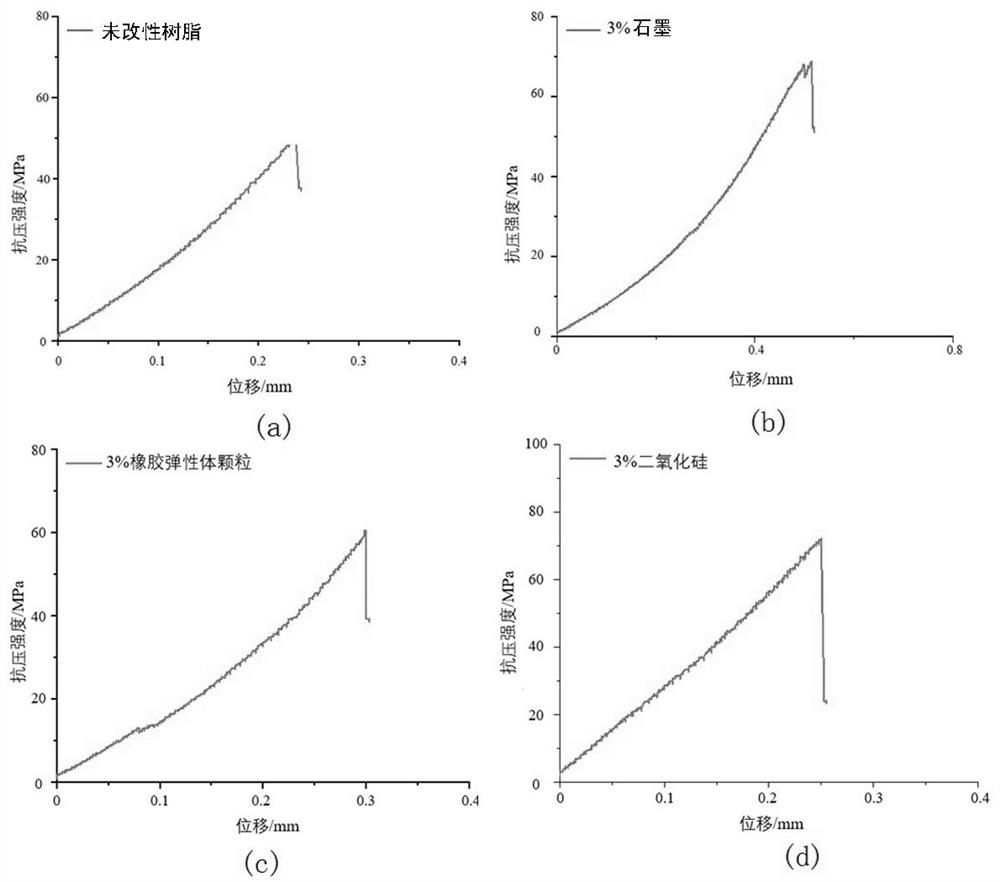

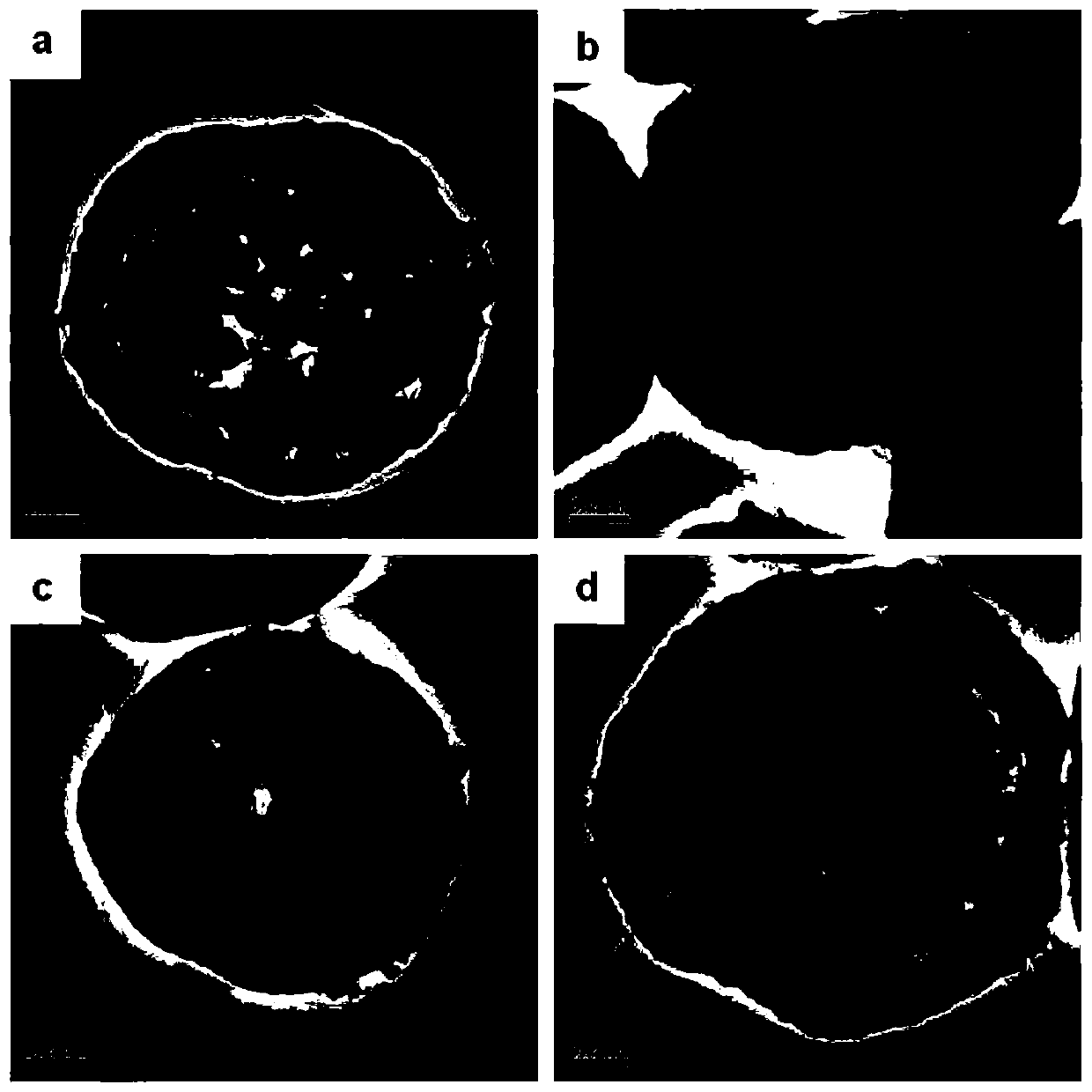

Preparation method of self-phase-change proppant based on emulsified toughened bio-based epoxy resin

The invention belongs to the technical field of oilfield development, and discloses a self-phase-change proppant based on emulsified toughened bio-based epoxy resin. Bio-based epoxy resin is subjected to toughening modification through graphite particles, then SiO2 particles are used as an emulsifier for emulsification, the propping agent is prepared, the proportion of different meshes in the propping agent is adjusted by changing the concentration of the emulsifier during emulsification, and the chemical formula of the bio-based epoxy resin is shown in the specification. The proppant particles have good sphericity, so that the fracture permeability is high after the proppant particles are laid, and residual oil in formation pores can be effectively exploited, so that the development efficiency of an oil field is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing self-heat-preservation building block by using aerogel sand and grouting

The fly ash, water and an exciting agent are proportionally put into a ball mill for ball milling, and slurry after ball milling is pumped into a fly ash exciting tank for thermal excitation at the temperature of 70 DEG C or above; a pre-prepared mold is filled with air-setting sand, paved and covered with a steel mesh gland. And adding a small amount of cement into the pre-excited fly ash slurry, uniformly stirring, pouring into a mold filled with air-setting sand, oscillating, exhausting, pre-curing, cutting by using a steel wire, and carrying out steam curing to obtain the inorganic homogeneous self-heat-preservation building block with the compression resistance of more than or equal to 5MPa and the heat conductivity coefficient of less than or equal to 0.12 W / (m.K). The technology is suitable for aerated block production equipment and production lines. The self-insulation building block is suitable for 75% energy-saving application in cold regions. And a new technology is imported into the traditional industry to quickly form large-scale productivity. The technology has obvious industrial upgrading and social benefits. The self-heat-preservation building block has the obvious cost performance advantage.

