Patents

Literature

37results about How to "High added value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

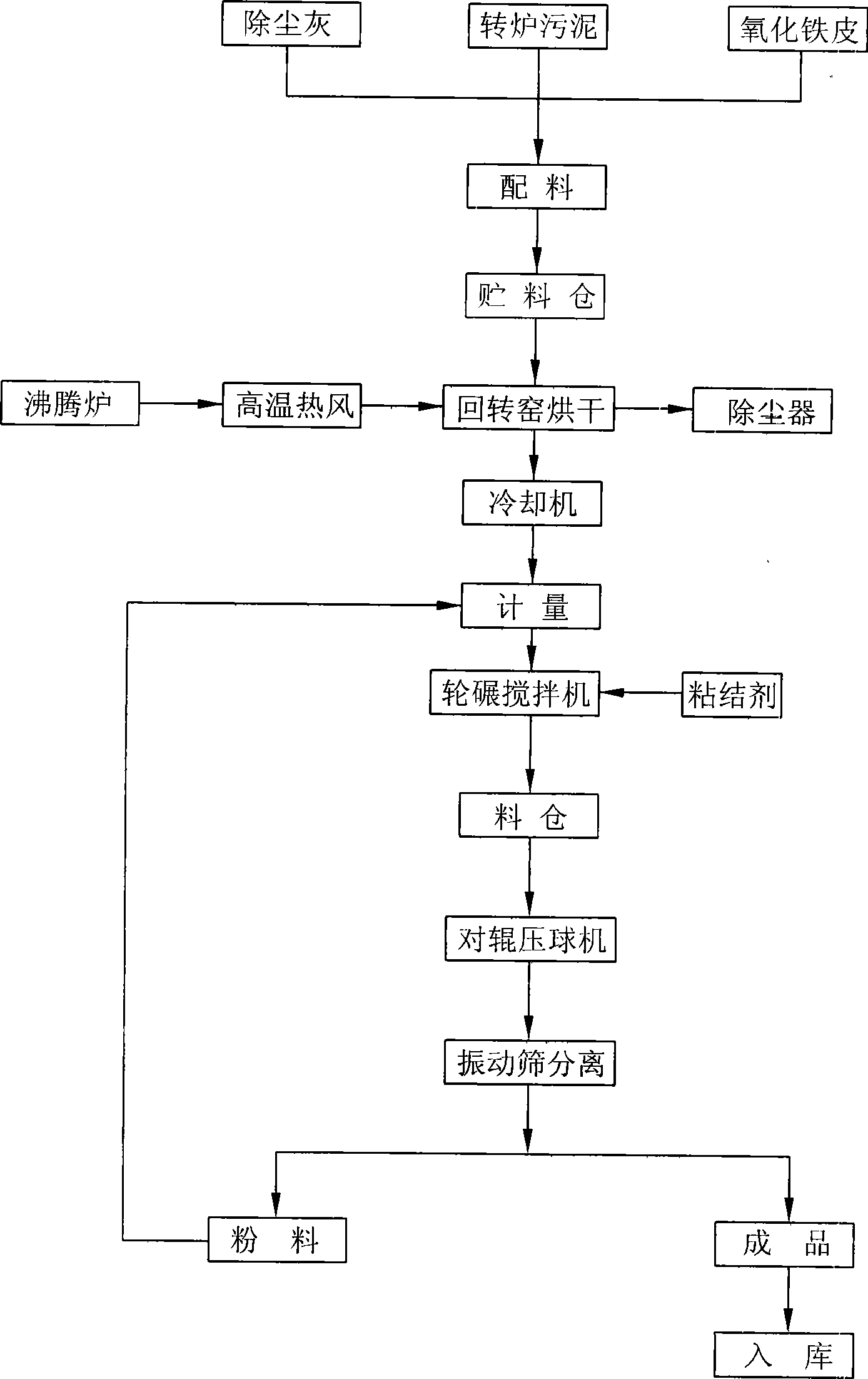

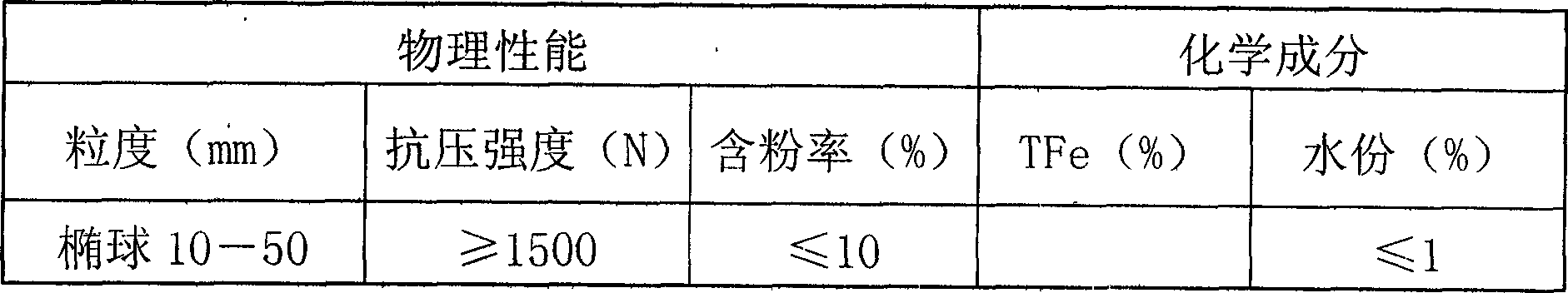

Method for utilizing iron containing metallurgical dust

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

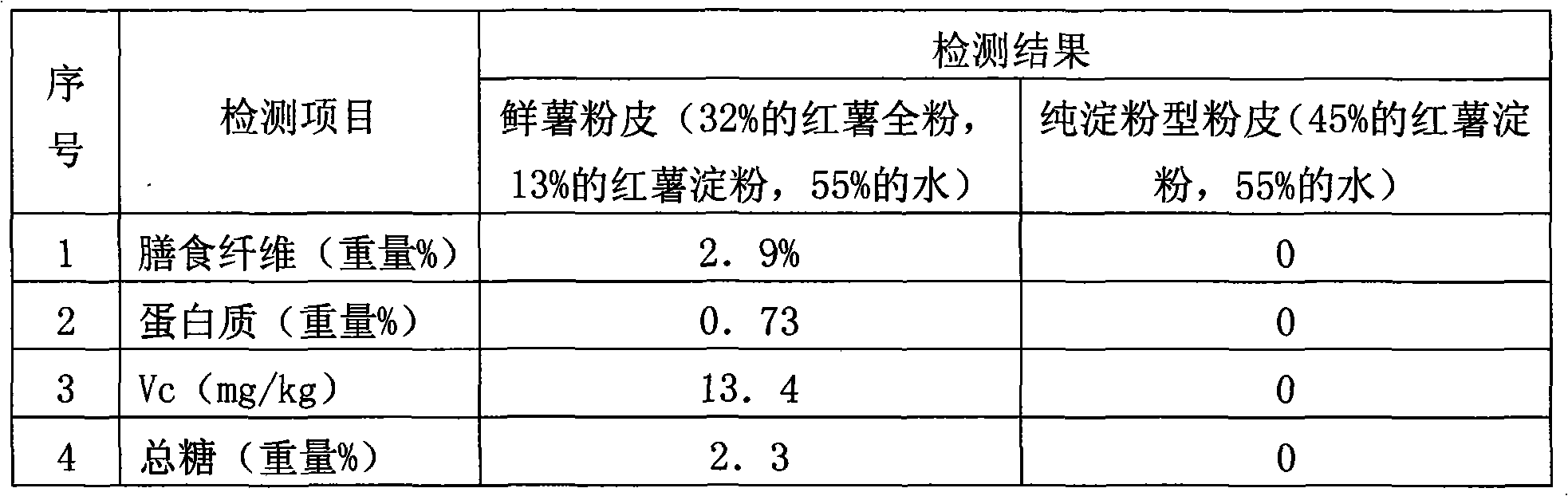

Processing method of sweet potato sheet jelly

A processing method of sweet potato sheet jelly, comprising the following steps of cleaning raw material sweet potatoes by water, and then continuously conveying the sweet potatoes to a crusher for crushing into sweet potato slurry with the particle size smaller than 3mm, weighing the sweet potato slurry, sweet potato graham flour or / and sweet potato starch in a weight ratio of the sweet potato slurry, the sweet potato graham flour or / and the sweet potato starch, which is 1: 0-100, adding water, mixing uniformly to prepare mixed slurry, wherein the water is added so that the water content in the mixed slurry is 48-65% by weight percentage, sending the mixed slurry to a spiral extrusion molding machine for curing and molding to form the sheet jelly, conveying the sheet jelly by a continuous conveyer, automatically cutting the sheet jelly according to a fixed length, and packing through an automatic packing machine or a vacuum packing machine so as to prepare the sheet jelly product. The invention uses mechanical continuous production and has a simple processing technology. The prepared sweet potato sheet jelly product maintains the nutrient components in the sweet potatoes and the active components capable of improving human immunity, and is excellent green health food.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

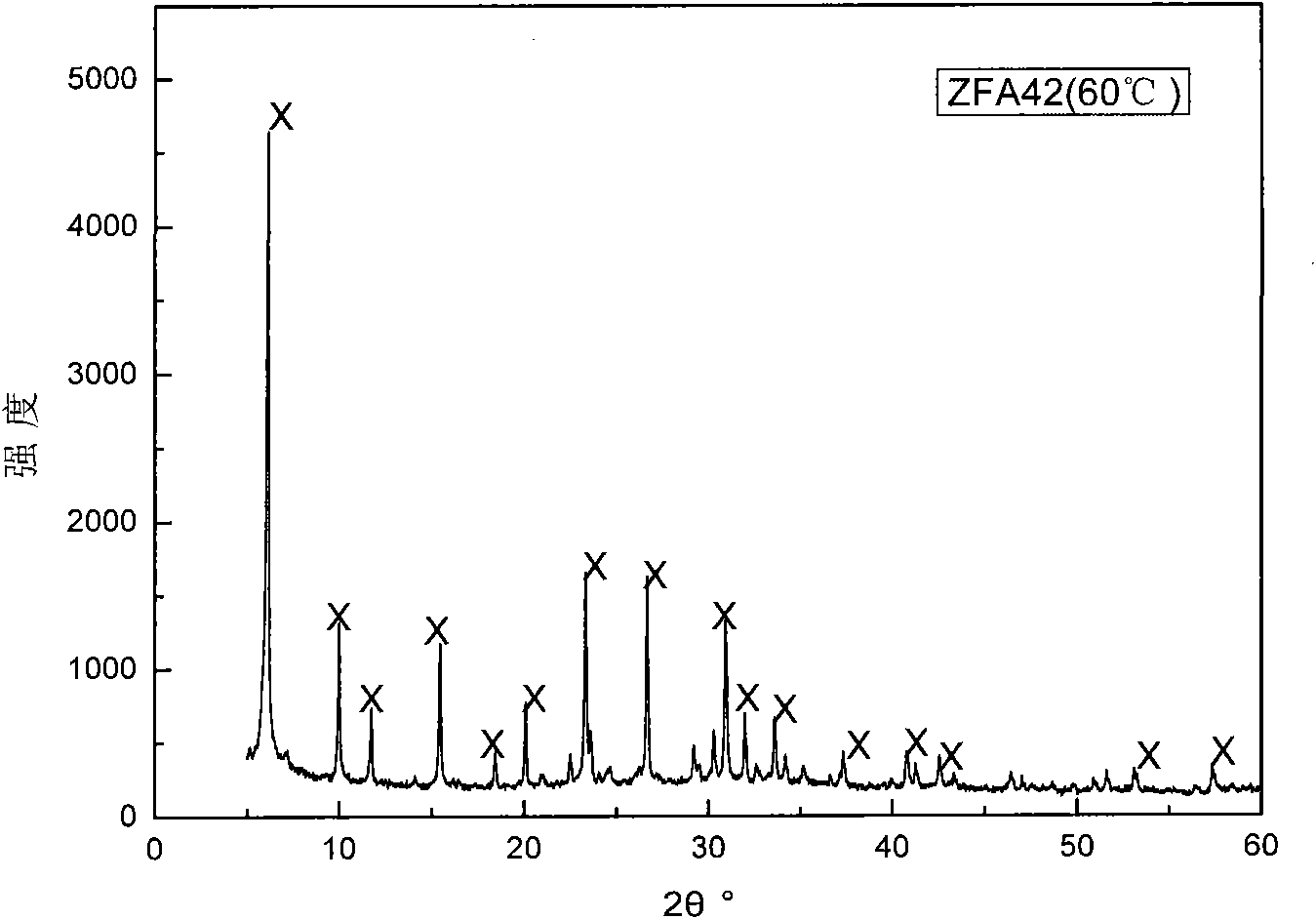

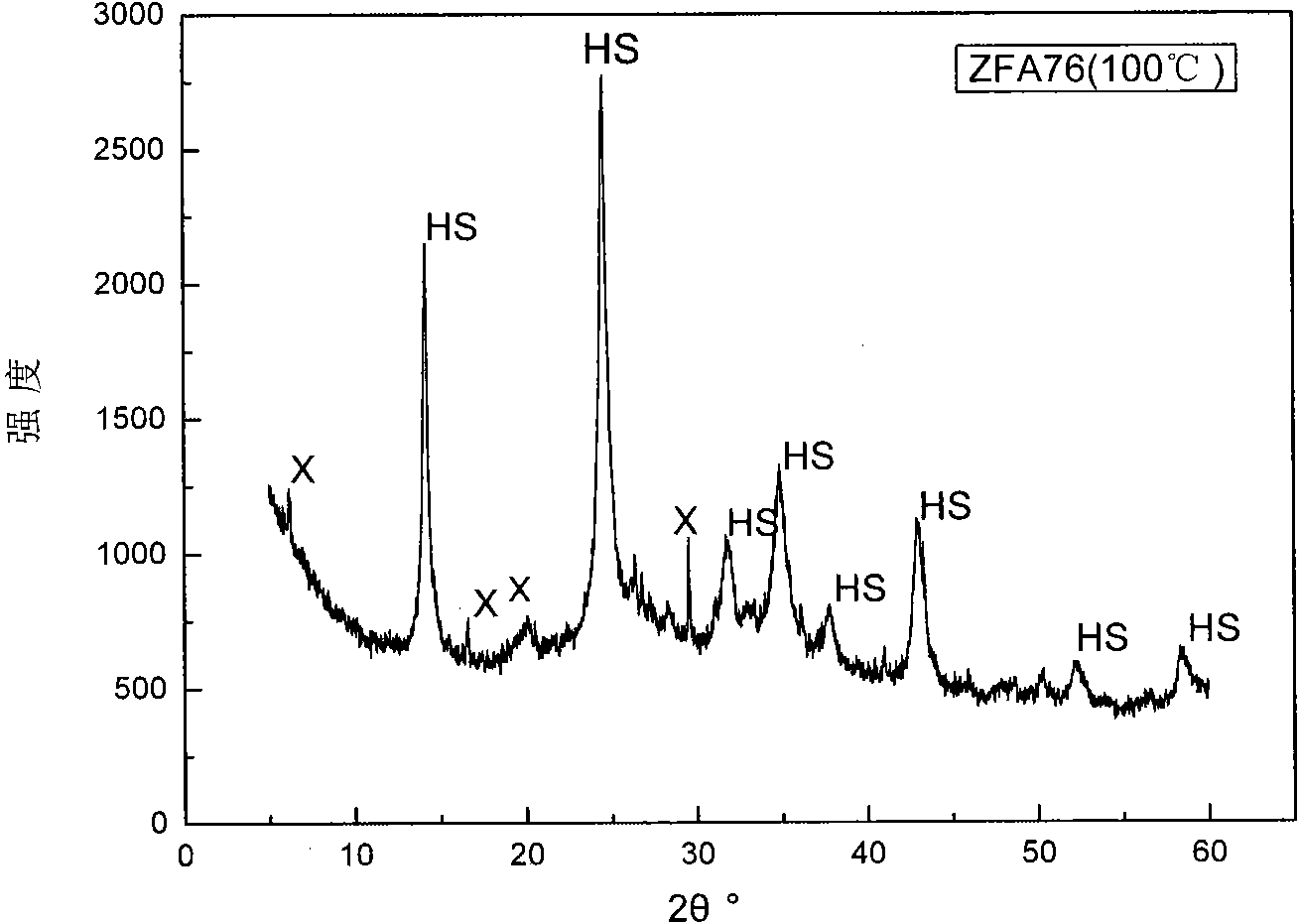

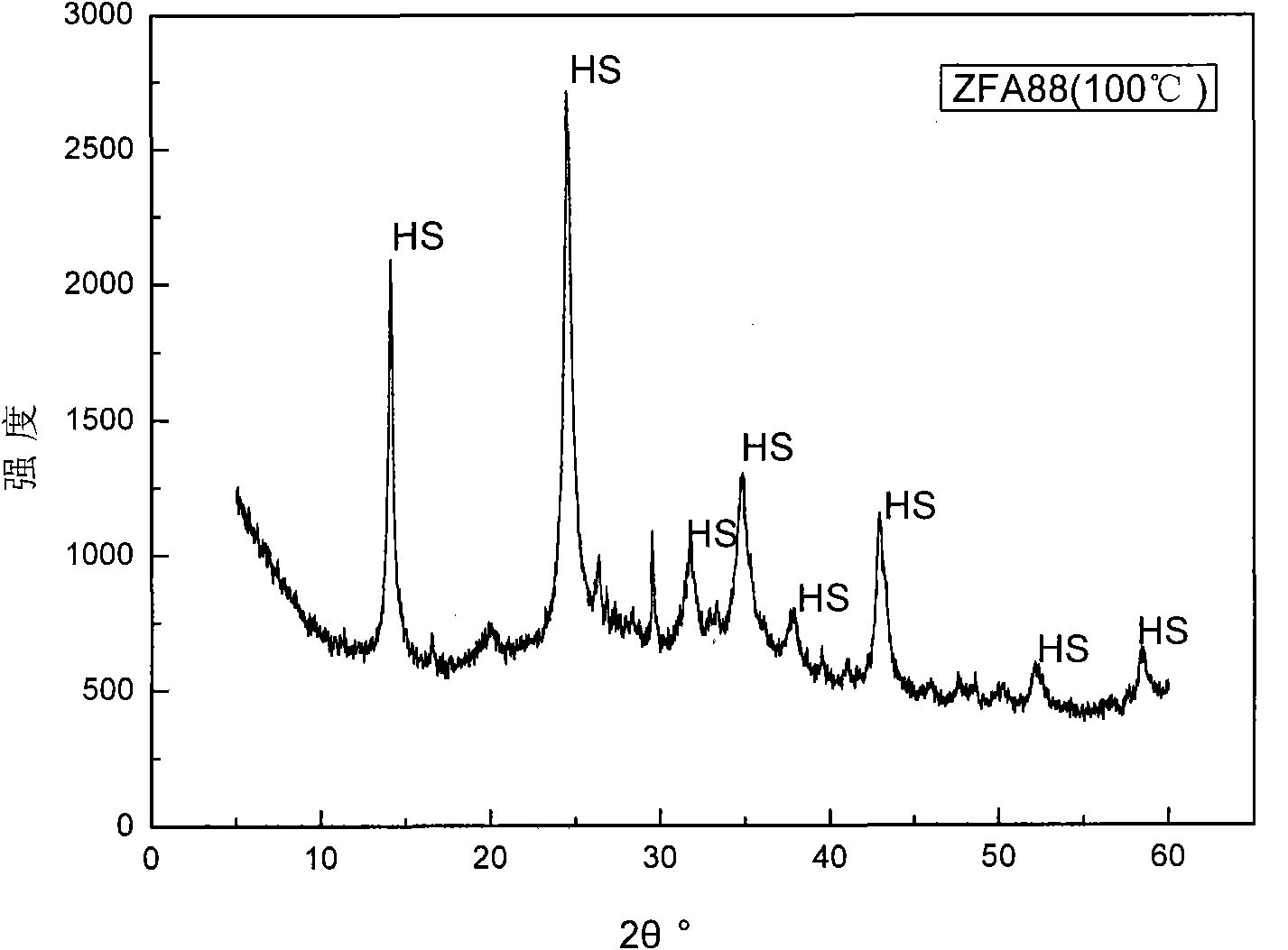

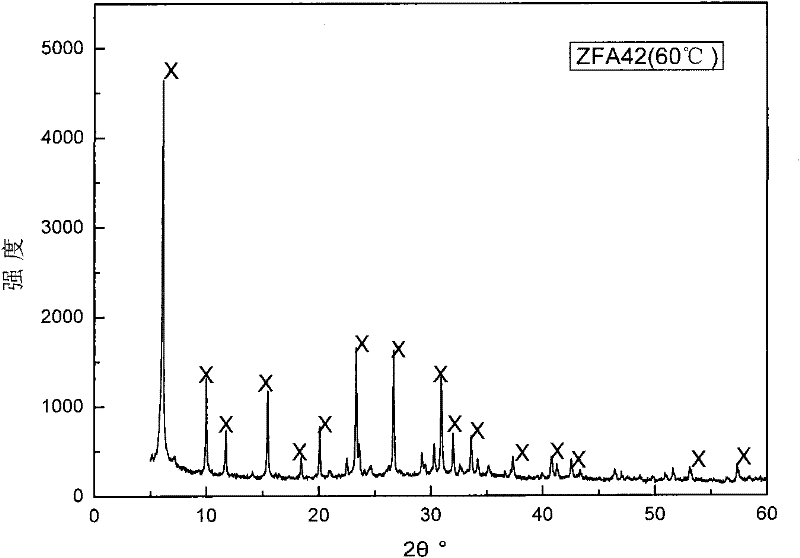

Method for preparing nano flyash zeolite

InactiveCN101993089ASmall particle sizeIncrease profitSolid waste disposalCrystalline aluminosilicate zeolitesIon exchangeSolvent

The invention relates to a method for preparing nano flyash zeolite. Flyash is used as a raw material in the method, and the method comprises the following steps of: firstly melting the flyash and sodium hydroxide at high temperature; mixing the molten flyash with concentrated seawater used as a solvent, stirring and aging to obtain silica-alumina gel; crystallizing the silica-alumina gel hydrothermally, and then washing with water to be neutral; and finally drying to obtain a powdery product. Based on the special aperture structure of zeolite, the synthesized zeolite can be applied to catalysis, adsorption, ion exchange and soil improvement. By using the flyash and the concentrated seawater which are both wastes, the method realizes the recycling of the flyash and the concentrated seawater and is a new environment-friendly production method which meets the requirement of sustainable development.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

