Patents

Literature

56results about How to "The ratio of ingredients is scientific and reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-toughness high-nitrogen austenitic stainless steel welding wire and preparation method thereof

ActiveCN108526750AIncrease contentImprove solid solubilityArc welding apparatusWelding/cutting media/materialsManganeseAustenite

The invention relates to a high-strength high-toughness high-nitrogen austenitic stainless steel welding wire and a preparation method thereof. The welding wire is prepared from the alloy components in percentage by weight: less than 0.1 percent of C, less than 0.02 percent of S, less than 0.03 percent of P, 0.1 to 0.9 percent of Si, 5 to 21 percent of Mn, 15 to 23 percent of Cr, 0 to 8 percent ofNi, 0 to 5 percent of Mo, 0.2 to 0.95 percent of N, the balance Fe, and less than 0.1 percent of other impurities. The preparation process comprises the steps of smelting through an induction furnace, electro slags remelting, hot forging, hot rolling, heat treating, and drawing of the welding wire. According to the welding wire provided by the invention, the component proportion is scientific andreasonable, the content of nitrogen elements is increased, the content of manganese elements is adjusted, and the solid solubility of the nitrogen is increased, so that the prepared welding wire is stable in welding process, less in escape amount of hydrogen elements, less in blowhole defects, good in welding processability, high in deposited metal strength, excellent in impact toughness at the temperature of minus 40 DEG C, suitable for welding high-nitrogen austenitic stainless steel, particularly suitable for welding the austenitic stainless steel with the requirement on low-temperature impact toughness, and capable of being surfacing-welded so as to be used as anti-corrosion layers for other steel and iron materials.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Full-degradable plastic film used for far-infrared food fresh-keeping and preparation method thereof

InactiveCN104910430AHigh strengthSmall particle sizeFlat articlesPolyvinyl alcoholPolyethylene glycol

The invention discloses a full-degradable plastic film used for far-infrared food fresh-keeping. The full-degradable plastic film is prepared from, by weight, 60 to 65 parts of corn starch, 7 to 9 parts of nano montmorillonite, 0.6 to 0.7 part of peanut oil, 1.2 to 1.4 parts of tetrabutyl titanate, 12 to 14 parts of ramie straw, 30 to 35 parts of polyvinyl alcohol, 13 to 15 parts of tributyl citrate, 5 to 7 parts of tourmaline, 2 to 3 parts of chitosan, 1.5 to 2 parts of magnesium stearate, 3 to 5 parts of polyethylene glycol, and 1 to 2 parts of talcum powder. The combination of the full-degradable plastic film is reasonable; the full-degradable plastic film can be made into food preservative film or fruit packaging bags, contains tourmaline powder, is capable of emitting far infrared ray and negative ions, and can be used for food fresh-keeping; a preparation method is convenient for industrialized control; obtained products are safe and nontoxic; complete biodegradation after discarding can be realized; and no harm is caused on the environment.