Owner:新疆土木工程检测科技有限公司

Sulfhydrylation calcium alginate microspheres as intestinal drug delivery carrier and preparation method of sulfhydrylation calcium alginate microsphere

InactiveCN109464424AEnhances mucoadhesionExtended stayPharmaceutical non-active ingredientsMicrocapsulesCalcium EDTAChemistry

The invention relates to sulfhydrylation calcium alginate microspheres as an intestinal drug delivery carrier and a preparation method of the sulfhydrylation calcium alginate microsphere. The method comprises the following steps: mixing sodium alginate with sulfhydrylation calcium alginate according to the mass ratio of (1 to 8) to 1 and preparing a solution with the mass concentration of 0.5 to 5percent, then adding an oil phase containing a surfactant and emulsifying at room temperature at 200 to 900 rpm for 45 minutes, adding CaCl2 powder and continuously stirring at 100 to 400 rpm for 0.5to 3 hours to realize cross-linking and solidifying of the microspheres, carrying out centrifugal demulsification, washing and then screening the microspheres to obtain the sulfhydrylation calcium alginate microspheres. The sulfhydrylation calcium alginate microspheres prepared with an emulsification method disclosed by the invention have uniform and controllable particle size and good monodispersity. The prepared sulfhydrylation calcium alginate microspheres have strong mucosal adhesion properties in small intestine and can prolong the residence time of the microspheres in the intestine, sothat the long-acting administration effect is achieved. Therefore, the sulfhydrylation calcium alginate microspheres prepared with the preparation method disclosed by the invention have potential market application prospects in the fields of a drug delivery system for bioactive drugs such as protein, polypeptide and the like as well as intestinal targeted drug delivery.