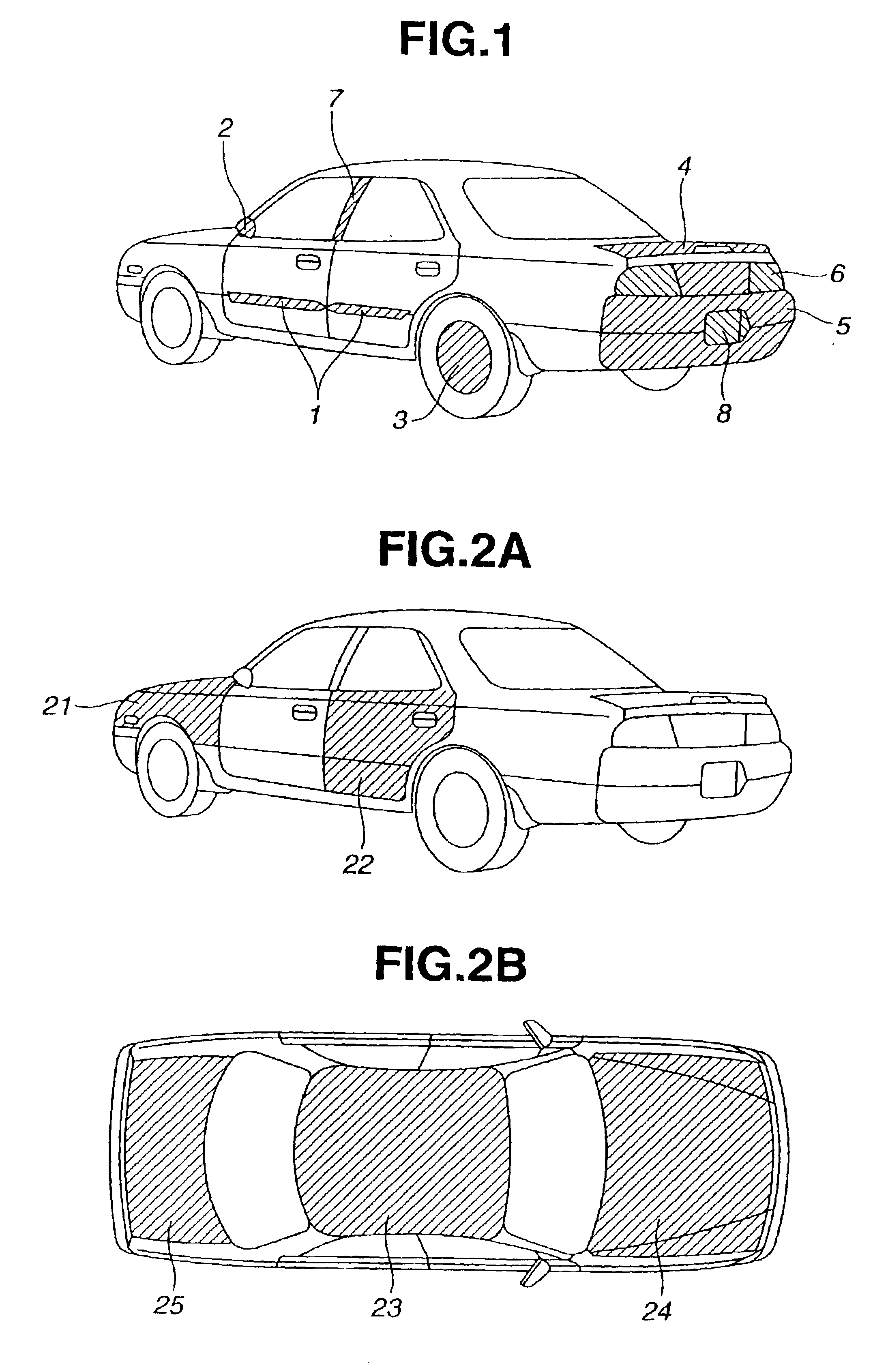

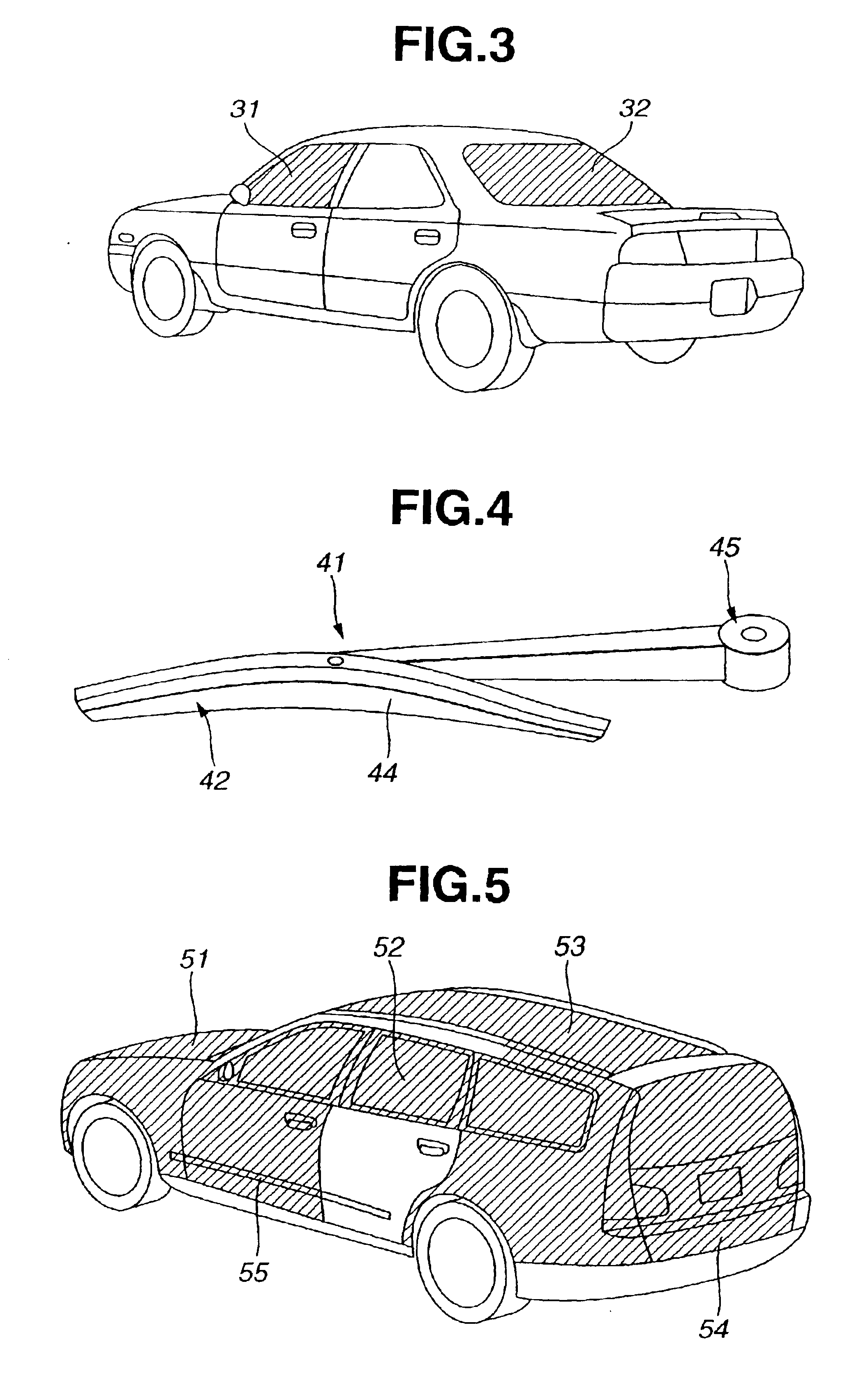

Resin composition, thermoplastic resin laminate, and production methods thereof

InactiveUS6916545B2Improve impact resistanceImprove rigidityLiquid surface applicatorsUnderstructuresHydroxy groupPolymer chemistry

A resin composition to be used as a material for a various part of an automotive vehicle. The resin composition comprises a copolymer (A) formed by copolymerization of a first unsaturated monomer (a) and a second mononer (b). The first unsaturated monomer has a functional group which is bondable by hydrogen bond to a hydroxyl group. The second monomer is copolymerizable with the first unsaturated monomer. A metal oxide (B) is dispersed in the copolymer and having hydroxyl groups and hydrophobic groups at surface of the metal oxide.

Owner:NISSAN MOTOR CO LTD +2

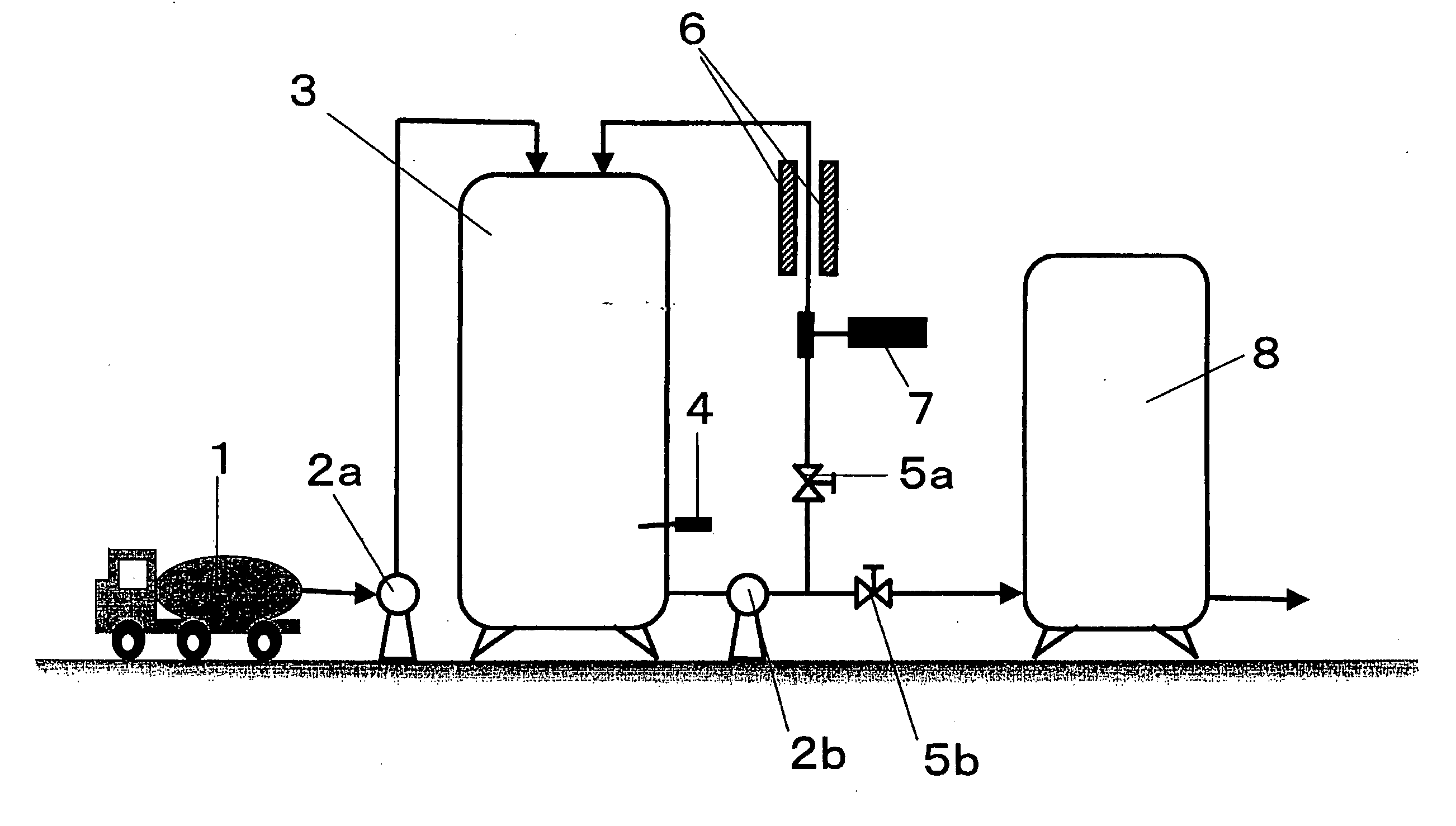

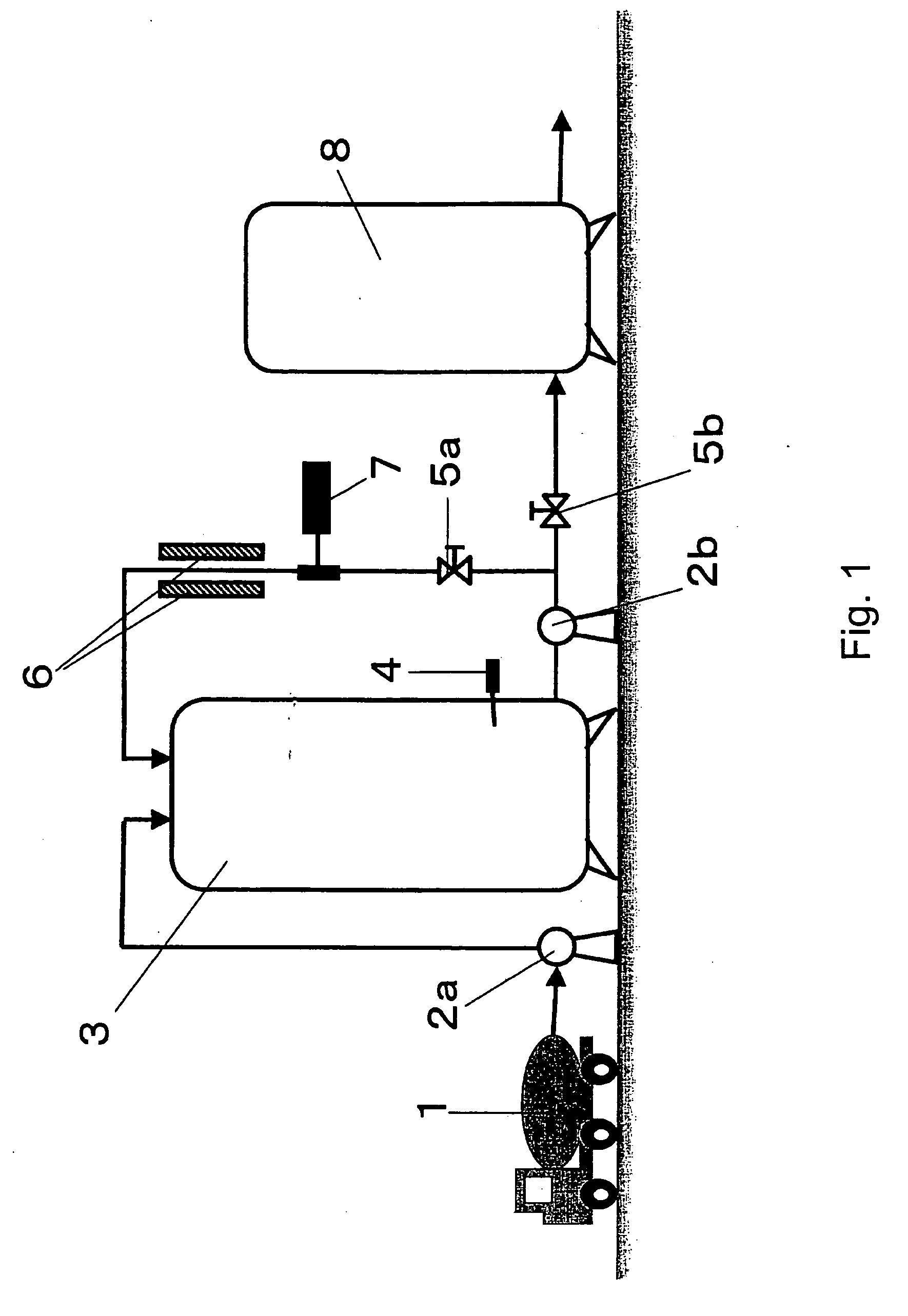

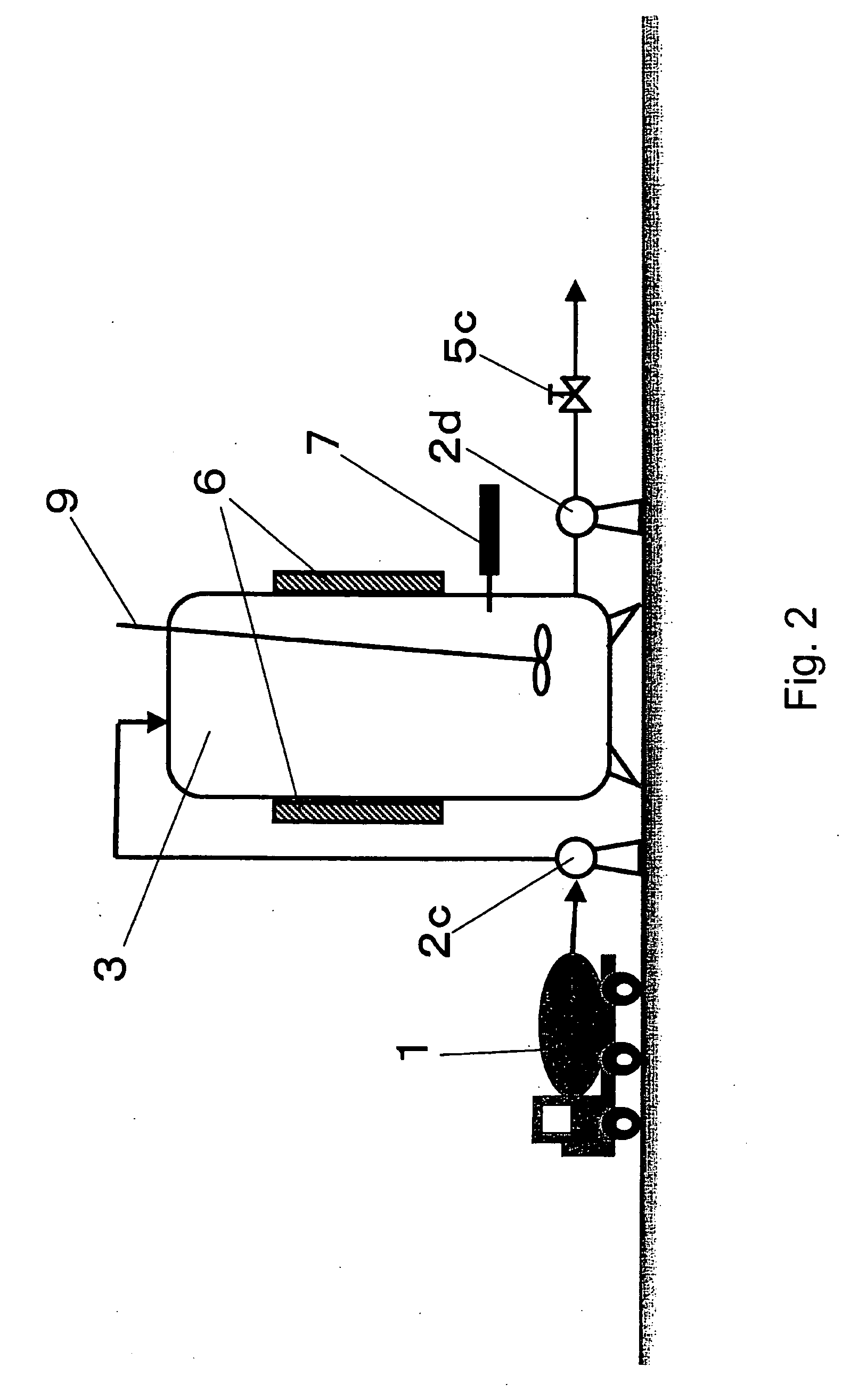

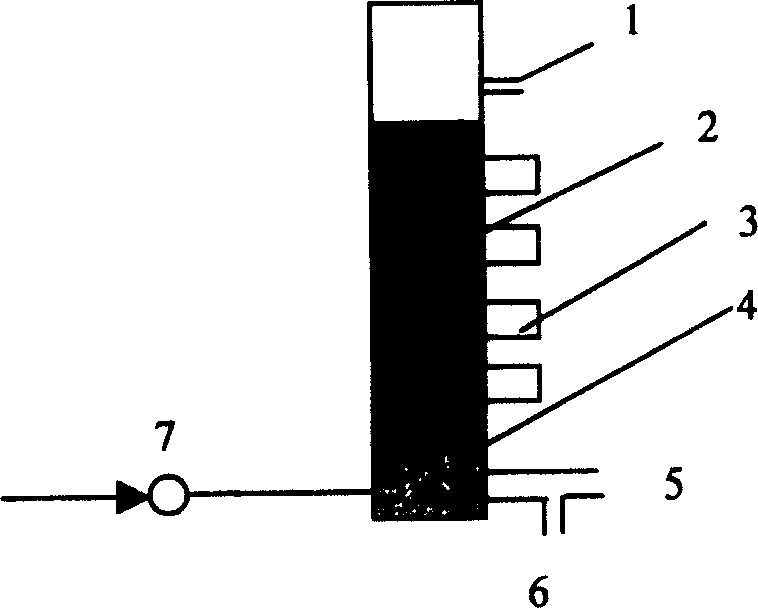

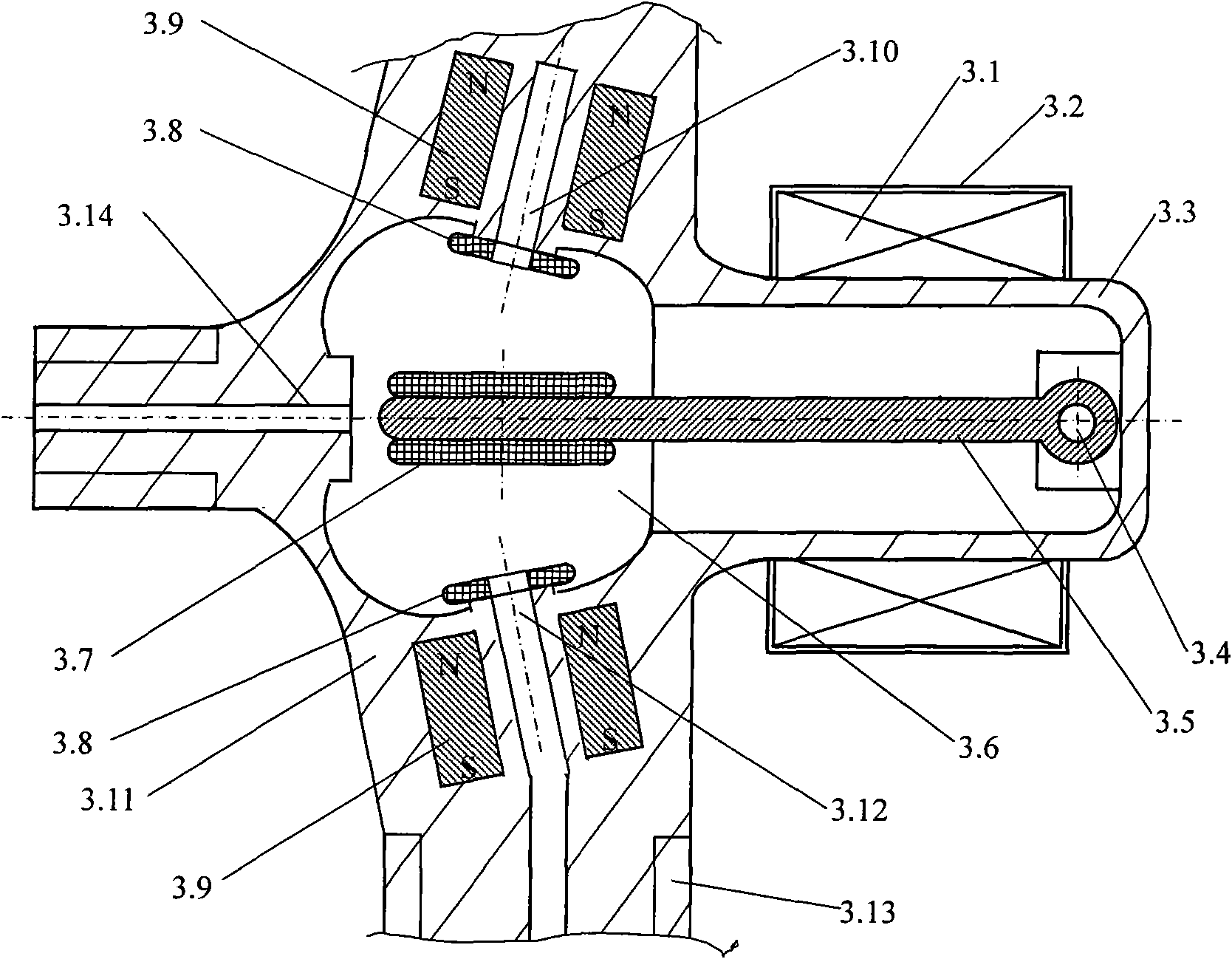

Apparatus for recycling waste sulfuric acid

InactiveUS20060144446A1High added valueReduce environmental loadServomotor componentsUsing liquid separation agentChemistrySulfuric acid

A recycling apparatus of waste sulfuric acid for recycling waste sulfuric acid in an industrially effective manner and for supplying the recycled sulfuric acid having a high added value can be provided. The recycling apparatus of waste sulfuric acid for collecting waste sulfuric acid generated at a source site A, transporting it by a carrier B, and recycling it for reuse at a user site C, the recycling apparatus of waste sulfuric acid including a receiving tank for receiving virgin sulfuric acid (a) and waste sulfuric acid (b) having a concentration different from that of the virgin sulfuric acid, and including (1) a mixer alone, (2) a mixer and a concentration monitor, or a mixer and a cooler in combination, or (3) a mixer, a concentration monitor, and a cooler in combination.

