Kudzu root nanocellulose fiber-polylactic acid plastic film and preparation method thereof

A nanocellulose and plastic film technology, applied in the field of plastic product preparation, can solve the problems of little significance and low utilization rate, and achieve the effects of improving wettability, low equipment requirements, and easy realization.

- Summary

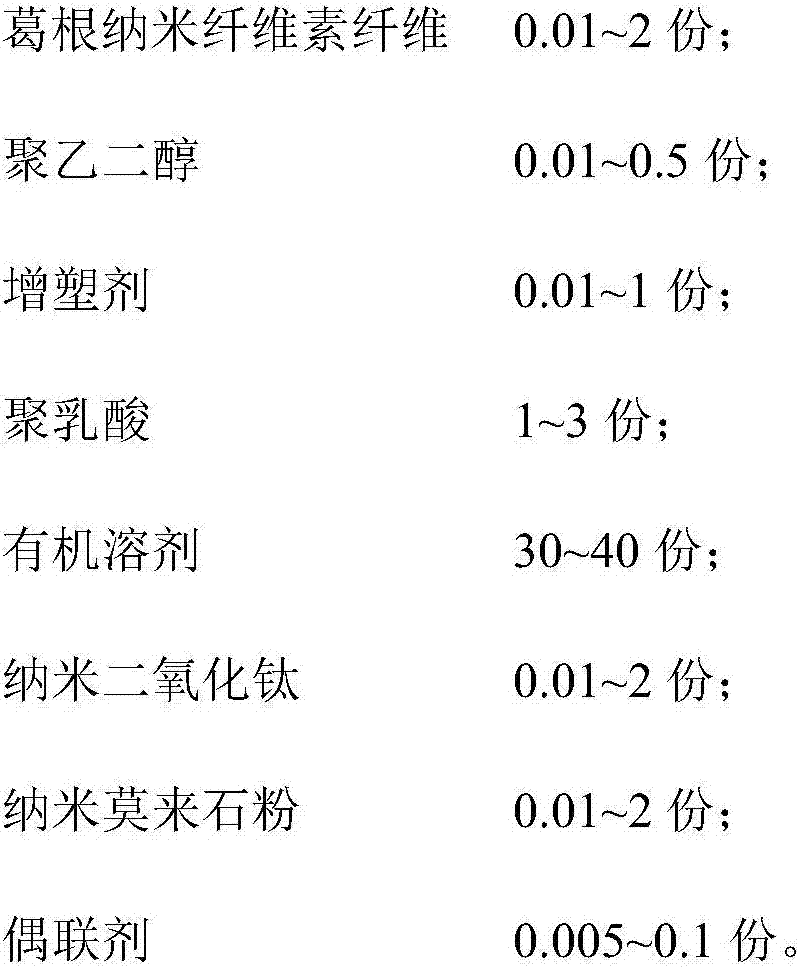

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

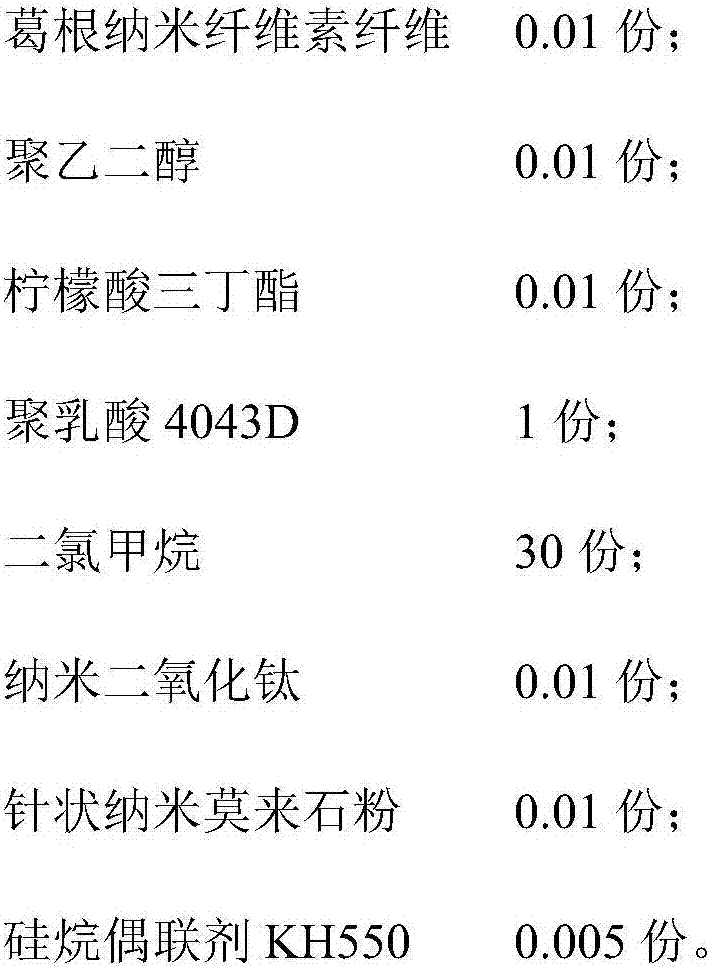

[0036] Embodiment 1: a kind of kudzu root nanocellulose fiber-polylactic acid fully degradable plastic film, comprises the raw material of following parts by weight to make:

[0037]