Owner:SICHUAN UNIV

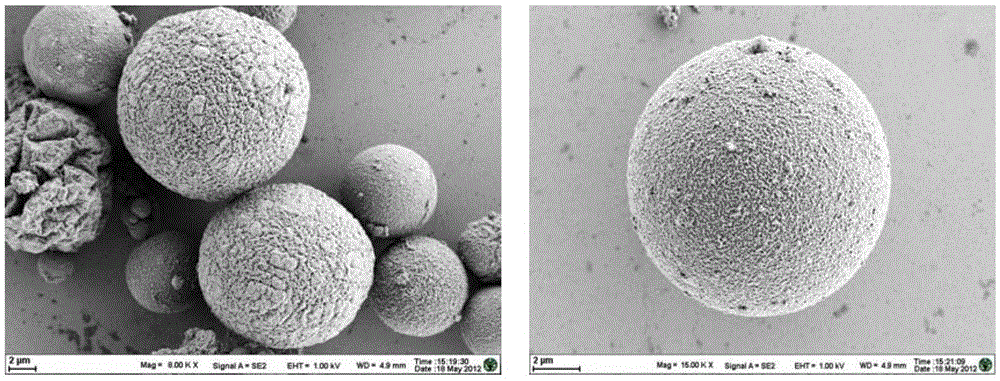

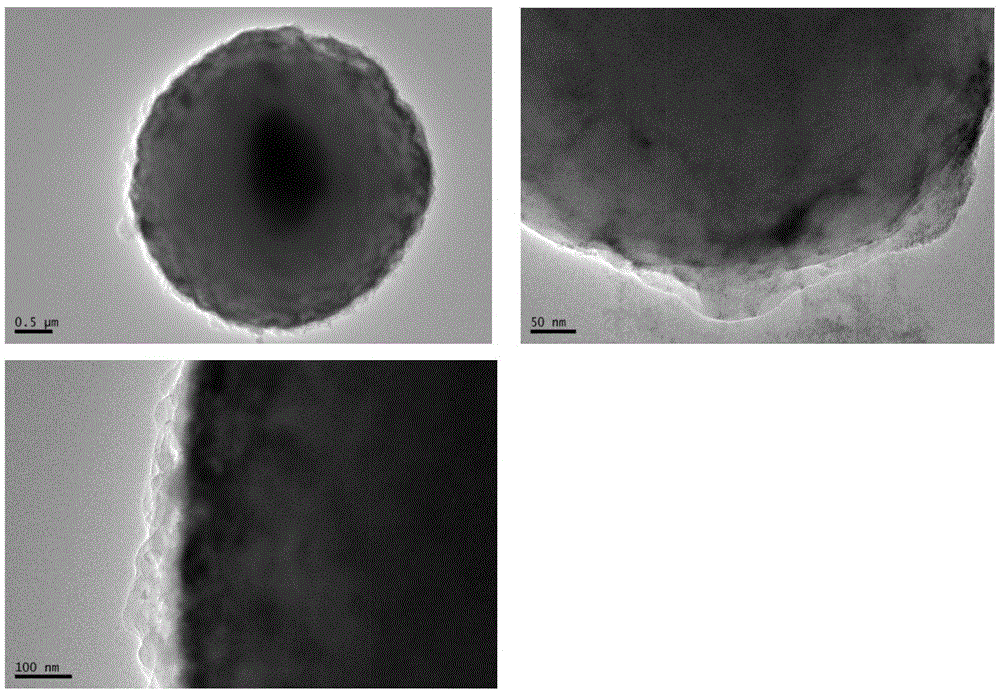

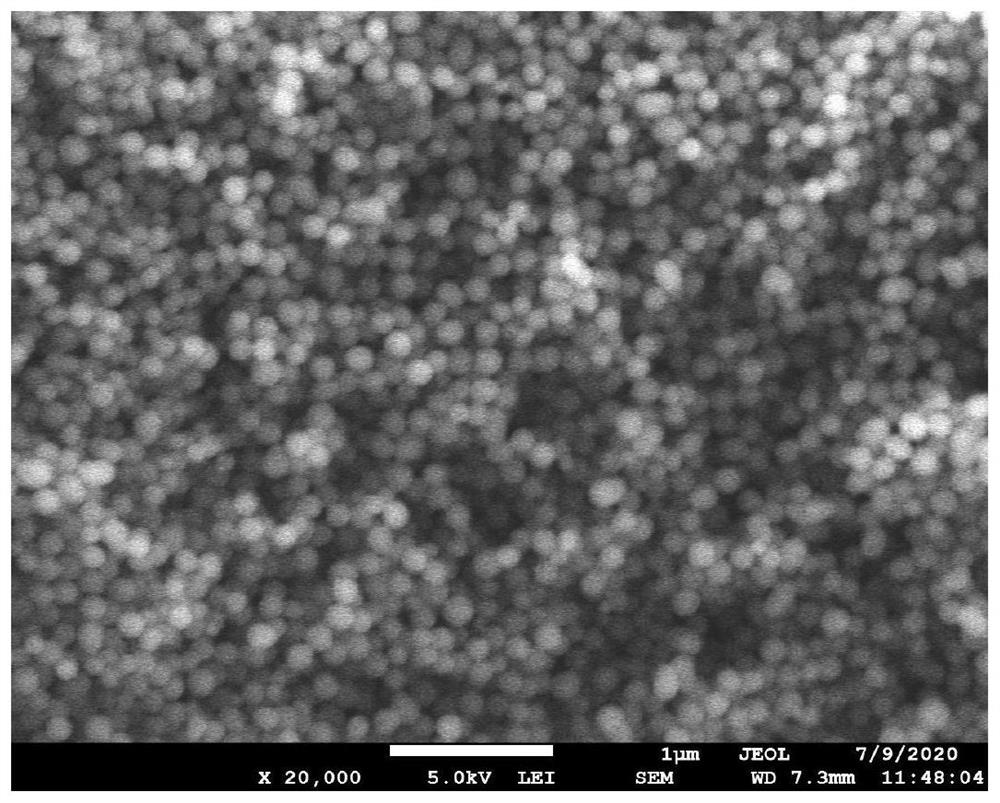

