Patents

Literature

30results about How to "Good flame retardant synergistic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

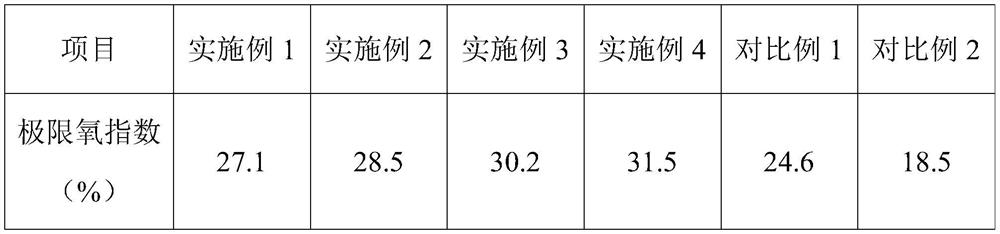

InactiveCN103724666AHigh flame retardant efficiencyOvercome moisture absorptionPolymer scienceHindered amine light stabilizers

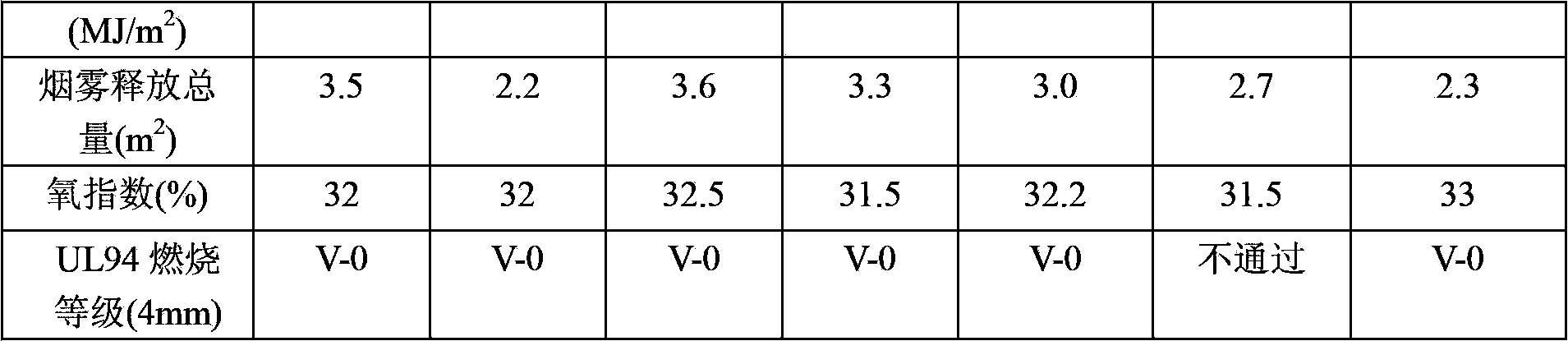

The invention belongs to the field of flame retardant materials, and particularly relates to a composite flame retardant containing a microcapsule-coated intumescent flame retardant and a preparation method. The composite flame retardant containing the microcapsule-coated intumescent flame retardant consists of the following components in percentage by mass: 60-94 percent of microcapsule intumescent flame retardant, 5-25 percent of flame-retardant synergist, 0.9-10 percent of smoke suppressant and 0.1-5 percent of hindered amine light stabilizer. The preparation method comprises the following steps: preparing the microcapsule-coated intumescent flame retardant; placing the microcapsule-coated intumescent flame retardant, the flame-retardant synergist, the smoke suppressant and the hindered amine light stabilizer into a high-speed mixer for mixing uniformly, and discharging to obtain the composite flame retardant containing the microcapsule-coated intumescent flame retardant. Multiple components in the composite flame retardant can play roles in retarding flame in a synergetic way, so that the flame retardance of a high polymer material is improved remarkably, the production of toxic and harmful smog in a burning process can be suppressed, and the flame retarding efficiency is increased greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