Owner:TONGLING FOUNDER PLASTICS TECH

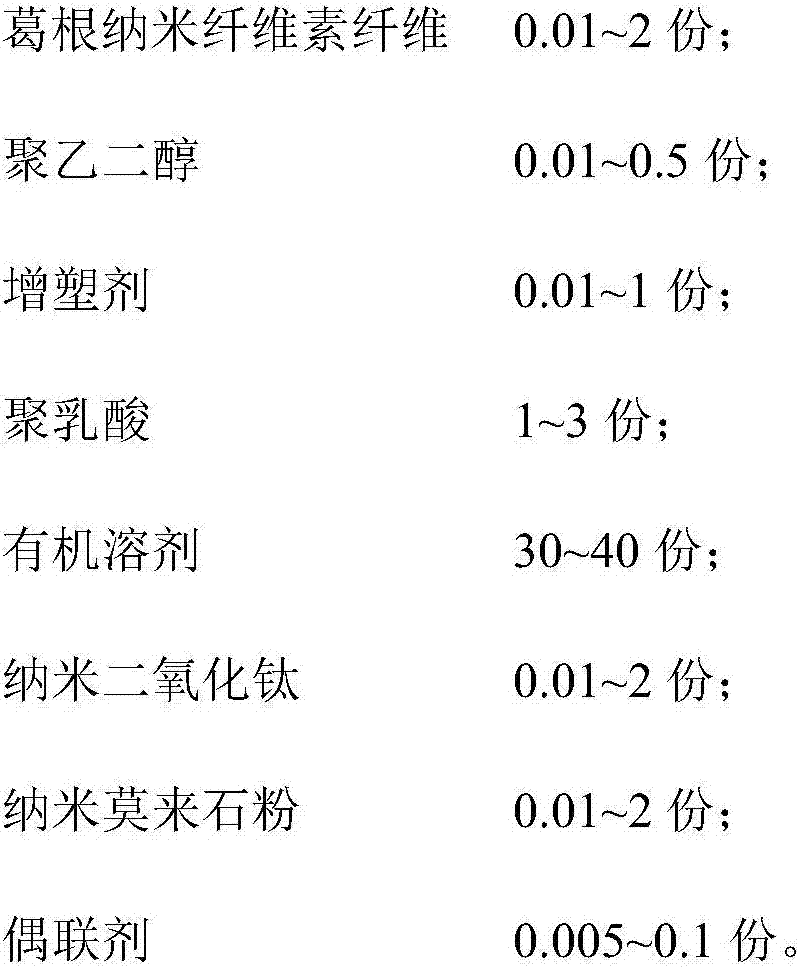

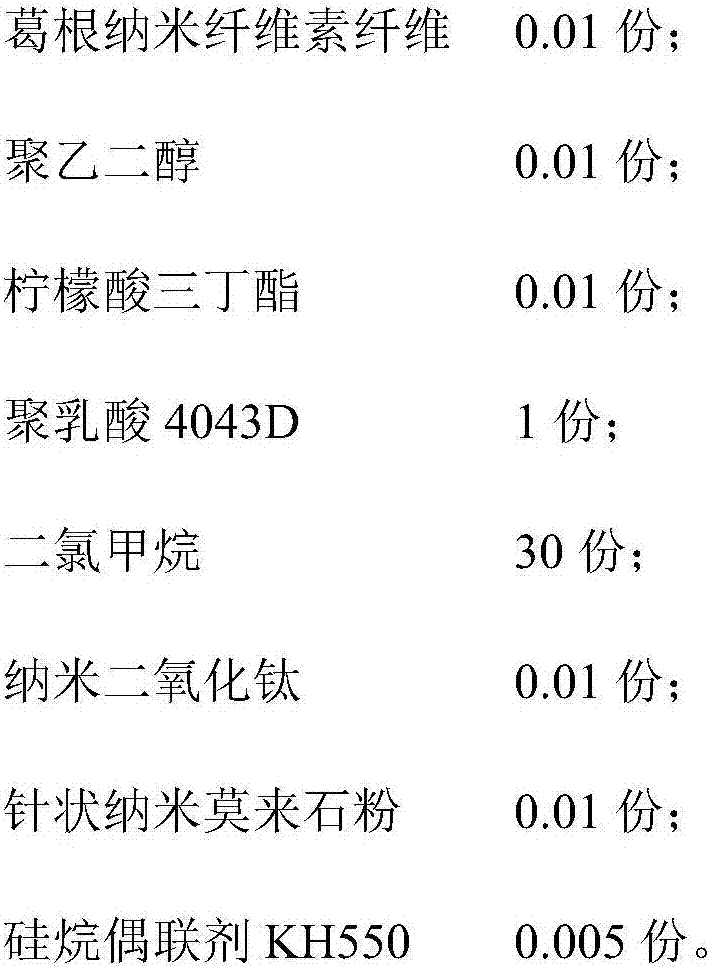

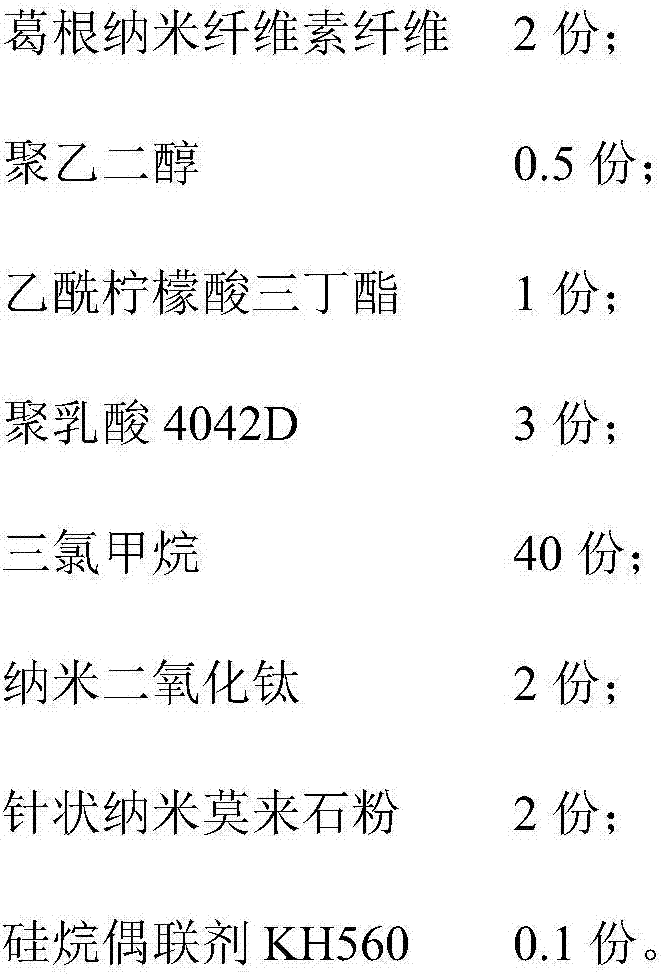

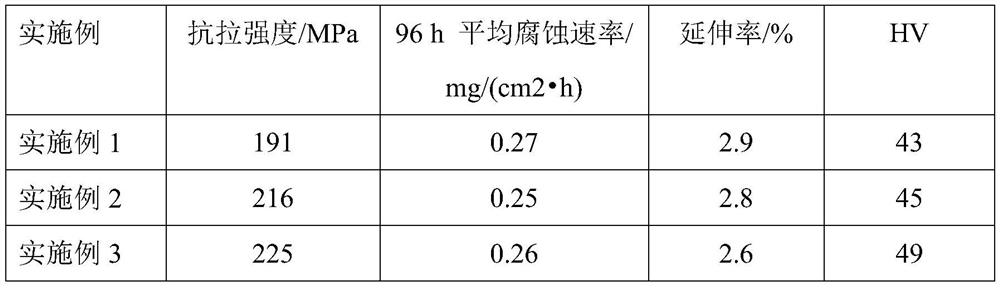

Kudzu root nanocellulose fiber-polylactic acid plastic film and preparation method thereof

The invention discloses a kudzu root nanocellulose fiber-polylactic acid full-degradable plastic film. The kudzu root nanocellulose fiber-polylactic acid full-degradable plastic film is prepared from raw materials in parts by weight as follows: 0.01-2 parts of kudzu root nanocellulose fibers, 0.01-0.5 parts of polyethylene glycol, 0.01-1 part of a plasticizer, 1-3 parts of polylactic acid, 30-40 parts of an organic solvent, 0.01-2 parts of nano-titania, 0.01-2 parts of nanometer mullite powder and 0.005-0.1 parts of a coupling agent. Environment-friendly polylactic acid is taken as a matrix, and nanocrystal cellulose fibers prepared from kudzu root residues are taken as a reinforcing material of the polylactic acid full-degradable plastic film, so that the strength, the modulus, the barrier property and the like of the film can be improved; organic combination for a nanocrystal cellulose fiber, inorganic material and polylactic acid ternary system is realized technologically, and the multifunctional polylactic acid full-degradable plastic film material is prepared.

Owner:YANCHENG INST OF TECH

Corrosion inhibitor used for preventing corrosion of brass

The invention relates to a corrosion inhibitor used for preventing corrosion of brass. The corrosion inhibitor is characterized by comprising the following components by weight parts: 40-70 parts of organic polymer components, 5-20 parts of azole components, 1-8 parts of dispersing components, 1-8 parts of zinc salts and 1-5 parts of sodium gluconate. A preparation method of the corrosion inhibitor comprises dissolving the organic polymer components in a solvent, firstly adding the azole components, uniformly stirring and dissolving, and then sequentially adding the dispersing components, the zinc salts and the sodium gluconate to obtain finish product. Finally, the produced corrosion inhibitor has a concentration of 10-60 mg / L. According to the invention, the corrosion inhibitor used for preventing corrosion of the brass does not contain phosphorus components, and thus does not pollute water body; meanwhile, polyaspartic acid and polyepoxysuccinic acid are added, wherein the two are high-efficient and environmental-friendly components and thus are environment-friendly products. The corrosion inhibitor is scientific and reasonable in formula, and the preparation method is simple to operate, thereby being suitable for large-scale production.

Owner:WEIHAI TIANYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Coal gangue and shale hollow brick with excellent frost resistance and manufacturing method thereof