Owner:SONY CORP

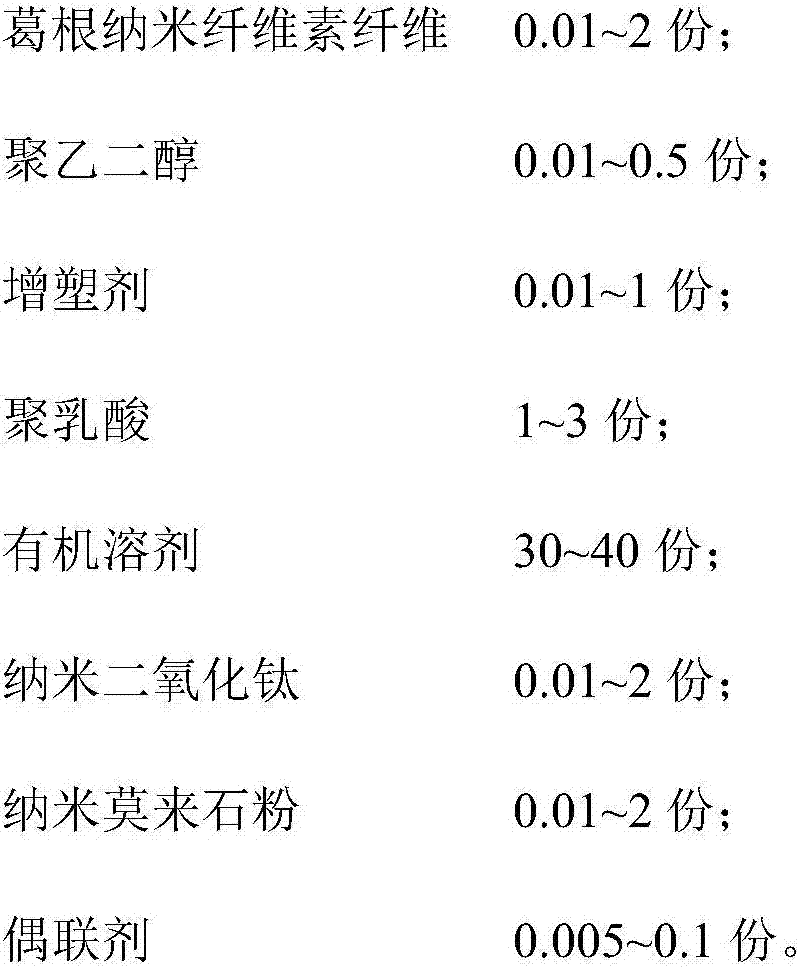

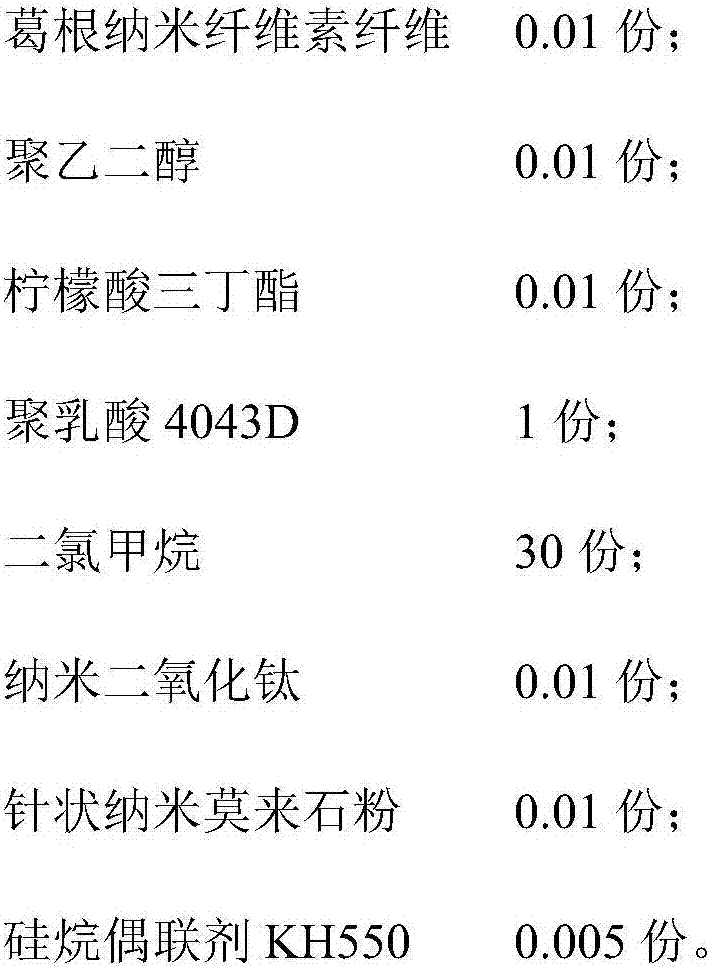

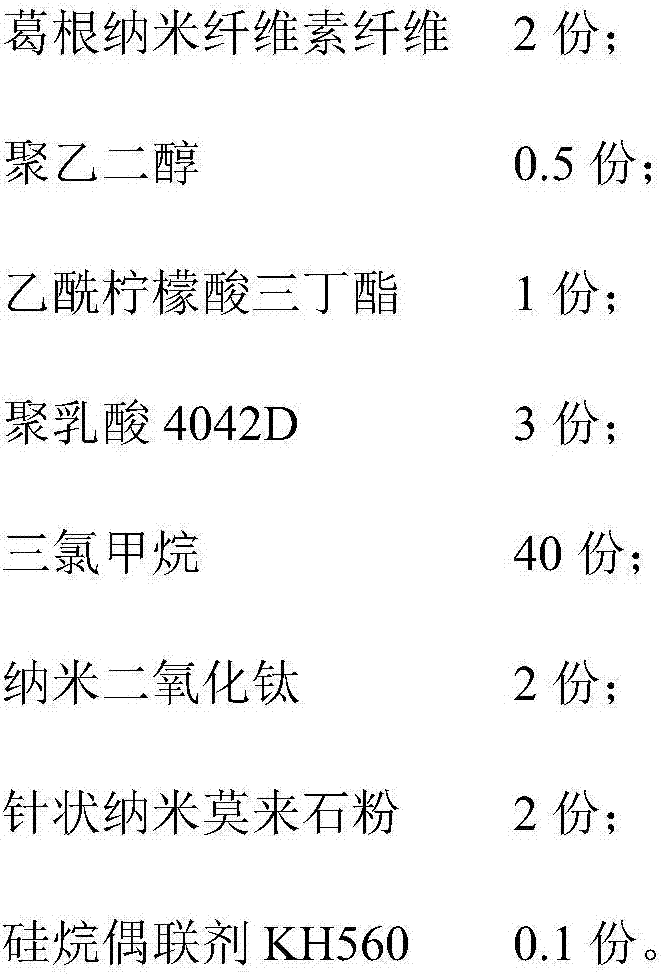

Kudzu root nanocellulose fiber-polylactic acid plastic film and preparation method thereof

The invention discloses a kudzu root nanocellulose fiber-polylactic acid full-degradable plastic film. The kudzu root nanocellulose fiber-polylactic acid full-degradable plastic film is prepared from raw materials in parts by weight as follows: 0.01-2 parts of kudzu root nanocellulose fibers, 0.01-0.5 parts of polyethylene glycol, 0.01-1 part of a plasticizer, 1-3 parts of polylactic acid, 30-40 parts of an organic solvent, 0.01-2 parts of nano-titania, 0.01-2 parts of nanometer mullite powder and 0.005-0.1 parts of a coupling agent. Environment-friendly polylactic acid is taken as a matrix, and nanocrystal cellulose fibers prepared from kudzu root residues are taken as a reinforcing material of the polylactic acid full-degradable plastic film, so that the strength, the modulus, the barrier property and the like of the film can be improved; organic combination for a nanocrystal cellulose fiber, inorganic material and polylactic acid ternary system is realized technologically, and the multifunctional polylactic acid full-degradable plastic film material is prepared.

