Halogen-free flame-retardant SEBS thermoplastic elastomer composition and preparation method thereof

A thermoplastic elastomer and composition technology, applied in the field of polymer material modification, can solve the problems of reduced mechanical properties, large smoke generation, and only 2.9 MPa tensile strength of composite materials, so as to achieve good processing performance and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

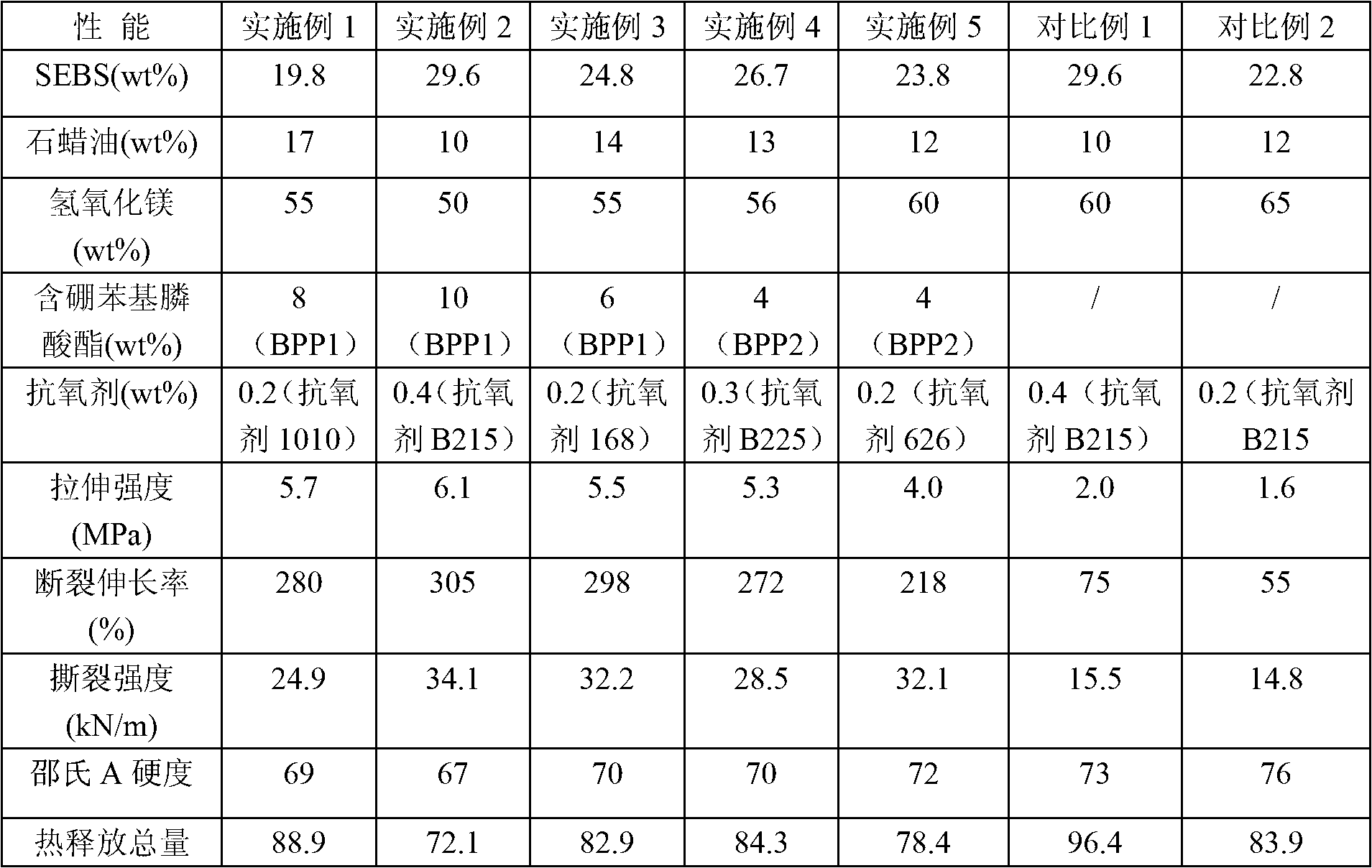

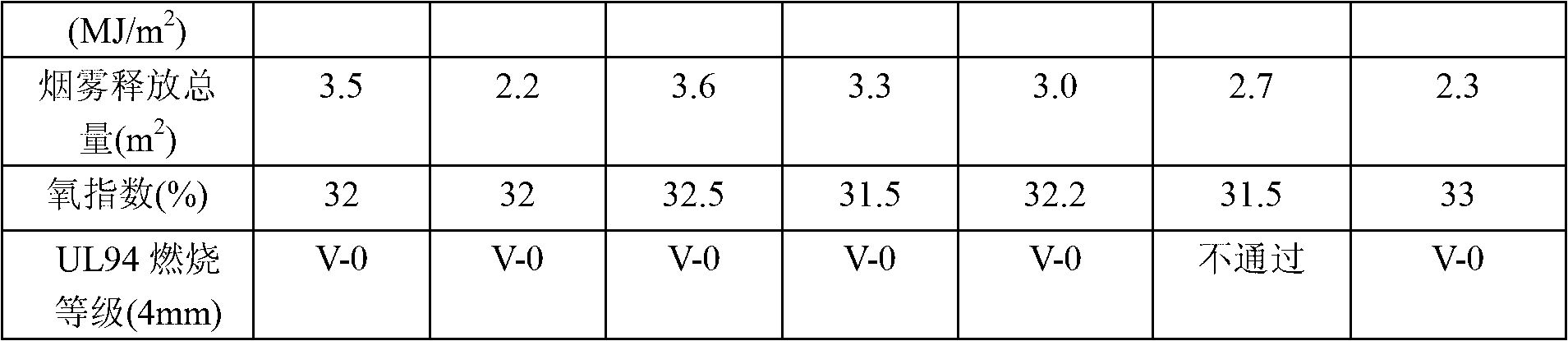

[0020] The present invention will be further described below in conjunction with embodiments, but the embodiments of the present invention are not limited thereto. The raw materials used in the examples of the present invention, SEBS, paraffin oil, and magnesium hydroxide were purchased from the market. The brands and manufacturers are shown in Table 1, and the antioxidants are brand names.

[0021] Table 1 Brands and manufacturers of main raw materials

[0022] Raw materials

Grade

manufacturer

SEBS

3151

Formosa Plastics

Paraffin oil

150N

Ssangyong co., ltd.

magnesium hydroxide

6000 mesh

Zhengzhou Fulong New Material Technology Co., Ltd.

[0023] The boron-containing phenylphosphonate flame retardant was prepared in accordance with Example 1 and Example 5 of the Chinese invention patent (CN201110249820.0). The number average molecular weights of the two flame retardants measured by gel chromatography were 1000 and 1400, respectively, which were recorded as B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com