Quicklime hydration method

A technology of quicklime and digester, which is applied in the direction of improving process efficiency, etc., can solve the problems of lower operating rate, no dust removal equipment, and blockage of exhaust pipes, so as to improve production and quality, solve blockage of digestion bin, and avoid equipment damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

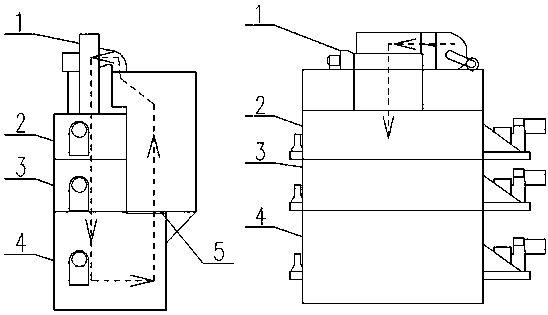

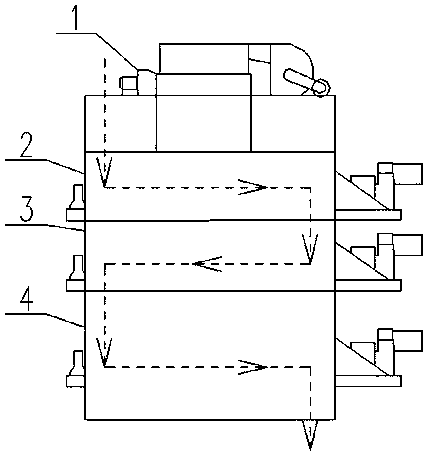

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

[0035] refer to Figure 1-2 , a quicklime digestion method described in this specific embodiment, its first-stage digester water distribution bin is composed of a box, blades, stirring shafts, thermocouples, and motors. The material falls into the water distribution bin of the internal screw propeller of the first-stage digestion through the feed port, and is pushed to the right under the action of gravity through the stacking method, and falls into the second-stage digestion bin from the right outlet. Because the fluidity of the lime is very good after adding water, the whole set of digestion bin adopts the material accumulation method, which has more uniform material humidity, higher digesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com