Owner:YANCHENG INST OF TECH

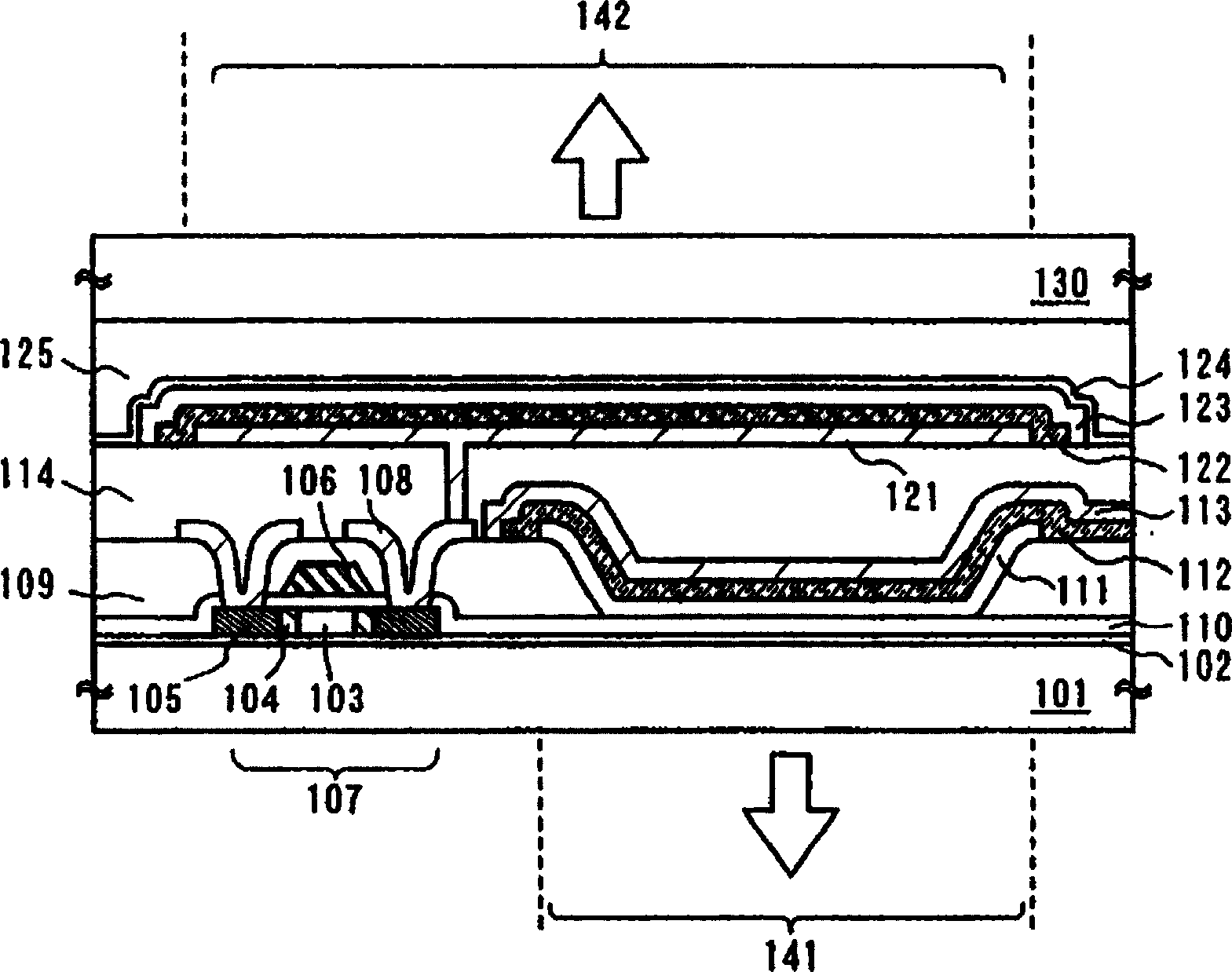

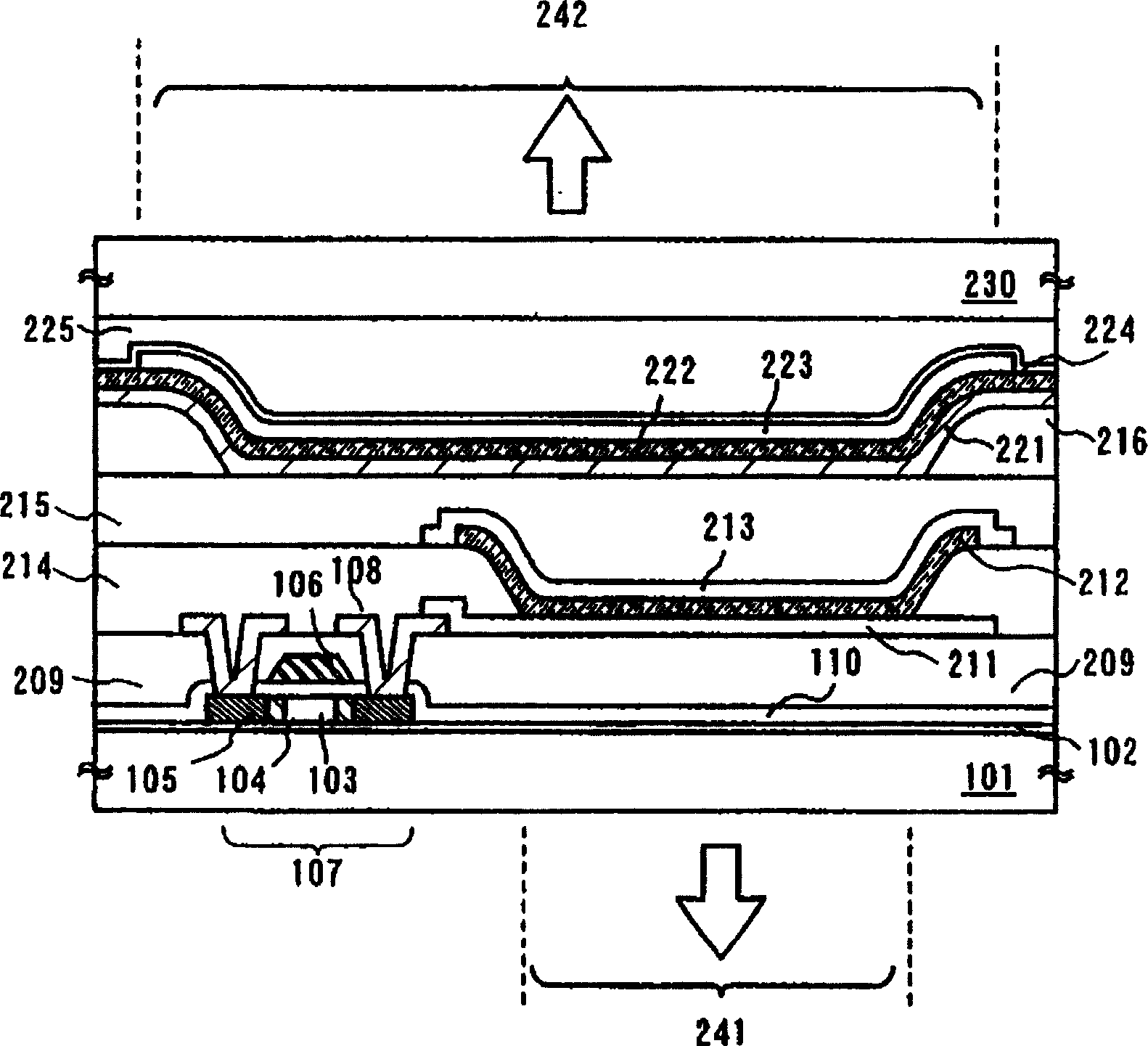

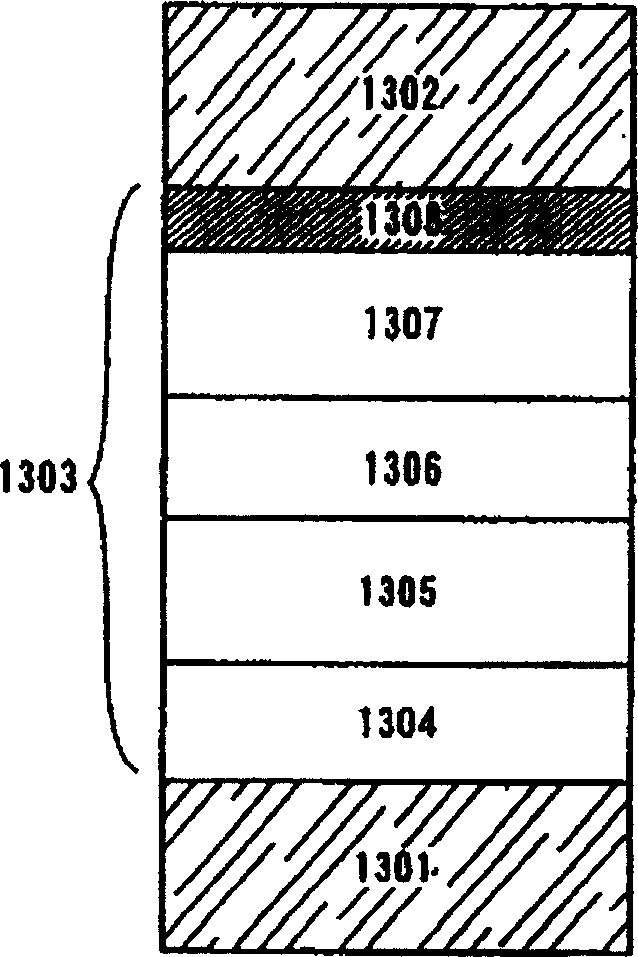

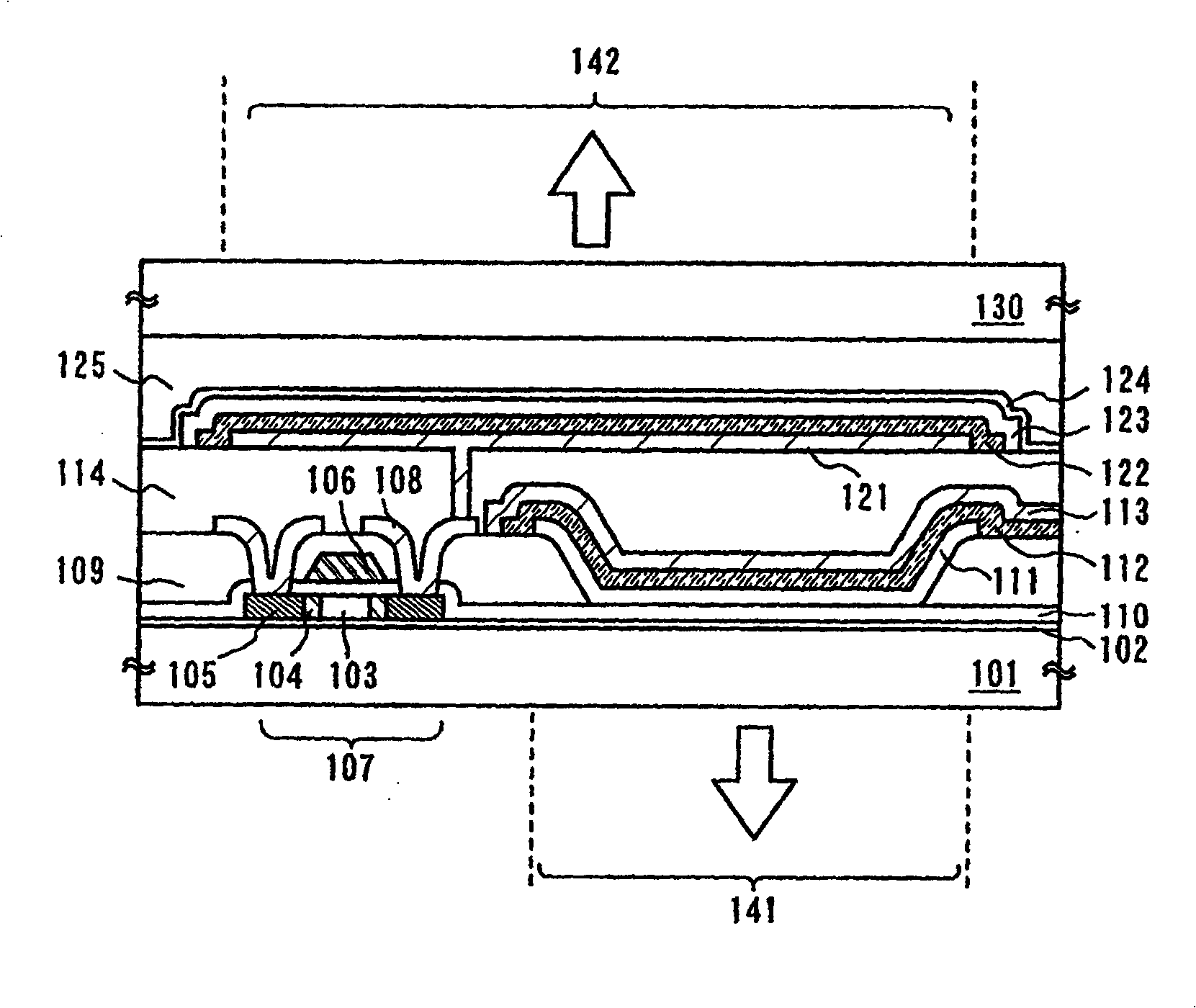

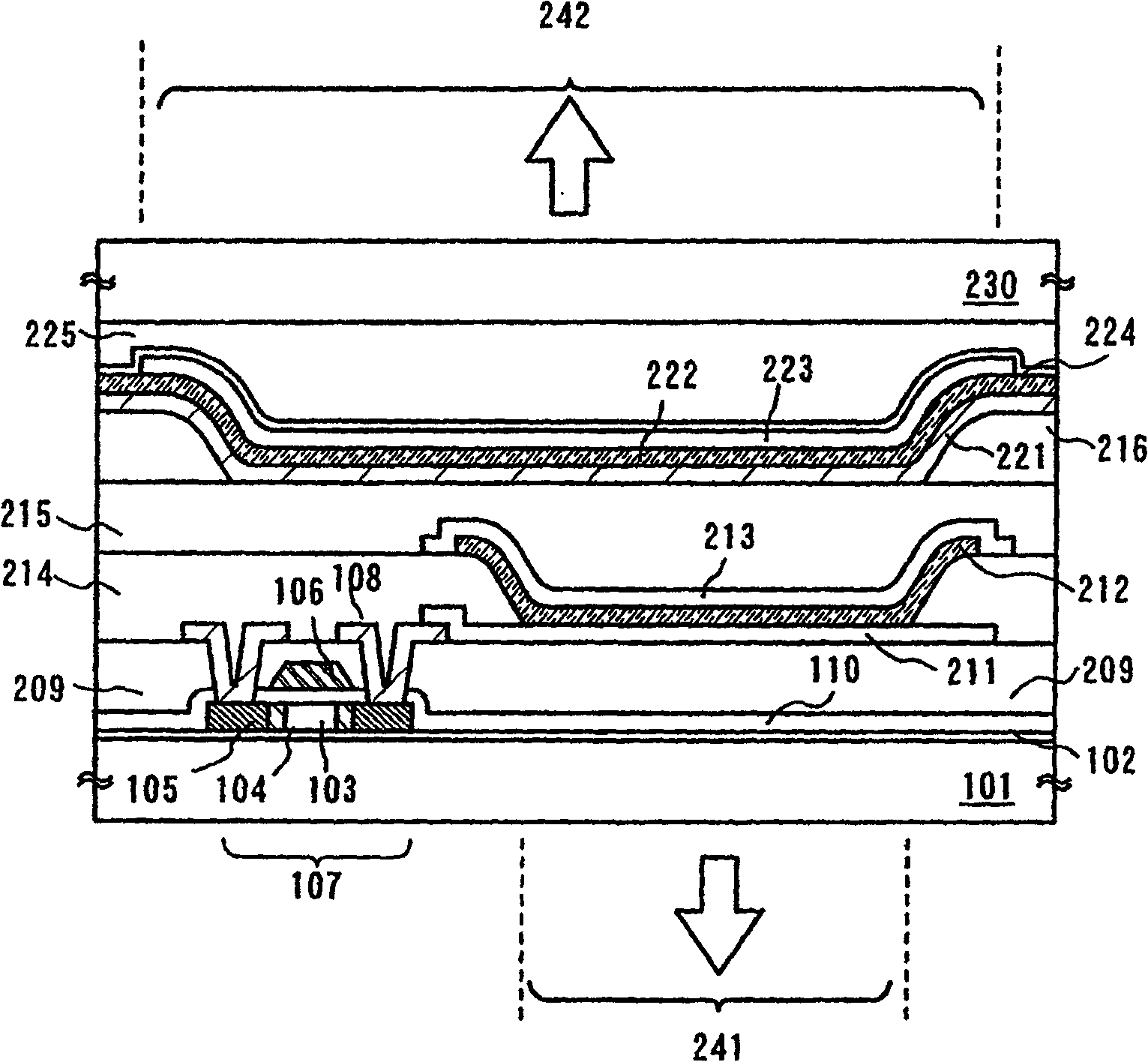

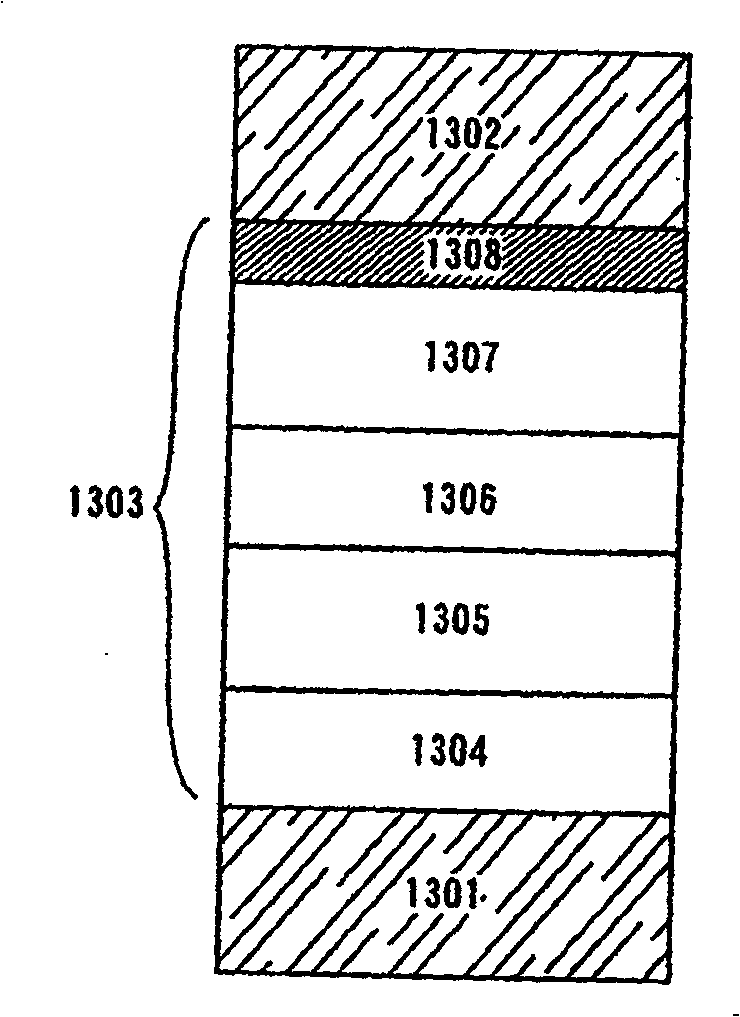

Light-emitting device and electronic device

ActiveCN1610460AAchieve modularityReduce volumeStatic indicating devicesElectroluminescent light sourcesDisplay deviceEngineering

The present invention provides a light-emitting device whose volume is small and that has plural display screens, and a personal digital assistant that realizes higher added value by using the same. A light-emitting device of the present invention has a plurality of light-emitting elements in a pixel, and these light-emitting elements emit light in a different direction from each other and a pixel driving element is provided in one of the light-emitting elements. The light-emitting device can display in both front and back sides and independently display images on the both sides. Further, it can provide a higher aperture ratio, which is obtained by adding the aperture ratios of the both sides. Furthermore, it is also possible to see different images on the both sides of an electronic device using a display device of the present invention. Moreover, weight saving and thinning of electronic devices can be realized.

Owner:SEMICON ENERGY LAB CO LTD

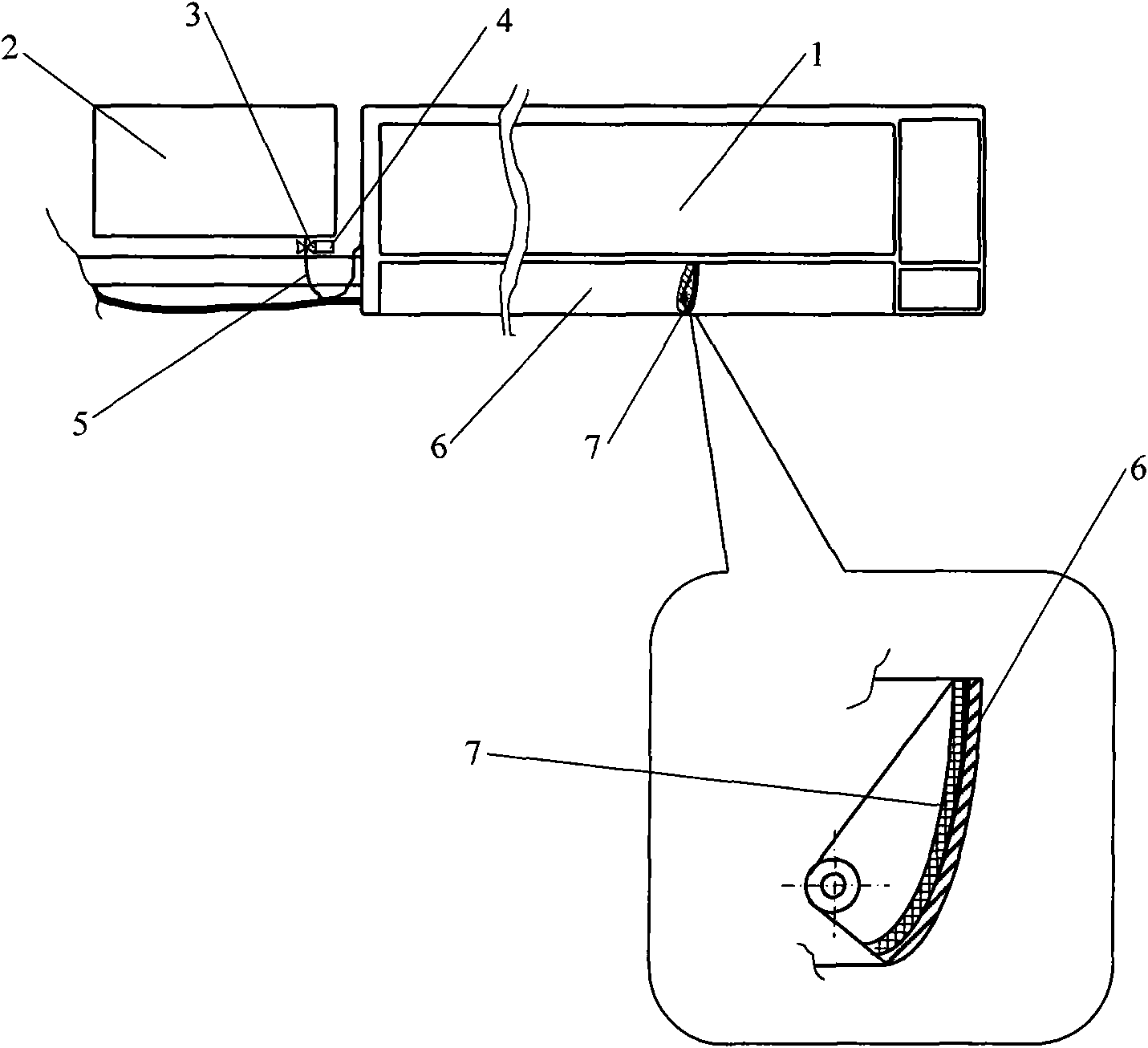

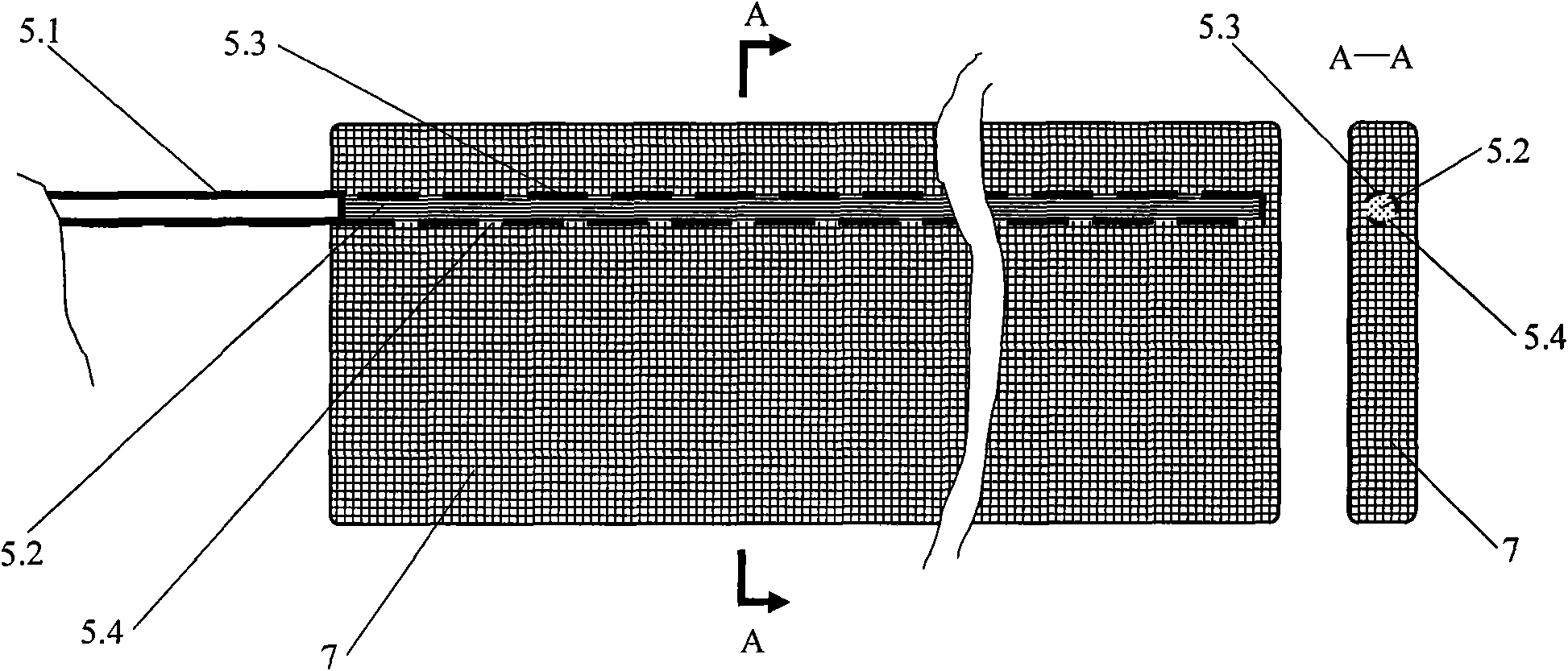

Method for preparing liquid fuel by step-by-step deoxidization of grease

ActiveCN107987868AReduce hydrogen consumptionReduce material consumptionLiquid hydrocarbon mixture productionBio-feedstockDeoxidizationFatty acid methyl ester

The invention discloses a method for preparing liquid fuel by step-by-step deoxidization of grease. The method comprises the following steps: (1) the grease is converted into fatty acid methyl ester by methyl esterification; (2) fatty acid methyl ester and hydrogen are converted into fatty alcohol under the action of a copper-based catalyst; (3) fatty alcohol is subjected to dehydration / isomerization under the action of a molecular sieve based catalyst, and olefins are prepared, wherein the content of isomerized olefins in olefins is higher than 86%, reaction temperature is 190-240 DEG C, absolute pressure of the reaction is 0.1-0.5 MPa, the volume space velocity of fatty alcohol is 0.2-3 h<-1>, and the molecular sieve based catalyst is one or more of ZSM-35, ZSM-5, ZSM-22, SAPO-31, SAPO-11, a Y molecular sieve, a beta molecular sieve and mordenite. The method for preparing the liquid fuel has the advantages that the catalysts are cheap and easily available, hydrogen consumption is reduced remarkably, glycerin yield is increased, and the like.