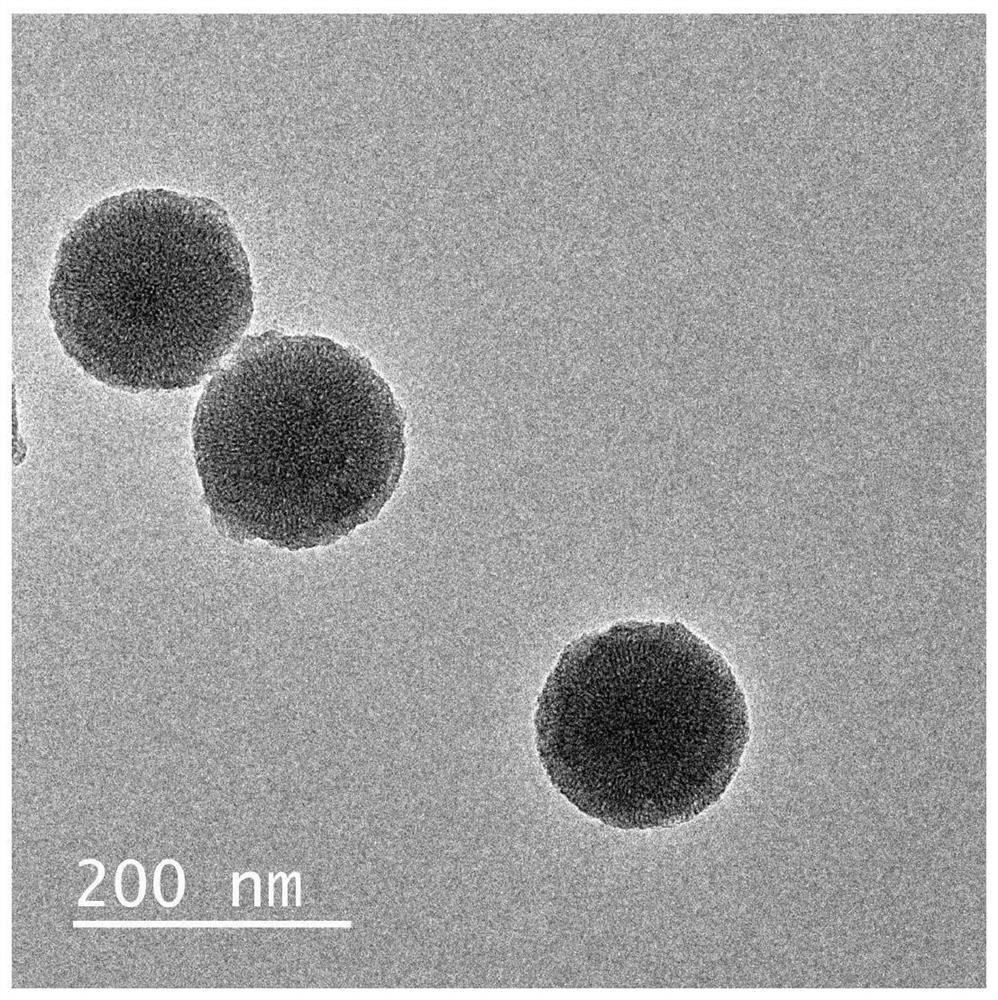

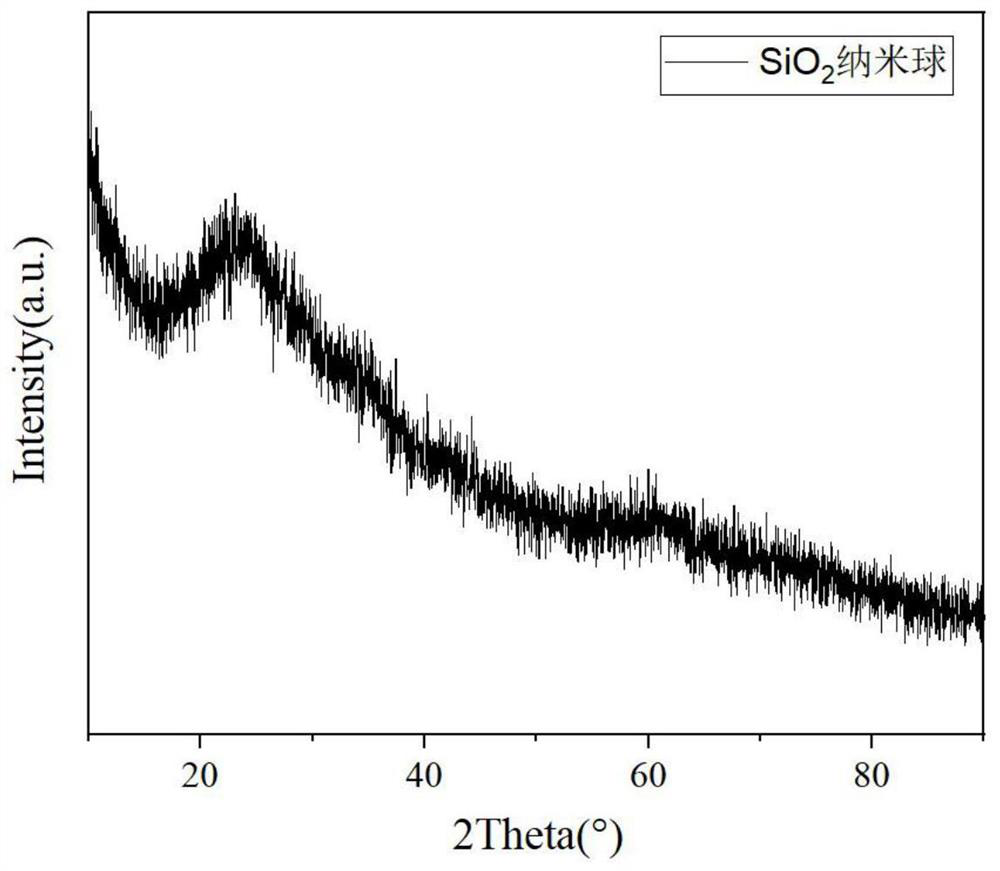

Mesoporous silica nanosphere with ultrahigh specific surface area and preparation method thereof

