Preparation method of porous magnetic polystyrene microspheres

A technology of polystyrene microspheres and polyvinylpyrrolidone, applied in the direction of magnetism of organic materials/organic magnetic materials, to achieve good shape, improved stability, and uniform distribution of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of materials.

[0031] Refinement of styrene: repeatedly wash with 200ml 5wt% NaOH aqueous solution until colorless to remove the polymerization inhibitor, wash three times with distilled water, and then add anhydrous CaCl 2 Dry and store in a brown bottle for later use.

[0032] Refining of benzoyl peroxide (BPO): Dissolve 10g BPO in 50ml chloroform, stir and dissolve, filter, drop the filtrate into 100ml methanol, put it in the refrigerator to stand to obtain white needle-like crystals, wash three times with a small amount of cold methanol, and vacuum at room temperature Dry for 10h, put into a brown jar, and refrigerate for later use.

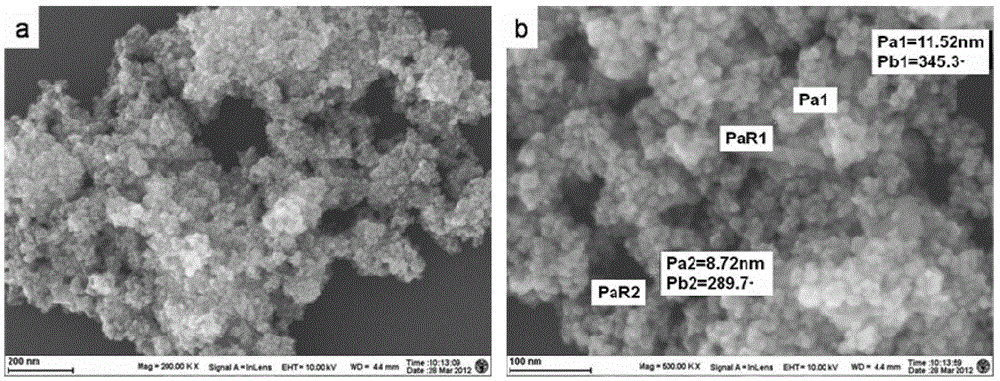

[0033] Fe 3 O 4 Preparation of magnetic nanoparticles: 4.28g FeCl 2 ·4H 2 O, 11.70g FeCl 3 ·6H 2 O was dissolved in 180ml of water, stirred to dissolve, purged with nitrogen for 0.5h, then heated to 60°C, and 20.0ml of NH was added rapidly under rapid stirring. 3 ·H 2 O, the system changes from transpar...