Owner:PETROCHINA CO LTD

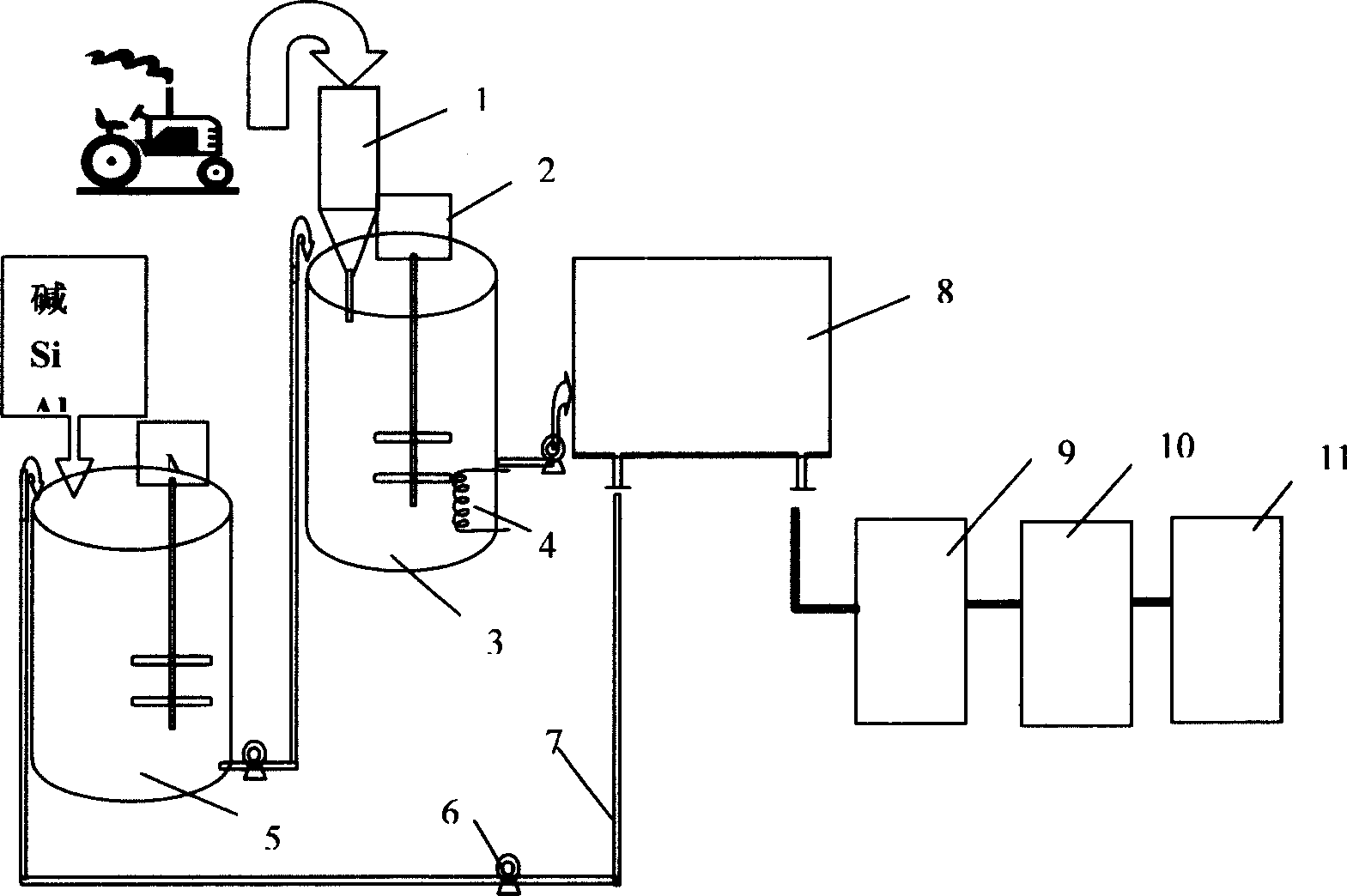

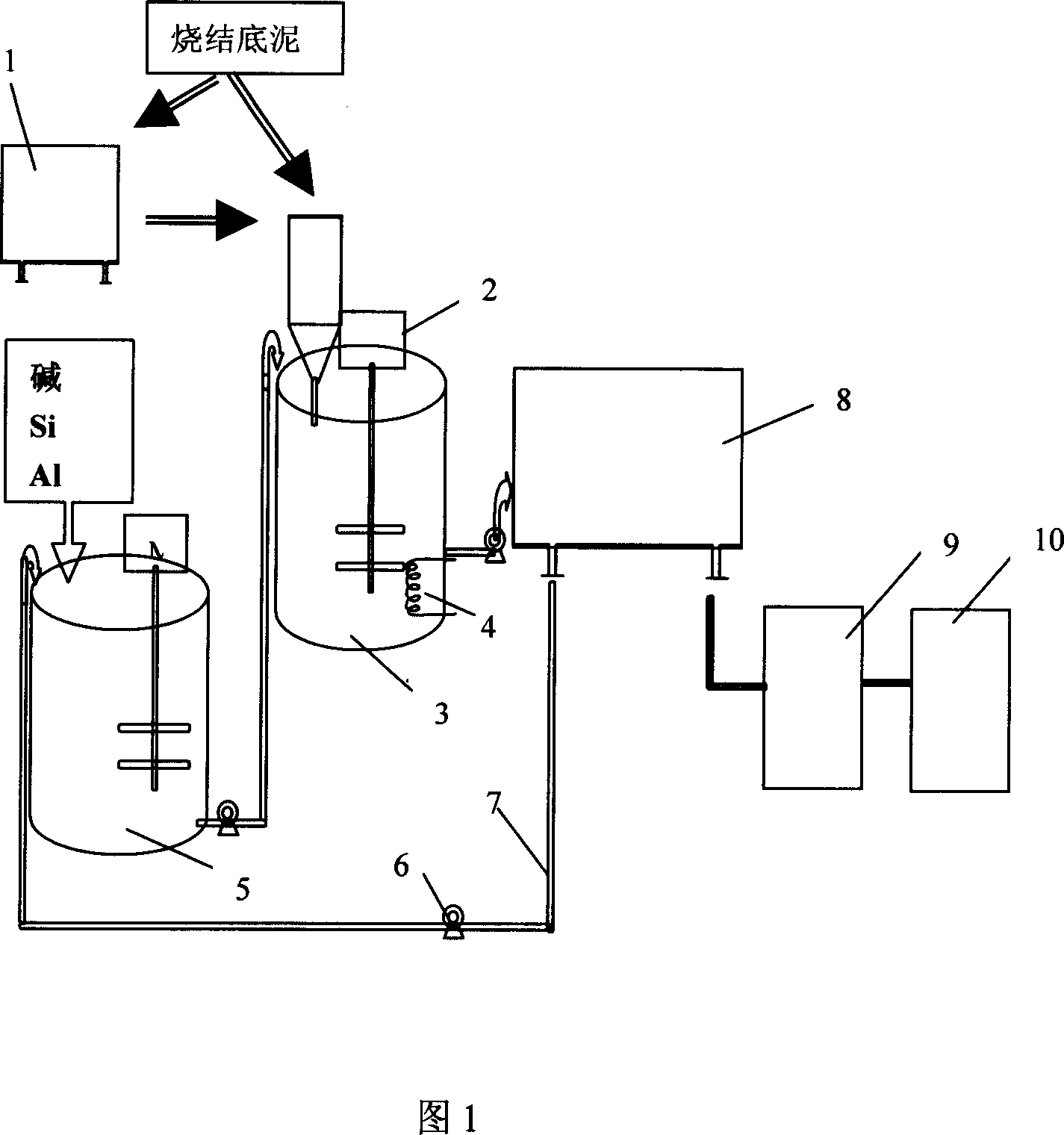

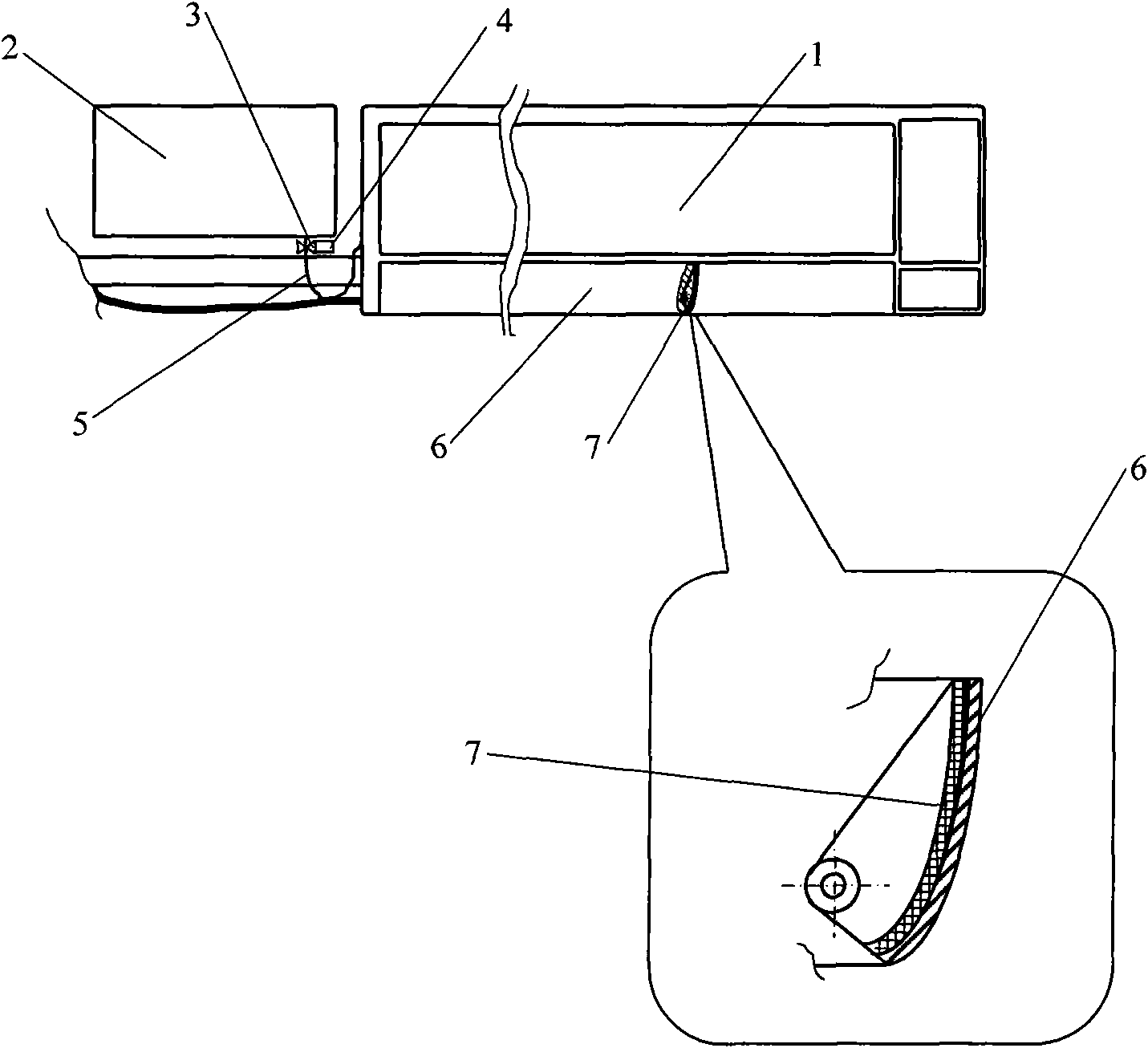

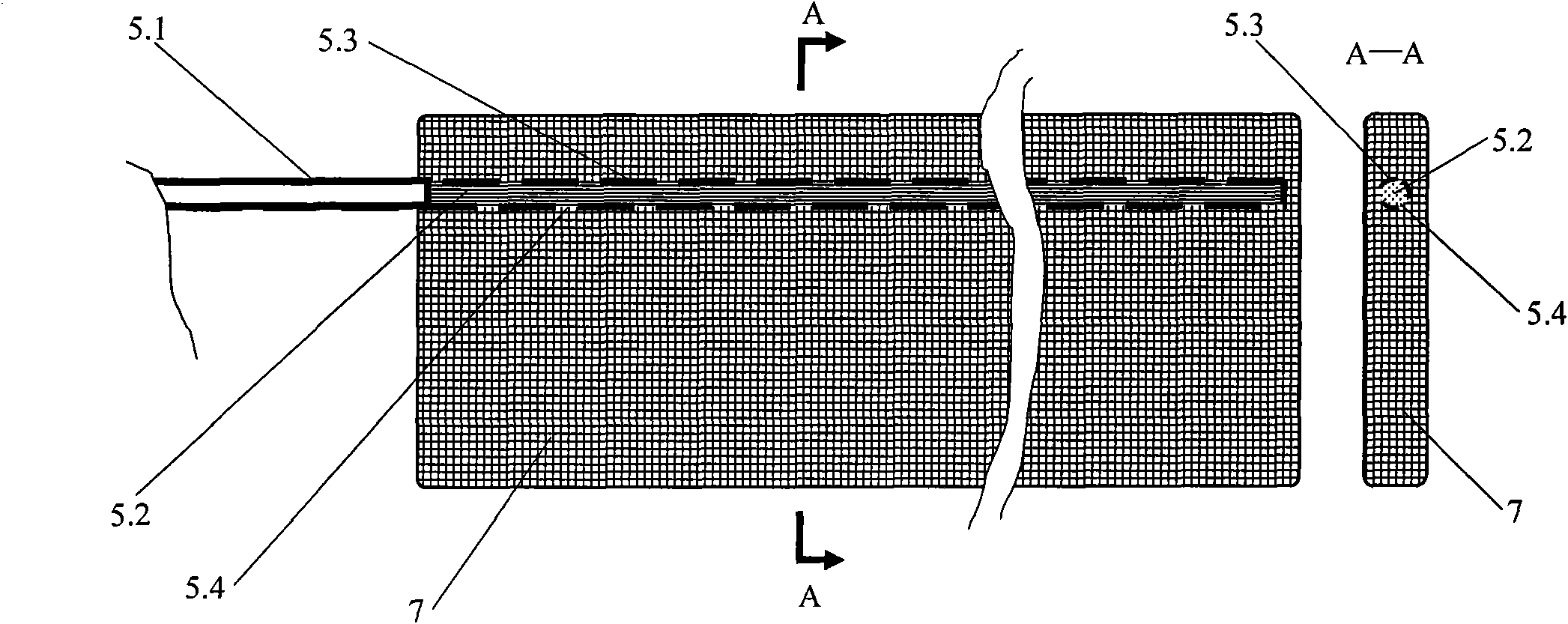

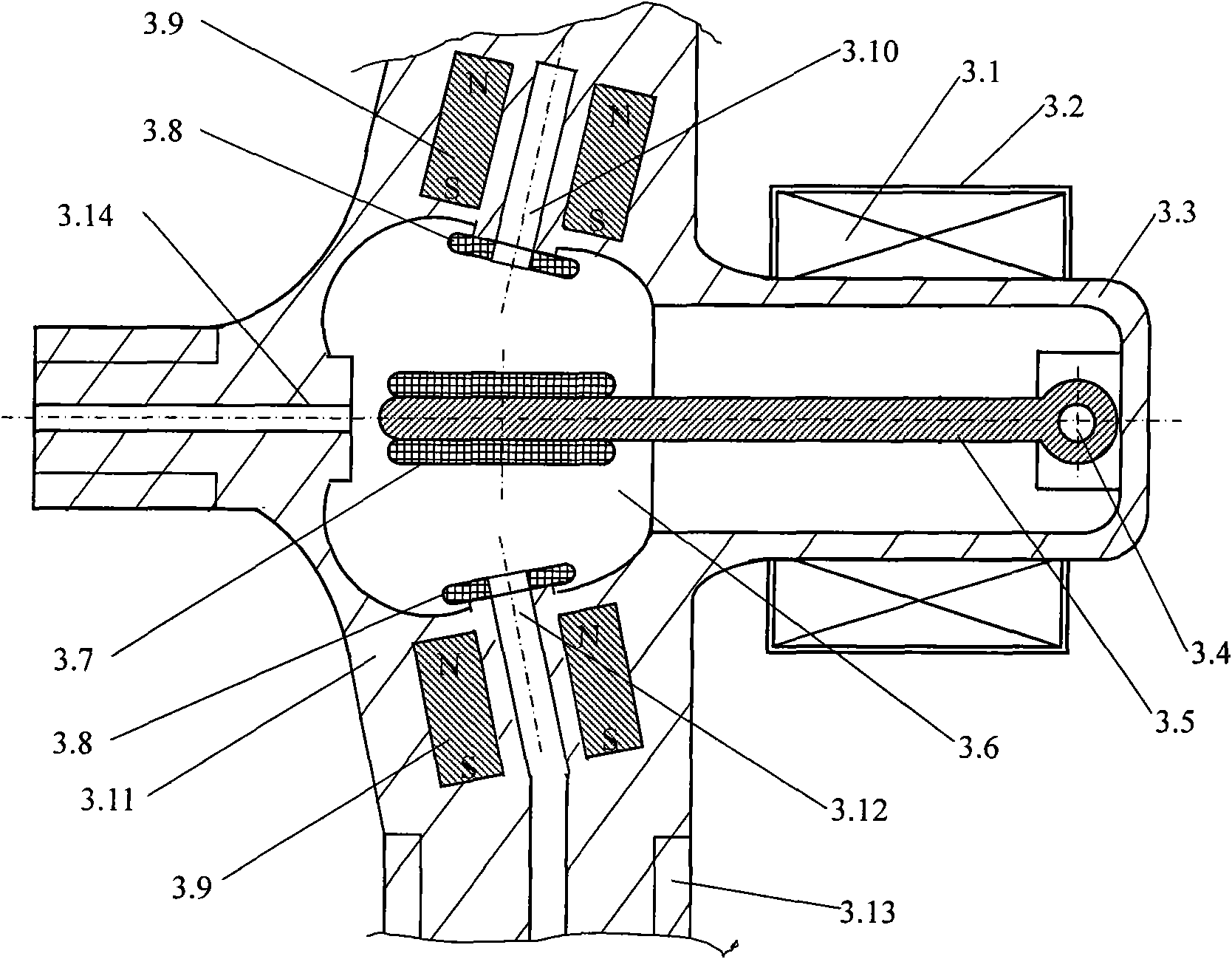

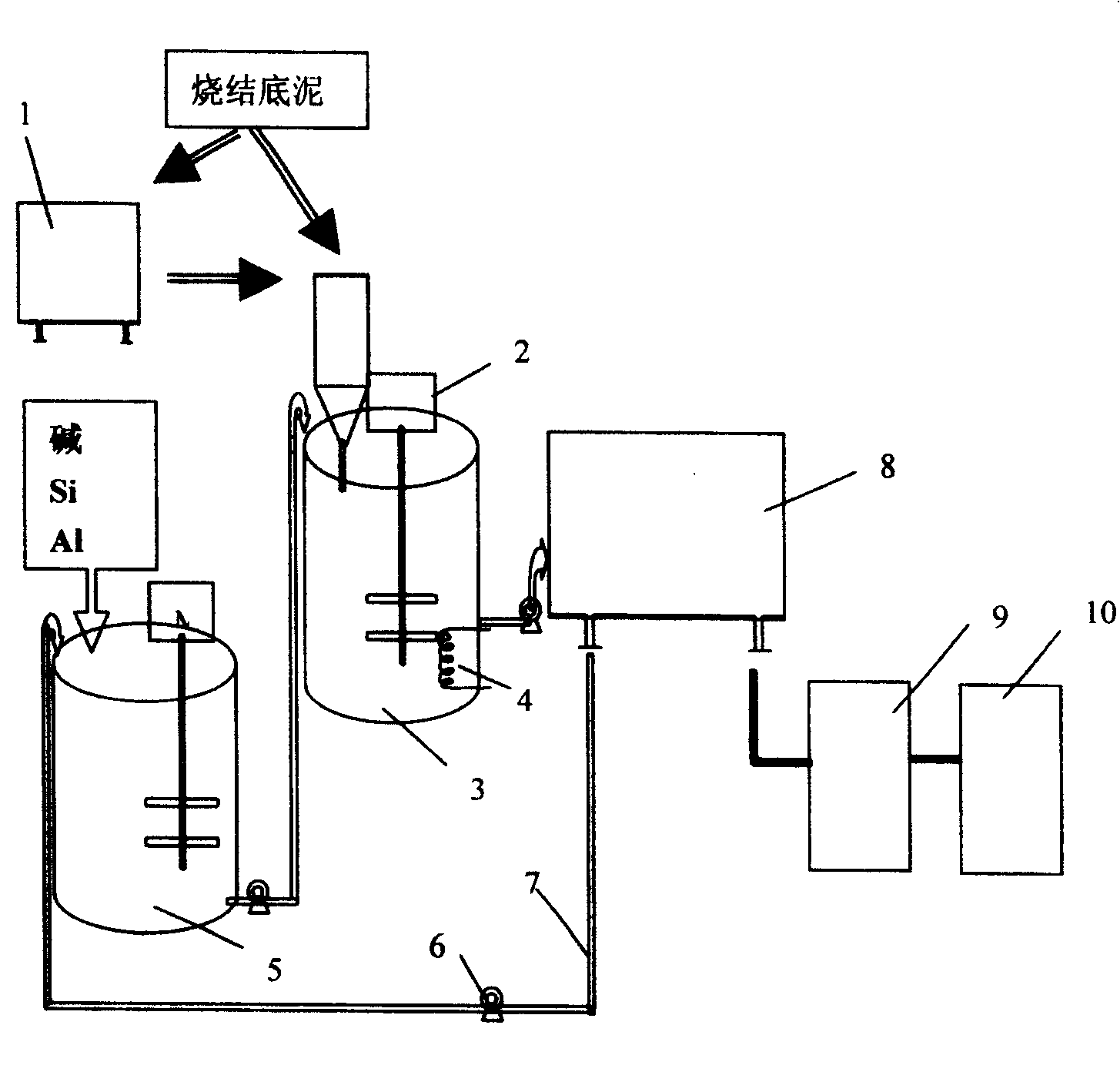

Method and device for preparing synthetic zeolite from flyash zero discharged waste alkali liquid

InactiveCN1683243AEliminate destructionQuality improvementCrystalline aluminosilicate zeolitesAlkalinitySolid phases

The present invention relates to preparation process and apparatus of synthetic zeolite with flyash as material and no waste alkali liquid exhaust. Except traditional zeolite synthesizing reaction tank and solid-liquid separating dewatering tank, the apparatus has one additional dissolving tank for the component and alkalinity regulation and circulating use of waste alkali liquid. The preparation process includes reaction between flyash and sodium carbonate in the reaction tank to convert into zeolite, solid-liquid separating in the solid-liquid separating dewatering tank to obtain solid phase zeolite product and waste alkali liquid, regulating the Si / Al ratio of waste alkali liquid in the dissolving tank and returning the used alkali liquid into the reaction tank for reuse. The present invention has saving of alkali and water and eliminates environmental pollution.

Owner:SHANGHAI JIAO TONG UNIV

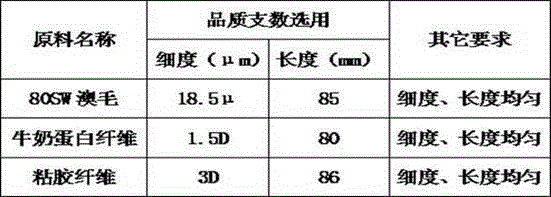

Preparation method of fabric with skin care effect

ActiveCN105200792AQuality assuranceImprove cohesionHeating/cooling textile fabricsDyeing processFiberPolymer science

The invention discloses a preparation method of a fabric with a skin care effect. The preparation method comprises the steps that a certain quantity of submicron-grade SiOx particles with extremely high hydrophilicity are added into an aqueous polyurethane solution, and a layer of rugged coarse PU thin film (wherein bulges and exposed portions are the SiOx particles) is cast on the surfaces of fibers by a padding and steaming technology, thus greatly increasing the friction coefficient among milk protein fibers, and improving the cohesive force among the fibers; meanwhile, the SiOx particles are extremely high in water absorbency, so that the fibers are endowed with higher antistatic property; therefore the problems of stickiness, twisting, winding, bar breakage and the like which are easily caused in a bar mixing working procedure are solved, and the production efficiency is greatly improved.

Owner:JIANGSU JIANLU WOOLEN

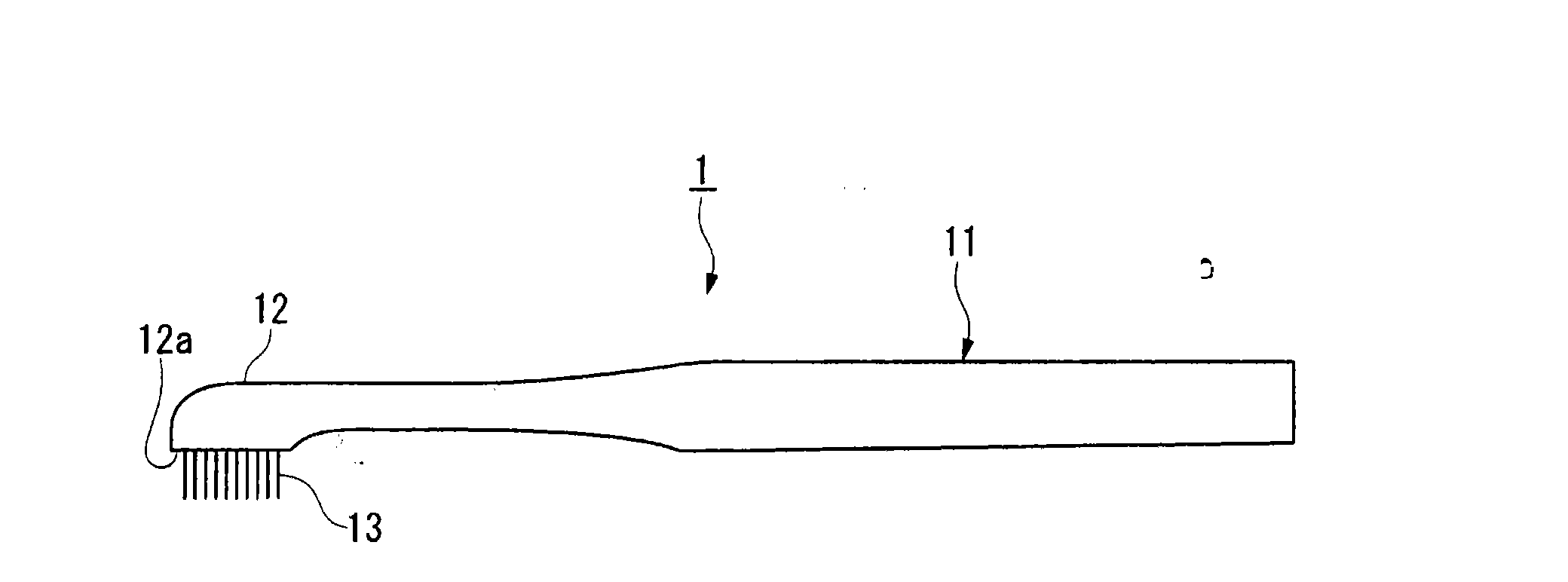

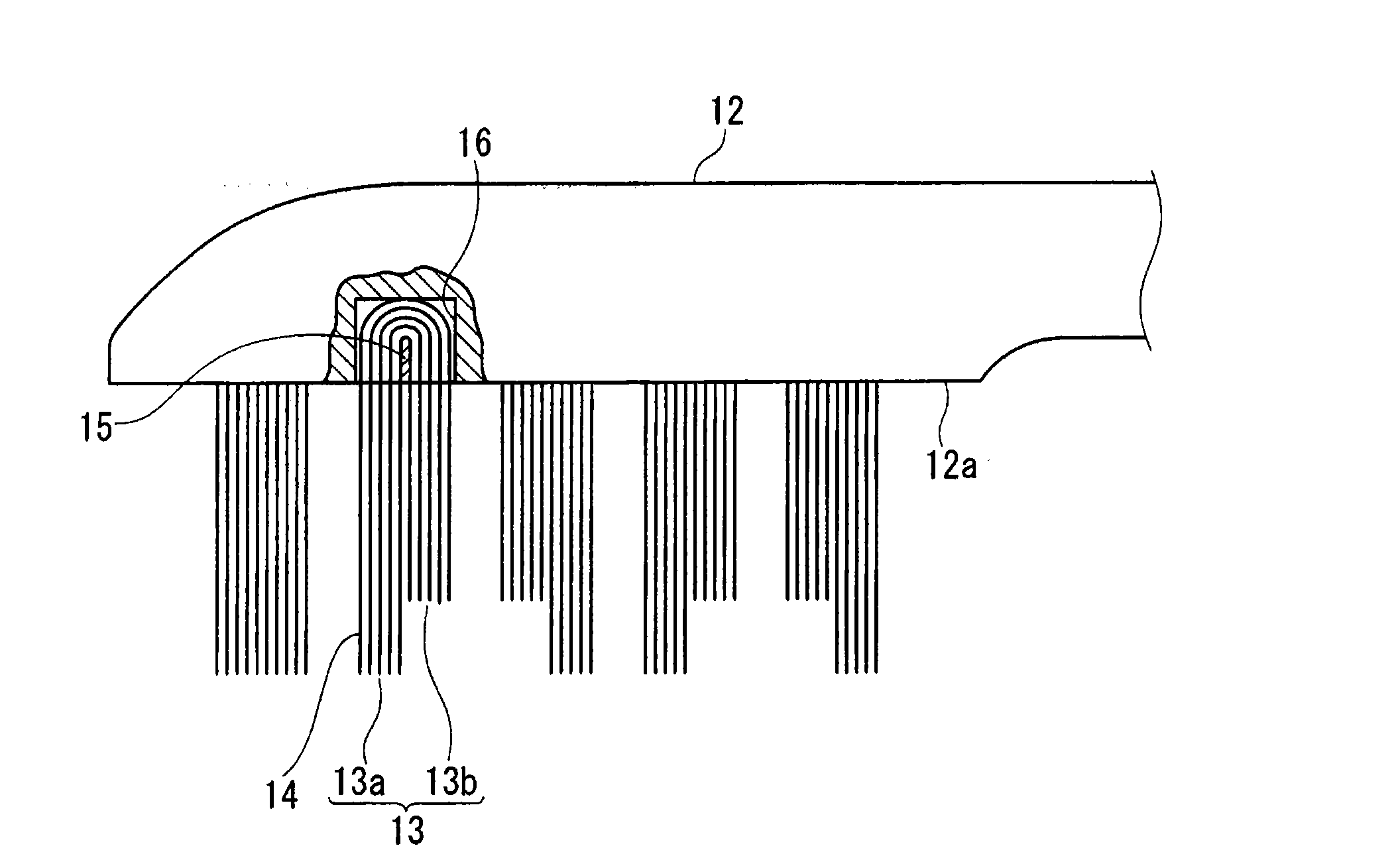

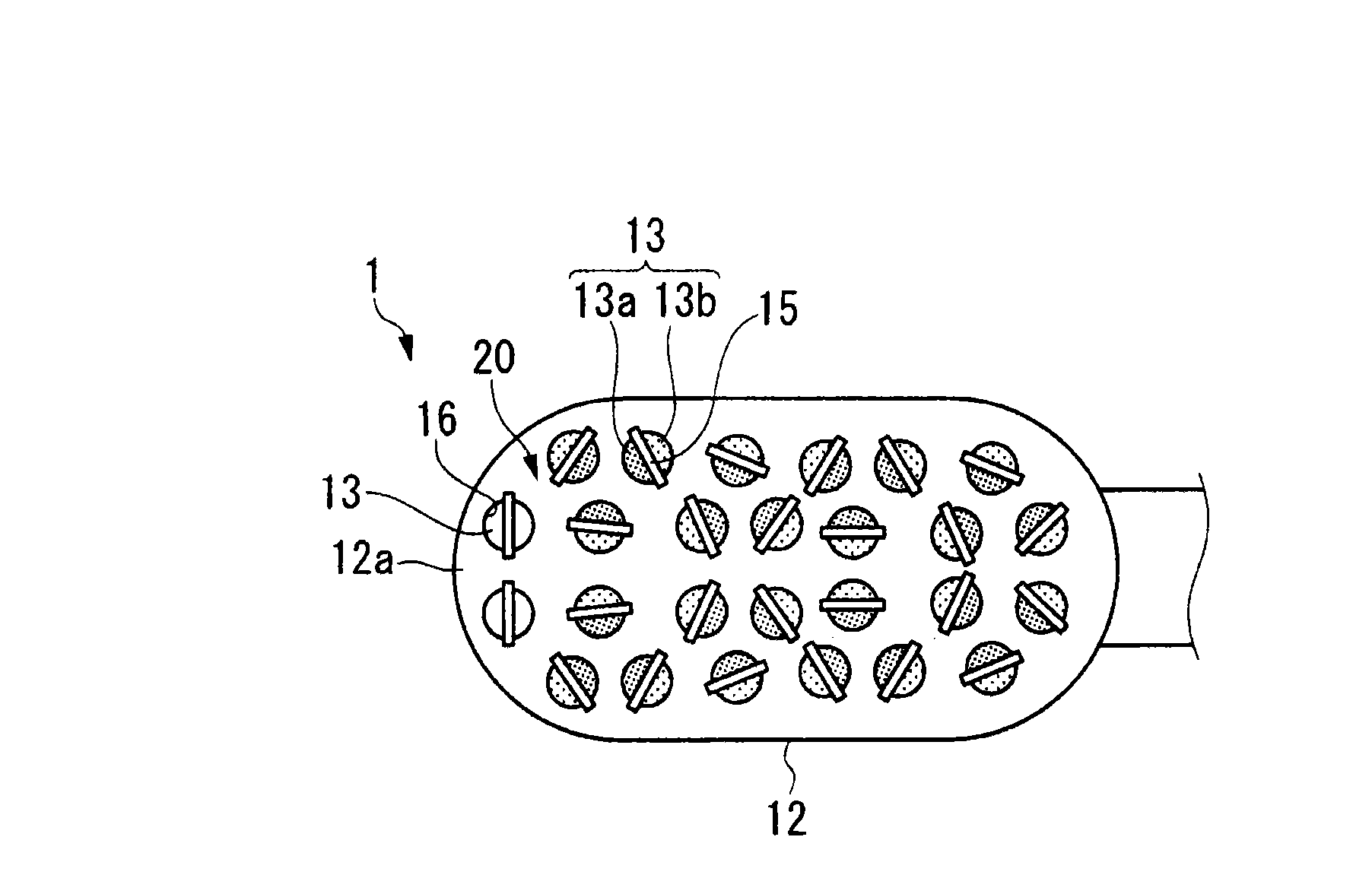

Toothbrush

A toothbrush which is compatible with various functional appeals of a toothbrush, has an appeal effect-exhibiting appearance, and is high in degree of design freedom. The toothbrush comprises a head unit (12) having a plurality of tuft holes (16) provided in its head surface (12a), wherein a brush bristle bundle (13) is folded into two and a wire (15) held between them is driven into the tuft hole (16), whereby the bristle bundle (13) is planted into the tuft hole (16). A bristle bundle group (20) constituted of at least three bristle bundles (13) is provided on the head surface (12a) of the head unit (12), and the direction of a wire (15) in each of bristle bundles (13) constituting the bristle bundle group (20) is set to a direction in which one enclosed area is sectioned by the extension line of each wire (15) or a direction in which an area held between the extension lines of wires is sectioned.

