A kind of ultra-white composite sericite and preparation method thereof

A technology of sericite and sericite powder, applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., to achieve bright and soft luster, good touch, and stable chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

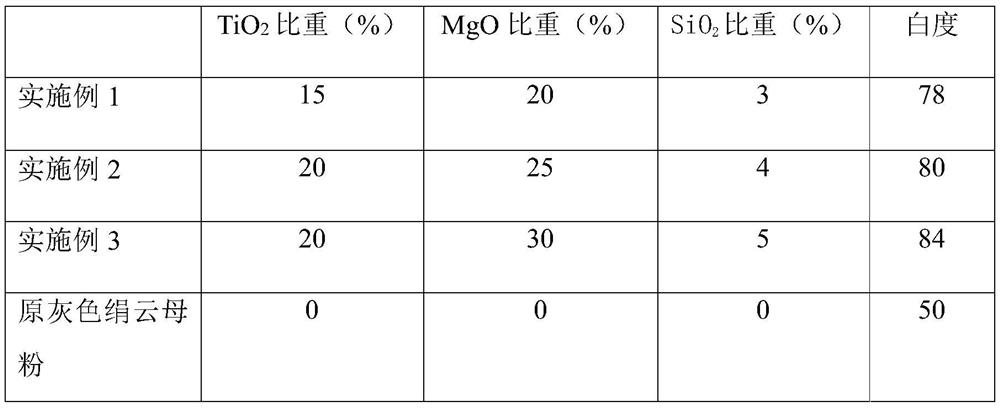

Embodiment 1

[0056] (1) Take 100g of gray sericite powder with a dry weight of 1-15 μm in particle size, put it into a 2L reaction kettle, add 1200 milliliters of deionized water, and stir to make it uniformly dispersed into a suspension;

[0057] (2) Heat the suspension in a constant temperature water bath and raise the temperature to 70°C. Adjust the pH of the suspension to 2.0 with hydrochloric acid solution, and add TiCl with a concentration of 2 mol / L 4 Solution 110ml (corresponding to TiO 2 With respect to the specific gravity of base material gray sericite powder (15%), the feeding can be stopped, and the pH value can be kept constant with liquid caustic soda solution. Stir at constant temperature for 30 minutes after stopping feeding;

[0058] (3) Keep the above temperature constant, adjust the pH of the suspension to 11 with liquid caustic soda solution, and add dropwise MgCl with a mass fraction of 15% in the solution 2 ·6H 2 O solution 840.8ml (corresponding MgO is 20% with ...

Embodiment 2

[0065] (1) Take 100g of gray sericite powder with a dry weight of 1-15 μm in particle size, put it into a 2L reaction kettle, add 1200 milliliters of deionized water, and stir to make it uniformly dispersed into a suspension;

[0066] (2) Heat the suspension in a constant temperature water bath and raise the temperature to 70°C. Adjust the pH of the suspension to 2.0 with hydrochloric acid solution, and add TiCl with a concentration of 2 mol / L 4 Solution 156.3ml (corresponding TiO 2 With respect to the proportion of base material gray sericite powder (20%), the feeding can be stopped, and the pH value can be kept constant with liquid caustic soda solution. Stir at constant temperature for 30 minutes after stopping feeding;

[0067] (3) Keep the above temperature constant, adjust the pH of the suspension to 11 with liquid caustic soda solution, and add dropwise MgCl with a mass fraction of 15% in the solution 2 ·6H 2 O solution 1120.9ml (corresponding MgO is 25% with respec...

Embodiment 3

[0074] (1) Take by weighing 100 g of gram dry weight particle diameter and be 1-15 μ m gray sericite powder, drop into a volume and be in the reactor of 2 L, add 1200 milliliters of deionized water, stir to make it evenly disperse into suspension;

[0075] (2) Heat the suspension in a constant temperature water bath and raise the temperature to 70°C. Adjust the pH of the suspension to 2.0 with hydrochloric acid solution, and add TiCl with a concentration of 2 mol / L 4 Solution 156.3ml (corresponding TiO 2 With respect to the proportion of base material gray sericite powder (20%), the feeding can be stopped, and the pH value can be kept constant with liquid caustic soda solution. Stir at constant temperature for 30 minutes after stopping feeding;

[0076] (3) Keep the above temperature constant, adjust the pH of the suspension to 11 with liquid caustic soda solution, and add dropwise MgSO with a mass fraction of 15% in the solution 4 ·7H 2 O solution 1747.5ml (corresponding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com