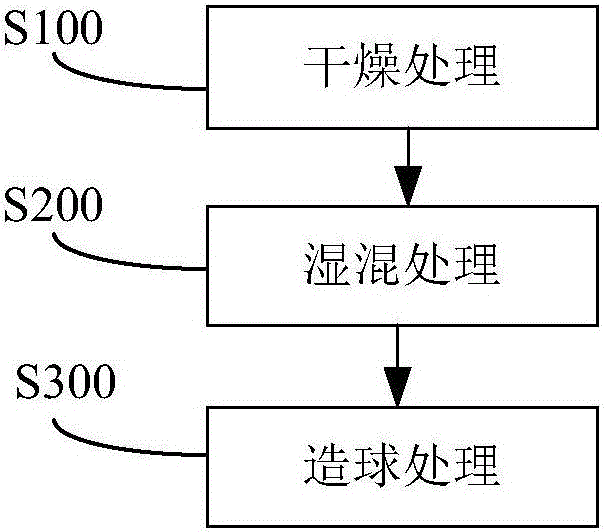

Method and system for preparing red mud pellets

A technology for red mud pellets and red mud, which is applied in the field of preparing red mud pellets, can solve the problems of high surface viscosity of the cue ball, increased capillary resistance, and low production rate of pelletizing, and achieves high porosity and easy pelletizing. , the effect of improving the ball-forming rate and ball-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Utilizing the method of the present invention, red mud pellets are prepared with red mud and calcium oxalate as raw materials, and the specific steps are as follows:

[0058] (1) Add 100 parts of red mud with water content of 35% and 5 parts of calcium oxalate into the drying cylinder at the same time. The temperature of the inlet in the drying cylinder is 400°C, the temperature of the material at the outlet is 550°C, and the drying time is 15 minutes. Finally, the moisture content of the mixed material is 12%.

[0059] (2) Add 15% reduced coal and 0.5% bentonite to the mixed material obtained in step (1) for wet mixing treatment to obtain wet mixed material.

[0060] (3) Transport the wet mixed material into the hopper of the disc pelletizer for disc granulation. The granulation time of the same batch of pellets is about 35 minutes, and the disc rotation speed is 19r / min. The primary pelleting rate of pelletizing is 50%, and the particle size range of the pellets is 6...

Embodiment 2

[0062] Utilizing the method of the present invention, red mud pellets are prepared with red mud and calcium oxalate as raw materials, and the specific steps are as follows:

[0063] (1) Add 100 parts of red mud with water content of 35% and 5 parts of calcium oxalate into the drying cylinder at the same time. The temperature of the inlet in the drying cylinder is 600°C, the temperature of the material at the outlet is 650°C, and the drying time is 20min Finally, the moisture content of the mixed material is 0.5%, and the specific surface area of the material is 12m 2 / g.

[0064] (2) Add 19% reduced coal and 1% bentonite to the mixed material obtained in step (1) for wet mixing treatment to obtain wet mixed material.

[0065] (3) Transport the wet mixed material into the hopper of the disc pelletizer for disc granulation. The granulation time of the same batch of pellets is about 15 minutes, and the disc rotation speed is 14r / min. The primary pelleting rate of pelletizing ...

Embodiment 3

[0067] Utilizing the method of the present invention, red mud pellets are prepared with red mud and calcium oxalate as raw materials, and the specific steps are as follows:

[0068] (1) Add 100 parts of red mud with water content of 35% and 5 parts of calcium oxalate into the drying cylinder at the same time. The temperature of the inlet in the drying cylinder is 600°C, the temperature of the material at the outlet is 650°C, and the drying time is 20min Finally, the moisture content of the mixed material is 0.5%, and the specific surface area of the material is 12m 2 / g.

[0069] (2) Add 19% reduced coal and 1% bentonite to the mixed material obtained in step (1) for wet mixing treatment to obtain wet mixed material.

[0070] (3) Transport the wet mixed material into the hopper of the disc pelletizer for disc granulation. The granulation time of the same batch of pellets is about 15 minutes, and the rotation speed of the disc is 17r / min. The primary pelleting rate of pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com