Owner:LION CORP

Method for synthesizing zeolite by fly ash and application thereof

InactiveCN1296129CAvoid the disadvantages that the treatment effect is affected by temperature, etc.Easy to operateOther chemical processesWater/sewage treatment by sorptionPhosphatePollution

The invention concerns a way of synthesize stone using coal powder and its applying in removing nitrogen and phosphorus in the waste water. Get the coal powder as the material, add the material including aluminum, silicon, or fluorine which can saluted in the alkaline solution, after mixing, add metal alkaline solution and synthesize fei stone by water heating reaction, then change shape by metal salt aqua, we get the fei stone after separating solid and liquid. Change the fei stone to the grains and put them in the filtering bed, achieving to remove nitrogen and phosphorus. The invention solves the environment problem, economy the resource of nitrogen and phosphorus in the coal powder, no second pollution.

Owner:SHANGHAI JIAOTONG UNIV

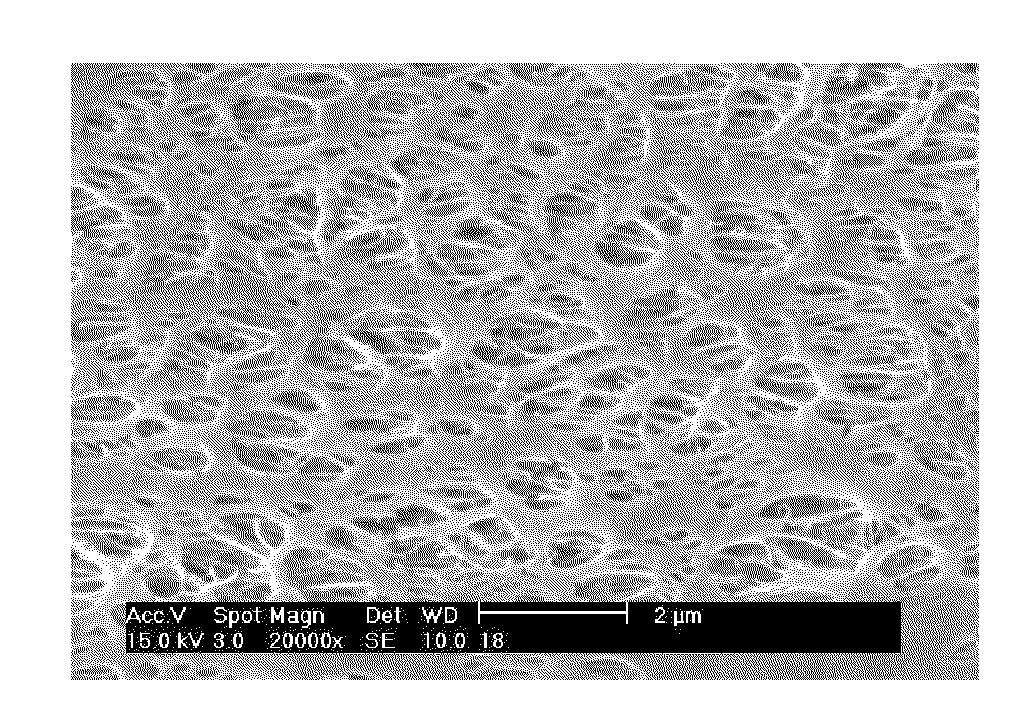

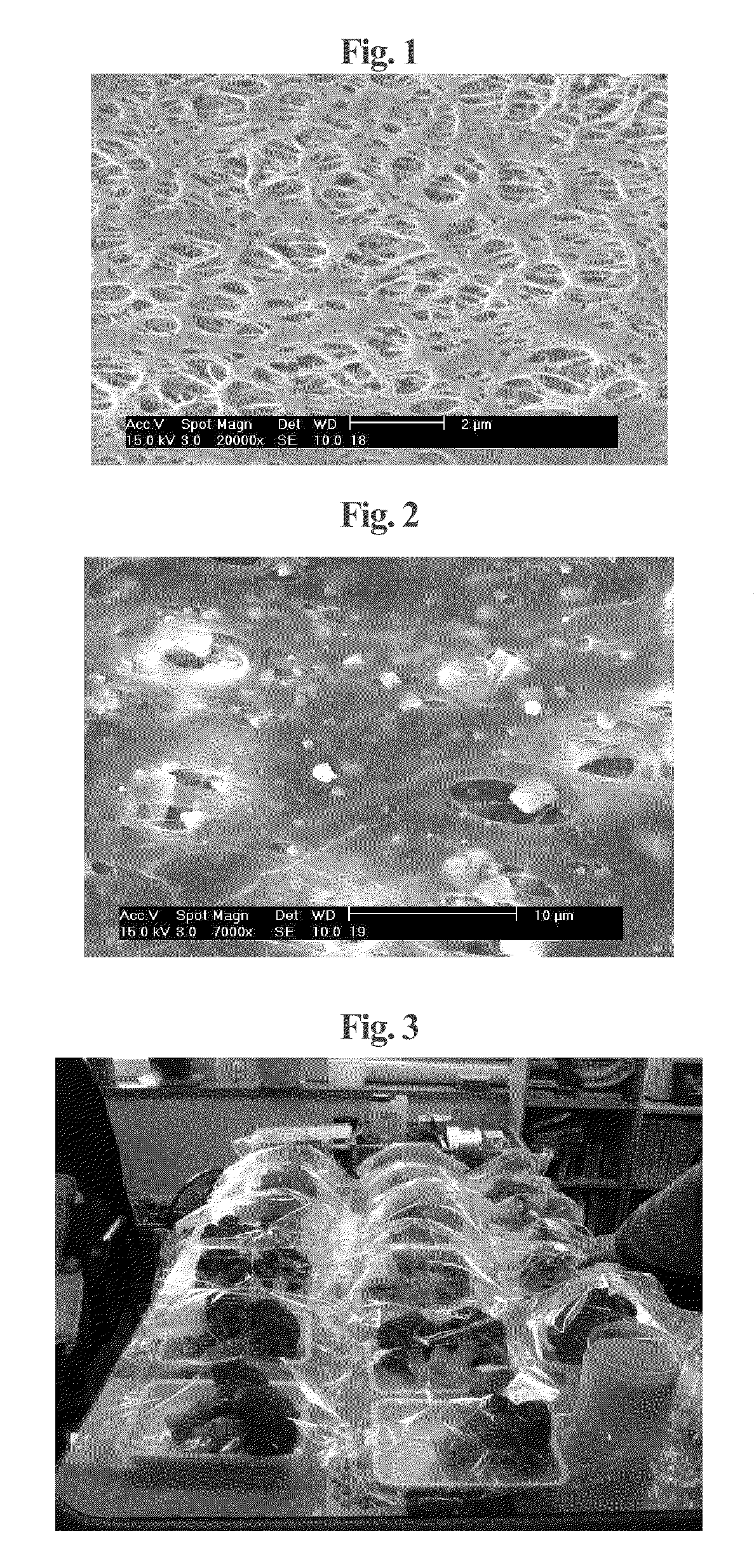

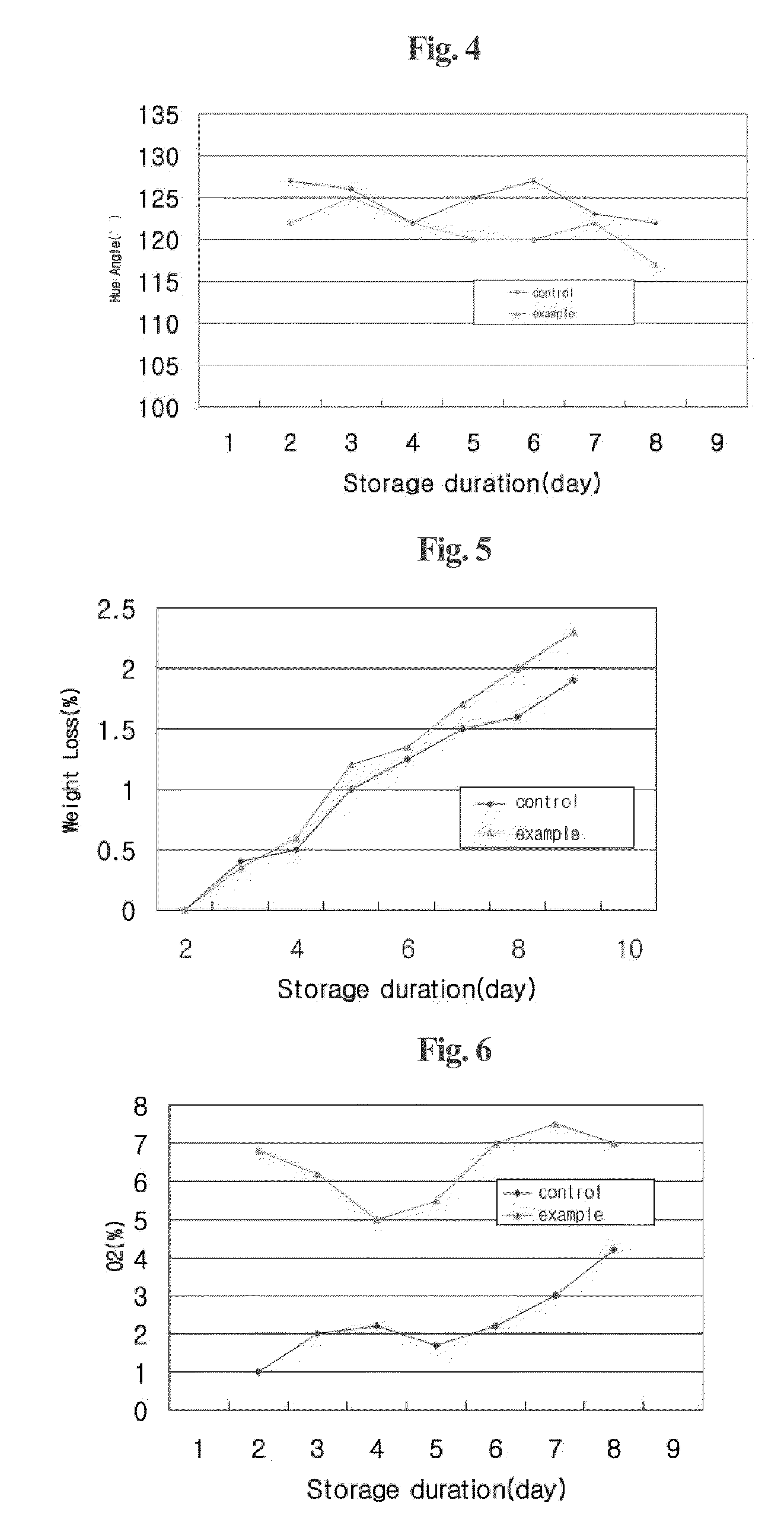

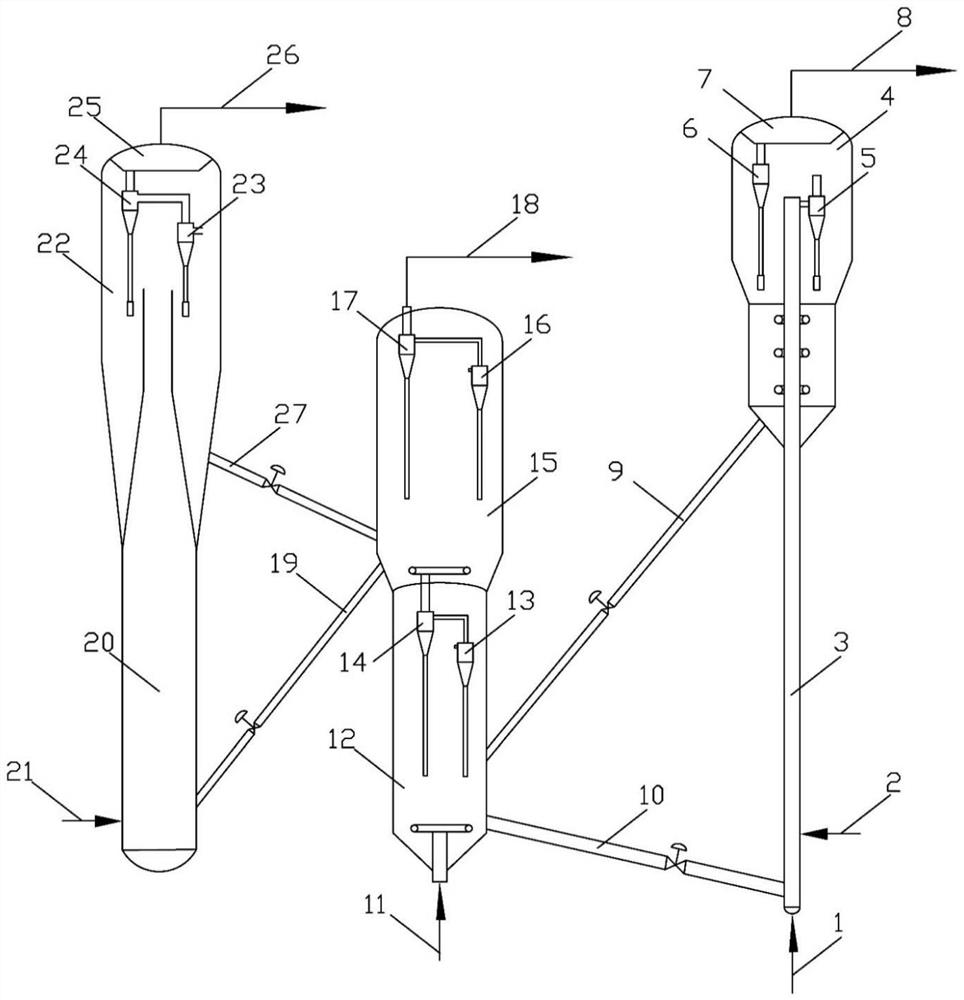

Film For Packaging Of Fresh Or Fermentation Food, Packaging Material and Container

InactiveUS20080299380A1Prolong storage durationHigh-added valueProductsReagentsSolventFood packaging

A fresh or fermentation food packaging film, a packaging material and a packaging container which use the film, are disclosed. The fresh or fermentation food packaging film whose average pore size is 0.01-2 μm and whose porosity is 10-80%, wherein the film is manufactured from pure crystalline polymer without addition of inorganic compounds or organic compounds for pore formation, so as to impart microporousness thereto by a dry stretching method which does not use an organic solvent and solvent. The packaging film which can pack fermentation food, such as Kimchi, etc., and fresh food, such as vegetables, etc., in which the packaging film can allow the food some operations, such as breathing and transpiration, etc., but restrain penetration of liquid, such as, water, etc., and can also effectively prevent leakage of smell, such that the food can be kept fresh, through a simple handling process.

Owner:INTERPORE

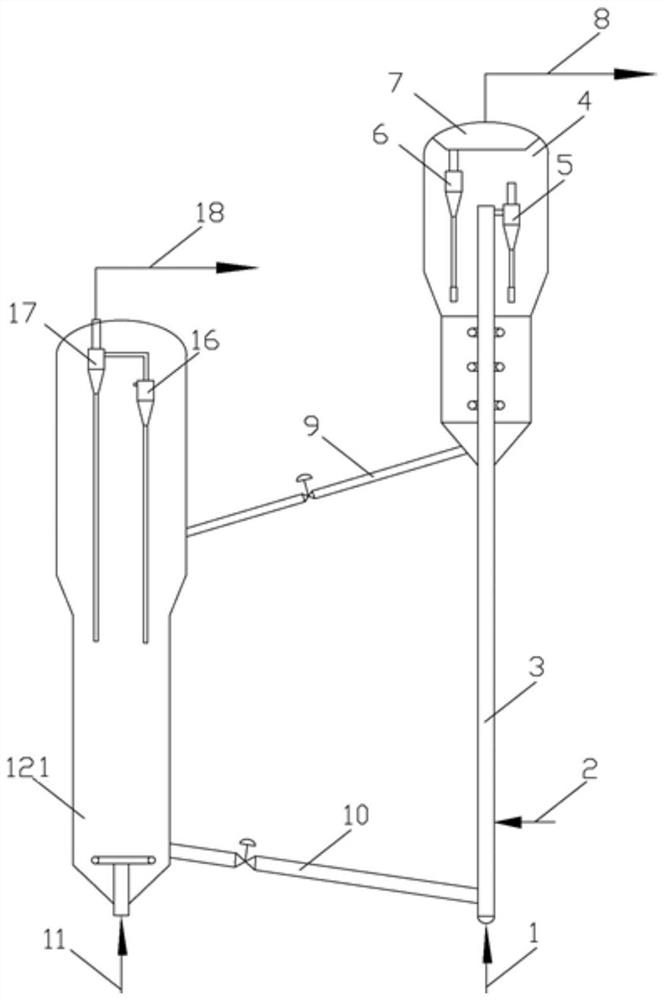

Device and method for increasing yield of low-carbon olefins

InactiveCN112939719AImprove reaction efficiencyHigh yieldHydrocarbonsBulk chemical productionAlkanePtru catalyst

The invention discloses a device and method for increasing the yield of low-carbon olefins, and belongs to the technical field of petroleum refining. According to the equipment, a first regenerator and a second regenerator which are connected in series are arranged, the first regenerator is connected with a catalytic cracking device, and the second regenerator is connected with an alkane dehydrogenation device, so that alkane dehydrogenation and catalytic cracking reaction are coupled, and the equipment is used for carrying out high-yield low-carbon olefin operation; the heat transfer problem of a fixed bed and a moving bed can be solved, continuous reaction regeneration is realized, the overall activity and the reaction efficiency of the alkane dehydrogenation catalyst are improved, the heat extraction cost and the heat supply cost are saved, and the process heat efficiency is remarkably improved; the alkane dehydrogenation reaction is maintained within the optimal reaction temperature by utilizing redundant heat of the catalytic cracking reaction, the reaction efficiency of alkane dehydrogenation is remarkably improved, in addition, alkane produced by the device can be recycled, the low-carbon olefin yield of the device is remarkably improved, meanwhile, hydrogen with the additional value higher than that of olefin is increased, and remarkable economic benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for recycling and regenerating plastic through homogenization and chain extending

InactiveCN107286697AQuality improvementHigh strengthPlastic recyclingInorganic particleInorganic particles

A method for recycling and regenerating plastic through homogenization and chain extending is provided. Waste plastic is subjected to impurity removing with an alkali solution and impurity removing. Through adding polyoxyethylene and an ethylene-vinylacetate copolymer, and by utilizing the hydrophilic and hydrophilic properties of the added compounds, the waste plastic is homogenized. Furthermore, through a tackifying chain extender, continuous tackifying and chain extending under high pressure are performed to achieve further homogenization and chain extending of the waste plastic to obtain high-quality recycled regenerated plastic. During chain extending, nanometer layered inorganic particles are used so that strength of the regenerated plastic is improved from a nanometer level and the nanometer layered structure allows chain extending of the regenerated plastic to occur in a same microcosmic plane, thus guiding the generation direction of a chain extending direction. A product can obtain good chain extending effects. Through the method, quality of the waste plastic is improved. The method can be further popularized and applied in actual industrial production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Air conditioning humidifying method

InactiveCN101581482AHumidification does not consume energyNon stick spaceSpace heating and ventilation safety systemsLighting and heating apparatusCold airEngineering

The invention provides an air conditioning humidifying method, and aims at realizing that the air conditioning brings comfortable indoor temperature, also brings comfortable humidity, and respectively leads the humidity of indoor air to be suitable no matter refrigeration or heating. By additionally arranging simple humidifying accessories at an air outlet and the end side of an indoor machine of the air conditioning, the method utilizes the airflow of the air outlet of the indoor machine to lead the humid gas to be dispersed with hot air or cold air exhausted by the air conditioning simultaneously and synchronously. The invention is a set of technology and configuration which does not increase equipment, save space, also save energy and protect environment.