The invention relates to a mesoporous silica nanosphere with an ultrahigh specific surface area and a preparation method of the mesoporous silica nanosphere. The preparation method of the mesoporous silica nanospheres with the ultrahigh specific surface area comprises the following steps: (1) dissolving tetraethoxysilane in an ethanol solution, and magnetically stirring and uniformly mixing to obtain a precursor solution A; and uniformly mixing ammonia water, water and a pore-forming agent to obtain a precursor solution B; (2) equivalently sucking the precursor solution A and the precursor solution B, placing the precursor solution A and the precursor solution B on a micro-injection pump, and quickly mixing the precursor solution A and the precursor solution B through a micro-channel reactor at the same injection speed to obtain a micro-emulsion; and (3) standing the micro-emulsion, carrying out water bath heating demulsification, carrying out suction filtration, drying, and carrying out high temperature calcination to obtain the mesoporous silica nanospheres. According to the preparation method disclosed by the invention, the mesoporous silica nanospheres with the specific surfacearea of about 700-1860m < 2 > / g can be rapidly and continuously prepared, the pelletizing effect is good, and the process time is short.

Owner:SHIHEZI UNIVERSITY

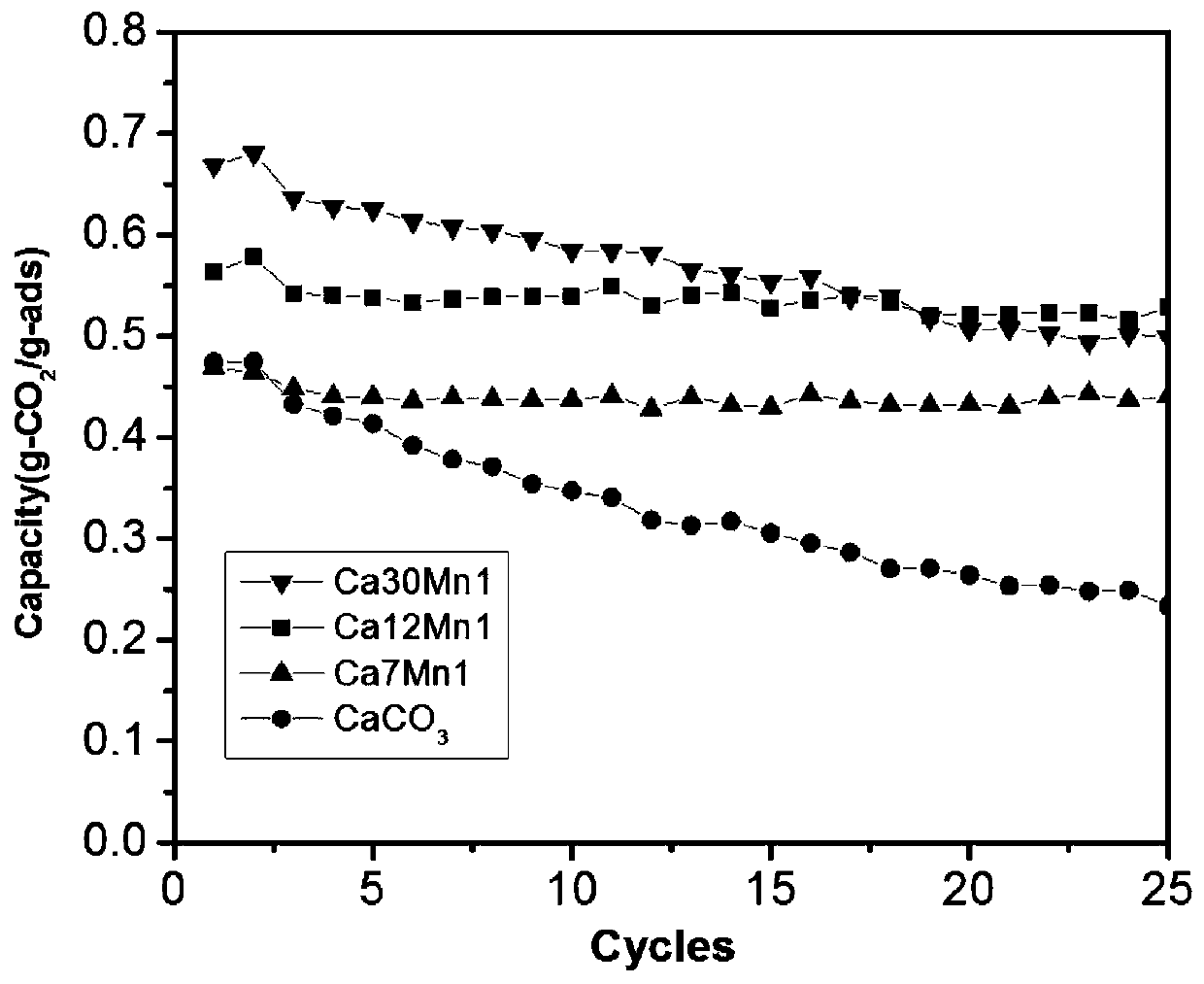

Preparation method of manganese doped double-shell-layer calcium carbonate hollow microsphere CO2 adsorbent

ActiveCN109954476AUniform particle sizeGood ballGas treatmentOther chemical processesWater bathsSorbent