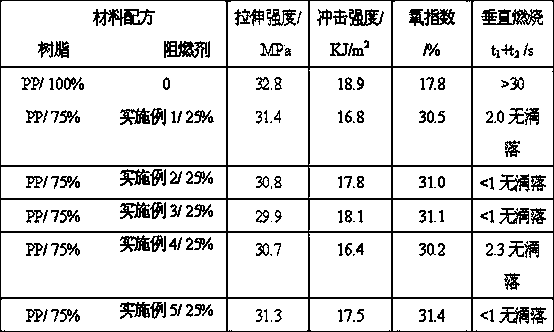

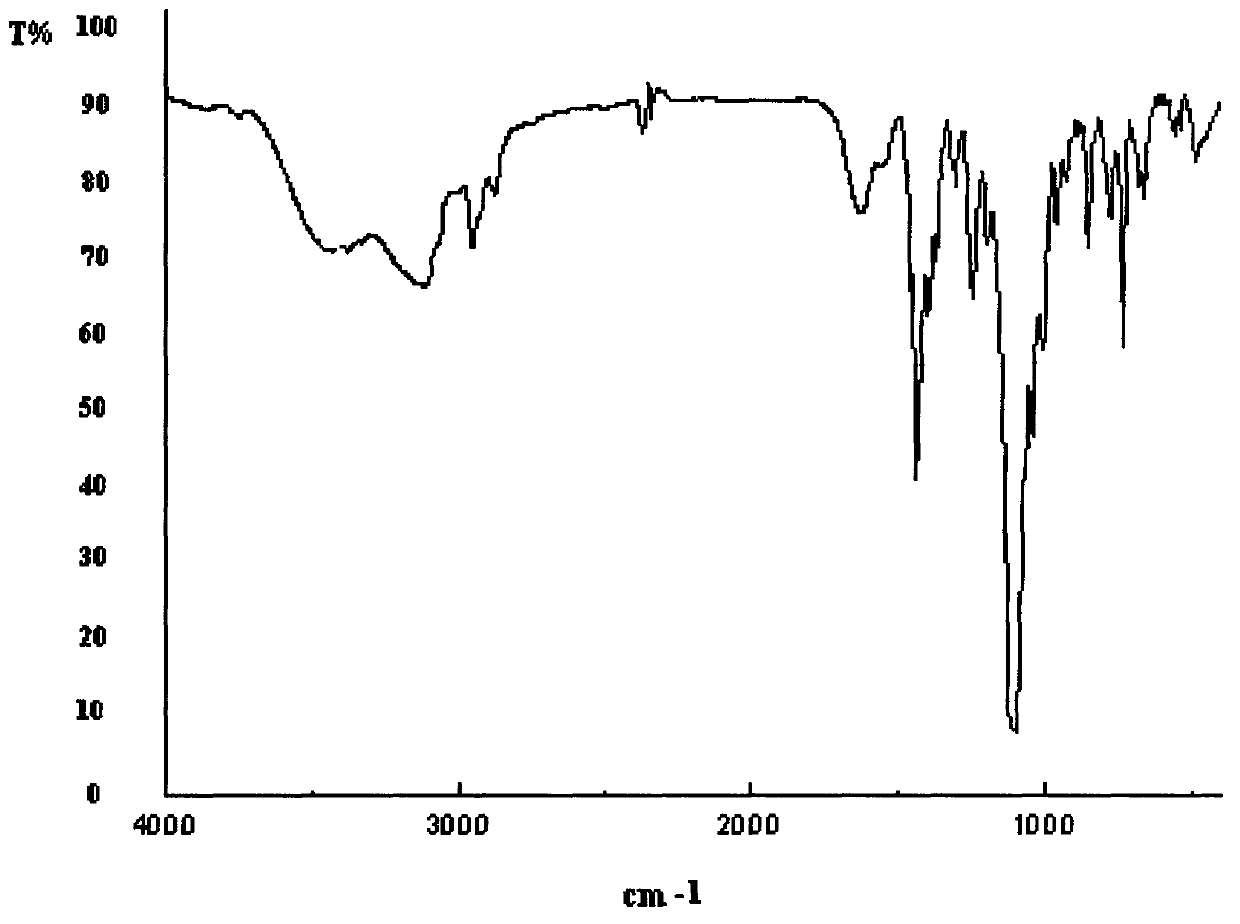

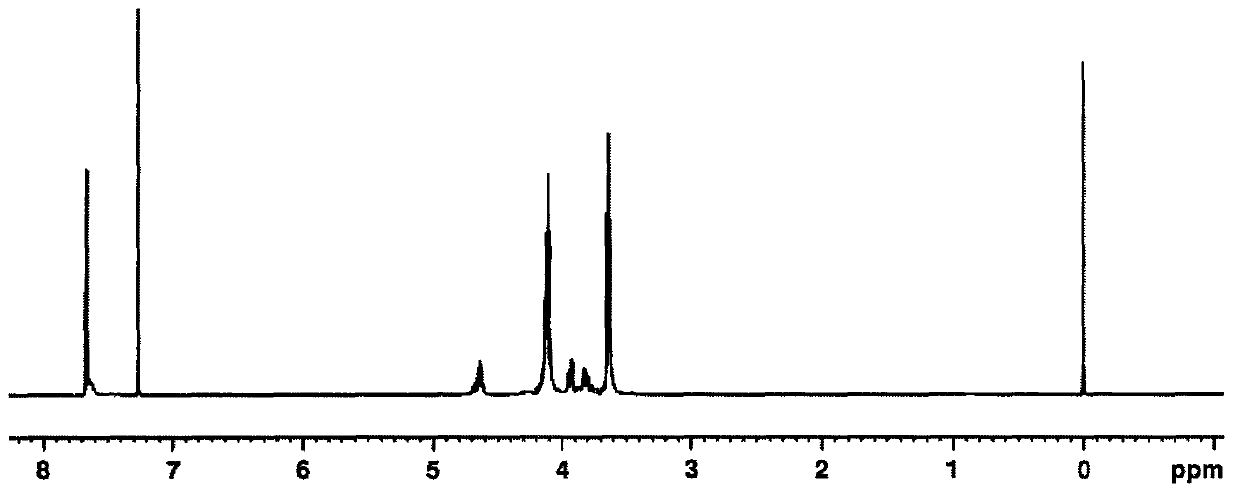

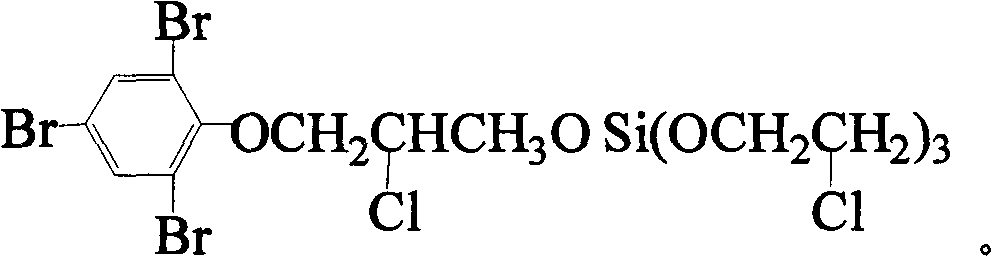

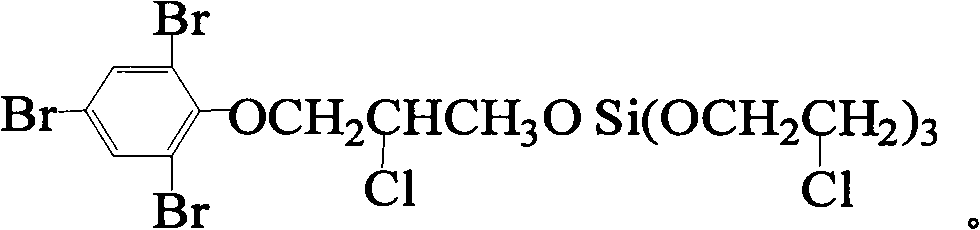

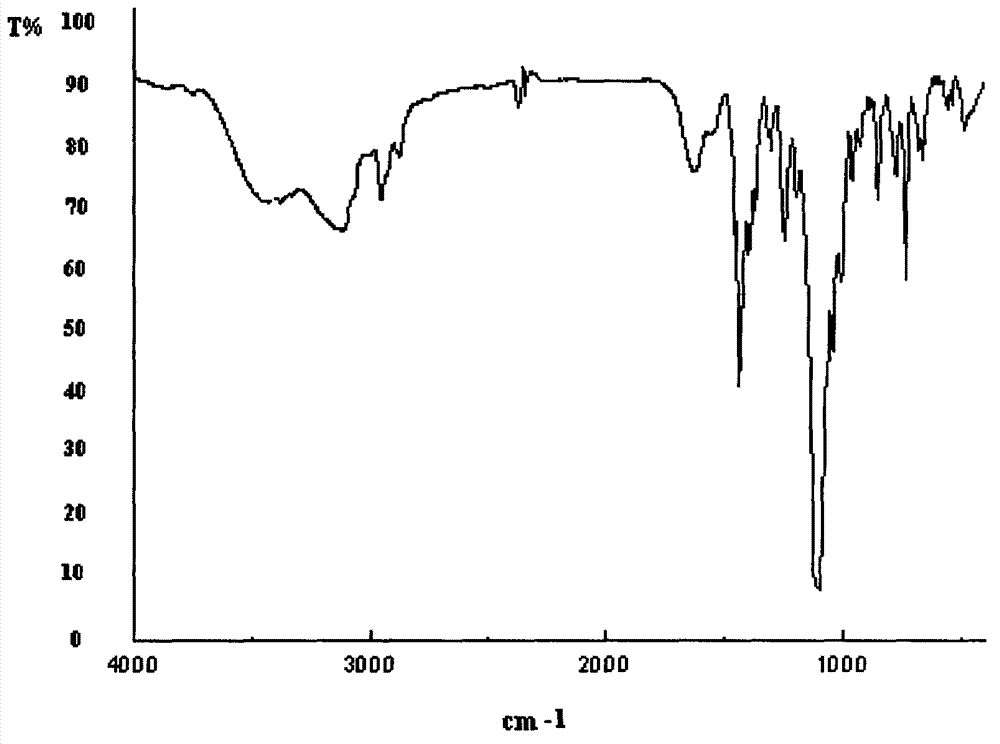

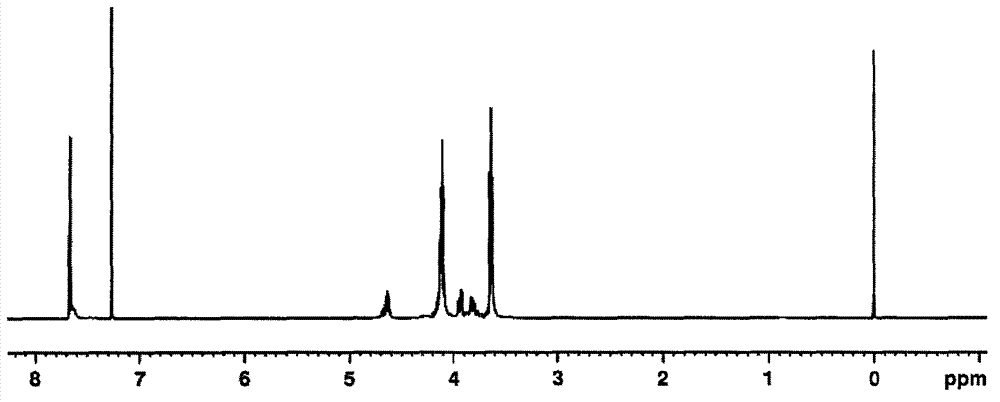

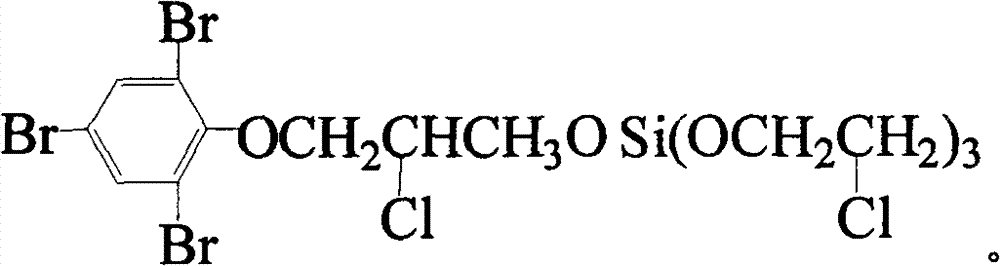

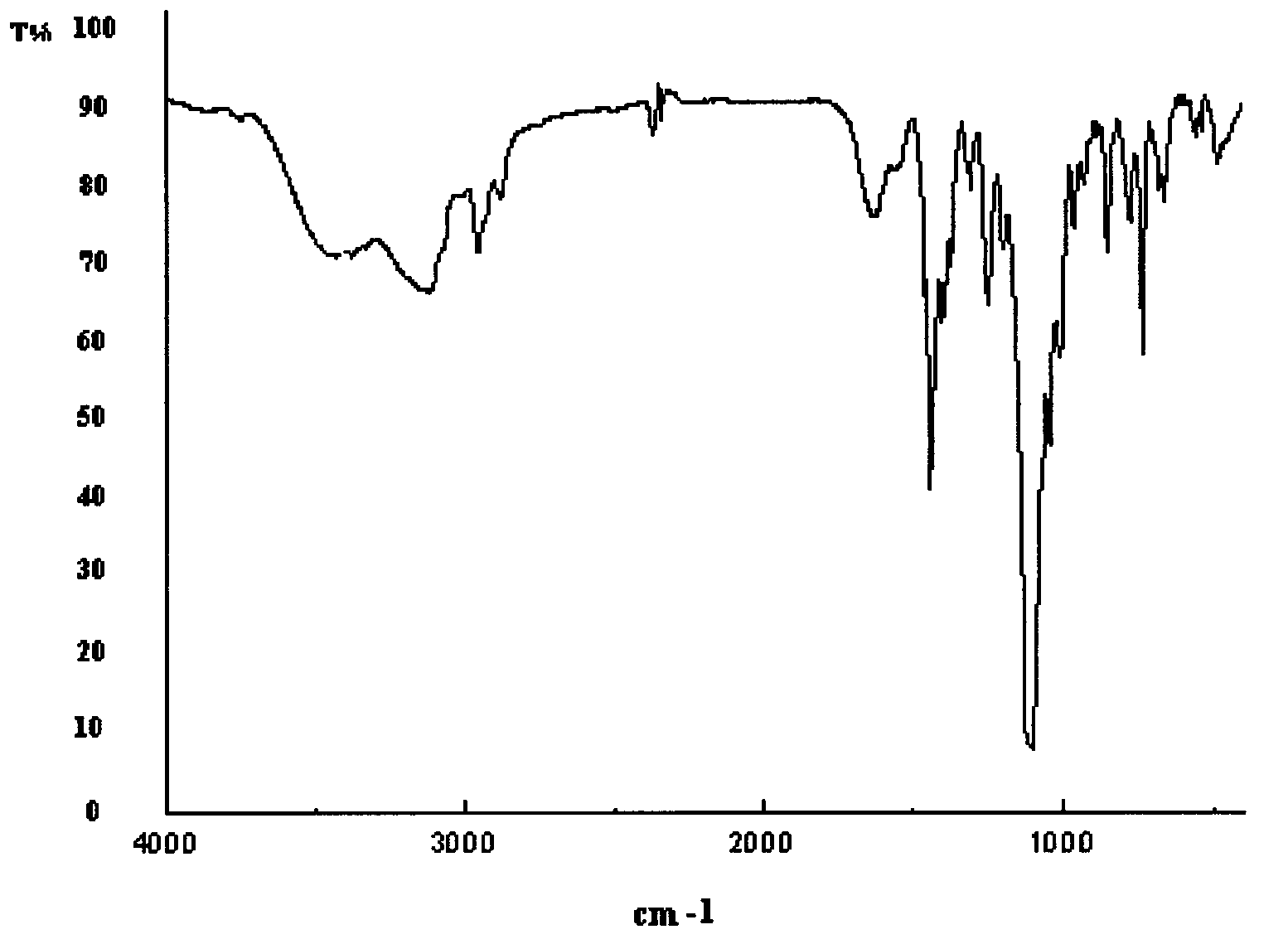

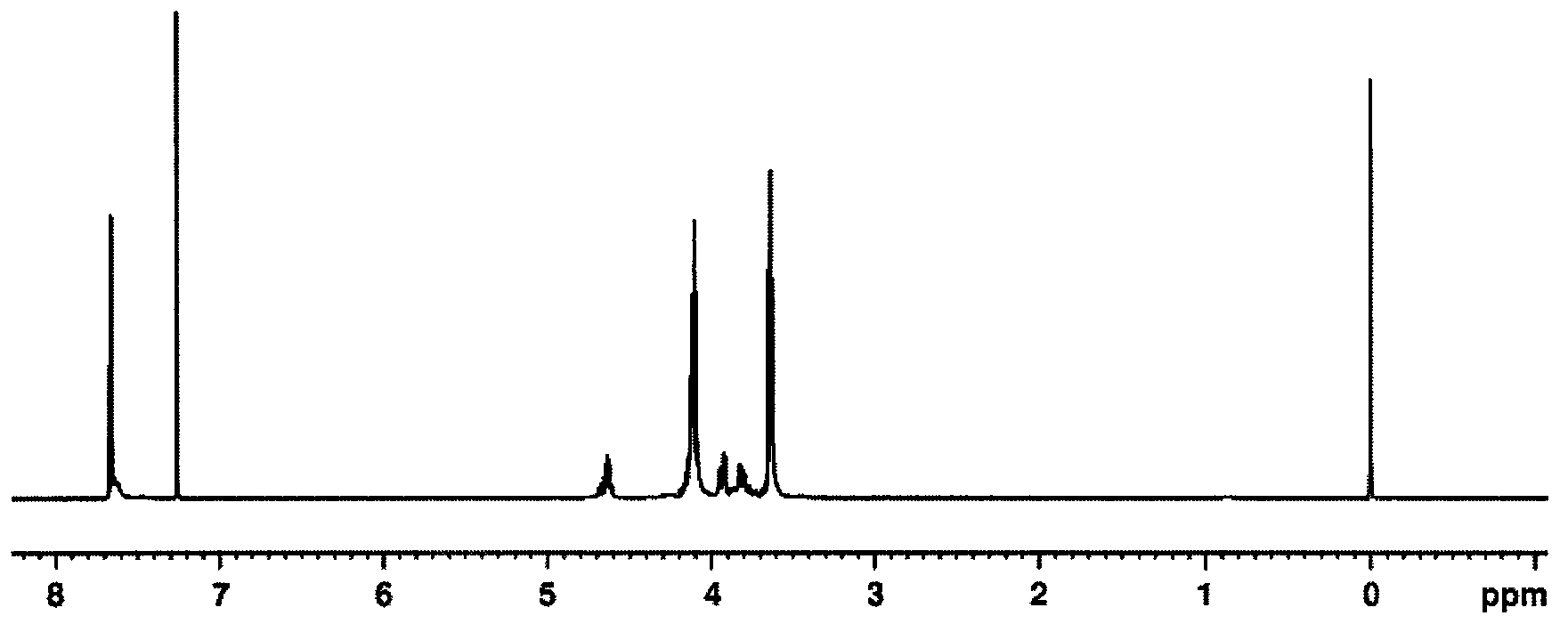

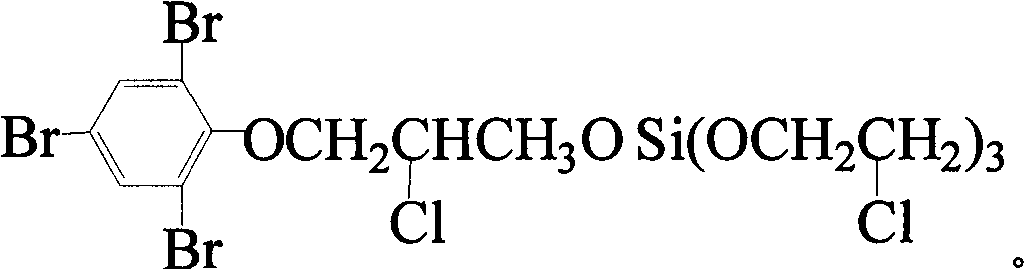

Chloro- and bromo-containing silicate flame retardant compound and preparation method thereof