Owner:黄艳芳

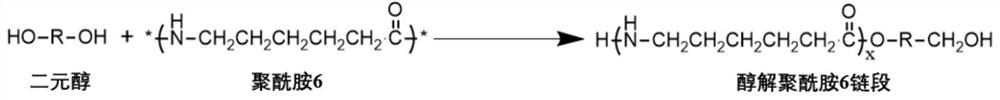

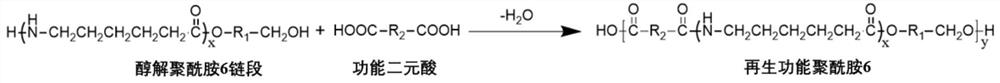

Preparation method of micro-alcoholysis functional regenerated polyamide 6

The invention relates to a preparation method of micro-alcoholysis functional regenerated polyamide 6. The preparation method comprises the following steps: adding a dihydric alcohol monomer into waste polyamide 6, and carrying out micro-alcoholysis reaction to generate an alcoholysis polyamide 6 chain segment; adding a functional binary acid monomer, and sequentially carrying out esterification, amidation and ester-amide exchange reaction to prepare functional regenerated polyamide 6, wherein the micro-alcoholysis reaction refers to generation of an alcoholysis polyamide 6 chain segment of which the number-average molecular weight is 7000-9000 g / mol and two ends are respectively a dihydric alcohol ester structure and an amino group; the relative viscosity of the prepared functional regenerated polyamide 6 is 2.4-3.6, the melting point is 190-250 DEG C, the number-average molecular weight is 18000-30000 g / mol, the molecular weight distribution is 2-4, the initial thermal decomposition temperature is 430-490 DEG C, the breaking strength is 40-60 MPa, and the elongation at break is 30-90%. According to the method, waste polyamide 6 plastic products and fiber products can be recycled and regenerated through a simple process, functional products with higher commodity additional values are polymerized, the price burden of regenerated products is made up, and the regenerated products have better popularization space.

Owner:DONGHUA UNIV

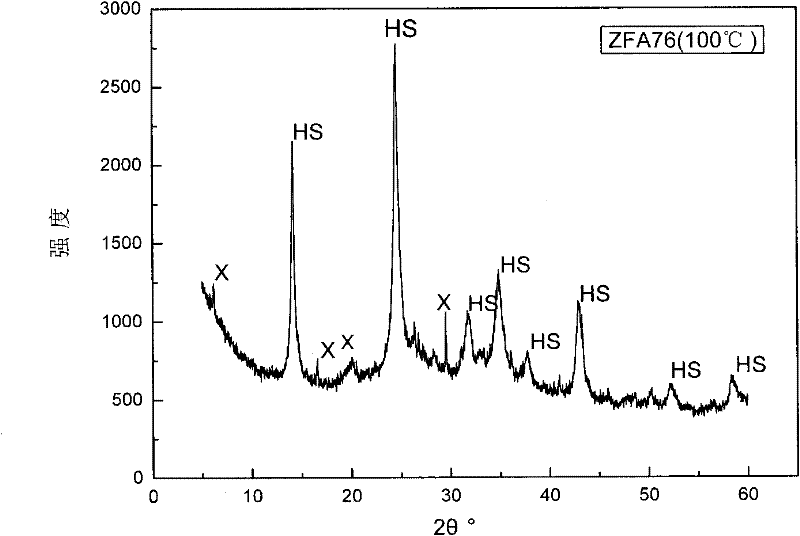

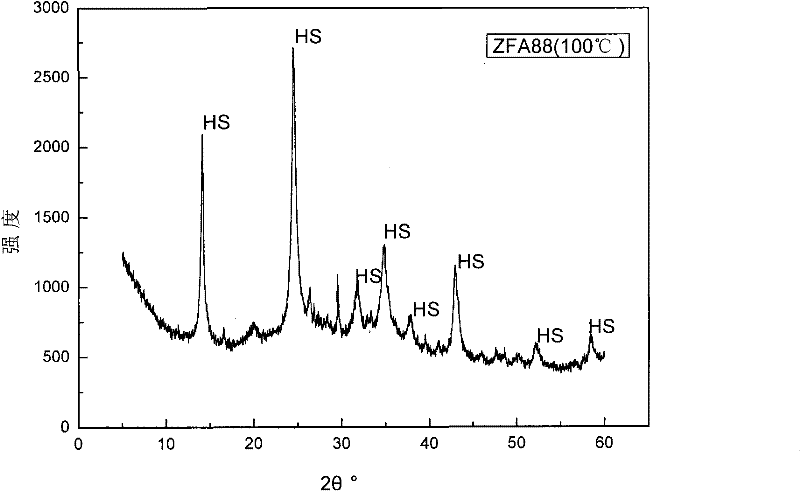

Method for preparing zeolite by using sintered bed mud as material

InactiveCN1958449ARealize resourcesHigh added valueSludge treatmentSolid waste disposalAlkalinitySludge

This invention relates to a method for preparing zeolite by using sintered bottom sludge as the raw material. The method comprises: adding Al, Si, Cl or F-containing additives that can be solved in alkaline solution to sintered bottom sludge, and performing traditional hydrothermal method or two-step method to prepare zeolite. The traditional hydrothermal method comprises: adding NaOH or KOH solution into the raw material and the additive, heating in a reaction kettle, and reacting to prepare zeolite. The two-step method comprises: mixing the raw material and the additive with solid NaOH or KOH, melting in a furnace, transferring into a reaction kettle, adding water and heating to prepare zeolite. After adjusted with alkalinity and Si / Al ratio, the waste alkaline solution can be recycled as the alkali source in the traditional method to prepare zeolite. Sintering technique is an effective means to realize harmless treatment of bottom sludge that is pollutive to water bodies. This invention can realize efficient utilization of sintered bottom sludge, and can obtain zeolite with high added value.

Owner:SHANGHAI JIAO TONG UNIV

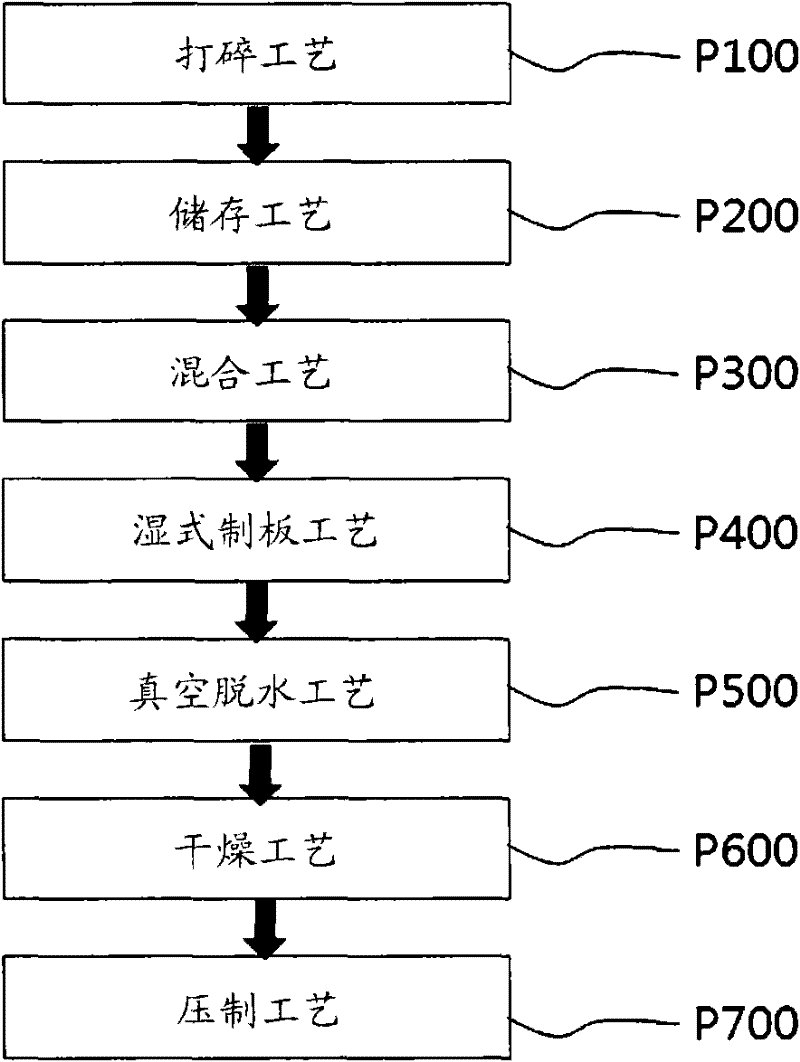

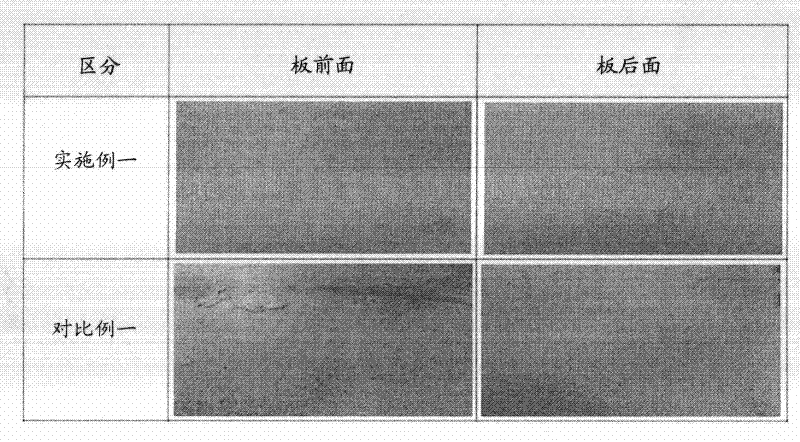

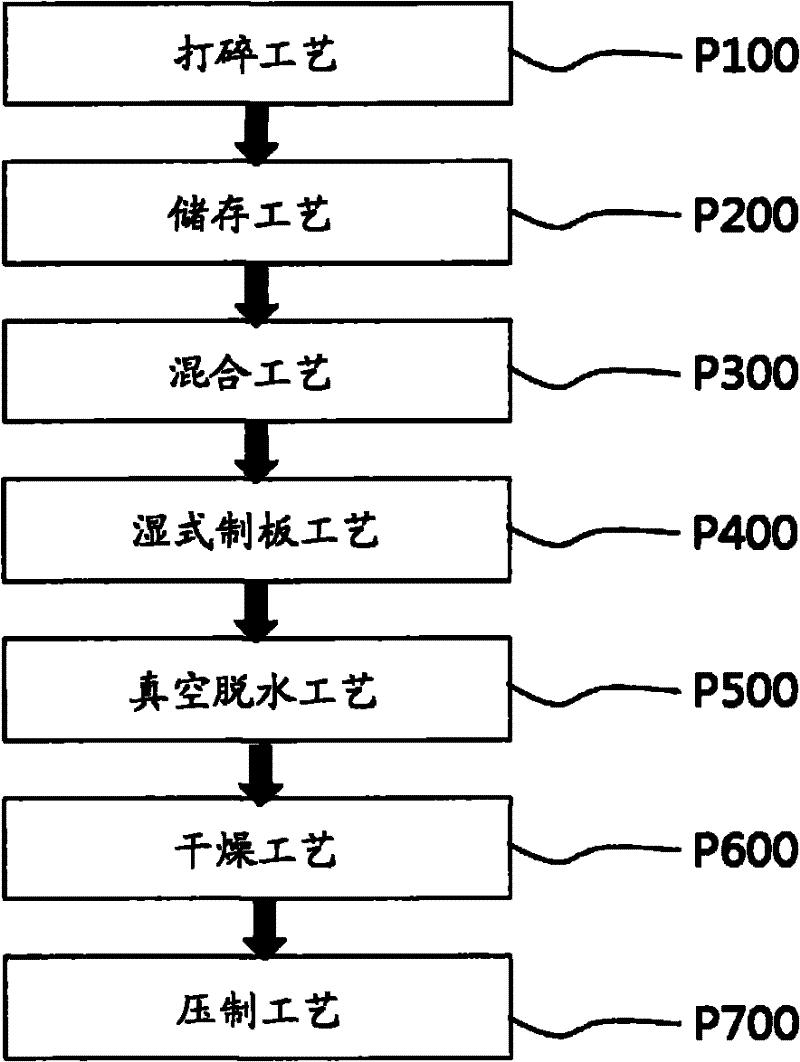

Method of manufacturing board with leather by-products and board manufactured by adopting the method

InactiveCN102345250AOvercome limitationsEasy to recycleFibreboardDomestic articlesFiberJoint compound

The invention relates to a method of manufacturing boards with leather by-products and a board manufactured by adopting the method, especially a gypsum board and a texture board suitable for being used as building interior materials manufactured with natural leather by-products and boards manufactured by adopting the method. According to the method, the shaving scraps of natural leather by-products are beating through physical means and then are bonded by binding materials through chemical means. Therefore, the adhesion, forming performance, shape stability, strength, moisture content, flexural load and the like of fiber materials are improved. Then the material is dried and pressed to be molded into boards.

Owner:郑镇度 +1

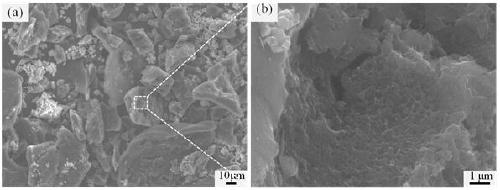

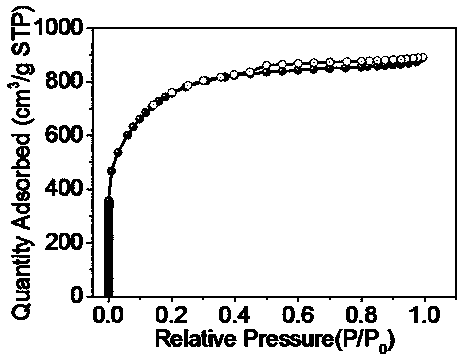

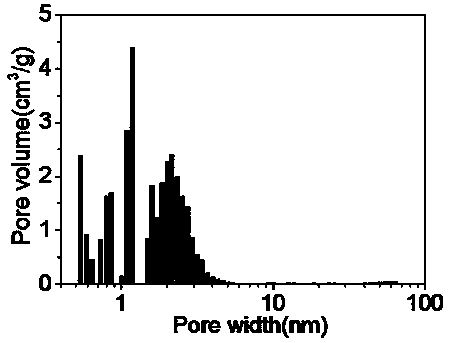

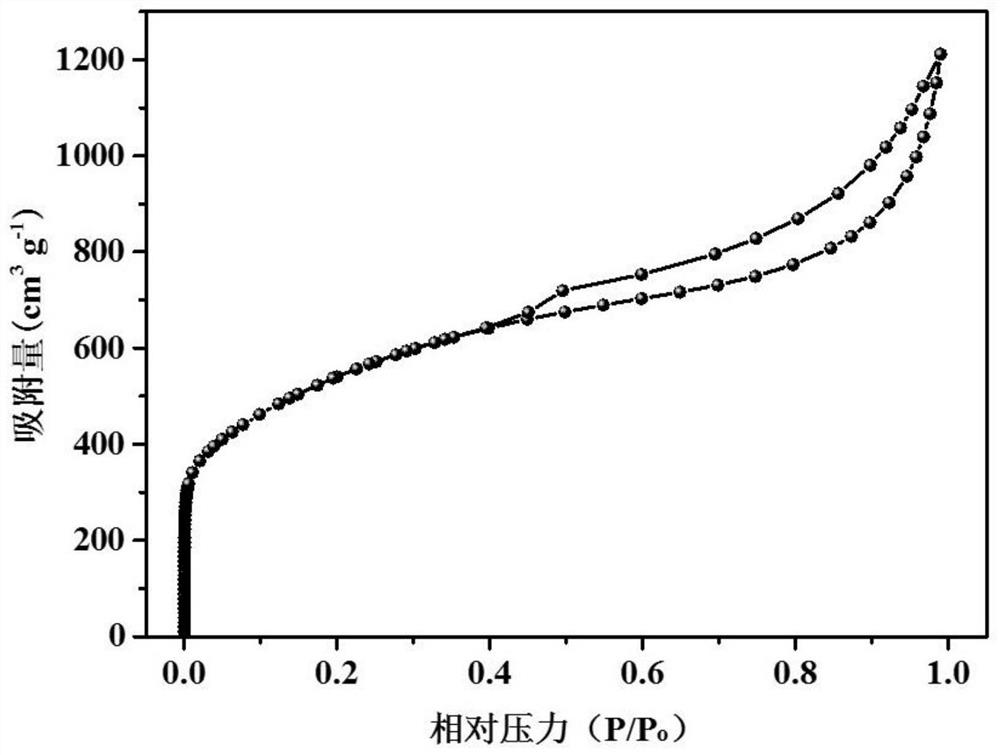

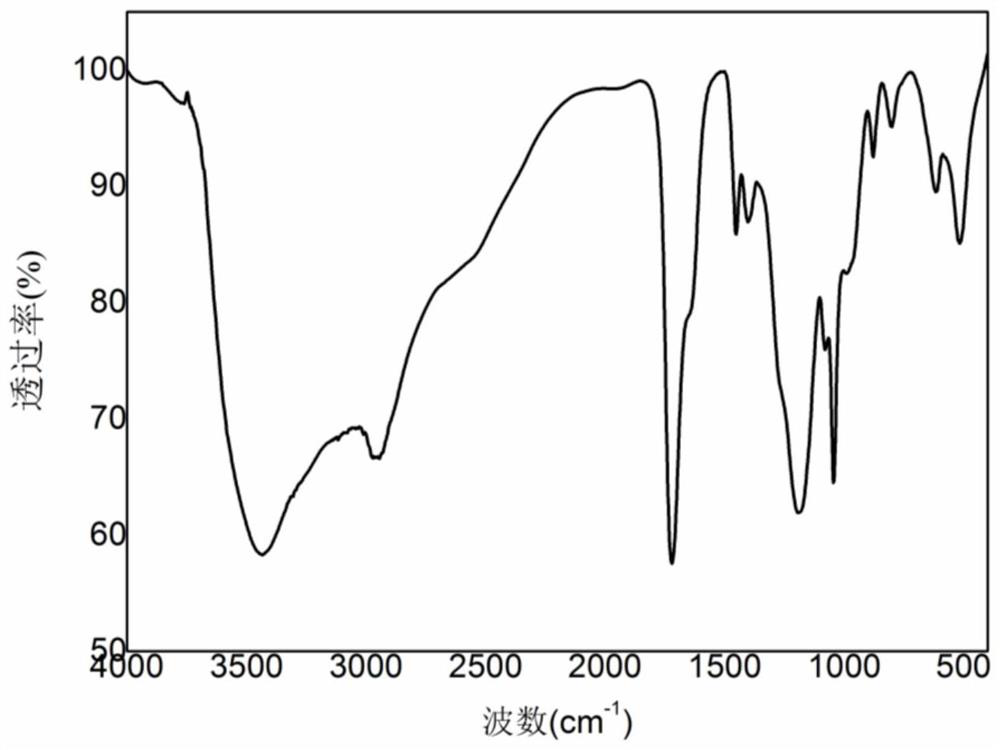

Preparation method and application of high-purity medium-temperature coal pitch based super active carbon

The invention discloses a preparation method and application of high-purity medium-temperature coal pitch based super active carbon. Medium-temperature coal pitch is used as a raw material, medium-temperature coal pitch grains are obtained through crushing / screening and are mixed with a hydrochloric acid solution, and heating stirring, filtration and drying are performed to obtain a pretreatment sample; then, the sample is mixed with a hydrofluoric acid solution, and heating stirring, filtration and drying are performed to obtain a low-ash-content medium-temperature coal pitch raw material; then, the medium-temperature coal pitch raw material is mixed with KOH grains, the two materials are fully mixed evenly by using deionized water, drying is performed, then the obtained mixture is put ina tubular carbonization furnace for high-temperature thermal treatment, natural cooling is performed to room temperature, and washing, acid pickling, filtration and drying are performed to obtain thesuper active carbon. The product has very high price advantages on the aspect of application of supercapacitor electrode materials and shows excellent electrochemical property. Efficient and high-added-value utilization of the medium-temperature coal pitch is achieved, and the adverse influence of impurities in supercapacitors on the specific capacity and cycling stability of electrodes is avoided.

Owner:山西煤炭进出口集团科学技术研究院有限公司

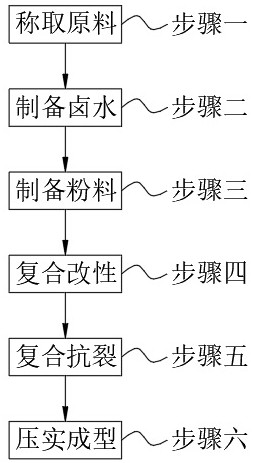

High-strength concrete taking carbon chromium slag as main aggregate, processing device and preparation process of high-strength concrete

The invention discloses high-strength concrete with carbon chromium slag as main aggregate, a processing device and a preparation process of the high-strength concrete. The high-strength concrete is prepared from high-strength aggregate, a magnesium chloride solution, a defoaming agent, light calcined magnesia, fly ash, deionized water, a composite modifier, polypropylene fiber powder, zinc maleate, acrylamide and dibenzoyl peroxide. According to the invention, the composite modified carbon chromium slag is used as a main aggregate, the nickel iron slag is used as an auxiliary aggregate, the solid waste is used for replacing the traditional gravel aggregate, and the magnesium cementing material is used for replacing the cement, so that the strength of the concrete is improved, the surface hardness is high, the wear resistance is strong, the concrete is not easy to crack and wear, and the use requirements of high-strength scenes are met; the carbon chromium slag is subjected to reduction, recycling and high-value comprehensive utilization, the added value is high, the utilization amount is large, the problem of accumulation of the carbon chromium slag is solved while gravel aggregate is replaced, and the carbon chromium slag is high in tensile strength, high in toughness, resistant to cracking and seepage, long in service life and reliable in work.