The invention discloses a coal gangue and shale hollow brick with excellent frost resistance. The coal gangue and shale hollow brick with excellent frost resistance is characterized by being prepared from the following raw materials in parts by weight: 70-73 parts of mixed powder of treated coal gangue and shale, 50-54 parts of pulverized fuel ash, 9-11 parts of saw dust, 4-6 parts of red mud, 3-5 parts of sodium sulfate, 2-3 parts of sodium chloride, 4-6 parts of spent pulping liquor and 9-10 parts of water. Compared with the prior art, the coal gangue and shale hollow brick disclosed by the invention has the advantage that the components are matched scientifically and reasonably; due to the addition of the mixed powder of treated coal gangue and shale and the ball-milled pulverized fuel ash, the plasticity index of the coal gangue and shale hollow brick is increased, the cohesiveness of particles is improved, and the adobe is compact, is low in water absorption rate and cracks less in the drying process; due to the addedsodium chloride, the frost resistance of the coal gangue and shale hollow brick is improved; due to the matched components, the coal gangue and shale hollow brick can be baked easily to have high cohesional strength and good frost resistance; and because the saw dust is burnt away in the baking process, the coal gangue and shale hollow brick is light in weight.

Owner:HEXIAN MINGSHENG ENVIRONMENTAL PROTECTION MATERIAL

Fully-degradable plastic film having fresh keeping function and used for packages and preparing method thereof

Fully-degradable plastic film having a fresh keeping function and used for packages is disclosed. The plastic film is characterized in that the plastic film is prepared from 80-85 parts by weight of polylactic acid, 25-30 parts by weight of China hemp fibers, 0.8-1 part by weight of a silane coupling agent kh-550, 20-25 parts by weight of corn starch, 12-14 parts by weight of glycerin, 1.6-2 parts by weight of epichlorohydrin, a proper amount of a sodium hydroxide solution having a concentration of 1 mol / L, a proper amount of hydrochloric acid having a concentration of 1 mol / L, a proper amount of distilled water, 5-6 parts by weight of porous starch, 1-2 parts by weight of magnesium stearate, 3-4 parts by weight of macroporous silica gel and 5-7 parts by weight of tourmaline powder; the plastic film is scientific and reasonable in component ratio, can be prepared into food fresh keeping film or fruit packaging bags, and the like, contains the tourmaline powder and other components, can emit far infrared light and negative ions, and keeps freshness for foods; a process is innovative and convenient in industrial control; and the plastic film is low in cost and wide in source and deserves popularization.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