ActiveCN102731825AImprove flame retardant performanceGood symmetrySilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a silicon-halogen synergistic flame retardant plasticizer tri(2-chloroethyl)-2-chloro-3-(2, 4, 6-tribromophenoxy)propyl silicate compound and a preparation method of the compound. The compound is characterized in that the structure is shown as follows in the specification. The method comprises the steps of adding tetrachlorosilane into a reactor, dripping equivalent molartribromophenylglycidyl ether organic solvent solution, performing a heat preservation process for a reaction at 60 DEG C-80 DEG C for 4-6 hours after the organic solvent solution is dripped, pumping ethylene oxide into the 40 DEG C solution at a certain molar ratio and below the liquid surface, performing another heat preservation process for another reaction at 50 DEG C-60 DEG C for 3-5 hours, and purifying to obtain a yellow liquid of tri(2-chloroethyl)-2-chloro-3-(2, 4, 6-tribromophenoxy) propyl silicate. The compound is a highly effective flame retardant and used as the flame retardant for poly(vinyl chloride), polyurethane, epoxy resin, unsaturated resin and the like. The method is simple in manufacturing technique, low in investment, and easily realizes the industrial production.

Owner:张家港市乐余科创园投资发展有限公司

Method for nano-dawsonite/lanthanum stannate/graphene oxide compounded flame-retardant modified PC (polycarbonate)/ABS (acrylonitrile butadiene styrene) alloy

InactiveCN106987109AGood flame retardant synergistic effectHigh flame retardant efficiencyIn situ polymerizationDawsonite

The invention discloses a method for a nano-dawsonite / lanthanum stannate / graphene oxide compounded flame-retardant modified PC (polycarbonate) / ABS (acrylonitrile butadiene styrene) alloy. The method includes the steps: preparing graphene oxide coated lanthanum stannate flame-retardant PC; preparing nano-dawsonite loaded graphene oxide flame-retardant ABS; preparing the PC / ABS alloy and the like. According to the method, graphene oxide coated lanthanum stannate is prepared by an ammonia precipitation-calcination method, the graphene oxide coated lanthanum stannate flame-retardant PC is prepared by an in-situ polymerization method, nano-dawsonite loaded graphene oxide is prepared by a hydrothermal synthesis method, the nano-dawsonite loaded graphene oxide flame-retardant ABS is prepared by an in-situ polymerization method, the graphene oxide coated lanthanum stannate flame-retardant PC and the nano-dawsonite loaded graphene oxide flame-retardant ABS are molten and blended to prepare the PC / ABS alloy, the flame-retardant efficiency of the PC / ABS alloy is remarkably improved, and the flame-retardant performance of the PC / ABS alloy can reach grade UL-94V-0.

Owner:郭峰

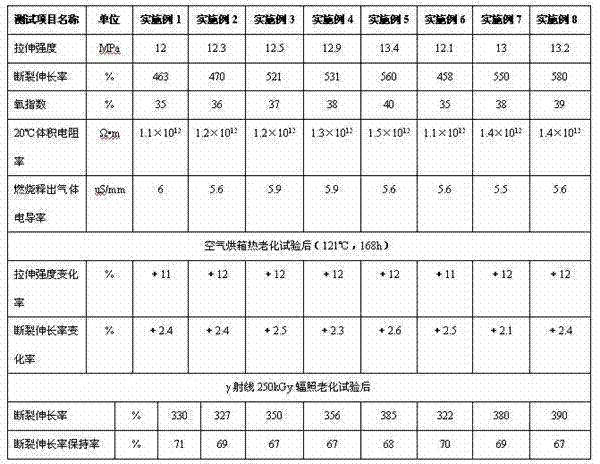

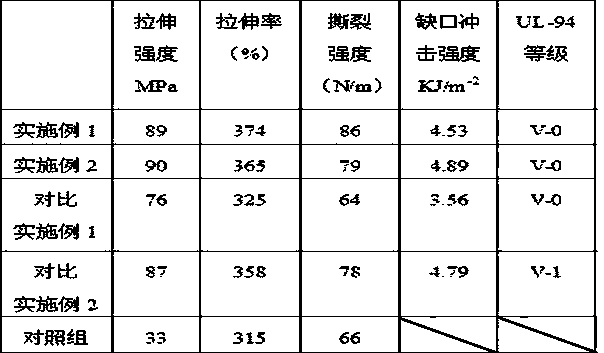

Grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for nuclear power plant and preparation method thereof

ActiveCN103087395AEnvironmental protection is goodReduce pollutionPlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention relates to a grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for a nuclear power plant and a preparation method thereof, belonging to the field of new chemical materials. The cable material comprises raw materials including base resin EVA (ethylene-vinyl acetate copolymer), flame retardants A and B, a flame retardant synergist, basic antioxidants 1010 and 168, a radiation-resistant auxiliary agent 4,4'-thiobis(6-tertiary-butyl-3-methylphenol) and a processing agent; and the preparation method comprises the process steps of material weighing, pretreatment, mixing, extrusion granulation, drying and the like. The cable material is a red-phosphorus-free halogen-free environment-friendly flame-retardant material, phenoxy polyphosphazene is used as a main flame retardant in a flame-retardant system of the cable material, an inorganic flame retardant is auxiliary, the flame-retardant system accounts for a small weight percentage of the material, and the cable material is high in flame-retardant efficiency and excellent in mechanical properties, processability and radiation resistance, so that the cable material is a novel environment-friendly flame-retardant material which has excellent comprehensive properties and is suitable for a nuclear power plant environment.

Owner:SICHUAN INST OF ATOMIC ENERGY +1

Halogen-free flame retardant LLDPE (linear low density polyethylene) material and preparation method thereof

ActiveCN103483676AImprove mechanical propertiesExcellent formabilityLow-density polyethyleneLinear low-density polyethylene

The invention discloses a halogen-free flame retardant LLDPE material and a preparation method thereof. The material comprises the components in parts by weight as follows: 100 parts of LLDPE resin, 10-30 parts of a toughening compatilizer, 10-20 parts of a lubricating dispersing agent and 350-450 parts of halogen-free composite flame retardant, wherein the halogen-free composite flame retardant comprises magnesium hydroxide / aluminum hydroxide, zinc borate and microencapsulated red phosphorus in a weight ratio of (10.5-11.5):1: (1.05-1.15). The preparation method of the material comprises the steps as follows: components are poured into a high-speed mixer for mixing until the temperature is increased to 90 DEG C-105 DEG C; the components are discharged, cooled and extruded in a melting manner; then, the components are cooled in a water tank; and finally, the material is obtained through traction granulation. The halogen-free flame retardant LLDPE material has a good flame retardant property, and the limit oxygen index is higher than 40 %; and meanwhile, a mechanical property is excellent, the tensile strength is higher than 18 MPa, and the breaking elongation ratio is higher than 75%.

Owner:NANTONG XING HUA DA GAO IND CO LTD +1

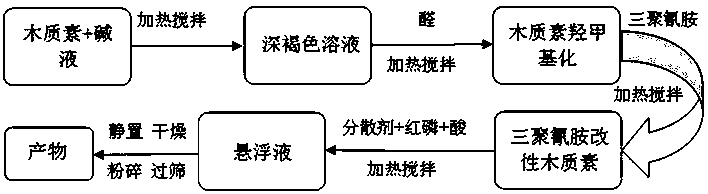

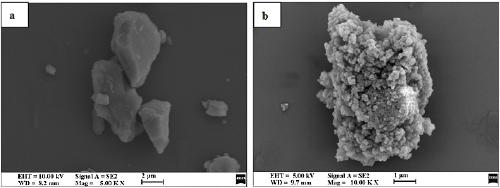

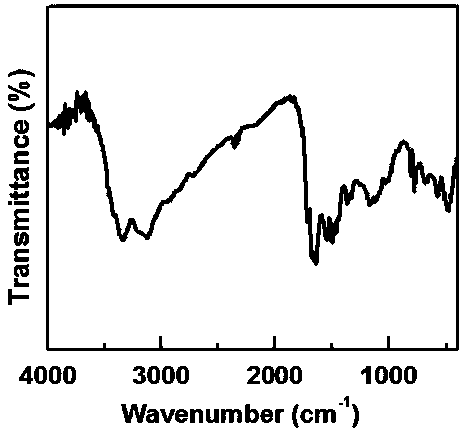

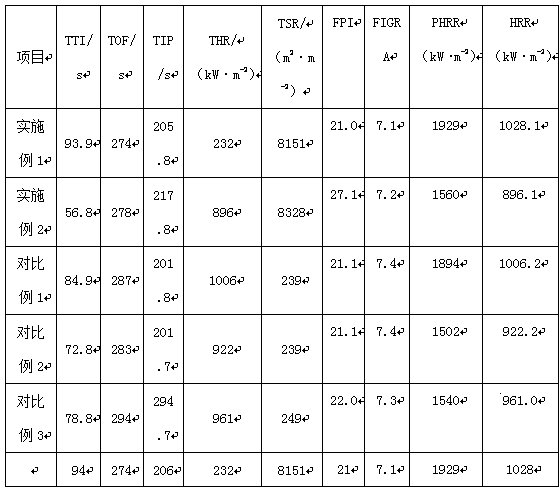

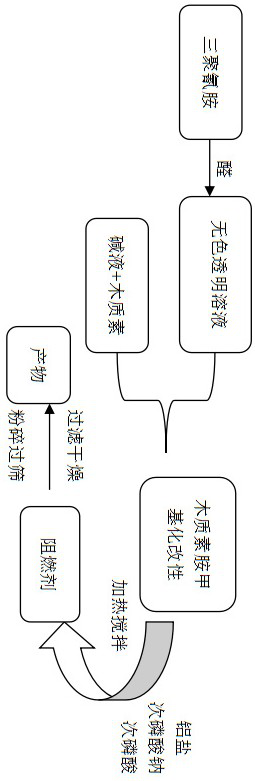

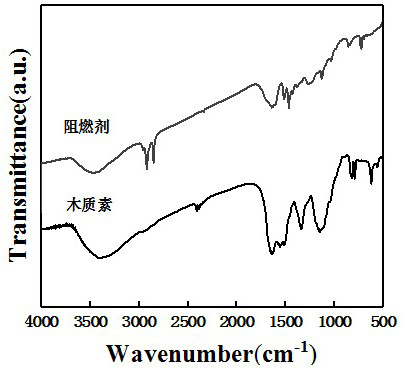

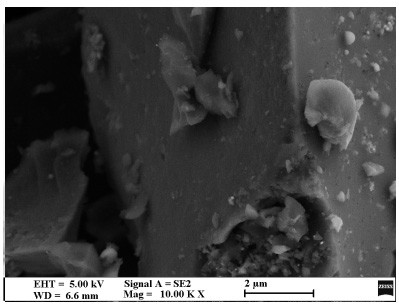

Melamine-modified lignin coated red phosphorus flame retardant and application thereof in ABS (Acrylonitrile Butadiene Styrene) resin

The invention discloses a melamine-modified lignin coated red phosphorus flame retardant and application thereof in ABS (Acrylonitrile Butadiene Styrene) resin, which belongs to the field of polymer materials. In the invention, lignin, aldehyde, melamine, red phosphorus and dispersant are mainly used as raw materials, and Mannich reaction and a chemical coprecipitation method are used to prepare melamine-modified lignin coated red phosphorus flame retardant. The melamine-modified lignin coated red phosphorus flame retardant disclosed by the invention can significantly improve the surface properties and instability of red phosphorus, and improve the compatibility with the polymer material. The flame retardant has a good flame retardant effect when applied in ABS resin, and the used lignin is a renewable biomass material, which is cheap and easy to obtain.

