Tectorial membrane proppant as well as preparation method and application thereof

A technology of proppant and film covering, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well parts, etc. It can solve the problems of quartz sand heating, smoke and gas generation, energy consumption, etc., and achieve low relative density and high production process. Simple, effective in increasing oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

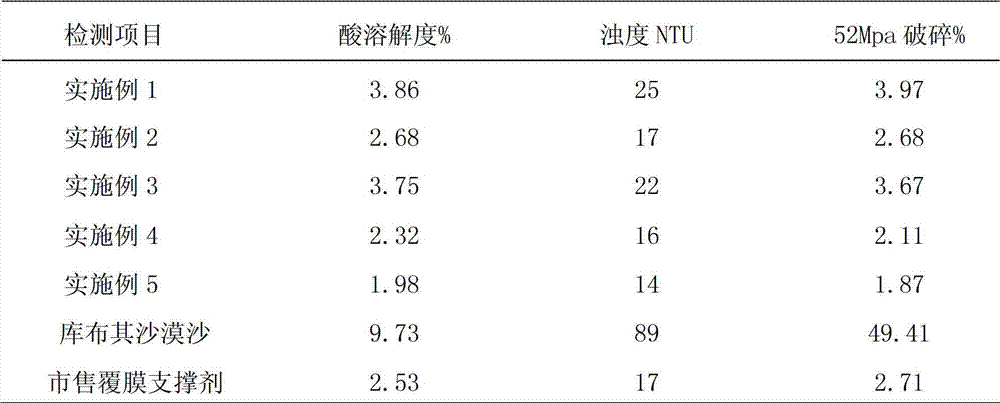

Examples

Embodiment 1

[0021] Accurately weigh the raw materials (Kg): Kubuqi Desert Sand 150 with a sand particle size of 0.106mm-3.35mm, water-based bisphenol A epoxy resin 4.5, water-based epoxy fatty amine curing agent 0.5, and water 15.

[0022] The preparation method of the novel coated proppant consists of the following steps:

[0023] (a) Pour the Kubuqi Desert sand into the sand mixer;

[0024] (b) Mix the metered resin and curing agent, add the solvent, stir evenly and fully dissolve;

[0025] (c) Add the mixture of resin binder and curing agent to the desert sand and stir for 50-100s to make the binder fully cover the desert sand aggregate; spread it flat on a horizontal surface and fully cure it for 24 hours;

[0026] (d) Smash;

[0027] (e) Screening and packaging.

Embodiment 2

[0029] Accurately weigh the raw materials (Kg): Kubuqi Desert Sand 180 with a sand particle size of 0.106mm-3.35mm, water-based bisphenol A epoxy resin 5, water-based epoxy fatty amine curing agent 0.7, and water 20.

[0030] The preparation method of the film-coated modified proppant consists of the following steps:

[0031] (a) Pour the Kubuqi Desert sand into the sand mixer;

[0032] (b) Mix the metered resin and curing agent, add the solvent, stir evenly and fully dissolve;

[0033] (c) Add the mixture of resin binder and curing agent to the desert sand and stir for 50-100s to make the binder fully cover the desert sand aggregate. Spread flat on a horizontal surface and fully solidify for 24h;

[0034] (d) Smash;

[0035] (e) Screening and packaging.

Embodiment 3

[0037] Accurately weigh the raw materials (Kg): Kubuqi Desert Sand 200 with a sand particle size of 0.106mm-3.35mm, water-based bisphenol A epoxy resin 14, water-based epoxy fatty amine curing agent 5, water 25.

[0038] The preparation method of the novel coated proppant consists of the following steps:

[0039] (a) Pour the Kubuqi Desert sand into the sand mixer;

[0040] (b) Mix the metered resin and curing agent, add the solvent, stir evenly and fully dissolve;

[0041] (c) Add the mixture of resin binder and curing agent to the desert sand and stir for 50-100s to make the binder fully cover the desert sand aggregate. Spread flat on a horizontal surface and fully solidify for 24h;

[0042] (d) Smash;

[0043] (e) Screening and packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com