Modified polycarboxylate water reducer capable of improving strength of concrete

The invention discloses a modified polycarboxylate water reducer capable of improving strength of concrete. The modified polycarboxylate water reducer is prepared from, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persuflate, 0.53-0.55 parts of thioglycolic acid, 13-14 parts of lignin, proper amounts of sodium hydroxide solution of 10wt% in concentration and deionized water, 26-28 parts of grapheme oxide, 2.5-3 parts of sodium pyrophosphate, 2-3 parts of waterborne epoxy resin, 8-10 parts of nano alumina, 5-6 parts of carbide slag, 2-3 parts of microcrystalline wax and 3-4 parts of sodium citrate. The modified polycarboxylate water reducer is scientific and reasonable in ingredient proportion, the water reducer which is prepared from a series of processing steps is high in water reducing rate and good in dispersity in the concrete, early strength and later strength of the concrete are improved obviously, and the water reducer is excellent in working performance, high in durability and low in bleeding rate and has good economic benefit and social benefit.

Owner:ANHUI XINRUN NEW MATERIALS

Novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material and manufacturing method thereof

InactiveCN105111667AGood flame retardant synergistic effectImprove carbon residue rate and oxygen indexPlastic/resin/waxes insulatorsInsulated cablesMaleic anhydrideChemistry

The invention discloses a novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material. The novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material is characterized by comprising, by weight, 100-104 parts of SEBS, 65-68 parts of paroline, 29-31 parts of polypropylene, 21-23 parts of maleic anhydride grafted polypropylene, 3-4 parts of antioxygen B215, 81-83 parts of magnesium hydroxide, 10.5-12 parts of expanded graphite, 1.6-1.7 parts of a silane coupling agent A-171, 8-9 parts of absolute ethyl alcohol, 2-3 parts of stearic acid, 9-11 parts of calcium carbonate, 2-3 parts of silicone master batch, 1-1.5 parts of zinc oxide, 5-7 parts of maleic acid and 1.5-2 parts of polyvinyl alcohol. According to the novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material, a blend of the paroline modified SEBS and the polypropylene is used as a matrix, and the composition proportion is scientific and reasonable, so that the obtained product is high in tensile strength, good in thermostability, pliable, tough, good in processing fluidity, remarkable in flame retardant efficiency, free of halogen, environmentally friendly, capable of being widely applied to power lines, data lines and the like.

Owner:YJH ELECTRICAL EQUIP

High-performance fluororesin coating applied to coiled steel

InactiveCN103805003AThe ratio is scientific and reasonableLow costCoatingsPolyvinylidene fluorideSolvent

The invention relates to a high-performance fluororesin coating applied to coiled steel. The coating consists of the following components in parts by weight: 23-30 parts of polyvinylidene fluoride resin, 9-13 parts of thermosetting acrylic resin, 50-57 parts of an organic solvent and 1-17 parts of pigment. The coating disclosed by the invention is scientific and reasonable in ingredient proportion, relatively low in cost, better in weather fastness, solvent resistance, drug resistance, machinability and wear resistance, and excellent in adhesive force.

Owner:天津市雅涂色彩工贸有限公司

Preparation method of porous polyvinyl chloride-graphene composite material

InactiveCN107213880AImprove hydrophobicityThe ratio of ingredients is scientific and reasonableFatty/oily/floating substances removal devicesOther chemical processesN dimethylformamideSurface layer

The invention discloses a preparation method of a porous polyvinyl chloride-graphene composite material. According to the preparation method, hydrophobic modified nano-graphene, an N,N-dimethylformamide solution of polyvinyl chloride and sodium chloride are mixed by virtue of a high energy ball milling method, and finally, the mixture is dropwise added into distilled water to form porous polyvinyl chloride-graphene particles; a pore-foaming agent is compatible with water to form a surface layer with less pore structures, the compatiblility speed of the pore-foaming agent with water in a sphere is decreased due to the blockage of the surface layer and generates a pore forming effect in a slow dissolving-out process, and formed holes are uniformly distributed and uniform in particle sizes and have good through-hole and opening performance; meanwhile, by adding hydrophobic modified nano-graphene, the prepared composite material has good hydrophobic property, and a porous structure can be applied to oil-water separation such as water pollution treatment; and furthermore, a process of the preparation process is convenient to industrial control, and the application field of polyvinyl chloride is expanded.

