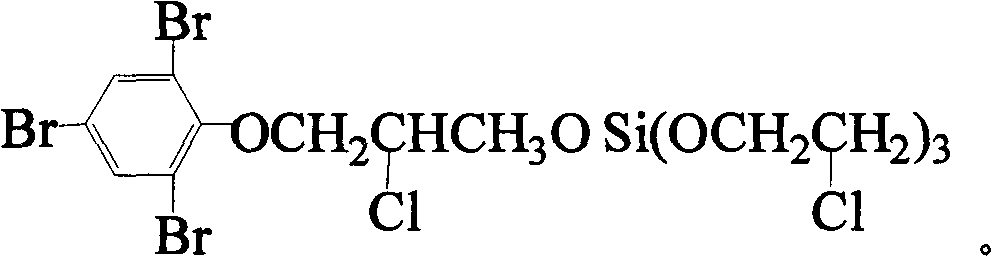

Chloro- and bromo-containing silicate flame retardant compound and preparation method thereof

A technology of compound and flame retardant plasticizer, which is applied in the field of tri-2-chloro-3-propyl silicate compound and its preparation, to achieve the effects of cheap and easy-to-obtain raw materials, easy large-scale production, and good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

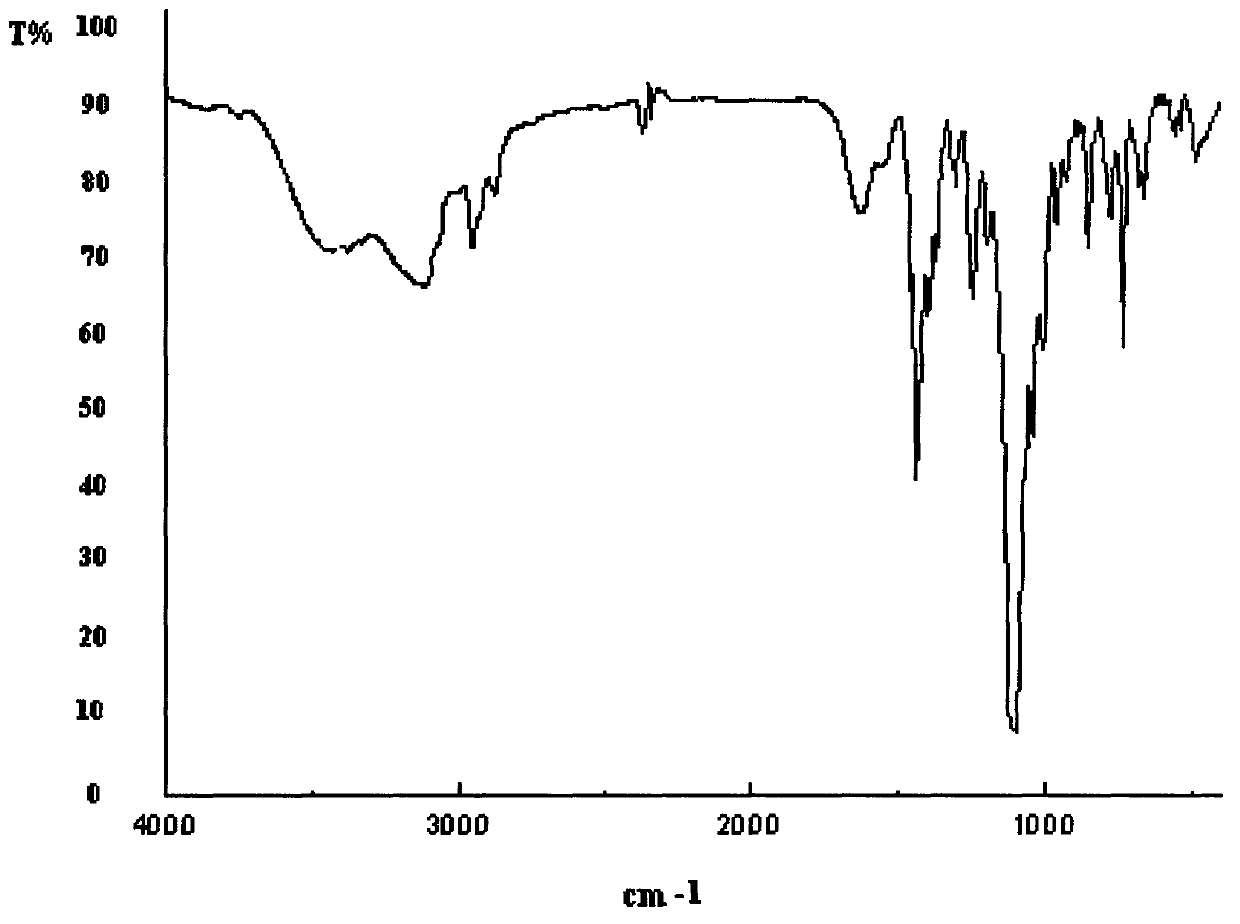

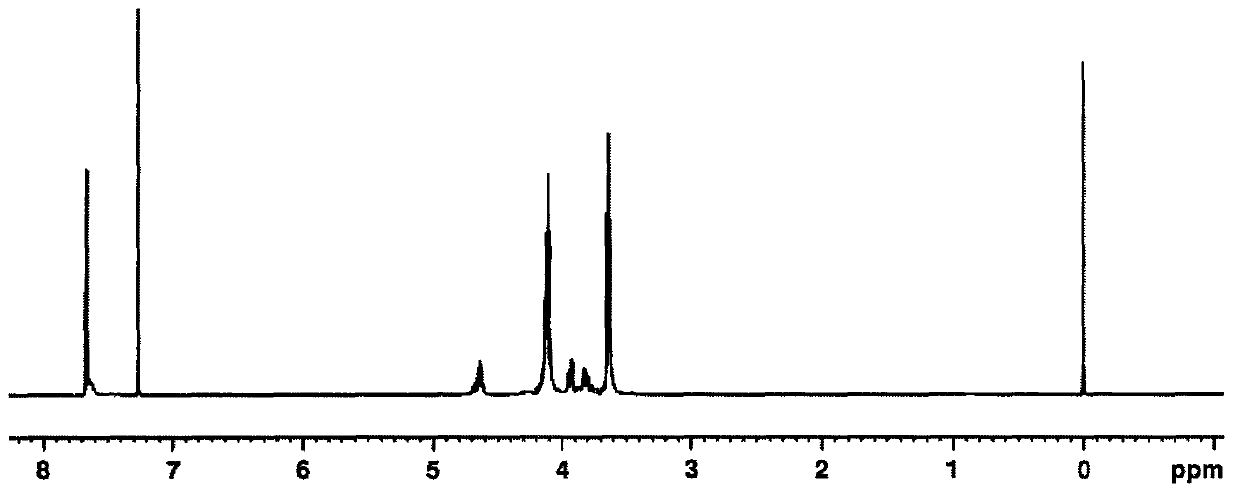

[0025] Example 1 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of tetrahydrofuran, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and add 50ml of it dropwise within 60min at 20°C. A solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in tetrahydrofuran, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 60°C within 1 hour, kept for 6 hours, and then cooled to 40°C , and an extremely flexible expansion soft sealing sleeve is installed on the upper mouth of the condenser tube, 4.0g (0.09mol) of ethylene oxide is introduced, and the temperature of the feeding process is controlled not to exceed 45°C, and then kept at 50°C for 5h, the pH of the reaction system When the value reaches 5-6, the reaction is over, and the tetrahydrofuran (recycled) is distilled off under reduced pressure to obtain a light yellow liquid si...

Embodiment 2