Owner:FUZHOU UNIV

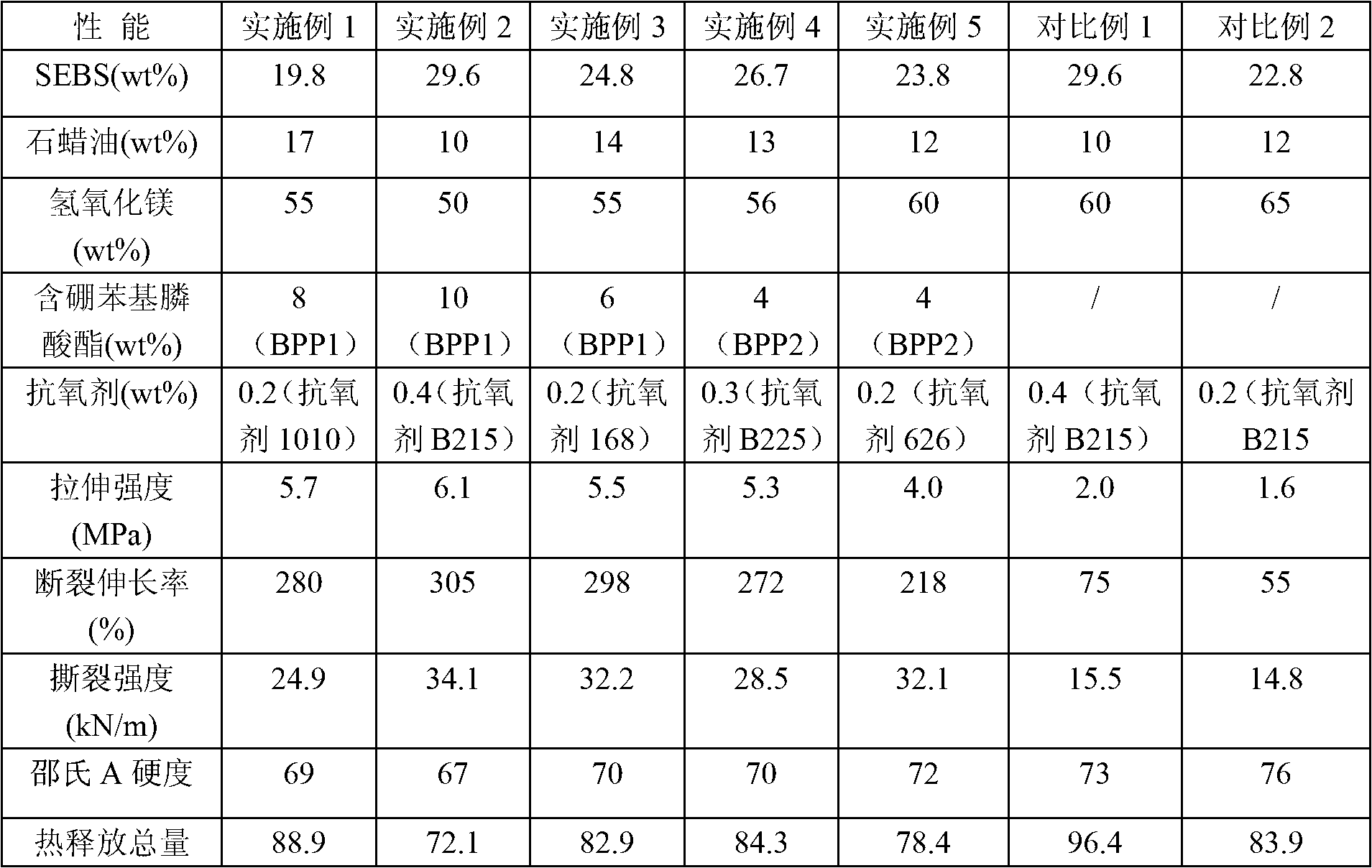

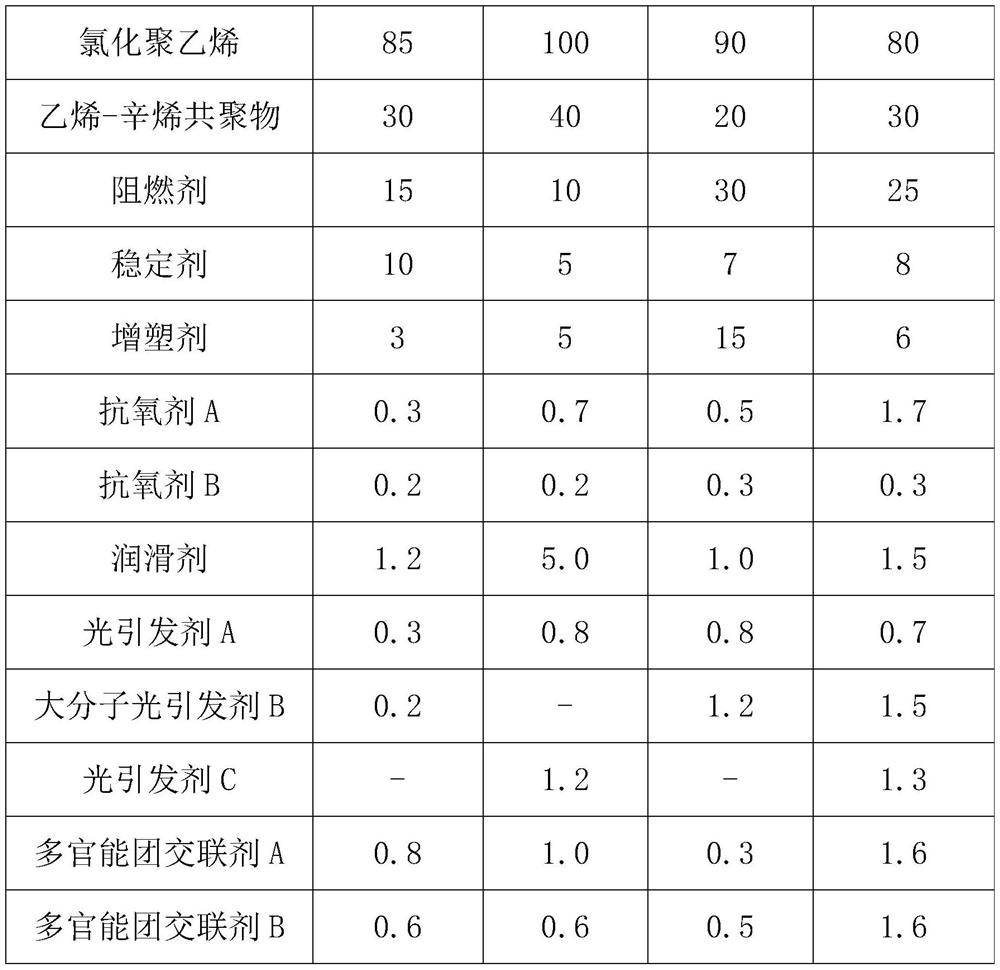

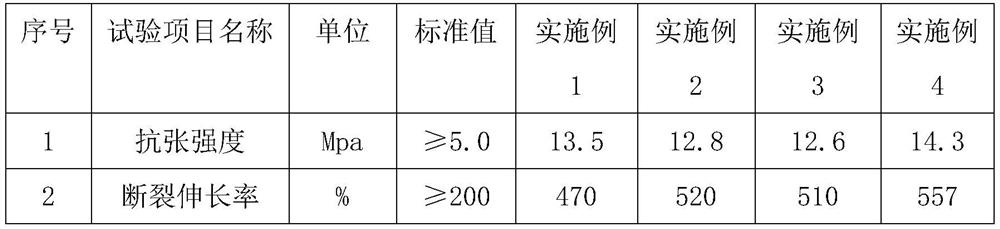

Halogen-free flame-retardant SEBS thermoplastic elastomer composition and preparation method thereof

The invention discloses a halogen-free flame-retardant SEBS (styrene-ethylene-butadiene-styrene block copolymer) thermoplastic elastomer composition and a preparation method thereof. The raw material formula of the composition is composed of the following components by mass percent: 19-30% of SEBS, 10-17% of paraffin oil, 50-60% of magnesium hydroxide, 4-10% of boron-containing phenyl phosphonate flame retardant and 0.2-0.4% of antioxidant. The composition is prepared by the steps: mixing the boron-containing phenyl phosphonate flame retardant with magnesium hydroxide in a high-speed mixer to obtain a halogen-free flame retardant complex; and sufficiently and uniformly mixing swelled SEBS, the halogen-free flame retardant complex and the antioxidant, melting, mixing and extruding by a twin-screw machine, cooling, pelleting and drying. According to the invention, the boron-containing phenyl phosphonate flame retardant not only has flame retardant synergistic action with magnesium hydroxide, but also has a effect, and can well improve the mechanical properties of the halogen-free flame-retardant SEBS thermoplastic elastomer composition, so that the processing performance of the composition is excellent.

Owner:广州市新兴电缆实业有限公司

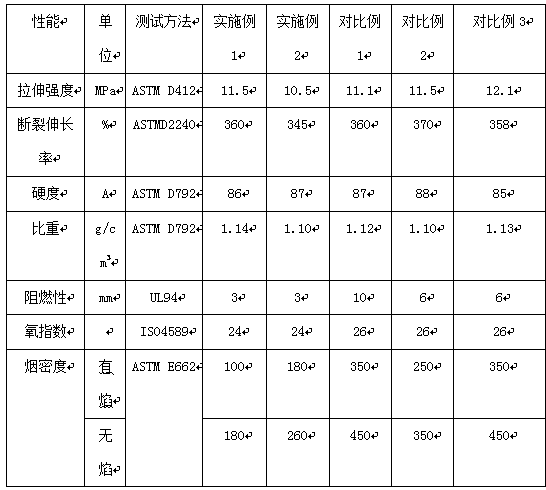

Novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material and manufacturing method thereof

InactiveCN105111667AGood flame retardant synergistic effectImprove carbon residue rate and oxygen indexPlastic/resin/waxes insulatorsInsulated cablesMaleic anhydrideChemistry

The invention discloses a novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material. The novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material is characterized by comprising, by weight, 100-104 parts of SEBS, 65-68 parts of paroline, 29-31 parts of polypropylene, 21-23 parts of maleic anhydride grafted polypropylene, 3-4 parts of antioxygen B215, 81-83 parts of magnesium hydroxide, 10.5-12 parts of expanded graphite, 1.6-1.7 parts of a silane coupling agent A-171, 8-9 parts of absolute ethyl alcohol, 2-3 parts of stearic acid, 9-11 parts of calcium carbonate, 2-3 parts of silicone master batch, 1-1.5 parts of zinc oxide, 5-7 parts of maleic acid and 1.5-2 parts of polyvinyl alcohol. According to the novel halogen-free flame retardant modification thermoplastic elastomer data line sheath material, a blend of the paroline modified SEBS and the polypropylene is used as a matrix, and the composition proportion is scientific and reasonable, so that the obtained product is high in tensile strength, good in thermostability, pliable, tough, good in processing fluidity, remarkable in flame retardant efficiency, free of halogen, environmentally friendly, capable of being widely applied to power lines, data lines and the like.