Owner:CHUZHOU HONGYUAN SPRAYING

Corrosion inhibitor for preventing brassware from being corroded

The invention relates to a corrosion inhibitor used for preventing corrosion of brass. The corrosion inhibitor is characterized by comprising the following components by weight parts: 40-70 parts of organic polymer components, 5-20 parts of azole components, 1-8 parts of dispersing components, 1-8 parts of zinc salts and 1-5 parts of sodium gluconate. A preparation method of the corrosion inhibitor comprises dissolving the organic polymer components in a solvent, firstly adding the azole components, uniformly stirring and dissolving, and then sequentially adding the dispersing components, the zinc salts and the sodium gluconate to obtain finish product. Finally, the produced corrosion inhibitor has a concentration of 10-60 mg / L. According to the invention, the corrosion inhibitor used for preventing corrosion of the brass does not contain phosphorus components, and thus does not pollute water body; meanwhile, polyaspartic acid and polyepoxysuccinic acid are added, wherein the two are high-efficient and environmental-friendly components and thus are environment-friendly products. The corrosion inhibitor is scientific and reasonable in formula, and the preparation method is simple to operate, thereby being suitable for large-scale production.

Owner:陈民

Coaxial cable-shielding corrosion-resistant aluminum-magnesium alloy wire and processing method thereof

InactiveCN102560207AThe ratio of ingredients is scientific and reasonableHigh tensile strengthSteal phenomenonCoaxial cable

The invention relates to a coaxial cable-shielding corrosion-resistant aluminum-magnesium alloy wire and a processing method thereof. The aluminum-magnesium alloy wire comprises the following components by weight percentage: 3.0-3.6 percent of magnesium, 0.18-0.30 percent of chromium, 0.2-0.6 percent of boron and aluminum in balancing amount. The coaxial cable-shielding corrosion-resistant aluminum-magnesium alloy wire is prepared by a process flow of smelting, drawing molding, heat treatment, roughly drawing, heat treatment, finely drawing and annealing and the like. The coaxial cable-shielding corrosion-resistant aluminum-magnesium alloy wire is scientific and reasonable in formulation of material components, advanced and simple in production process, high in efficiency, low in cost and resistivity and high in tensile strength and breaking elongation; the resistivity at the temperature of 20DEG C is less than or equal to 0.052 ohmmm<2> / m; the demands of the market can be met; the coaxial cable-shielding corrosion-resistant aluminum-magnesium alloy wire is an ideal coaxial cable shielding material; the coaxial cable-shielding and corrosion-resistant performance, the tensile strength and the breaking elongation can be improved; and compared with a copper wire, the aluminum-magnesium alloy wire is poor in recovery value, so that a cable stealing phenomenon can be reduced and avoided.

Owner:YANGZHOU SAIGE WIRING TECH GRP CO LTD

Die alloy

InactiveCN104911442AThe ratio of ingredients is scientific and reasonableImprove wear resistanceChromiumTungsten

The invention relates to a die alloy, which comprises the following components by weight part: 2-5 parts of chromium, 10-15 parts of iron, 12-18 parts of zinc, 6-10 parts of tungsten, 12-15 parts of silicon, 8-10 parts of calcium, 2-3 parts of niobium. The die alloy has the advantages that the composition proportion is scientific and reasonable, wear resistance and intensity are high, service life is greatly prolonged, manufacture cost is reduced, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

Antibacterial aluminum alloy filter net for air purifier

InactiveCN106381423AThe ratio of ingredients is scientific and reasonableMeet needsAntifouling/underwater paintsPaints with biocidesAntibacterial coatingAluminium alloy

The invention discloses an antibacterial aluminum alloy filter net for an air purifier. An aluminum alloy filter net casting comprises alloying components: by weight, 0.8-1.2% of C, 0.7-1.1% of Si, 2.3-2.5% of Cr, 0.25-0.45% of Mn, 0.09% or smaller of P, 0.009% or smaller of S, 1.25-1.45% of Ni, 0.35-0.55% of V, 0.15-0.19% of Ti, 0.03-0.05% of Cu, 0.05-0.09% of Nb and the balance aluminum. Due to the way that the surface is sprayed with an antibacterial coating, both the antibacterial property and the oxidation resistance are high, the service life is greatly prolonged, the manufacturing cost is reduced, and user requirements are met.

Owner:安徽名杰净化科技有限公司

Die alloy

InactiveCN104911450AThe ratio of ingredients is scientific and reasonableIncreased strength and wear resistanceTungstenZinc

The invention relates to a die alloy, which comprises the following components by weight part: 2-5 parts of copper, 10-15 parts of iron, 12-18 parts of zinc, 6-10 parts of tungsten, 12-15 parts of silicon, 8-10 parts of calcium, 2-3 parts of niobium. The die alloy has the advantages that the composition proportion is scientific and reasonable, wear resistance and intensity are high, service life is greatly prolonged, manufacture cost is reduced, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

A high-strength, high-toughness, high-nitrogen austenitic stainless steel welding wire and preparation method thereof

ActiveCN108526750BIncrease contentImprove solid solubilityArc welding apparatusWelding/cutting media/materialsManganeseSS - Stainless steel

