Process for preparing compound slag agent by silicon-manganese alloy fly ash

A technology of silicon-manganese alloy and composite slag agent is applied in the field of metallurgy, which can solve the problems of affecting process production and low comprehensive utilization efficiency, and achieve the effects of improving smelting effect, good environmental protection benefit and uniform composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

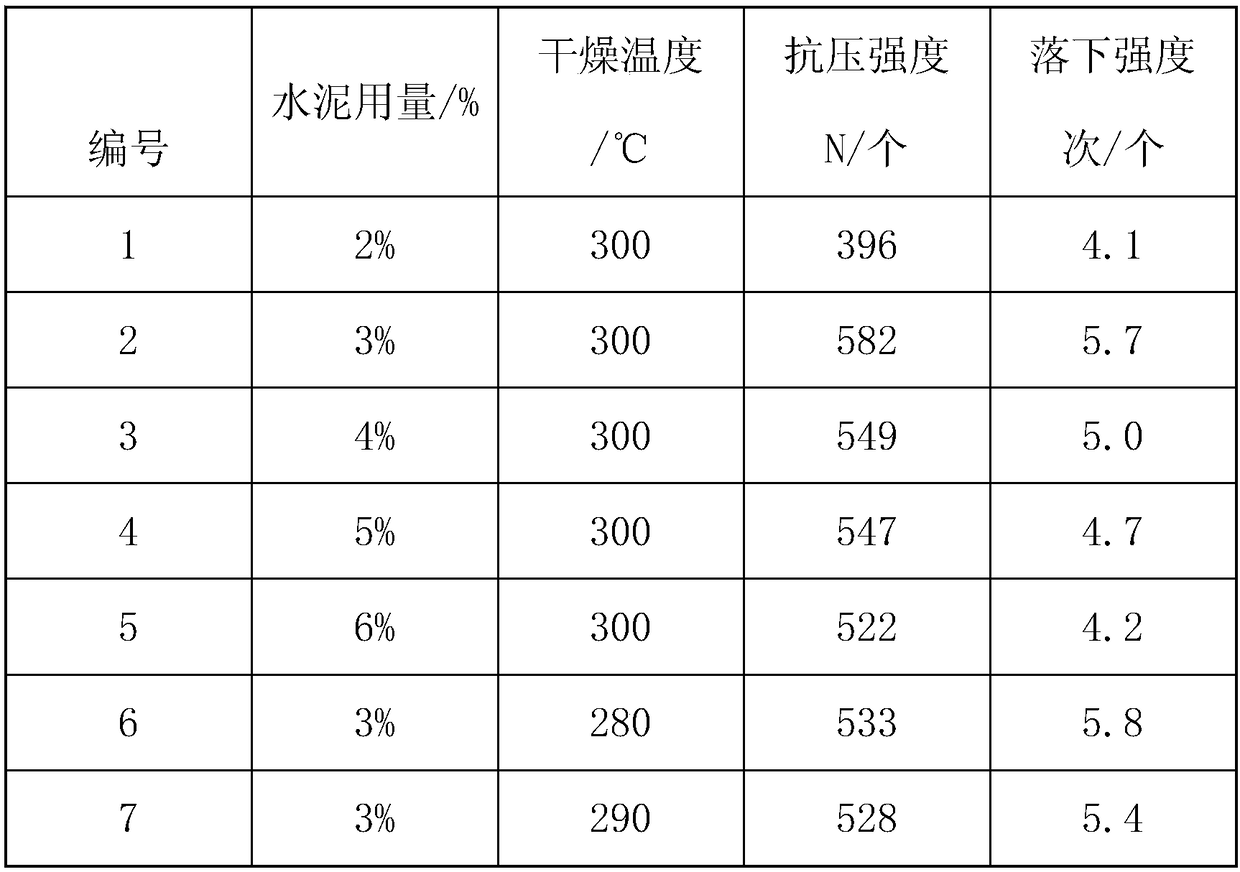

[0024] Embodiment 1: A kind of technology of silicon-manganese alloy dedusting dust preparation composite slag agent, the steps are as follows:

[0025] Raw material ratio: Portland cement is used as binder, and the addition amount is 2-6%; 2% of additives are added, and CaO is added to adjust the binary alkalinity of the mixture to 2;

[0026] Pelletizing: Use a disc pelletizing machine to pelletize, add 12% of the total amount of water, continue to roll for 15 minutes after the particle size reaches the requirement, and the particle size of the raw pellets is 12mm;

[0027] Pellet drying: place the pellets at room temperature to dry naturally for 24 hours, and then dry them in a muffle furnace at 250-300°C for 3 hours.

[0028] Finally, the compressive strength and drop strength of the dried pellets were tested, and the specific data are shown in Table 2.

Embodiment 2

[0029] Embodiment 2: A kind of technology of silicon-manganese alloy dedusting dust preparation composite slag agent, steps are as follows:

[0030] Raw material ratio: use bentonite as binder, the addition amount is 0.5%-2.5%; add 2% additives, add CaO to adjust the binary alkalinity of the mixture to 2;

[0031] Pelletizing: Use a disc pelletizing machine to pelletize, add 11% of the total amount of water, continue to roll for 10 minutes after the particle size reaches the requirement, and the particle size of the raw pellets is 12mm;

[0032] Drying of pellets: Place the pellets at room temperature to dry naturally for 28 hours, and dry in a heating furnace at 280-300°C for 3-4 hours.

[0033] Finally, the compressive strength and drop strength of the dried pellets were tested, and the specific data are shown in Table 3.

Embodiment 3

[0034] Embodiment 3: A kind of technology of silicon-manganese alloy dedusting dust preparation composite slag agent, the steps are as follows:

[0035] Raw material ratio: water glass is used as binder, and the addition amount is 2%-6%; 2% of additives are added, and CaO is added to adjust the binary alkalinity of the mixture to 2;

[0036] Pelletizing: Use a disc pelletizing machine to pelletize, add 10% of the total amount of water, continue to roll for 15 minutes after the particle size reaches the requirement, and the particle size of the raw pellets is 11mm;

[0037] Drying of pellets: Place the pellets at room temperature to dry naturally for 30 hours, and dry in the flue at 250-280°C for 3-4 hours.

[0038] Finally, the compressive strength and drop strength of the dried pellets were tested, and the specific data are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com