Owner:YJH ELECTRICAL EQUIP

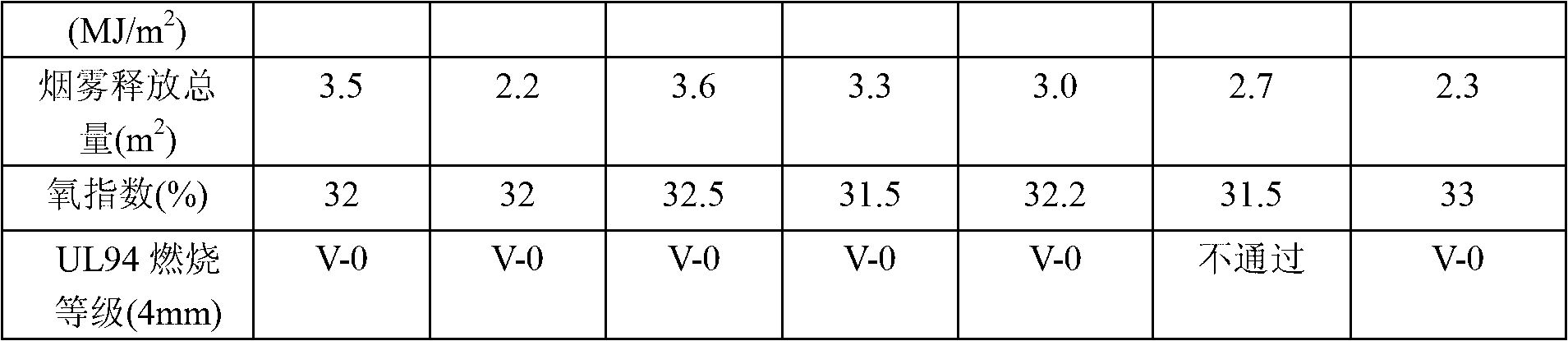

Method for reinforcing polypropylene composite material by coupling modified short carbon fiber and pyridinium-modified montmorillonite

The invention discloses a method for reinforcing polypropylene composite material by coupling modified short carbon fiber and pyridinium-modified montmorillonite. The method comprises the following steps of putting a polypropylene plastic thin sheet, a thermoplastic elastomer and a compatilizer into an air blowing drying box to dry; uniformly mixing with the short carbon fiber treated by a silanecoupling agent, the surface-modified basalt fiber and a montmorillonite-reinforced flame-retardant system; melting, mixing and extruding at the setting processing temperature; cooling the extruded strip material, blow-drying and cutting into particles; putting the particle material into a constant-temperature drying box to dry; feeding into an injection molding machine to perform injection molding. The method has the advantages that by using the pyridinium-modified montmorillonite as a reinforcing material, and using the decabromodiphenyl ethane / antimony trioxide as a flame-retardant system, after the flame-retardant agent is added, the interlayer spacing of the montmorillonite in the polypropylene composite material is increased, and the dispersivity of the montmorillonite is improved; the thermal stability and flame-retardant property of the composite material are obviously improved, and the montmorillonite and the flame-retardant system can reach better flame-retardant synergistic effect in the polypropylene material.

Owner:QUANJIAO XIANGRUI PLASTIC

Heat-resistant fire-retardant anti-freeze thermoplastic elastomer material

The invention discloses a heat-resistant fire-retardant anti-freeze thermoplastic elastomer material. The heat-resistant fire-retardant anti-freeze thermoplastic elastomer material is prepared from the following raw materials: SEBS, PP, HDPE, LDPE, naphthenic oil, maleic anhydride, terpene resin, a lubricant, silicone master batch, ethylene propylene rubber, coumarone, chlorinated polyether, organic modified bentonite, organic silicon resin, other auxiliaries, hydrated alumina, an auxiliary fire retardant, an antistatic agent and turpentine. A wear-resistant heat-resistant fire-retardant anti-freeze thermoplastic elastomer presents good heat resistance performance, and has excellent low temperature resistance performance at the same time, a low temperature brittle temperature of the wear-resistant heat-resistant fire-retardant anti-freeze thermoplastic elastomer can reach -65 DEG C, and the defect that existing elastic materials are brittle at low temperatures and easy to soften at high temperatures is overcome; an obtained shaped product is in elasticity and plasticity balance, and has a good fire retardant effect, and the thermoplastic elastomer is light in weight, excellent in weather resistance performance, and is environmentally friendly.

Owner:合肥旭亚新材料科技有限公司

Core-shell flame retardant modified epoxy resin coating and preparation method thereof

InactiveCN113402919AGood flame retardant synergistic effectReduce thermal weight loss rateFireproof paintsEpoxy resin coatingsPhosphatePolyglutamate

The invention discloses a core-shell flame retardant modified epoxy resin coating and a preparation method thereof. The preparation method comprises the following six steps: preparing an ammonium polyphosphate suspension, preparing a chitosan solution, preparing a polyglutamate solution, preparing chitosan coated ammonium polyphosphate, preparing ammonium polyphosphate co-coated with polyglutamate and chitosan, and preparing the core-shell flame retardant modified epoxy resin coating. The core-shell flame retardant prepared by the invention has a good flame retardant synergistic effect. In the thermal decomposition process, phosphoric acid and polyphosphate derived from ammonium polyphosphate promote dehydration and carbonization of chitosan and polyglutamate, so that more carbon residues are left, further decomposition of the epoxy resin is inhibited along with the residue of more carbon residues, the maximum thermal weight loss rate is reduced, and the thickness of the shell layer of the ammonium polyphosphate core-shell flame retardant co-coated with the polyglutamate and the chitosan is controllable, so that the formation of a carbon layer can be further controlled, and the flame retardance of the epoxy resin is obviously improved.

Owner:深圳市晶孚科技有限公司

Melamine hypophosphite modified lignin coated aluminum hypophosphite flame retardant as well as preparation method and application thereof in PA66 (polyamide 66)

ActiveCN114196075ASimple preparation processEase of industrial productionMelamine phosphateSodium phosphates

The invention discloses a melamine hypophosphite modified lignin coated aluminum hypophosphite flame retardant as well as a preparation method and application thereof. According to the preparation method, lignin, melamine, aldehyde, hypophosphorous acid, sodium hypophosphite and soluble aluminum salt are taken as raw materials, an amine methylation reaction, a phosphoramidation reaction and a chemical coprecipitation method are combined, a melamine modified lignin polymer is taken as a capsule wall material, in-situ generated aluminum hypophosphite is taken as a core material, and the composite material is prepared. The aluminum hypophosphite flame retardant modified by the melamine hypophosphite and coated by the lignin is prepared. The flame retardant prepared by the preparation method disclosed by the invention is wide in raw material source, simple in synthesis process and good in thermal stability, the capsule wall material melamine hypophosphite modified lignin in the flame retardant is good in compatibility with a high polymer material, and the influence of the flame retardant on the mechanical property of PA66 can be reduced; and the capsule material melamine hypophosphite modified lignin and the core material aluminum hypophosphite have a remarkable flame-retardant synergistic effect, so that the flame-retardant material has very high flame-retardant efficiency when being used in PA66, and molten drops of PA66 can be effectively inhibited.

Owner:FUZHOU UNIV

Heat-resisting and flame-retardant epoxy resin adhesive

InactiveCN107400492AImprove adhesionImprove heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCalcium silicateAluminum silicate

The invention discloses a heat-resisting and flame-retardant epoxy resin adhesive. The heat-resisting and flame-retardant epoxy resin adhesive is prepared from the following raw materials in parts by weight: 65 to 85 parts of epoxy resin with a fluorene-containing structure, 3 to 15 parts of phenolic epoxy resin, 10 to 25 parts of 2-ethyl-hexyl glycidyl ether, 20 to 35 parts of 9,9-bis(4-aminophenyl) fluorene, 5 to 12 parts of 2,6,10-trimethyl-2,6,10-triazaundecane, 2 to 4.5 parts of curing accelerator, 20 to 35 parts of flexibilizer, 2 to 8 parts of pentaerythritol, 1 to 5 parts of ammonium polyphosphate, 2 to 15 parts of phosphorus and nitrogen flame retardant, 0.2 to 1.3 parts of defoaming agent, 0.2 to 1.5 parts of stabilizer, 1 to 5 parts of polyetheretherketone, 2 to 5 parts of calcium silicate, 1 to 5 parts of chlorite, 1 to 4 parts of aluminum silicate, 1 to 2 parts of magnesium oxide and 2 to 5 parts of expandable graphite. The heat-resisting and flame-retardant epoxy resin adhesive disclosed by the invention has the advantages of high heat resistance, excellent flame retardant property and high bonding strength with a matrix.

Owner:安徽大松树脂有限公司

Flame-retardant anti-bacterial sizing agent of cotton-linen fiber fabric, and preparation method and application method of flame-retardant anti-bacterial sizing agent

InactiveCN108018711ACurb spreadEffective isolationBiochemical fibre treatmentHeat resistant fibresFiberBromine

The invention discloses a flame-retardant anti-bacterial sizing agent of a cotton-linen fiber fabric, and a preparation method and an application method of the flame-retardant anti-bacterial sizing agent. After a special phosphorus-bromine synergic system is applied to the cotton-linen fiber fabric, a brominated flame retardant is decomposed under high temperature so as to be quickly dispersed toa surface of a cotton-linen fiber, so that short-time combustion and flame spread of the cotton-linen fiber fabric are inhibited; a phosphorus flame retardant is decomposed to obtain phosphoric acid,and the phosphoric acid is adsorbed to a surface of a cotton fiber so as to form a carbonization layer, so that combustible materials can be effectively isolated, and a favorable flame-retardant synergistic effect is achieved.