The invention relates to a high-strength high-toughness high-nitrogen austenitic stainless steel welding wire and a preparation method thereof. The welding wire is prepared from the alloy components in percentage by weight: less than 0.1 percent of C, less than 0.02 percent of S, less than 0.03 percent of P, 0.1 to 0.9 percent of Si, 5 to 21 percent of Mn, 15 to 23 percent of Cr, 0 to 8 percent ofNi, 0 to 5 percent of Mo, 0.2 to 0.95 percent of N, the balance Fe, and less than 0.1 percent of other impurities. The preparation process comprises the steps of smelting through an induction furnace, electro slags remelting, hot forging, hot rolling, heat treating, and drawing of the welding wire. According to the welding wire provided by the invention, the component proportion is scientific andreasonable, the content of nitrogen elements is increased, the content of manganese elements is adjusted, and the solid solubility of the nitrogen is increased, so that the prepared welding wire is stable in welding process, less in escape amount of hydrogen elements, less in blowhole defects, good in welding processability, high in deposited metal strength, excellent in impact toughness at the temperature of minus 40 DEG C, suitable for welding high-nitrogen austenitic stainless steel, particularly suitable for welding the austenitic stainless steel with the requirement on low-temperature impact toughness, and capable of being surfacing-welded so as to be used as anti-corrosion layers for other steel and iron materials.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Fast growing wood modifier capable of achieving hydrophobicity synergetic enhancement through alkyl ketene dimers and nano titanium dioxide

InactiveCN106393361APlay a stabilizing roleImprove impregnation modification rateWood treatment detailsWood impregnation detailsHexamethylenetetramineStearic acid

The invention discloses a fast growing wood modifier capable of achieving hydrophobicity synergetic enhancement through alkyl ketene dimers and nano titanium dioxide. The modifier is prepared from the following raw materials in parts by weight: 3 to 3.5 parts of formaldehyde, 2 to 3 parts of urea, 1.5 to 2 parts of hexamethylenetetramine, 0.02 to 0.03 part of maleic anhydride, a proper amount of acetic acid, a proper amount of ammonium hydroxide, a proper amount of deionized water, 20 to 23 parts of DMDHEU of which the solid content is 42wt%, 1.5 to 2 parts of magnesium chloride hexahydrate, 10 to 11 parts of silica sol, 3 to 4 parts of alkyl ketene dimers, 2 to 3 parts of stearic acid, 10 to 11 parts of butyl titanate, a proper amount of absolute ethyl alcohol and 4 to 5 parts of glacial acetic acid. According to the modifier, the mechanical property of the tissue structure of the fast growing wood can be improved, the size stability is improved, the modified wood has excellent hydrophobic and dampproof capacities, effective components are not liable to lose, and outdoor furniture and outdoor wood equipment manufactured through the modified wood are durable, flame-resistant and waterproof, and are high in market competitiveness.

Owner:FUYANG WEIYE FURNITURE

Composite flame retardant and waterproof modifying agent for modification of fast-growing wood for manufacturing outdoor furniture

InactiveCN106363738APlay a stabilizing roleImprove impregnation modification rateWood treatment detailsWood impregnation detailsCrack resistancePyrophosphate

The invention discloses a composite flame retardant and waterproof modifying agent for modification of fast-growing wood for manufacturing outdoor furniture. The composite flame retardant and waterproof modifying agent is prepared from the following raw materials in parts by weight: 3 to 3.5 parts of formaldehyde, 2 to 3 parts of urea, 1.5 to 2 parts of hexamethylene tetramine, 0.02 to 0.03 part of maleic anhydride, a proper amount of acetic acid, a proper amount of ammonium hydroxide, a proper amount of deionized water, 20 to 23 parts of DMDHEU of which the solid content is 42wt%, 1.5 to 2 parts of magnesium chloride hexahydrate, 10 to 11 parts of silica sol, 3 to 4 parts of melamine pyrophosphate, 0.8 to 1 part of 1H,1H,2H,2H-perfluorooctyltrimethoxysilane, 2 to 3 parts of ammonium dihydrogen phosphate, 2 to 3 parts of sodium silicate, a proper amount of glacial acetic acid and a proper amount of absolute ethyl alcohol. According to the composite flame retardant and waterproof modifying agent, the corrosion resistance, waterproofness, deformation resistance and crack resistance of the wood modified through the product are greatly improved, and the outdoor furniture, wooden equipment and wooden tools manufactured through the modified wood have good utilization performance and long service life.

Owner:FUYANG WEIYE FURNITURE

A kind of mg-y-nd-(la+ce)-zr biodegradable magnesium alloy and its preparation method

ActiveCN110468319BImprove mechanical propertiesAccelerated corrosionSurgeryHuman bodyCardiovascular stent

A Mg-Y-Nd-(La+Ce)-Zr biodegradable magnesium alloy, characterized in that: the magnesium alloy is composed of the following components in mass percentage: Y: 3.0-4.5%, Nd: 2.0-3.5% , Zr: 0.3-1.0%, lanthanum-cerium composite rare earth: 0.05-0.5%, the rest is magnesium and unavoidable impurities, impurity content ≤ 0.1%, wherein the content of lanthanum and cerium in the lanthanum-cerium composite rare earth each accounts for 50%; preparation method As follows: batching - melting and casting - annealing - extrusion - finished product. The magnesium alloy of the present invention adopts a multi-element and small amount of design method, the proportioning is scientific and reasonable, the preparation process is simple, the prepared magnesium alloy has high density, reliable quality, excellent mechanical properties and corrosion resistance, and at the same time, the degradation rate is controllable, biophase It has excellent capacity, which can ensure that it will not be deformed and damaged after being made into a cardiovascular stent, and can be better matched with human tissues, so it has a wide application prospect in the medical field.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Hot work die

