In-situ generated proppant for hydraulic fracturing

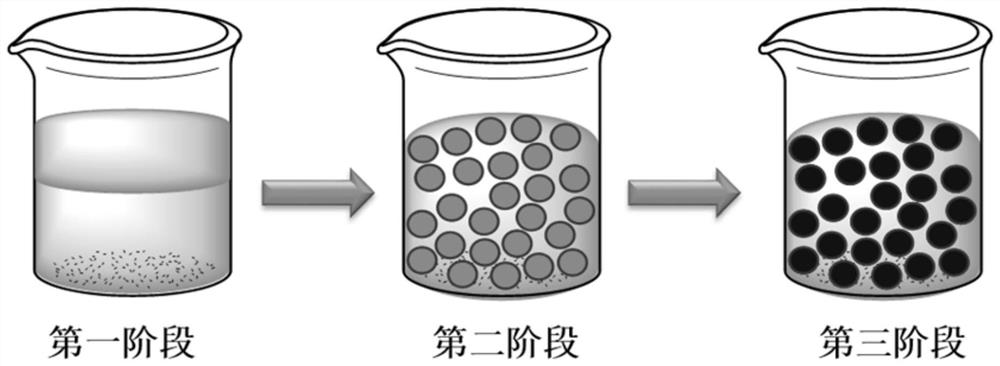

An in-situ generation and hydraulic fracturing technology, which is applied to drilling compositions, wellbore/well components, and production fluids, etc., can solve the problems of difficult access of solid proppant, reduced fracture conductivity, and broken gel, etc. Achieve controllable ball formation time, maintain diversion channels, and improve mining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of preparation method of proppant raw material liquid of the present invention, comprises the following steps:

[0051] 1) Mix thermoplastic phenolic resin and ethanol at a mass ratio of 1:1, stir or sonicate for 10 minutes until the two are evenly mixed to obtain a mixed solution 1;

[0052] 2) Add hexamethylenetetramine 0.2 times the mass of the thermoplastic phenolic resin to the mixed solution 1, stir or sonicate for 5 minutes to obtain a homogeneous mixed solution 2;

[0053] 3) Add triethylamine 0.05 times the mass of the thermoplastic phenolic resin to the mixed solution 2, adjust the pH to 10, stir or sonicate for 5 minutes to obtain a uniform solution, which is the proppant raw material solution.

Embodiment 2

[0055] A kind of preparation method of proppant raw material liquid of the present invention, comprises the following steps:

[0056] 1) Mix thermoplastic phenolic resin and ethanol at a mass ratio of 1:1, stir or sonicate for 10 minutes until the two are evenly mixed to obtain a mixed solution 1;

[0057] 2) Add hexamethylenetetramine 0.2 times the mass of the thermoplastic phenolic resin to the mixed solution 1, stir or sonicate for 5 minutes to obtain a homogeneous mixed solution 2;

[0058] 3) Add triethylamine 0.05 times the mass of the thermoplastic phenolic resin to the mixed solution 2, adjust the pH to 10, stir or sonicate for 5 minutes to obtain a uniform solution 3;

[0059] 4) Add 0.05 nanometer SiO of thermoplastic phenolic resin quality to solution 3 2 , stirred or ultrasonicated for 5 minutes to obtain a uniform solution, which is the proppant raw material solution.

[0060] Compared with the proppant raw material liquid in Example 1, the proppant raw material...

Embodiment 3

[0062] The preparation method of the carrier fluid (fracturing fluid) of in-situ generation proppant of the present invention, comprises the following steps:

[0063] 1) Add a certain amount of pure water into the mixing container;

[0064] 2) Weigh slick water with a mass of 0.001 times the pure water, add it to a mixing container, stir or sonicate for 5 minutes to obtain a homogeneous mixture;

[0065] 3) Weigh 0.01 times the mass of dodecyl glucoside in pure water, add it into a mixing container, stir or sonicate for 5 minutes, and obtain a uniform solution, which is the carrier solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com