Embodiment 2

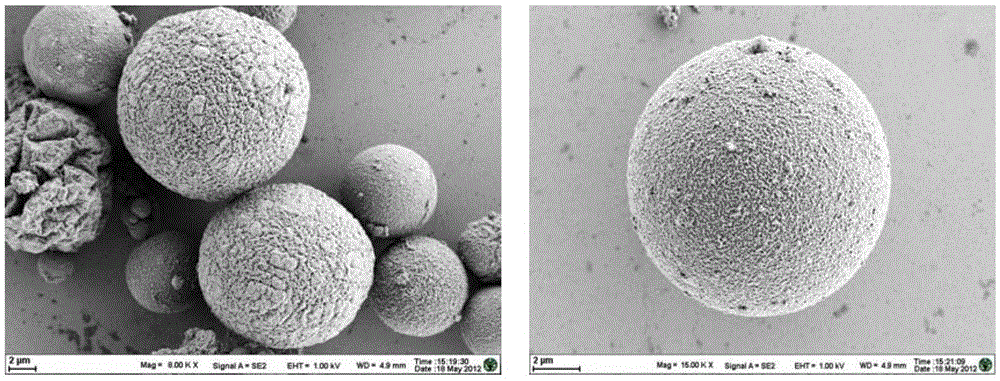

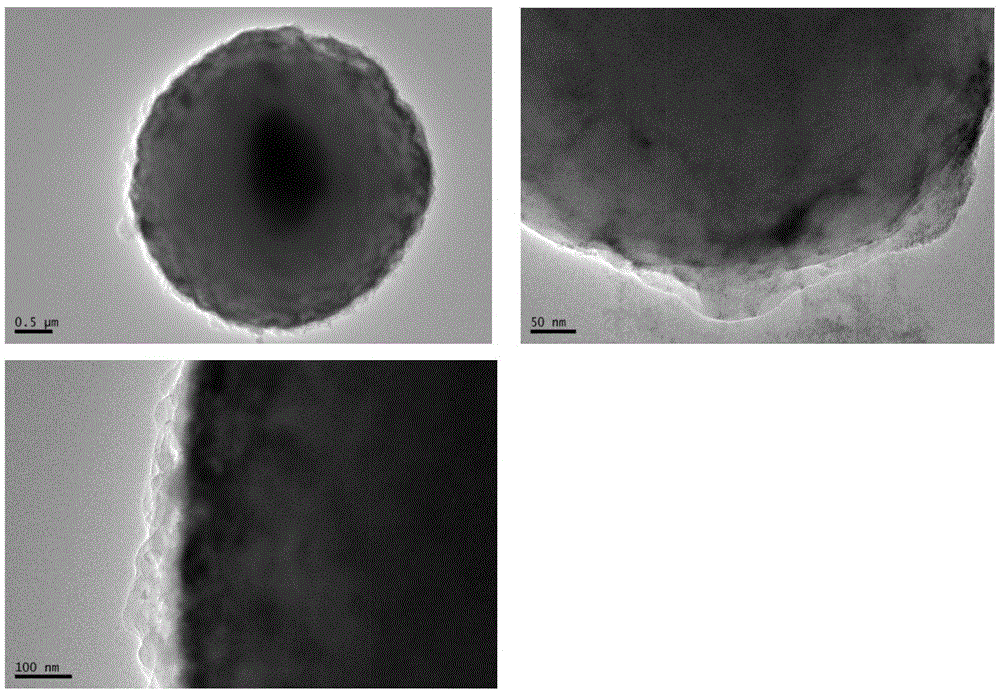

[0034] Example 2: Preparation of porous magnetic polystyrene microspheres.

[0035] Specifically include the following steps:

[0036] (1) Take 0.8g of dry Fe prepared in Example 1 3 O 4 Magnetic nanoparticles were added to 100ml of 50(v / v)% ethanol aqueous solution, then the mixture was ultrasonically treated for 30min, and 1ml of vinyltriethoxysilane was gradually added dropwise to dissolve Fe 3 O 4 in the suspension. After that, it was transferred into a 250m1 three-necked flask, under N2 Under the protection, rapid stirring at 40 ° C for 12 h constant temperature aging. The obtained product was washed three times with absolute ethanol and twice with deionized water, then vacuum-dried at 40° C. and ground into powder.

[0037] (2) Take 0.5 g of the powder obtained in step (1) and 0.2 g of purified BPO, add them to a test tube containing 6 ml of styrene, 2 ml of toluene, 1 ml of n-heptane and 0.5 ml of DVB cross-linking agent, and place them in a test tube. Ultrasonic ...

Embodiment 3

[0041] Specifically include the following steps:

[0042] (1) Take 1 g of dry Fe prepared in Example 1 3 O 4 Magnetic nanoparticles were added to 100ml of 40(v / v)% ethanol aqueous solution, then the mixture was ultrasonically treated for 20min, and 2ml of vinyltriethoxysilane was gradually added dropwise to dissolve Fe 3 O 4 in the suspension. After that, it was transferred into a 250m1 three-necked flask, under N 2 Under the protection, rapid stirring at 50 ℃ for 24h constant temperature aging. The obtained product was washed three times with absolute ethanol and three times with deionized water, then was vacuum dried at 60° C. and ground into powder.

[0043] (2) Take 0.34 g of the powder obtained in step (1) and 0.17 g of purified BPO, add them to a test tube containing 8 ml of styrene, 2 ml of toluene, 1 ml of n-heptane and 0.5 ml of DVB cross-linking agent, and place them in a test tube. Ultrasonic mixing in ultrasonic for 0.5h.

[0044] (3) Measure 100ml of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com