The invention discloses a preparation method of a manganese doped double-shell-layer calcium carbonate hollow microsphere CO2 adsorbent. The preparation method comprises following steps: cane sugar solution hydro-thermal reaction is carried out to prepare carbon spheres; the carbon spheres are taken as a sacrificial template, and are added into a mixed solution of a calcium salt and a manganese salt, and then water bath processing, drying, and roasting are carried out so as to obtain the manganese doped double-shell-layer calcium carbonate hollow microsphere CO2 adsorbent. According to the preparation method, the calcium / manganese ratio, the carbon sphere template, and solvent composition are adjusted, so that accurate control on the shell layer thickness, microsphere size, and the calcium / manganese ratio in the manganese doped double-shell-layer calcium carbonate hollow microsphere can be realized, the prepared manganese doped double-shell-layer calcium carbonate hollow microsphere CO2 adsorbent is relatively high in adsorption capacity and stability in adsorption and desorption circulation; the highest initial adsorption capacity of the adsorbent with the best performance is 0.62g CO2 / g adsorbent, and the adsorption capacity is still maintained to be 0.53g CO2 / g adsorbent after 25 times of circulation.

Owner:TIANJIN UNIV

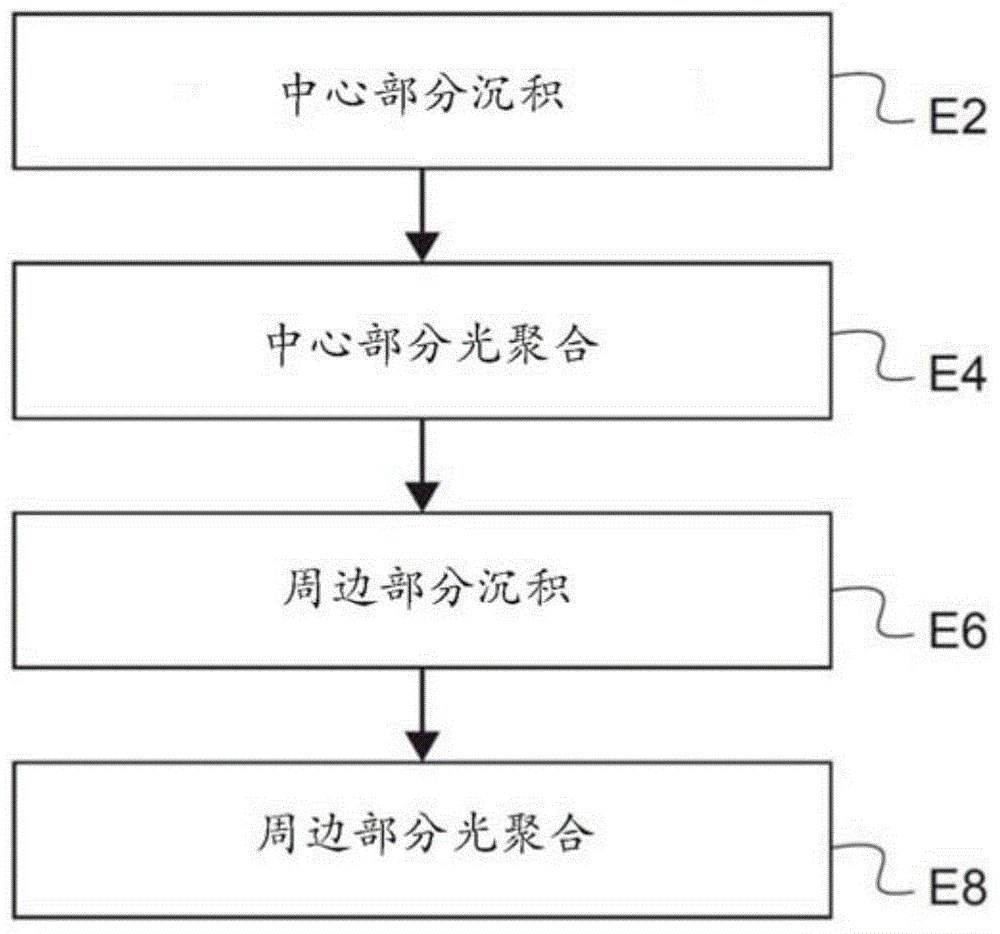

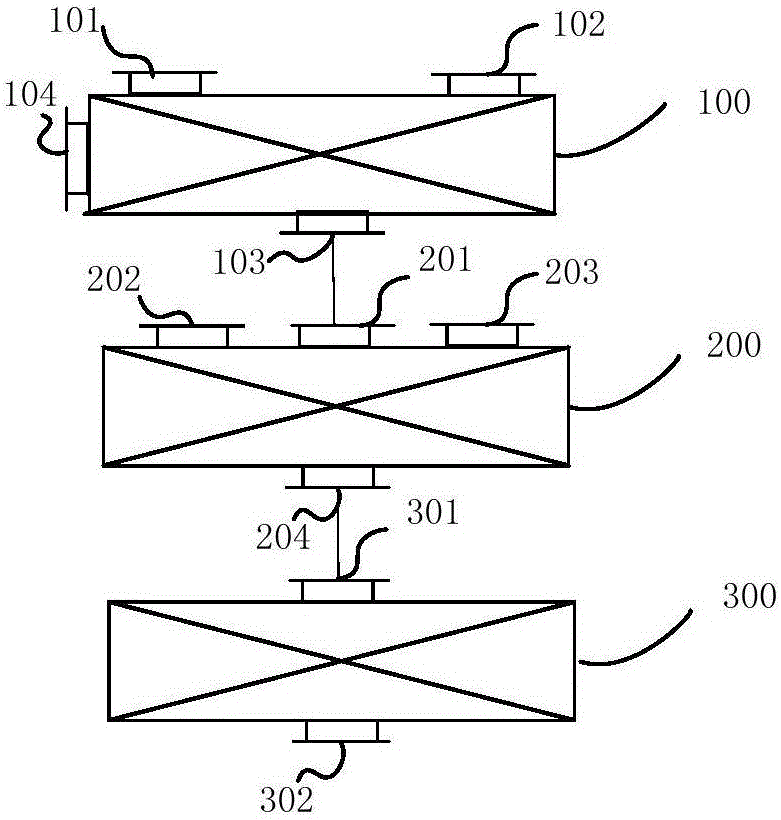

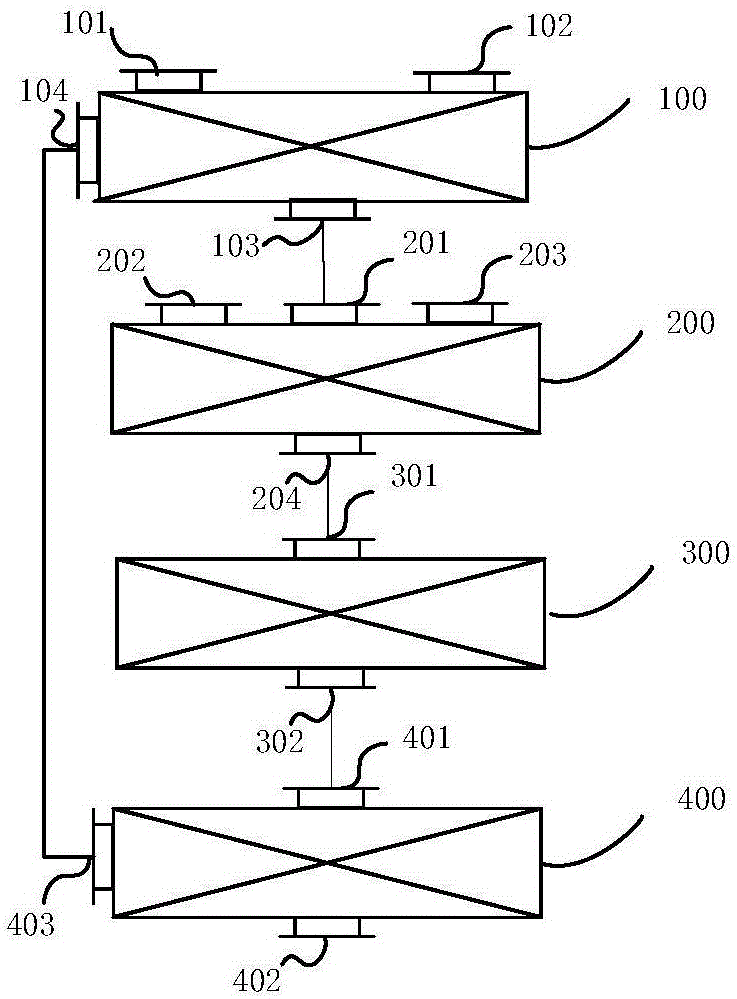

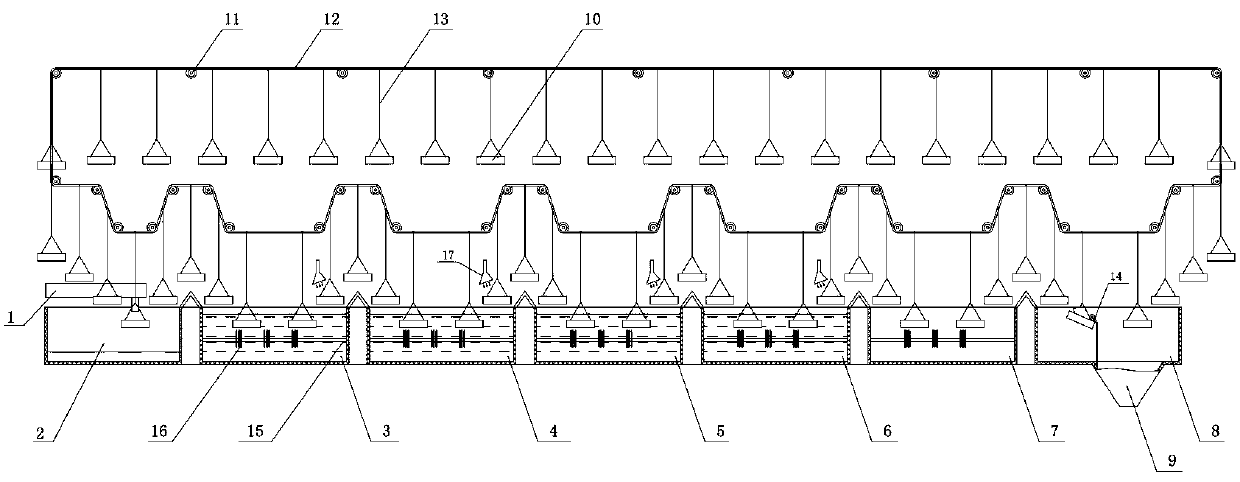

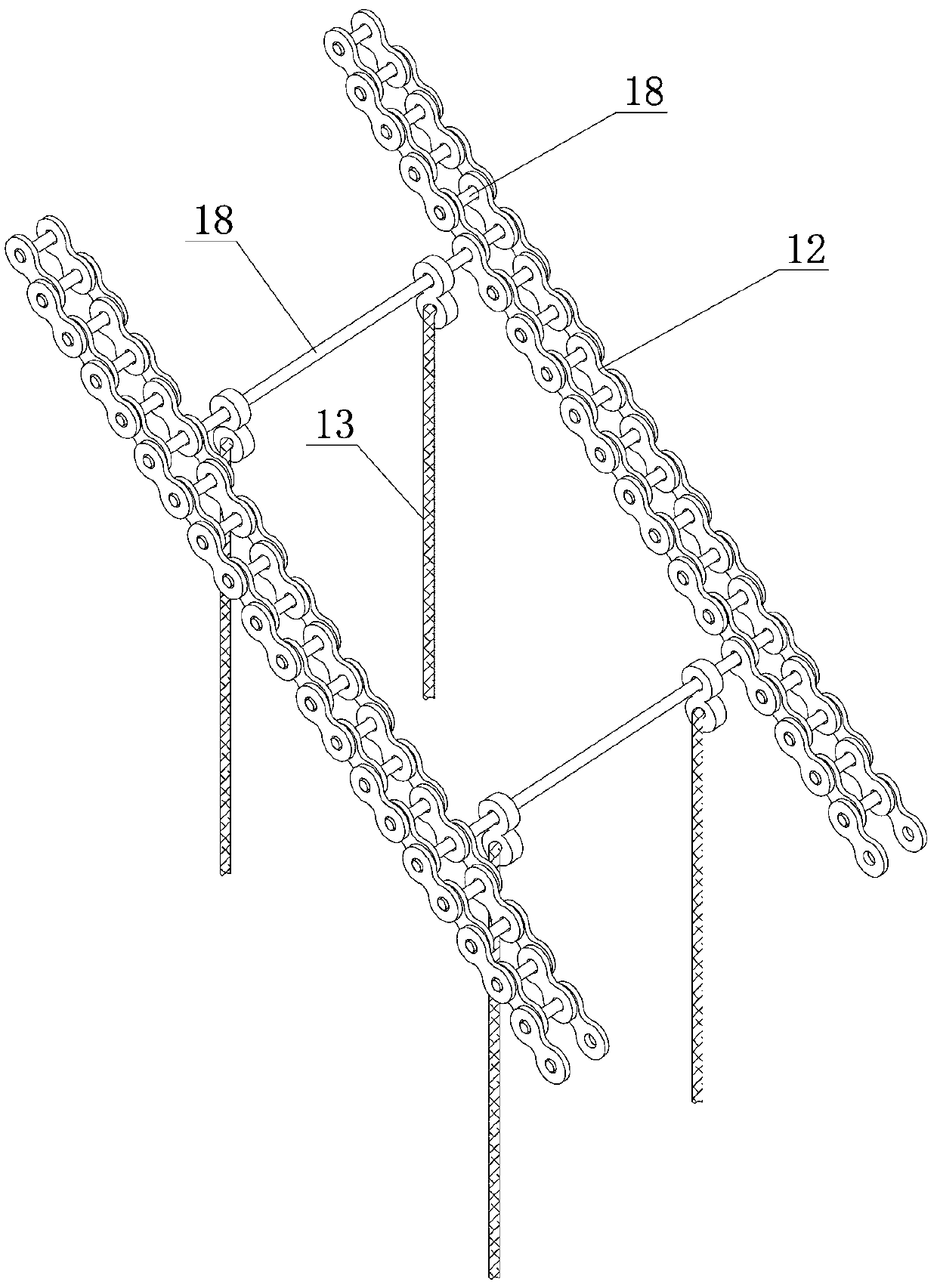

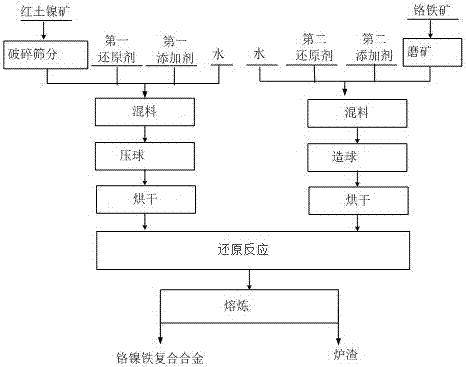

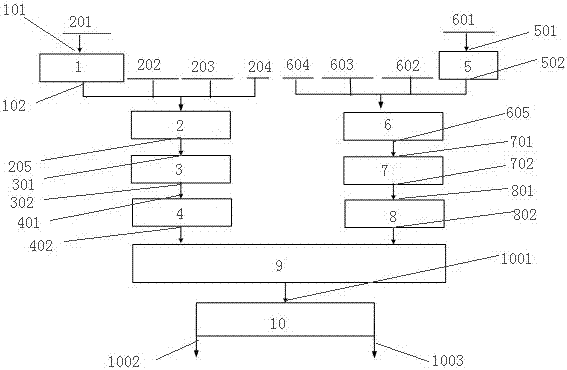

System and method for producing Cr-Ni-Fe composite alloy in double-process pelleting mode

PendingCN107142352AImprove heat utilizationIncrease production capacityHearth type furnacesGranularityDistribution system

The invention relates to a system and method for producing Inconel composite alloys by double-process ball making, wherein the system includes: a crushing and screening device, a first mixing device, a ball pressing device and a first drying device connected in sequence; The ore grinding device, the second mixing device, the pelletizing device and the second drying device; the rotary hearth furnace with a double-layer material distribution system connected to the first drying device and the second drying device respectively; A smelting device connected to a rotary hearth furnace. The present invention uses the mixed pellets of chromite and lateritic nickel ore as raw material, and adopts double-layer material distribution system and double-process ball making method according to the unique characteristics of raw materials, strictly controls the particle size and diameter of the two raw material pellets, and improves the speed of rotation. Heat utilization and production capacity of the hearth furnace.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com