[0038] The acicular nano mullite powder has a diameter of 3nm and a length of 40nm.

Embodiment 2

[0039] Embodiment 2: A kind of kudzu root nanocellulose fiber-polylactic acid fully degradable plastic film, including the following raw materials by weight:

[0040]

[0041] The acicular nano mullite powder has a diameter of 5nm and a length of 150nm.

Embodiment 3

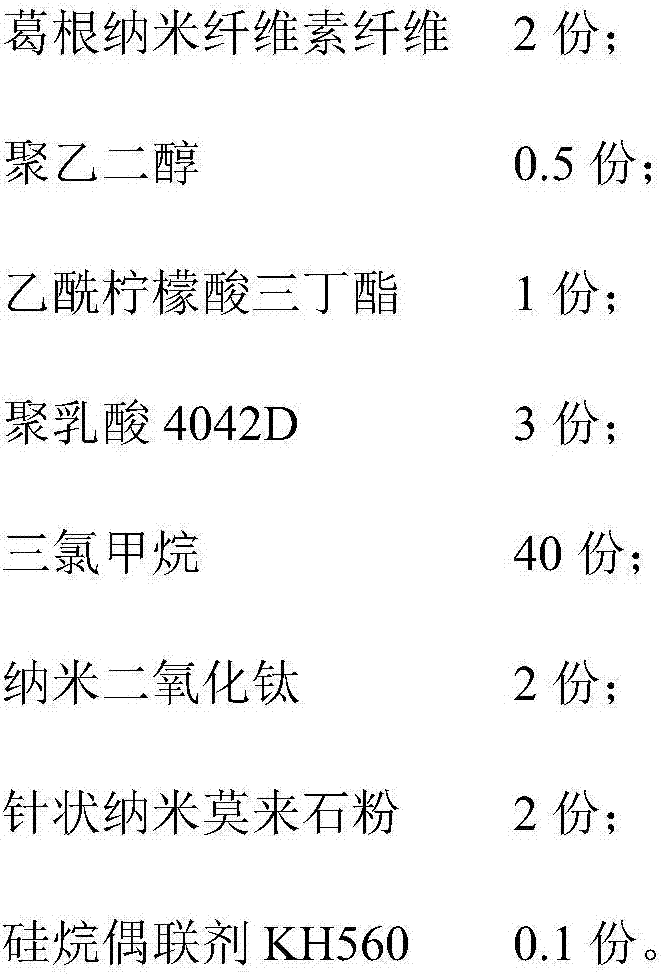

[0042] Embodiment 3: A kind of kudzu root nanocellulose fiber-polylactic acid fully degradable plastic film, including the following raw materials by weight:

[0043]

[0044]

[0045] The acicular nano mullite powder has a diameter of 4nm and a length of 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com