Heat-resistant fire-retardant anti-freeze thermoplastic elastomer material

A thermoplastic elastomer and heat-resistant technology, which is applied in the field of heat-resistant, flame-retardant and frost-resistant thermoplastic elastomer materials, can solve the problems of cable electrical performance and environmental resistance, unsatisfactory high-temperature and low-temperature resistance, and inability to be strongly hydrophobic. , to achieve the effects of reducing smoke generation, good mechanical properties and processing properties, and solving the impact on the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

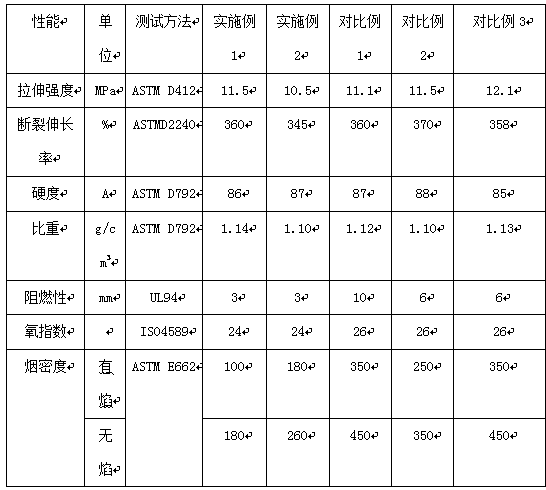

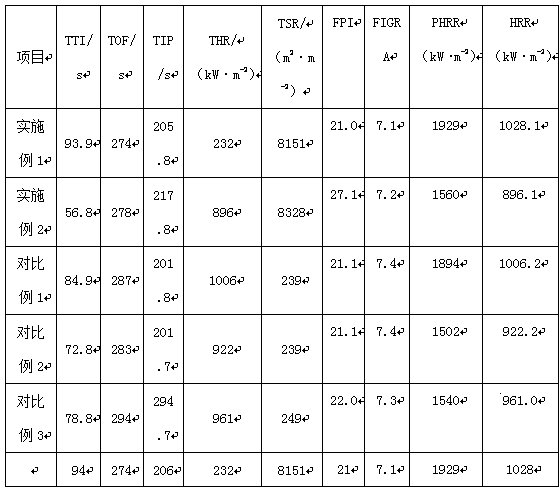

Embodiment 1

[0020] A heat-resistant, flame-retardant and antifreeze thermoplastic elastomer material, which is prepared from the following raw materials in parts by weight: 44 parts of SEBS, 55 parts of PP, 47 parts of HDPE, 7 parts of LDPE, 35 parts of naphthenic oil, 2 parts of maleic anhydride, and terpene resin 3 parts, 1 part of lubricant, 2 parts of silicone masterbatch, 2.4 parts of ethylene propylene rubber, 0.43 parts of coumarone, 4 parts of chlorinated polyether, 13 parts of organic modified bentonite, 0.2 parts of silicone resin, other additives 0.5 parts, 9.4 parts of hydrated alumina, 2.4 parts of auxiliary flame retardant, 1.0 parts of antistatic agent, and 0.2 parts of turpentine.

[0021] A heat-resistant, flame-retardant, and frost-resistant thermoplastic elastomer material. The preparation method includes the following steps: weighing each raw material, placing SEBS in a high-speed mixer, adding naphthenic oil, and stirring at a low speed to make SEBS fully absorb oil an...

Embodiment 2

[0028] A heat-resistant, flame-retardant and antifreeze thermoplastic elastomer material, prepared from the following raw materials in parts by weight: 51 parts of SEBS, 65 parts of PP, 46 parts of HDP, 8 parts of LDPE, 45 parts of naphthenic oil, 2 parts of maleic anhydride, and terpene resin 3 parts, 2 parts of lubricant, 2 parts of silicone masterbatch, 2.4 parts of ethylene propylene rubber, 0.42 parts of coumarone, 6 parts of chlorinated polyether, 13 parts of organic modified bentonite, 0.2 parts of silicone resin, other additives 0.5 parts, 8.1 parts of hydrated alumina, 2.4 parts of auxiliary flame retardant, 0.8 parts of antistatic agent, and 0.2 parts of turpentine.

[0029]A heat-resistant, flame-retardant, and frost-resistant thermoplastic elastomer material. The preparation method includes the following steps: weighing each raw material, placing SEBS in a high-speed mixer, adding naphthenic oil, and stirring at a low speed to make SEBS fully absorb oil and expand a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com