Owner:绍兴再成阻燃科技有限公司

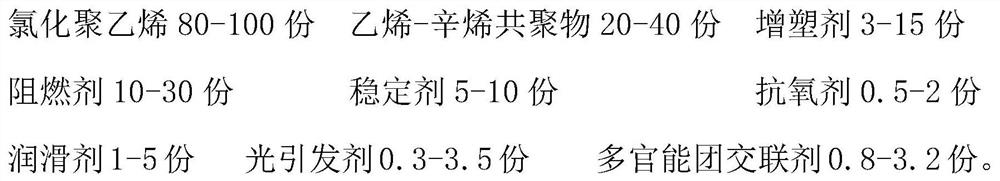

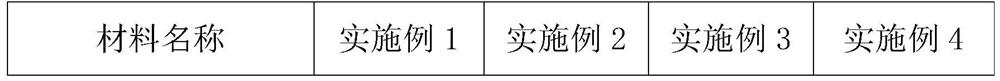

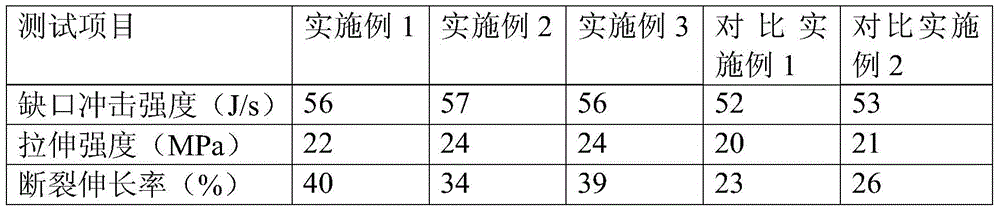

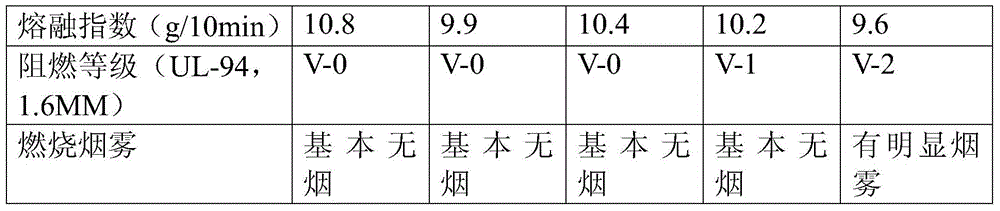

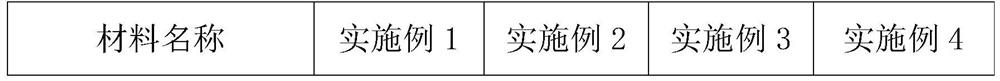

Ultraviolet irradiation crosslinked chlorinated polyethylene cable material and preparation method thereof

ActiveCN112574518AGood compatibilityInitiation efficiency is highPlastic/resin/waxes insulatorsPolymer sciencePlasticizer

The invention discloses an ultraviolet irradiation crosslinked chlorinated polyethylene cable material and a preparation method thereof. The cable material comprises the following raw material components, by weight: 80-100 parts of chlorinated polyethylene, 20-40 parts of ethylene-octene copolymer, 3-15 parts of a plasticizer, 10-30 parts of a flame retardant, 5-10 parts of a stabilizer, 0.5-2 part of an antioxidant, 1-5 parts of a lubricant, 0.3-3.5 parts of a photoinitiator and 0.8-3.2 parts of a polyfunctional crosslinking agent. The cable material is prepared in an ultraviolet irradiationcrosslinking mode, energy consumption is low, the cable material is environmentally friendly, online crosslinking can be achieved after the material is extruded, procedures are reduced in the production process, chlorinated polyethylene is excellent in mechanical property, flame retardant property and heat resistance after ultraviolet crosslinking, and actual industrial production requirements canbe met. All the properties of the cable material can meet the requirements of IE4 type in GB / T 5013-2008.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Halogen-free flame-retardant SEBS thermoplastic elastomer composition and preparation method thereof

ActiveCN102702663BGood flame retardant synergistic effectImprove mechanical propertiesPolymer scienceAntioxidant

The invention discloses a halogen-free flame-retardant SEBS (styrene-ethylene-butadiene-styrene block copolymer) thermoplastic elastomer composition and a preparation method thereof. The raw material formula of the composition is composed of the following components by mass percent: 19-30% of SEBS, 10-17% of paraffin oil, 50-60% of magnesium hydroxide, 4-10% of boron-containing phenyl phosphonate flame retardant and 0.2-0.4% of antioxidant. The composition is prepared by the steps: mixing the boron-containing phenyl phosphonate flame retardant with magnesium hydroxide in a high-speed mixer to obtain a halogen-free flame retardant complex; and sufficiently and uniformly mixing swelled SEBS, the halogen-free flame retardant complex and the antioxidant, melting, mixing and extruding by a twin-screw machine, cooling, pelleting and drying. According to the invention, the boron-containing phenyl phosphonate flame retardant not only has flame retardant synergistic action with magnesium hydroxide, but also has a effect, and can well improve the mechanical properties of the halogen-free flame-retardant SEBS thermoplastic elastomer composition, so that the processing performance of the composition is excellent.

Owner:广州市新兴电缆实业有限公司

Flame retardant trichloroethyltribromophenoxychloropropylsilicate ester compound and preparation method thereof

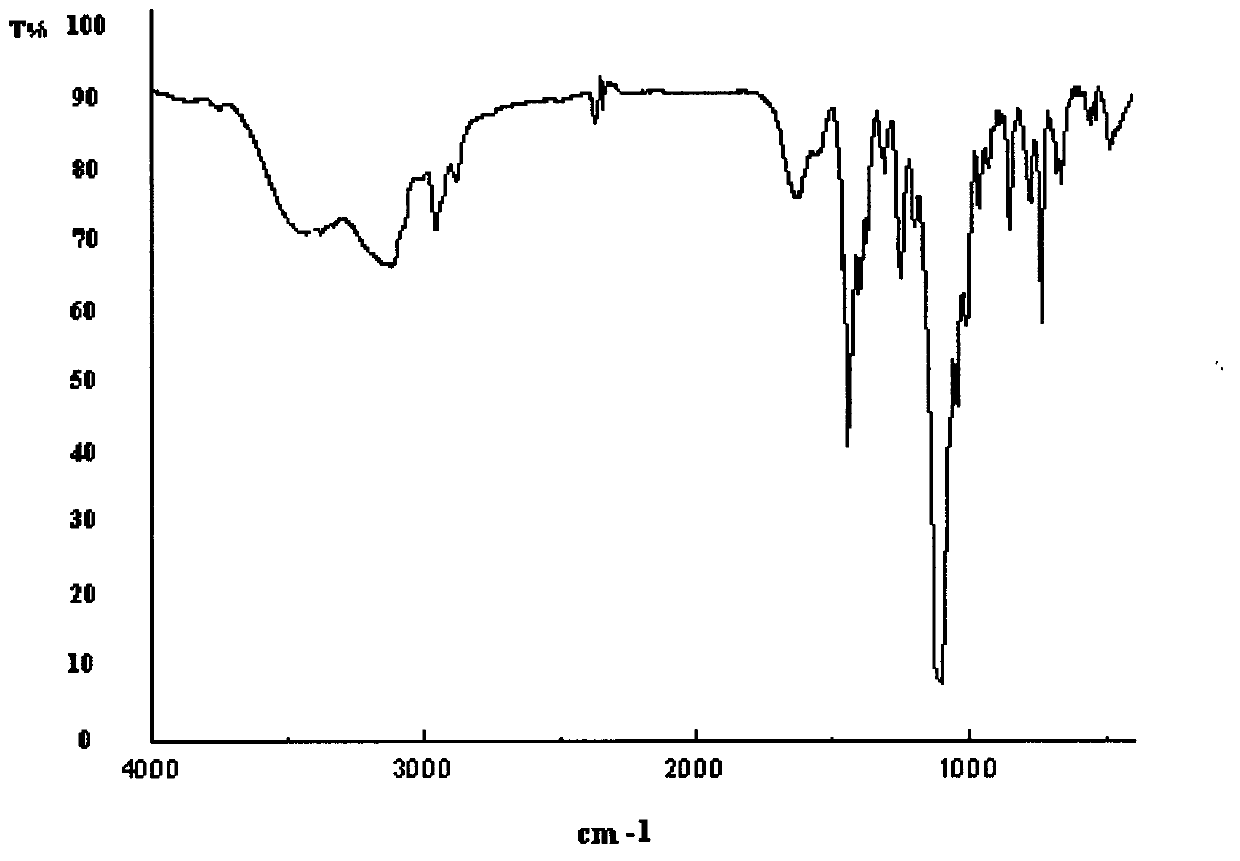

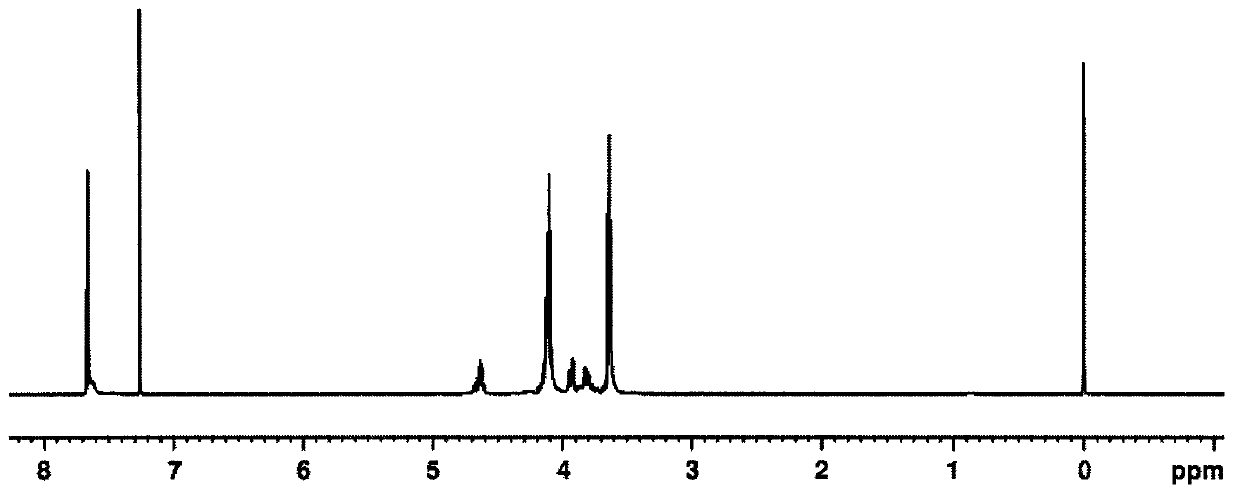

ActiveCN102731546AImprove flame retardant performanceGood symmetrySilicon organic compoundsEpoxyLiquid product

The invention relates to a silicon-halogen synergic flame retardant compound and a preparation method thereof. The compound has the structural formula shown in the specification. The preparation method comprises the following steps of: at 20 DEG C, dropwise adding equimolar organic solvent solution of tribromophenylepoxypropyl ester into silicon tetrachloride; after the solution is completely added dropwise, keeping temperature at 60-80 DEG C, and reacting for 4-6 hours; dropwise adding chloroethanol of a certain molar ratio at 35 DEG C; keeping temperature at 50-70 DEG C and reacting for 3-6 hours; and purifying to obtain a light yellow liquid product tri(2-chloroethyl)-2-chloro-3-(2,4,6-tribromophenoxy)propyl silicate. The compound is an efficient flame retardant and is suitable to be used as a flame-retardant plasticizer of polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the production technology is simple, the equipment investment is low, and the industrial production is easy to realize.

Owner:张家港市乐余科创园投资发展有限公司

A kind of flame retardant molecular chain grafted mesoporous silica modified epoxy resin coating and preparation method thereof

ActiveCN113265186BGood flame retardant synergistic effectInhibitionFireproof paintsEpoxy resin coatingsEpoxyPolymer science

The invention specifically discloses a preparation method of flame retardant molecular chain grafted mesoporous silica modified epoxy resin coating and the preparation method thereof. The method involves the synthesis of flame-retardant molecular chains and the preparation process of aminated mesoporous silicon dioxide, and the flame-retardant molecular chain grafted mesoporous silicon dioxide is obtained through ammonium phosphate reaction. Using epoxy resin, flame retardant molecular chain grafted mesoporous silica, monoglyceride stearate, organic microwax powder, and dimethyl silicone oil as raw materials, a flame retardant molecular chain grafted mesoporous silica modified epoxy resin was synthesized. Resin coating. This invention solves the problems of weak flame retardancy of inorganic compound flame retardants and poor toughness of traditional epoxy resin coatings. Through the good synergistic effect of flame retardant molecular chains and mesoporous silica, the resistance of epoxy resin coatings is improved. flammability and mechanical properties.

