Ophthalmic lens and process for manufacturing such a lens

一种制造方法、负眼镜片的技术,应用在眼镜/防护镜、眼镜/护目镜、制造工具等方向,能够解决降低佩戴者视觉舒适度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

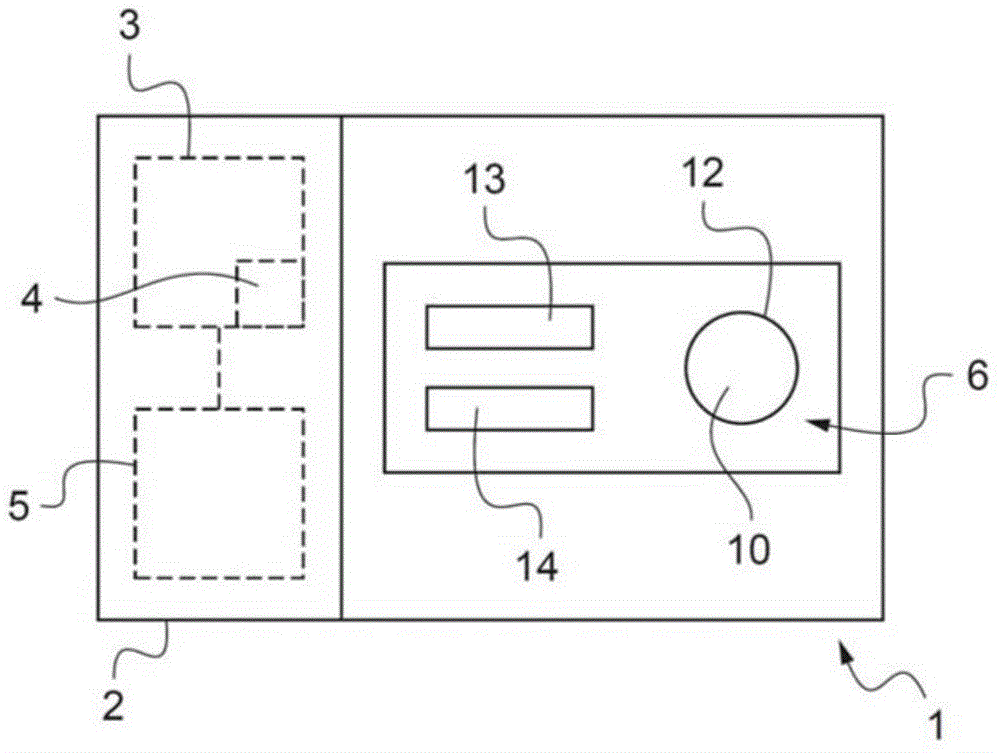

[0054] figure 1 An additive manufacturing machine 1 that can be used in the context of the present invention is shown.

[0055] By way of non-limiting example, the following description given with respect to the accompanying drawings will allow an understanding of what constitutes the invention and how it can be carried out.

[0056] This additive manufacturing machine 1 comprises a command / control unit 2 , a first nozzle 13 , a second nozzle 14 and a manufacturing support member 12 on which an ophthalmic lens 10 is to be manufactured by an additive manufacturing method as described below.

[0057] The additive manufacturing machine 1 also comprises the aperture 6 , covered here during the manufacturing phase by a movable shield, thereby allowing the ophthalmic lens 10 to be obtained on the manufacturing support member 12 after being manufactured by the additive manufacturing method.

[0058] The manufacturing support member 12 comprises a body with manufacturing surfaces hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com