InactiveCN104911479AThe ratio of ingredients is scientific and reasonableGood heat resistanceAluminiumLithium

The invention relates to a hot work die, which comprises the following components by weight part: 0.15-0.36 parts of carbon, 0.03-0.08 parts of lithium, 0.3-0.45 parts of copper, 0.06-0.18 parts of calcium, 0.1-0.5 parts of aluminum, 0.04-0.67 parts of caesium, 0.4-0.8 parts of phosphor, 0.25-0.36 parts of potassium and 95-98 parts of iron. The hot work die has the advantages that the composition proportion is scientific and reasonable, heatproof effect is good, crack phenomenon can not be generated after long-term usage, fatigue resistance is good, production cost is greatly reduced, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

Hot working die

InactiveCN103966501AThe ratio of ingredients is scientific and reasonableImprove heat resistancePotassiumRare earth

The invention provides a hot working die which comprises components in parts by weight as follows: 0.15-0.36 parts of carbon, 0.03-0.08 parts of oxygen, 0.3-0.45 parts of rare earth, 0.06-0.18 parts of calcium, 0.1-0.5 parts of aluminum, 0.04-0.67 parts of cesium, 0.4-0.8 parts of phosphorus, 0.25-0.36 parts of potassium and 95-98 parts of iron. The hot working die has the advantages as follows: the composition proportion of die steel is scientific and reasonable, the heat resistant effect is good, cracking is avoided after long-term use, the anti-fatigue performance is good, the production cost is reduced greatly, and requirements of enterprises are met.

Owner:KUNSHAN LTK AUTOMATION EQUIP TECH

Wear-resisting enhancement polyurethane polystyrene foam for switch cabinet sealing

InactiveCN106221662AHigh oxygen indexImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiethyl phosphatePolyvinyl alcohol

The invention discloses wear-resisting enhancement polyurethane polystyrene foam for switch cabinet sealing. The wear-resisting enhancement polyurethane polystyrene foam is prepared from, by weight, 150-160 parts of diphenyl-methane-diisocyanate, 100-105 parts of propoxylated glycerin, 100-110 parts of castor oil, 5-6 parts of glycerin, 40-43 parts of diethyl phosphate, a proper amount of 1 mol / L sodium hydroxide solution, 13-15 parts of kieselguhr, 5-6 parts of distilled water, 2-3 parts of triethanolamine, 3-4 parts of dibutyltin dilaurate, 3-4 parts of sorbitan ester, 3-4 parts of silicon resin polyether emulsion, 3-4 parts of silicon carbide, 2-3 parts of fumed silica, 2-3 parts of EVA emulsion, 2-3 parts of polyvinyl alcohol, 1-1.5 parts of nickel powder and a proper amount of deionized water. The wear-resisting enhancement polyurethane polystyrene foam is used for switch cabinet sealing, on-site foaming can be conducted, foam cells are dense, sealing performance is high, wear resistance is high, and service life is long.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

Die alloy

InactiveCN104911448AThe ratio of ingredients is scientific and reasonableIncreased strength and wear resistanceRosinTungsten

The invention relates to a die alloy, which comprises the following components by weight part: 2-5 parts of chromium, 10-15 parts of iron, 12-18 parts of zinc, 6-10 parts of tungsten, 12-15 parts of rosin, 8-10 parts of calcium, 2-3 parts of niobium. The die alloy has the advantages that the composition proportion is scientific and reasonable, wear resistance and intensity are high, service life is greatly prolonged, manufacture cost is reduced, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

Preparation method of wear-resistant ball with antioxidant wear-resistant coating

InactiveCN106086610AThe ratio of ingredients is scientific and reasonableMeet needsCoatingsWear resistantOxidation resistant

The invention discloses a preparation method of a wear-resistant ball with an antioxidant wear-resistant coating. The preparation method comprises the following process step that a wear-resistant ball casting is prepared, wherein a wear-resistant ball casting alloy comprises, by weight percentage, 1.4-1.6% of C, 1.2-1.4% of Si, 2.65-2.95% of Cr, 1.05-1.25% of Mn, 0.003-0.09% of P, 0.004-0.009% of S, 1.15-1.45% of Ni, 0.15-0.35% of V, 0.15-0.35% of Te, 0.04-0.08% of Ti, 0.02-0.05% of Cu, 0.05-0.11% of Nb and the balance Fe. The wear-resistant ball casting alloy is scientific and reasonable in composition proportion; and by spraying the wear-resistant coating on the surface, wear resistance and oxidation resistance are improved at the same time; the service life is greatly prolonged; manufacturing cost is lowered; and the requirements of an enterprise are met.