Owner:深圳市锦旺兴绝缘材料有限公司

Composite flame retardant containing microcapsule-coated expansion flame retardant and preparation method thereof

InactiveCN103724666BHigh flame retardant efficiencyImprove flame retardant performancePolymer scienceHindered amine light stabilizers

Owner:LIAONING TECHNICAL UNIVERSITY

Halogen-free flame-retardant linear low-density polyethylene material and preparation method thereof

ActiveCN103483676BImprove mechanical propertiesExcellent formabilityLow-density polyethyleneLinear low-density polyethylene

The invention discloses a halogen-free flame-retardant linear low-density polyethylene material and a preparation method thereof. The material is prepared from the following components in parts by weight: 100 parts of LLDPE resin, 10-30 parts of a toughening compatibilizer, a lubricant 10-20 parts of dispersant, 350-450 parts of halogen-free composite flame retardant; halogen-free composite flame retardant is composed of magnesium hydroxide / aluminum hydroxide, zinc borate and microcapsule red phosphorus according to (10.5-11.5):1:( 1.05~1.15) weight ratio composition. The preparation method of the material is as follows: pour the components into a high-speed mixer and mix until the temperature rises to 90°C to 105°C, the material is cooled, melted and extruded, then cooled in a water tank, and finally pulled and pelletized. The halogen-free flame-retardant linear low-density polyethylene material of the invention has good flame-retardant performance and a limiting oxygen index of more than 40%; meanwhile, it has excellent mechanical properties, has a tensile strength of more than 18 MPa and an elongation at break of more than 75%.

Owner:NANTONG XING HUA DA GAO IND CO LTD +1

Chloro- and bromo-containing silicate flame retardant compound and preparation method thereof

ActiveCN102731825BImprove flame retardant performanceGood symmetrySilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a silicon-halogen synergistic flame retardant plasticizer tri(2-chloroethyl)-2-chloro-3-(2, 4, 6-tribromophenoxy)propyl silicate compound and a preparation method of the compound. The compound is characterized in that the structure is shown as follows in the specification. The method comprises the steps of adding tetrachlorosilane into a reactor, dripping equivalent molartribromophenylglycidyl ether organic solvent solution, performing a heat preservation process for a reaction at 60 DEG C-80 DEG C for 4-6 hours after the organic solvent solution is dripped, pumping ethylene oxide into the 40 DEG C solution at a certain molar ratio and below the liquid surface, performing another heat preservation process for another reaction at 50 DEG C-60 DEG C for 3-5 hours, and purifying to obtain a yellow liquid of tri(2-chloroethyl)-2-chloro-3-(2, 4, 6-tribromophenoxy) propyl silicate. The compound is a highly effective flame retardant and used as the flame retardant for poly(vinyl chloride), polyurethane, epoxy resin, unsaturated resin and the like. The method is simple in manufacturing technique, low in investment, and easily realizes the industrial production.

Owner:张家港市乐余科创园投资发展有限公司

Method for preparing mesoporous silica/ammonium polyphosphate compound fire retardant

InactiveCN102643655BImprove thermal stabilityImprove protectionFireproof paintsO-Phosphoric AcidNanoparticle

A method for preparing a mesoporous silica / ammonium polyphosphate composite flame retardant, comprising the following steps: adding 85% phosphoric acid and urea into a reactor according to a certain ratio, mixing, and reacting at a low temperature for a period of time to obtain a transparent solution; Then add an appropriate amount of mesoporous silica, fully soak, filter and separate, rinse with absolute ethanol, and dry naturally; send the obtained powder into a box furnace, foam at high temperature, polymerize and solidify for a period of time, crush and sieve, that is A mesoporous silica / ammonium polyphosphate composite flame retardant is obtained. The composite flame retardant prepared by the invention is nano-particles with good dispersibility, ammonium polyphosphate is generated "in situ" in the silica carrier, has good moisture resistance, is not easy to migrate, has excellent synergistic flame retardant and smoke suppression effects, and can Widely used in flame retardant of various materials.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

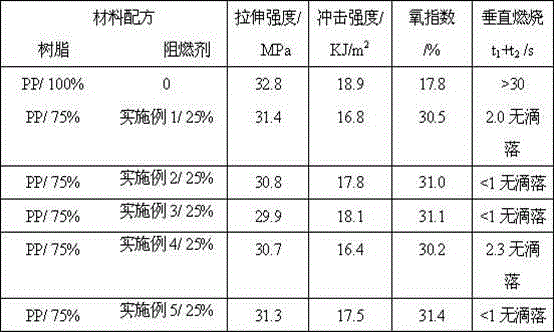

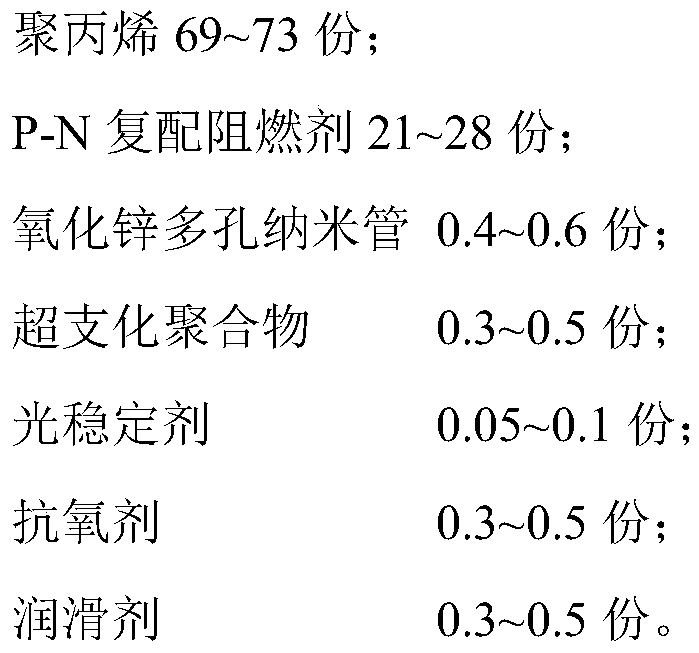

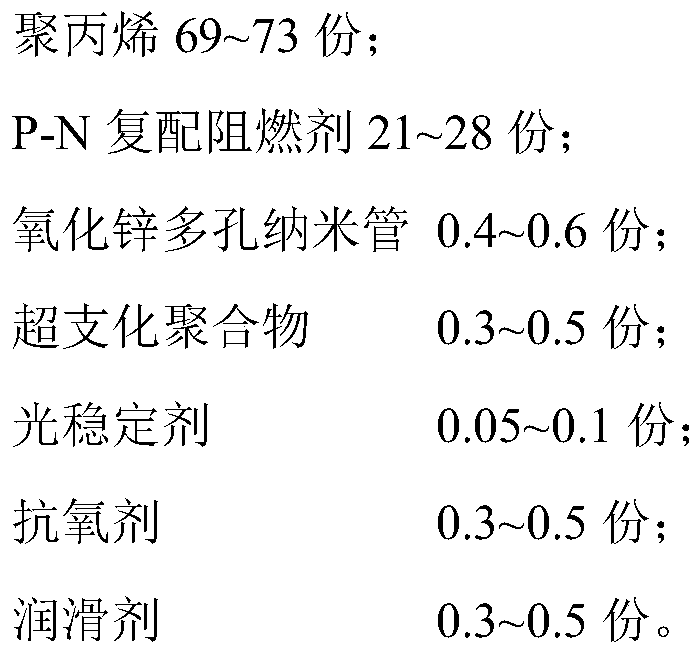

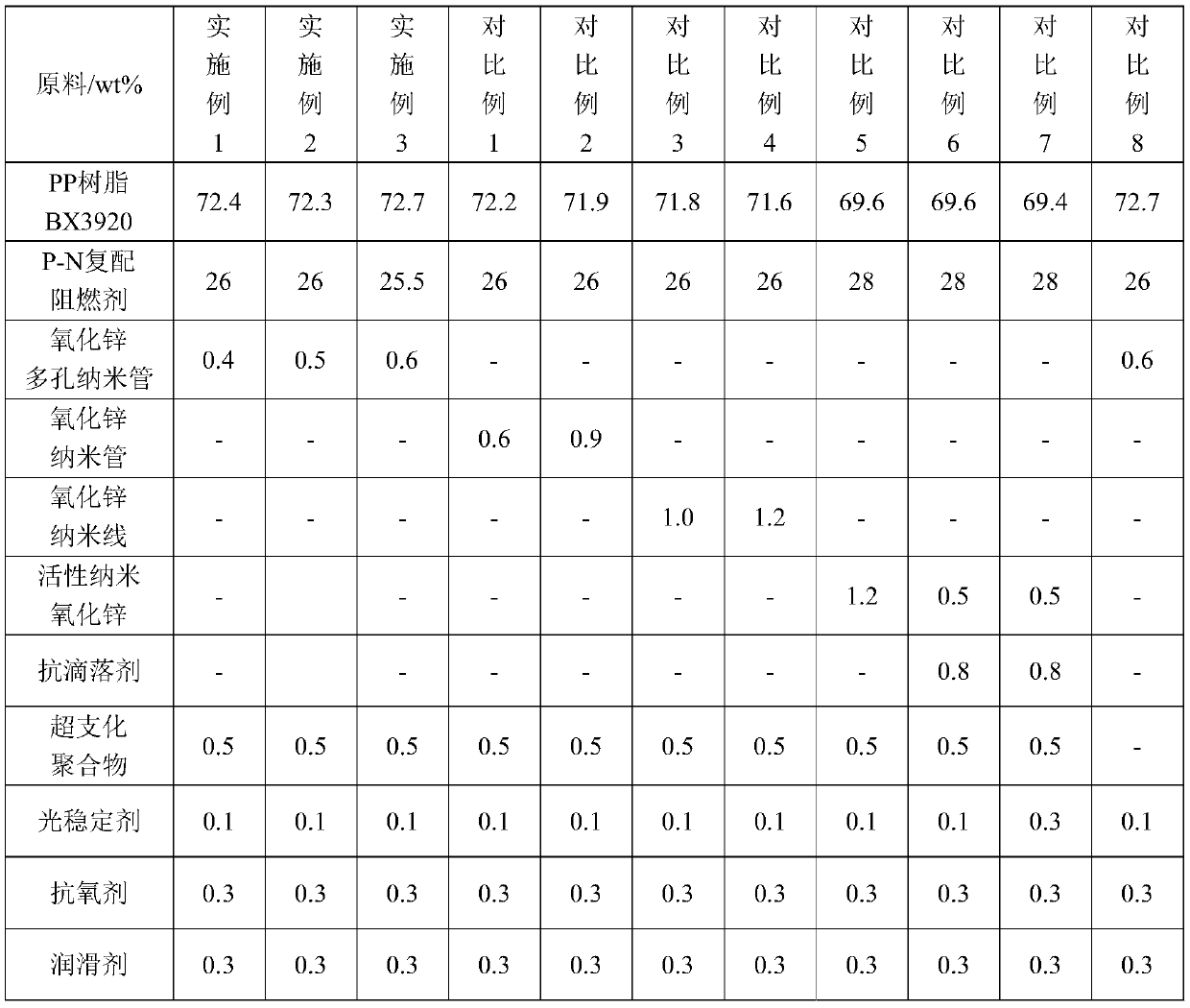

A kind of zinc oxide porous nanotube synergistic anti-ultraviolet and halogen-free flame-retardant polypropylene composite material and its preparation method

