High-strength coated quartz sand, and preparation technology and preparation device thereof

A quartz sand and high-strength technology, which is applied in the fields of mining fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of short shelf life of coated sand products, low strength of quartz sand, high manufacturing cost, etc., and is easy to promote and use, high degree of automation and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The high-strength coated sand of the present embodiment consists of 12kg of quartz sand, 3.25kg of modified phenolic resin, 1.25kg of modified bismaleimide resin, 0.5kg of silicon ether resin, and 1.2kg of ultra-short glass fiber powder , antioxidant 8kg, urotropine 1kg, organosilane 1 kg and talcum powder 0.1kg.

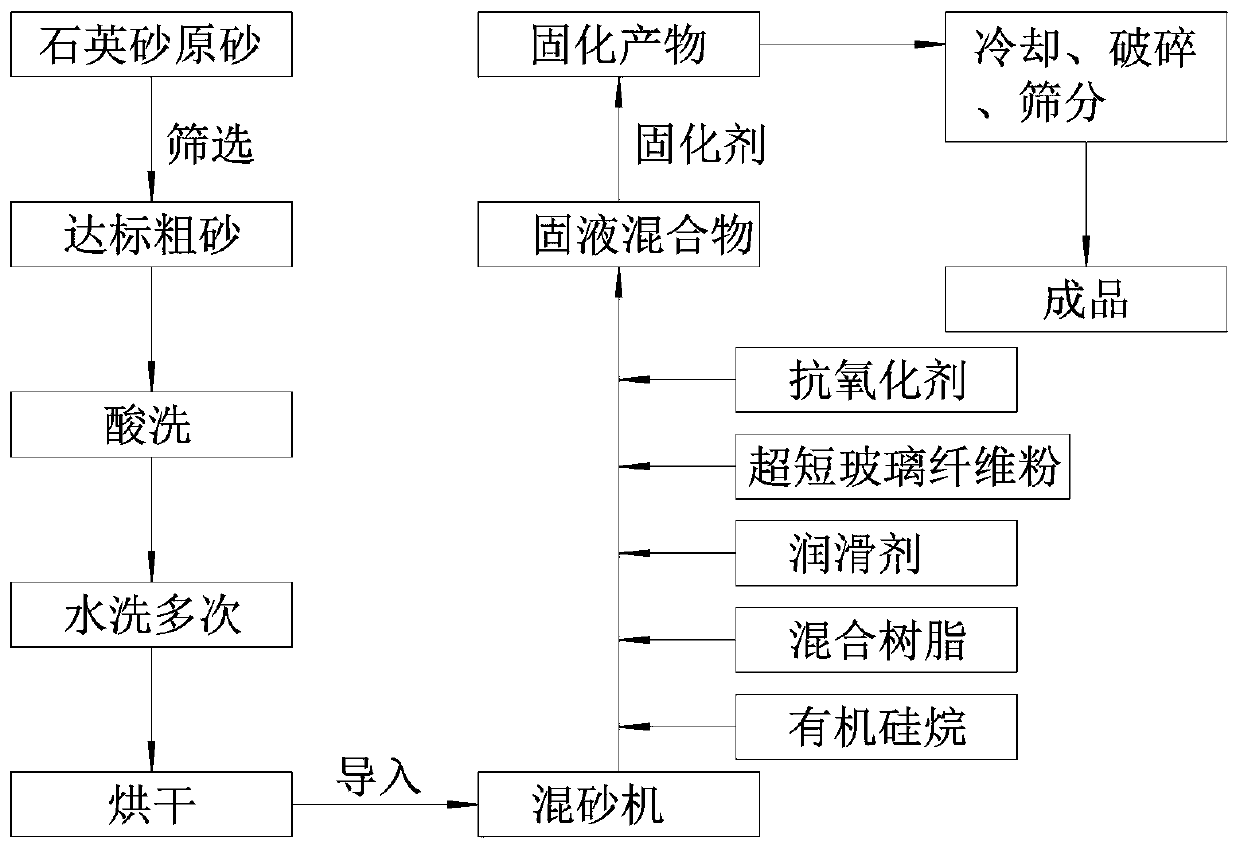

[0028] The preparation process of the high-strength coated quartz sand in this embodiment includes the following steps.

[0029] (1) Accurately weigh the above raw materials by weight, and mix the modified phenolic resin, modified bismaleimide resin and silicon ether resin evenly to obtain a mixed resin for use.

[0030] (2) Then filter the original quartz sand through a 80-16 mesh sieve to obtain coarse sand; then the coarse sand is processed by pickling, cleaning and drying equipment to obtain the supporting layer quartz sand, and the pickling uses hydrogen peroxide and A mixture of concentrated sulfuric acid 1:2-3, washed repeatedly with cle...

Embodiment 2

[0034] Embodiment 2: The high-strength coated quartz sand of the present embodiment comprises the following components: 10kg of quartz sand, 2.6kg of modified phenolic resin, 1kg of modified bismaleimide resin, 0.4kg of silicon ether resin, ultra-short glass Fiber powder 1 kg, polyisocyanate 0.8 kg, organosilane 0.5 kg, calcium sodium stearate 0.08 kg.

[0035] The preparation process of the high-strength coated quartz sand in this embodiment includes the following steps.

[0036] (1) Accurately weigh the above raw materials by weight, and mix the modified phenolic resin, modified bismaleimide resin and silicon ether resin evenly to obtain a mixed resin for use.

[0037] (2) The coarse sand is treated with pickling, cleaning and drying equipment to obtain the supporting layer of quartz sand. The pickling uses a mixture of hydrogen peroxide and concentrated sulfuric acid 1:2-3, repeated washing with water 4 times, filtering and drying Dry until the moisture content is below 0....

Embodiment 3

[0041] Embodiment 3: The high-strength coated quartz sand of this embodiment includes the following raw materials: 7kg of quartz sand, 0.65kg of modified phenolic resin, 0.25kg of modified bismaleimide resin, 0.1kg of silicon ether resin, ultra-short Glass fiber powder 1.5 kg, polyisocyanate 0.3 kg, urotropine 0.2 kg, organosilane KH550 0.5 kg, calcium stearate 0.08 kg.

[0042] The preparation process of the high-strength coated quartz sand in this embodiment includes the following steps.

[0043] (1) Accurately weigh the above raw materials by weight, and mix the modified phenolic resin, modified bismaleimide resin and silicon ether resin evenly to obtain a mixed resin for use.

[0044] (2) Then put the quartz sand into a glass container, add a mixture of hydrogen peroxide and concentrated sulfuric acid, stir for 13 minutes, then filter, repeat washing 5 times, filter, and dry until the moisture content is lower than 0.5%.

[0045] (3) Heat the quartz sand to 200°C and pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com