Owner:MAANSHAN YIFENG INDAL GROUP

Die alloy

InactiveCN103938054AThe ratio of ingredients is scientific and reasonableImprove wear resistanceHigh wear resistanceUltimate tensile strength

The invention relates to a die alloy. The die alloy comprises, by weight, 2-5 parts of Cr, 10-15 parts of Fe, 12-18 parts of talcum, 6-10 parts of W, 12-15 parts of Si, 8-10 parts of Ca and 2-3 parts of Nb. The die alloy has the advantages of scientific and reasonable component proportions, high wear resistance and strength, substantially prolonged service life, making cost reduction, and enterprise demand meeting.

Owner:KUNSHAN LTK AUTOMATION EQUIP TECH

Mold alloy

InactiveCN103966497AThe ratio of ingredients is scientific and reasonableImprove wear resistanceNiobiumAlloy

The invention discloses a mold alloy which comprises components in parts by weight as follows: 2-5 parts of chromium, 10-15 parts of iron, 12-18 parts of zinc, 6-10 parts of tungsten, 12-15 parts of grape straws, 8-10 parts of calcium and 2-3 parts of niobium. The mold alloy has the advantages as follows: the composition proportion is scientific and reasonable, simultaneously, the wear resistance and the strength are higher, the service life is greatly prolonged, the manufacturing cost is reduced, and the enterprise demand is met.

Owner:KUNSHAN LTK AUTOMATION EQUIP TECH

Die alloy

InactiveCN104911447AThe ratio of ingredients is scientific and reasonableImprove wear resistanceNiobiumAlloy

The invention relates to a die alloy, which comprises the following components by weight part: 2-5 parts of chromium, 10-15 parts of iron, 12-18 parts of zinc, 6-10 parts of tungsten, 12-15 parts of silicon, 8-10 parts of fluorite, 2-3 parts of niobium. The die alloy has the advantages that the composition proportion is scientific and reasonable, wear resistance and intensity are high, service life is greatly prolonged, manufacture cost is reduced, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

Health care product with effect of preventing senile dementia

InactiveCN102813869AImprove brain agingPrevent Alzheimer's EfficacyNervous disorderFood preparationGastrodia elataGinseng

The invention discloses a health care product with an effect of preventing senile dementia. The health care product is made of the following raw materials, by weight, of 5-25 parts of fructus alpiniae oxyphyllae, 5-15 parts of ginkgo, 10-30 parts of walnut, 3-9 parts of ginseng, 3-6 parts of lucid ganoderma and 4-16 parts of gastrodia elata. The health care product with the effect of preventing the senile dementia is scientific and reasonable in matching of each composition which is pure natural plant extracts, has good the plant extracts for preventing the senile dementia, is free of chemical matters and is safe in medicine taking and wide in application scope.

Owner:SUZHOU GULI BIOTECH

High temperature resistant die steel

InactiveCN103938120AThe ratio of ingredients is scientific and reasonableHigh temperature resistanceTemperature resistanceProlongation

The invention relates to a high temperature resistant die steel. The die steel comprises, by weight, 1-3.5 parts of C, 0.05-0.08 parts of Zn, 0.013-0.025 parts of Mg, 0.057-0.086 parts of lime powder, 0.036-0.05 parts of Sn, 0.03-0.065 parts of Sb, 0.15-0.25 parts of Pb, 0.05-0.063 parts of Y and 80-95 parts of Fe. The die steel has the advantages of scientific and reasonable component proportions, strong high temperature resistance, stable performances, great prolongation of the service life, and realization of unlikely deformation, high tensile strength and high molding precision in use.

Owner:KUNSHAN LTK AUTOMATION EQUIP TECH

Whitening anti-aging traditional Chinese medicine facial mask and preparation method thereof

InactiveCN108210424AAnti-agingPromote absorptionCosmetic preparationsToilet preparationsLiquoricesGLYCYRRHIZA EXTRACT

The invention discloses a whitening anti-aging traditional Chinese medicine facial mask. The traditional Chinese medicine facial mask comprises the following components by weight: 40-50 parts of a liquorice extract, 5-10 parts of carrot, 20-28 parts of pearl powder, 18-22 parts of white poria cocos, 6-8 parts of Chinese angelica, 10-15 parts of soyabean protein, and 20-25 parts of collagen. The invention further discloses a preparation method of the whitening anti-aging traditional Chinese medicine facial mask. The whitening anti-aging traditional Chinese medicine facial mask has the beneficial effects that the composition proportion is scientific and reasonable, and the liquorice extract and the pearl powder have a whitening effect, in addition, the traditional Chinese medicines have an anti-aging effect, and the liquorice extract and the pearl powder are combined with the traditional Chinese medicines, so that whitening and anti-aging are integrated; the modes of low-temperature grinding and drying and low-temperature stirring are adopted, and the molecular structure of the materials is not damaged, so that an optimal effect is achieved; the whitening anti-aging traditional Chinese medicine facial mask does not contain chemical ingredients, is suitable for long-term use and meets the daily needs; and the absorption effect of the skin is good.

Owner:TIANJIN HIMALAYA HEALTH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com