Owner:中科镁基(北京)科技有限公司

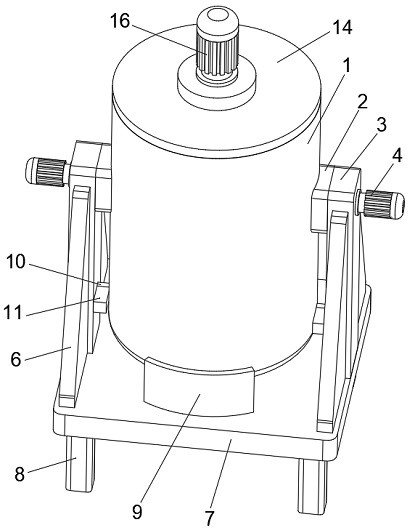

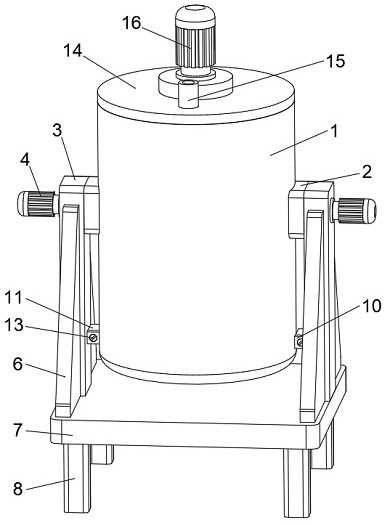

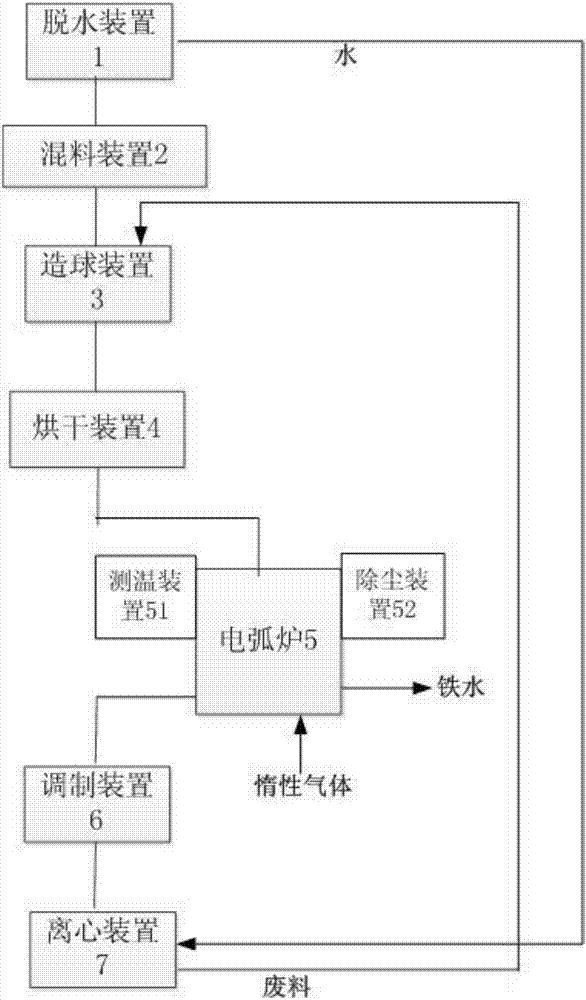

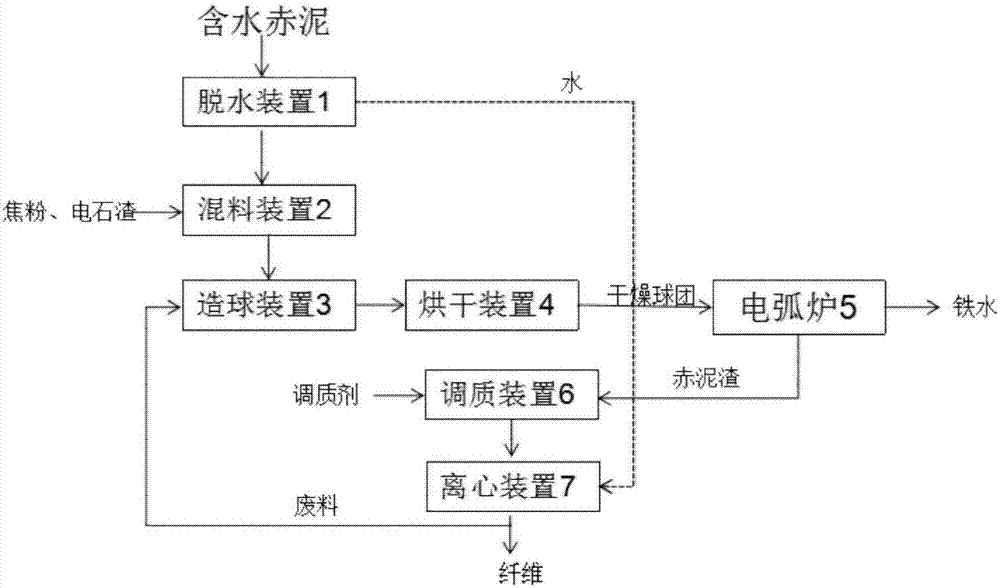

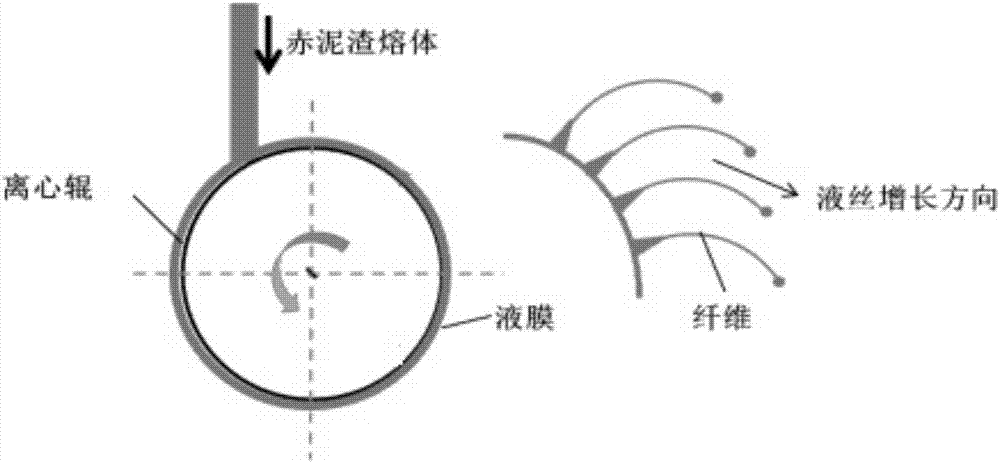

System and method for treating red mud through electric arc furnace

PendingCN107385204AAchieve recyclingHigh added valueElectric furnaceElectric arc furnaceThermal state

The invention relates to a system for treating red mud through an electric arc furnace. The system comprises a dehydrating device, a material mixing device, a pelletizing device, a belt conveyer, a drying device, an automatic feeding device, the electric arc furnace, a temperature measuring device, a hardening and tempering device and a centrifuging device. The invention further relates to a method for treating the red mud through the electric arc furnace. The system and method are free of secondary pollution, sensible heat of thermal state slag is directly utilized, the operating cost is low, the waste heat recovery rate is high, the red mud is converted into cellucotton and metallic iron for sale, industrialized application of the red mud is promoted, and real harmless treatment, reduction and reclamation are achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for microwave high-temperature cracking of circuit board and application of method

ActiveCN112570416ARapid lysisEfficient recyclingTransportation and packagingSolid waste disposalThermodynamicsCombustible gas

The invention discloses a method for microwave high-temperature cracking of a circuit board and application of the method. The method comprises the following steps that the circuit board is in contactwith a porous composite material, a microwave field is applied to the circuit board and the porous composite material in a vacuum or inert atmosphere, an electric arc is generated by the porous composite material under microwaves and a high temperature is rapidly reached, an organic compound of the circuit board is cracked to obtain a combustible gas product mainly composed of carbon monoxide, and a metal and nonmetal mixed solid product, wherein the metal and nonmetal mixed solid product is loose in structure and easy to separate. According to the method, the electric arc generated in the microwaves is used for rapidly triggering high temperature, so that the waste circuit board is rapidly cracked, the process is efficient, gas products are high-added-value combustible gas, the recoveryefficiency of solid metal and nonmetal is high, and all components of the waste circuit board can be recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

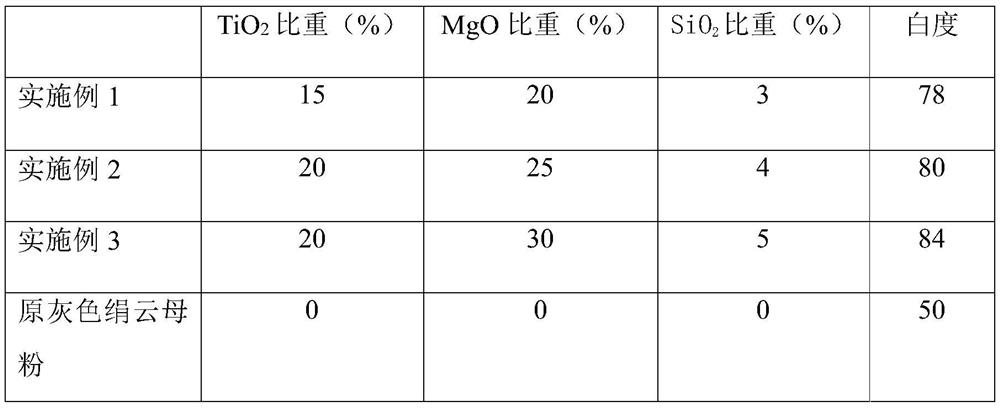

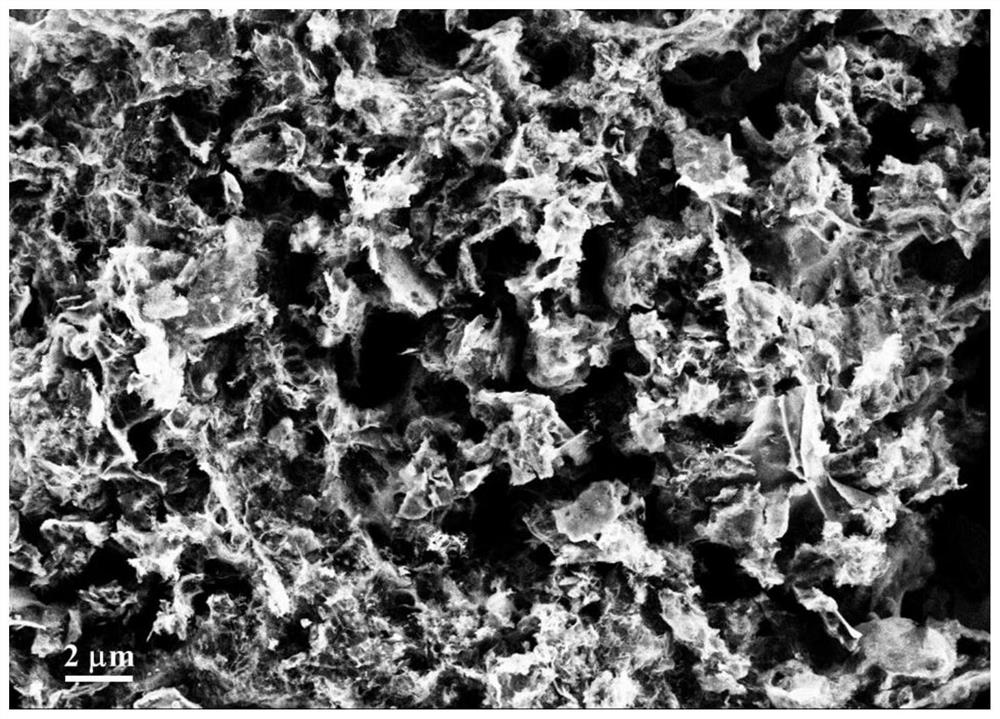

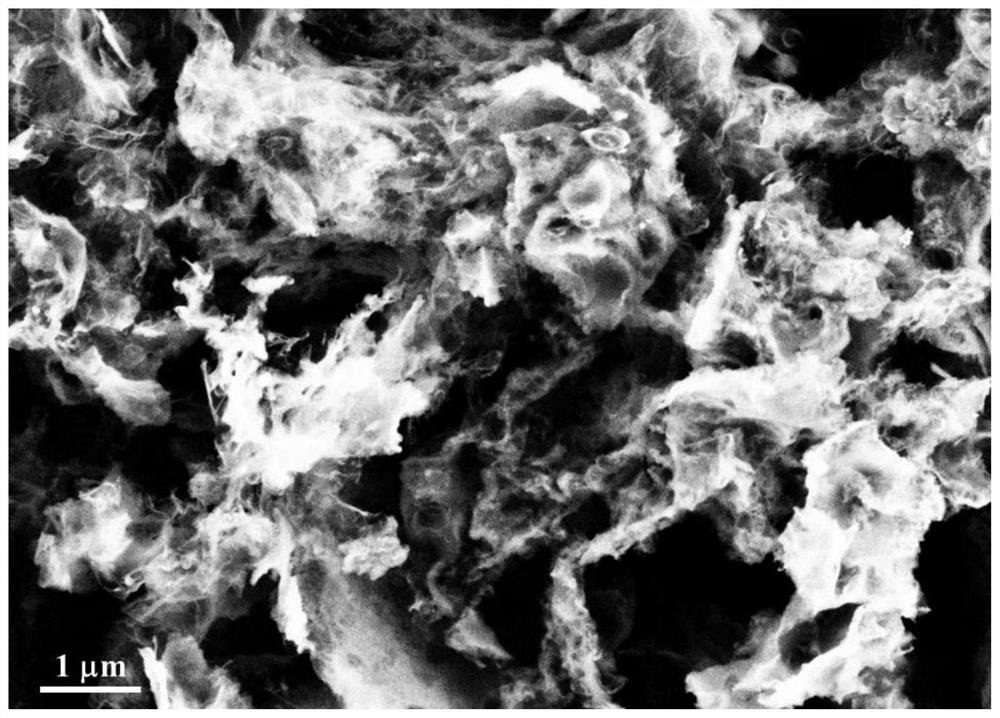

A kind of ultra-white composite sericite and preparation method thereof

ActiveCN110283479BImprove smoothnessGood touchPigment physical treatmentPhysical chemistrySilicon dioxide

Provided is an ultra-white composite sericite product, which includes sericite as a base material or core, and a titanium dioxide layer, a magnesium oxide layer and a silicon dioxide layer coated sequentially on the surface of the sericite. Also provided is a method of preparing the ultra-white composite sericite product from gray sericite with low whiteness.

Owner:四川赛和新材料科技有限责任公司

Preparation method of yellow brown soil derived porous carbon material

ActiveCN112158836AMeet needsImprove the degree of graphitizationCarbon compoundsCarbon layerSoil science

The invention discloses a preparation method of a yellow brown soil derived porous carbon material. The preparation method comprises the following steps: by using yellow brown soil in Yangtze River Delta as the main component of a hard template, synthesizing yellow brown soil derived porous carbon by means of a mechanical ball milling path and a heat treatment technique under the assistance of carbonate, thereby showing a high-graphitization-degree graded porous structure; and rich specific surface area. The selected yellow brown soil not only has the characteristics of rich source, convenience in collection, environmental friendliness and the like, but also can improve the graphitization degree of the porous carbon, and embodies the advantages of recycling, high added value and industrialization; a mixed hard template obtained by the mechanical ball milling path can provide an effective place for constructing the hierarchical porous structure; the microstructure compounded by the two-dimensional carbon layer and the three-dimensional porous carbon skeleton can be adjusted by controlling the mass ratio of the yellow brown soil to the carbonate; and the low-cost carbonate is mainlyused as an activating agent and plays a positive role in the aspect of enhancing the carbon porosity.

Owner:YANGZHOU POLYTECHNIC INST

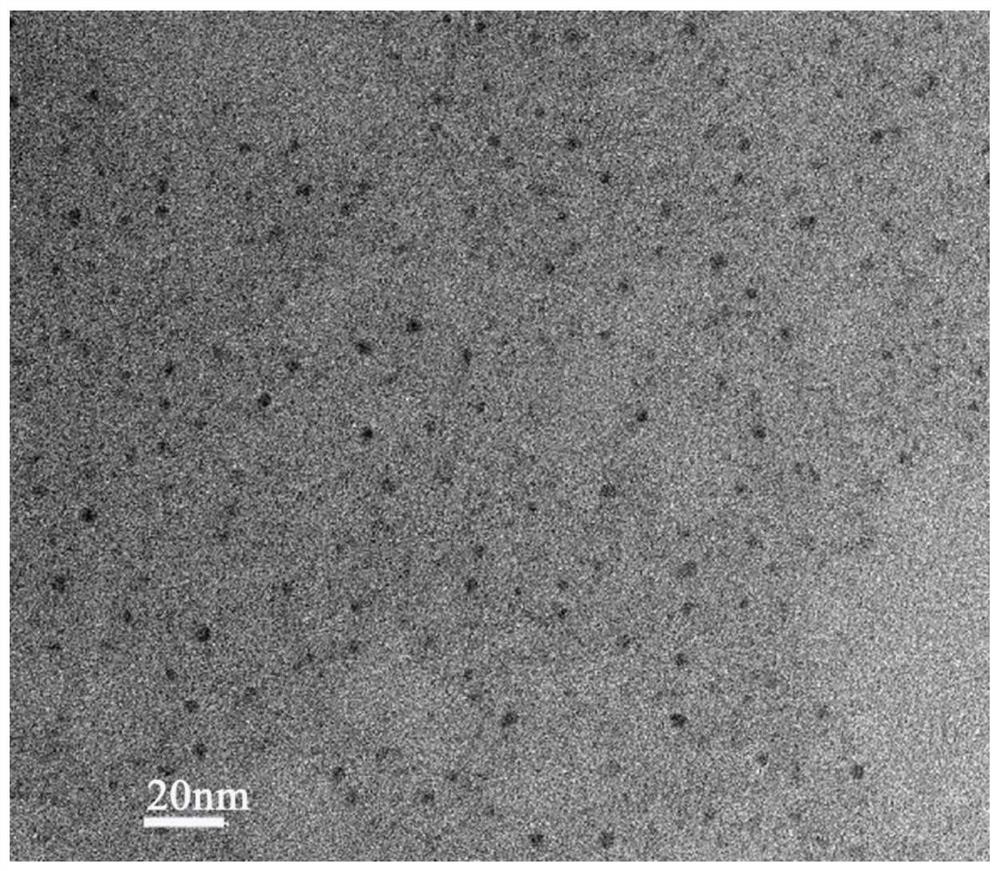

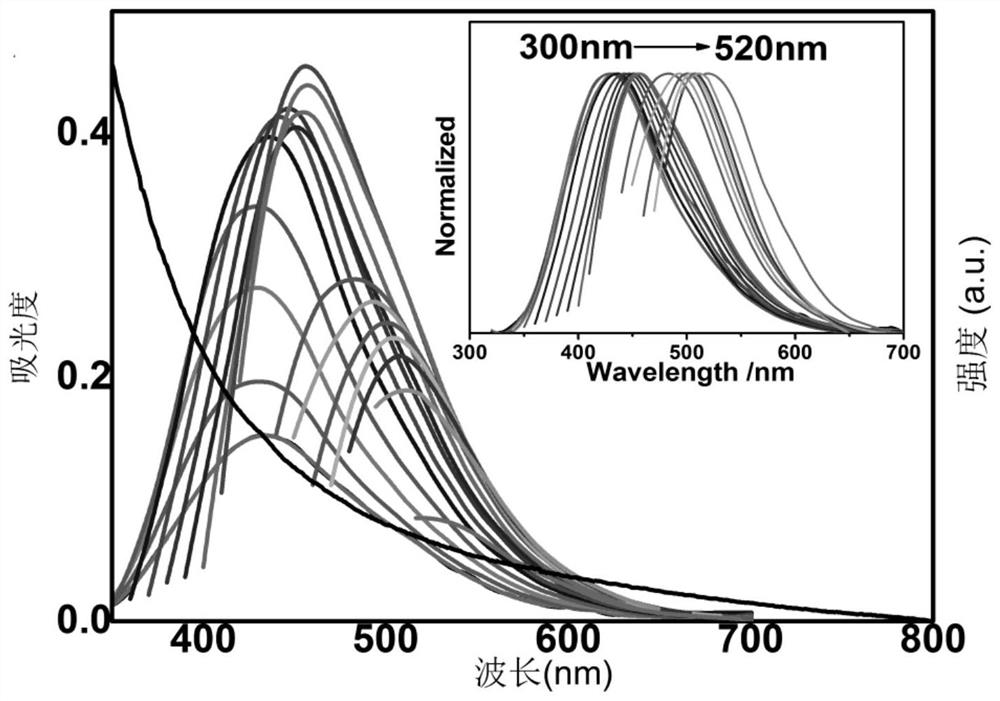

Preparation method of carbon nanoparticles and carbon dots using activated carbon as precursor

InactiveCN108910862BGuaranteed reuseReduce adsorption efficiencyOther chemical processesNano-carbonDialysis membranesNanocarriers

The invention discloses a method for preparing carbon nano particles and carbon dots by using activated carbon as a precursor. The method is characterized by comprising the following steps: taking theactivated carbon, performing drying, and performing grinding to obtain powder; adding the powdery activated carbon into an oxide aqueous solution, performing stirring at room temperature, performingheating to temperature of 30-130 DEG C, and performing a reaction for 12-48 h; allowing the obtained material to stand, extracting the supernatant part, adding deionized water, performing concentration for 5-10 times, and performing dialysis by using a dialysis membrane with 100-500 D; mixing an aqueous solution containing the carbon nano particles and a compound containing amino or other functional groups by using deionized water as a medium, performing heating, and performing a heat induction reaction to obtain a crude product of carbon nano particles with a modified surface containing an organic passivation layer; and performing post-treatment to obtain the carbon dots. According to the method disclosed by the invention, the prepared carbon nano particles can be used for functional fillers such as conductive materials, nucleating agents, nano carriers and the like, and the prepared carbon dots can be used as a fluorescent marker, a sensing or detecting probe, and a photocatalyst andused in photoelectric conversion devices such as LEDs.

Owner:MIANYANG HONGQI NEW MATERIAL SCI & TECH

Air conditioning humidifying method

InactiveCN101581482BHumidification does not consume energyNon stick spaceSpace heating and ventilation safety systemsLighting and heating apparatusCold airEngineering

The invention provides an air conditioning humidifying method, and aims at realizing that the air conditioning brings comfortable indoor temperature, also brings comfortable humidity, and respectivelyleads the humidity of indoor air to be suitable no matter refrigeration or heating. By additionally arranging simple humidifying accessories at an air outlet and the end side of an indoor machine ofthe air conditioning, the method utilizes the airflow of the air outlet of the indoor machine to lead the humid gas to be dispersed with hot air or cold air exhausted by the air conditioning simultaneously and synchronously. The invention is a set of technology and configuration which does not increase equipment, save space, also save energy and protect environment.

Owner:黄艳芳

Method for preparing nano flyash zeolite

InactiveCN101993089BIncrease profitHigh yieldSolid waste disposalCrystalline aluminosilicate zeolitesIon exchangeSolvent

The invention relates to a method for preparing nano flyash zeolite. Flyash is used as a raw material in the method, and the method comprises the following steps of: firstly melting the flyash and sodium hydroxide at high temperature; mixing the molten flyash with concentrated seawater used as a solvent, stirring and aging to obtain silica-alumina gel; crystallizing the silica-alumina gel hydrothermally, and then washing with water to be neutral; and finally drying to obtain a powdery product. Based on the special aperture structure of zeolite, the synthesized zeolite can be applied to catalysis, adsorption, ion exchange and soil improvement. By using the flyash and the concentrated seawater which are both wastes, the method realizes the recycling of the flyash and the concentrated seawater and is a new environment-friendly production method which meets the requirement of sustainable development.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Method for preparing zeolite by using sintered bed mud as material

InactiveCN100424013CRealize resourcesHigh added valueSludge treatmentSolid waste disposalAlkalinitySludge

This invention relates to a method for preparing zeolite by using sintered bottom sludge as the raw material. The method comprises: adding Al, Si, Cl or F-containing additives that can be solved in alkaline solution to sintered bottom sludge, and performing traditional hydrothermal method or two-step method to prepare zeolite. The traditional hydrothermal method comprises: adding NaOH or KOH solution into the raw material and the additive, heating in a reaction kettle, and reacting to prepare zeolite. The two-step method comprises: mixing the raw material and the additive with solid NaOH or KOH, melting in a furnace, transferring into a reaction kettle, adding water and heating to prepare zeolite. After adjusted with alkalinity and Si / Al ratio, the waste alkaline solution can be recycled as the alkali source in the traditional method to prepare zeolite. Sintering technique is an effective means to realize harmless treatment of bottom sludge that is pollutive to water bodies. This invention can realize efficient utilization of sintered bottom sludge, and can obtain zeolite with high added value.

Owner:SHANGHAI JIAOTONG UNIV

Light-emitting device and electronic device

ActiveCN100479224CAchieve modularityReduce volumeStatic indicating devicesElectroluminescent light sourcesDisplay deviceEngineering

The present invention provides a light-emitting device whose volume is small and that has plural display screens, and a personal digital assistant that realizes higher added value by using the same. A light-emitting device of the present invention has a plurality of light-emitting elements in a pixel, and these light-emitting elements emit light in a different direction from each other and a pixel driving element is provided in one of the light-emitting elements. The light-emitting device can display in both front and back sides and independently display images on the both sides. Further, it can provide a higher aperture ratio, which is obtained by adding the aperture ratios of the both sides. Furthermore, it is also possible to see different images on the both sides of an electronic device using a display device of the present invention. Moreover, weight saving and thinning of electronic devices can be realized.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com