[0026] Example 2 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of chloroform, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and add 50ml of it dropwise within 60min at 20°C. A solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in chloroform, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 60°C within 1h, kept for 5h, and then cooled to 40°C , and an extremely flexible expansion soft sealing sleeve is installed on the upper opening of the condenser tube, 4.4g (0.099mol) of ethylene oxide is introduced, and the temperature is controlled not to exceed 45 °C during the introduction process, and then kept at 50 °C for 4 hours, the pH of the reaction system When the value reaches 5-6, the reaction is over, and the chloroform (recycled) is removed by distillation under reduced pressure to obtain a light yellow liqu...

Embodiment 3

[0027] Example 3 In a 100ml four-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of acetonitrile, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and add 50ml of it dropwise within 60min at 20°C. A solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in acetonitrile, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 70°C within 1 hour, kept for 4 hours, and then cooled to 40°C , and an extremely flexible expansion soft sealing sleeve is installed on the upper mouth of the condenser tube, and 4.8g (0.108mol) of ethylene oxide is introduced into the process. When the value reaches 5-6, the reaction is over, and the acetonitrile (recycled) is distilled off under reduced pressure to obtain a light yellow liquid tris(2-chloroethyl)-2-chloro-3-(2,4,6-tribromobenzene) Oxygen) propyl ester, product yield 97.3%. Its flash point (open cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com