Fluorescent microsphere and preparation method and application thereof

A fluorescent microsphere and fluorescent technology, applied in the field of polymers, can solve problems such as gelation, easy adhesion, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

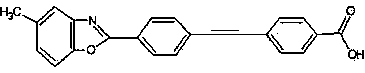

[0121] (1) According to the molar ratio, mix 0.25mol of 3-aminopropyltriethoxysilane and 0.21mol of the chemical formula:

[0122]

[0123] After mixing, 4 mol of ethanol was added, the temperature was raised to 80°C, and the mixture was stirred for 4 hours, and the low boilers were removed by vacuum to obtain a light yellow liquid. Its reaction process can be represented by the following formula:

[0124] +

[0125] +HCl

[0126] (2) At 25°C, add 1.12mol of methyltriethoxysilane, 0.04mol of dimethyldimethoxysilane and 0.035mol of tetramethoxysilane to a solution containing 11.2mol of deionized water and 0.001mol of hydrochloric acid In the reaction kettle, adiabatic reaction was carried out under stirring for 4 hours to obtain a transparent homogeneous hydrolyzate.

[0127] (3) Mix the solution obtained in step (1) and the solution obtained in step (2) evenly, cool down to 20°C, add 0.5mol methyl cellulose and 0.005mol sodium dodecylsulfonate, and stir after th...

Embodiment 2

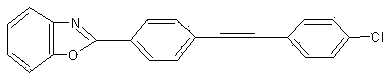

[0132] (1) In molar ratio, mix 0.15mol of N-(2-aminoethyl)-3-aminopropyltriethoxysilane and 0.13mol of the chemical formula

[0133]

[0134] After mixing, 6 mol of ethanol was added, the temperature was raised to 80°C, and the mixture was stirred for 4 hours, and the low boilers were removed by vacuum to obtain a yellow liquid. Its reaction process can be represented by the following formula:

[0135] +

[0136] +HCl

[0137] (2) At 35°C, add 1 mol of methyltriethoxysilane, 0.04 mol of dimethyldimethoxysilane and 0.01 mol of tetramethoxysilane to a reaction kettle containing 20 mol of deionized water and 0.001 mol of hydrochloric acid , Adiabatic reaction under stirring for 3 hours, a transparent homogeneous hydrolyzate was obtained.

[0138] (3) Mix the solution obtained in step (1) and the solution obtained in step (2) evenly, cool down to 15°C, add 0.5mol methyl cellulose and 0.005mol sodium dodecylsulfonate, and stir after they are uniformly dispersed Add ...

Embodiment 3

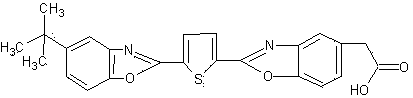

[0142] (1) In molar ratio, mix 0.006mol of 3-aminopropyltriethoxysilane and 0.005mol of chemical formula

[0143]

[0144] After mixing, add 6 mol of ethanol, raise the temperature to 80°C, and react for 4 hours under stirring, and remove the low boilers by vacuum to obtain a light yellow liquid. The sample was tested by FT-IR spectroscopy (KBr tablet method), and its structural formula is:

[0145]

[0146] (2) At 25°C, add 1mol methyltrimethoxysilane, 0.05mol dimethyldimethoxysilane and 0.1mol tetraethoxysilane to a reaction kettle containing 40mol deionized water and 0.001mol hydrochloric acid , Adiabatic reaction under stirring for 4 hours, a transparent homogeneous hydrolyzate was obtained.

[0147] (3) Mix the solution obtained in step (1) and the solution obtained in step (2) evenly, cool down to 15°C, add 0.5 g of polyvinyl alcohol and 0.05 g of sodium dodecylsulfonate, and after they are uniformly dispersed, add them under stirring 2 grams of ammonia water wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com