ActiveCN108239344BOvercome the disadvantages of reducing material fluidityGood compatibilityPolypropylene compositesPoly tetra fluoro ethylene

The invention discloses a zinc oxide porous nanotube synergized anti-ultraviolet halogen-free flame-retardant polypropylene composite material and a preparation method thereof. The polypropylene composite material consists of the following raw materials in parts by mass: polypropylene, P-N compound flame retardant, zinc oxide porous nanotubes, hyperbranched polymer, light stabilizer, antioxidant and lubricant. The invention also discloses the preparation method of the anti-ultraviolet halogen-free flame-retardant polypropylene composite material. According to the zinc oxide porous nanotube synergized anti-ultraviolet halogen-free flame-retardant polypropylene composite material and the preparation method thereof, surface treated zinc oxide porous nanotubes are used to assist the dispersionof the hyperbranched polymer, so that the compatibility and dispersibility of the hyperbranched polymer in a polypropylene matrix are improved, and better UV resistance and a better flame retardant synergistic effect are further exerted; the zinc oxide nanotubes of porous size scale are more prominent on carbon formation efficiency and drip-proofing effect, so that the prepared polypropylene composite material also overcomes the drawback that a traditional anti-dripping agent PTFE significantly reduces the fluidity of a material, thereby bringing a great convenience for the processing of thin-walled multi-mold cavity products.

Owner:GUANGDONG JUSHI CHEM CO LTD

A kind of halogen-free flame-retardant cross-linked polypropylene and its preparation method and application

The invention belongs to the technical field of high-molecular materials, and discloses halogen-free flame-retardant crosslinked polypropylene as well as a preparation method and application thereof. The halogen-free flame-retardant crosslinked polypropylene is obtained through melt extrusion and granulation by uniformly mixing the following materials in parts by mass: 37.5-50 parts of polypropylene, 25 parts of melamine, 0.1-0.6 part of cross-linking agents, 0.03-0.2 part of nanometer organic silicon, 0.4-0.8 part of lubricating agents and 0.2-0.4 part of antioxidants and then adding the materials to a double-screw extruder. The halogen-free flame-retardant crosslinked polypropylene disclosed by the invention obviously enhances the flame retardance and strength of a material through the addition of the nanometer organic silicon and forms the crosslinked grid through the addition of the cross-linking agents; the obtained material has low-smoke property.

Owner:广州市海弘塑料科技有限公司

A kind of ultraviolet light irradiation cross-linked chlorinated polyethylene cable material and preparation method thereof

ActiveCN112574518BGood compatibilityInitiation efficiency is highPlastic/resin/waxes insulatorsUltraviolet lightsCross linker

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Flame retardant trichloroethyltribromophenoxychloropropylsilicate ester compound and preparation method thereof

ActiveCN102731546BImprove flame retardant performanceGood symmetrySilicon organic compoundsEpoxyLiquid product

The invention relates to a silicon-halogen synergic flame retardant compound and a preparation method thereof. The compound has the structural formula shown in the specification. The preparation method comprises the following steps of: at 20 DEG C, dropwise adding equimolar organic solvent solution of tribromophenylepoxypropyl ester into silicon tetrachloride; after the solution is completely added dropwise, keeping temperature at 60-80 DEG C, and reacting for 4-6 hours; dropwise adding chloroethanol of a certain molar ratio at 35 DEG C; keeping temperature at 50-70 DEG C and reacting for 3-6 hours; and purifying to obtain a light yellow liquid product tri(2-chloroethyl)-2-chloro-3-(2,4,6-tribromophenoxy)propyl silicate. The compound is an efficient flame retardant and is suitable to be used as a flame-retardant plasticizer of polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the production technology is simple, the equipment investment is low, and the industrial production is easy to realize.

Owner:张家港市乐余科创园投资发展有限公司

Calcium molybdate migration-resistant flame-retardant sheath material and preparation method thereof

InactiveCN106751368AGood flame retardant synergistic effectImprove carbon residue rate and oxygen indexMaleic anhydrideCarbon black

The invention discloses a calcium molybdate migration-resistant flame-retardant sheath material which is prepared from the following raw materials in parts by weight: 90-94 parts of SEBS (styrene-ethylene-butadiene-styrene), 65-68 parts of paraffin oil, 29-31 parts of stearic acid, 21-23 parts of stearic acid graft maleic anhydride, 3-4 parts of antioxidant B215, 81-83 parts of magnesium hydroxide, 4.3-5 parts of graphene, 1.6-1.7 parts of silane coupling agent A-171, 8-9 parts of anhydrous ethanol, 6-8 parts of pentaerythritol, 12-14 parts of carbon black, 6-7.5 parts of calcium molybdate, 3-4 parts of antioxidant 168, 13-15 parts of natural rubber and 1-1.5 parts of calcium zinc heat stabilizer. By using the paraffin-oil-modified SEBS / stearic acid blend as the matrix, the components are proportioned scientifically and reasonably, so the matrix has favorable compatibility with the flame retardant and other compounding agents and does not have the phenomenon of compounding agent migration. The product has the advantages of excellent flame retardancy, favorable mechanical properties and favorable low-temperature flexibility, can not have the phenomenon of migration and precipitation after being used for a long time, and can be used for data lines and the like.

Owner:饶欢欢

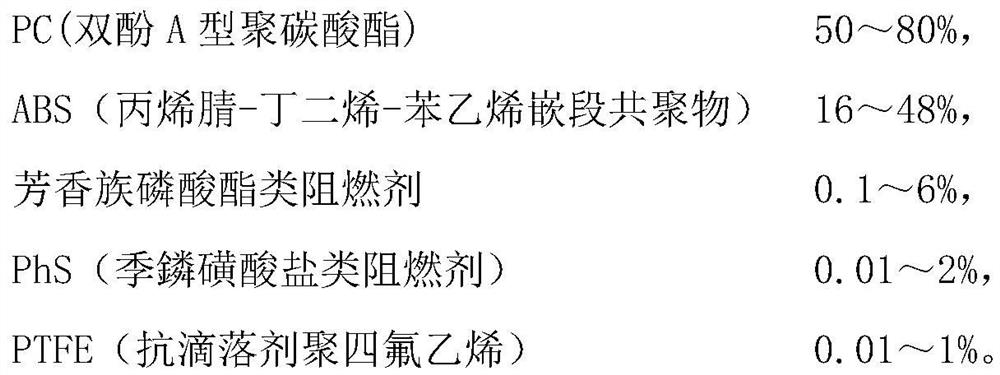

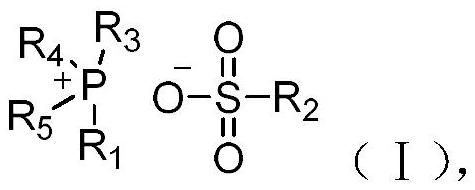

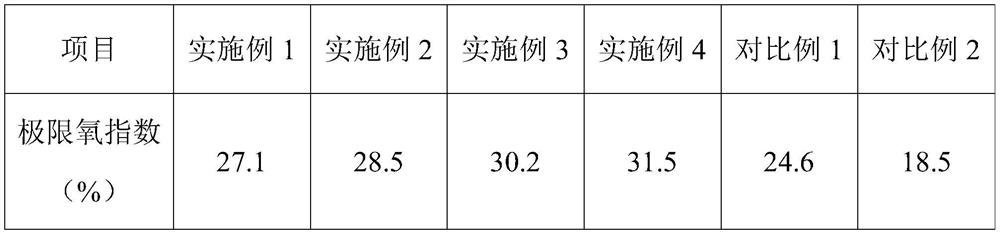

A kind of pc/abs flame retardant composite material and preparation method thereof

ActiveCN111117198BImprove thermal stabilityImprove water resistancePhosphoric Acid EstersPolymer science

The invention discloses a PC / ABS flame-retardant composite material and a preparation method thereof; the material comprises: 50-80% of bisphenol A polycarbonate, acrylonitrile-butane 16-48% ene-styrene block copolymer, 0.1-6% aromatic phosphate flame retardant, 0.01-2% quaternary phosphonium sulfonate flame retardant, 0.01-2% anti-dripping agent polytetrafluoroethylene 1%. In the present invention, specific quaternary phosphonium sulfonate flame retardants and aromatic phosphate flame retardants are synergistically used in PC / ABS alloys to obtain a good flame retardant synergistic effect, and maintain good thermal stability of the material, Hydrolysis resistance and tensile properties, etc., to prepare flame-retardant composite materials with excellent properties.

Owner:SHANGHAI JIAO TONG UNIV

Flame-retardant molecular chain grafted mesoporous silica modified epoxy resin coating and preparation method thereof

ActiveCN113265186AGood flame retardant synergistic effectInhibitionFireproof paintsEpoxy resin coatingsSilicone fluidInorganic chemical compound

The invention particularly discloses a flame-retardant molecular chain grafted mesoporous silica modified epoxy resin coating and a preparation method of the flame-retardant molecular chain grafted mesoporous silica modified epoxy resin coating. The method relates to synthesis of a flame-retardant molecular chain and a preparation process of aminated mesoporous silica, and the flame-retardant molecular chain grafted mesoporous silica is obtained through an ammonium phosphate reaction. The flame-retardant molecular chain grafted mesoporous silica modified epoxy resin coating is synthesized by taking epoxy resin, flame-retardant molecular chain grafted mesoporous silica, glycerol monostearate, organic micronized wax powder and simethicone as raw materials. The problems that an inorganic compound flame retardant is weak in flame retardance, a traditional epoxy resin coating is poor in toughness and the like are solved; and the flame retardance and mechanical performance of the epoxy resin coating are improved through the good synergistic effect of the flame-retardant molecular chain and mesoporous silica.

Owner:深圳市锦旺兴绝缘材料有限公司

Composite protection sleeve material with added carbon fibers for high-shielding data line and preparing method of composite protection sleeve material

The invention discloses a composite protection sleeve material with added carbon fibers for a high-shielding data line. The composite protection sleeve material is composed of, by weight, 100-104 parts of SEBS, 65-68 parts of paraffin oil, 29-31 parts of polypropylene, 21-23 parts of maleic anhydride grafted polypropylene, 3-4 parts of antioxidant B215, 81-83 parts of magnesium hydrate, 4.3-5 parts of expanded graphite, 1.6-1.7 parts of silane coupling agent A-171, 8-9 parts of absolute ethyl alcohol, 2-3 parts of zinc borate, 8-9.5 parts of natural rubber, 13-15 parts of carbon fiber, 4-6 parts of superfine carbon black, 2-2.5 parts of sodium dodecyl benzene sulfonate and a proper amount of distilled water. According to the composite protection sleeve material with the added carbon fibers for the high-shielding data line, the blend of the paroline, the modified SEBS and the polypropylene serves as the base, in the process of processing the surfaces of the carbon fibers and the superfine carbon black and adding the carbon fibers and the superfine carbon black to a product, the dispersibility of powder can be improved, meanwhile, a very good shielding effect is achieved, the bending resisting performance of the product can be improved, and the composite protection sleeve material can be used for manufacturing flexible lines such as data lines.

Owner:YJH ELECTRICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com