Melamine-modified lignin coated red phosphorus flame retardant and application thereof in ABS (Acrylonitrile Butadiene Styrene) resin

A melamine-coated red phosphorus technology, which is applied in the field of polymer materials, can solve the problems of easy explosion, limit the application of red phosphorus, increase the difficulty of red phosphorus transportation and storage, and achieve good weather resistance, broad application prospects, and thermal stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

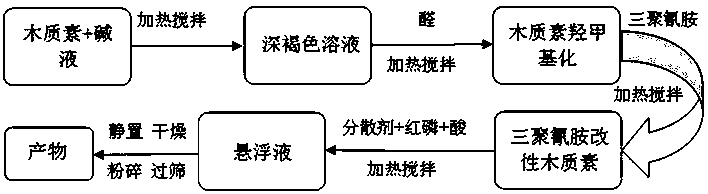

Method used

Image

Examples

Embodiment 1

[0025] Weigh 5.6g (0.1mol) potassium hydroxide in a beaker, add deionized water to make a 2wt% potassium hydroxide solution, then add 10g organic lignin to the obtained potassium hydroxide solution, heat and stir to dissolve, then pour Put it into a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser, heat it in an oil bath to 80°C under the stirring condition of 200 rpm, add 0.2mol of formaldehyde, react for 3 hours, then add 12.6g (0.1mol) of melamine, and continue to keep warm After stirring and reacting for 3 hours, pour the reaction product into a beaker, add 6g of red phosphorus and 0.03g of sodium dodecylbenzenesulfonate, stir well to completely disperse the red phosphorus, then slowly add hydrochloric acid to neutralize until the solution is neutral, Then stir the reaction at 80°C and 200 rpm for 2h, age the suspension obtained from the reaction for 12h, vacuum filter, and dry the filtered product in an oven at 80°C for 24h, crush...

Embodiment 2

[0029] Weigh 8g (0.2mol) sodium hydroxide in a beaker, add deionized water to make 4wt% sodium hydroxide solution, then add 10g enzymatic lignin to the obtained sodium hydroxide solution, heat and stir to dissolve, pour Put it into a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser, heat it in an oil bath to 90 °C under the stirring condition of 400 rpm, add 0.3 mol of formaldehyde, react for 2 hours, then add 12.6 g (0.1 mol) of melamine, and continue to keep warm After stirring and reacting for 2 hours, pour the reaction product into a beaker, add 8g of red phosphorus and 0.04g of sodium dodecylbenzenesulfonate, stir well to completely disperse the red phosphorus, then slowly add sulfuric acid to neutralize until the solution is neutral. Then stir the reaction at 90°C and 400 rpm for 1h, age the suspension obtained from the reaction for 18h, vacuum filter, and dry the filtered product in an oven at 90°C for 18h, then crush and sieve ...

Embodiment 3

[0031] Weigh 12g (0.3mol) sodium hydroxide in a beaker, add deionized water to make a 6wt% sodium hydroxide solution, then add 20g of enzymatic lignin to the obtained sodium hydroxide solution, heat and stir to dissolve, pour Put it into a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser, heat it in an oil bath to 100 °C under the stirring condition of 300 rpm, add 0.4 mol of butyraldehyde, react for 1 hour, then add 25.2 g (0.2 mol) of melamine, continue After insulated and stirred for 1 hour, pour the reaction product into a beaker, add 10g of red phosphorus and 0.1g of sodium lauryl sulfate, stir well to completely disperse the red phosphorus, then slowly add hydrochloric acid to neutralize until the solution is neutral, then Stir the reaction at 100°C and 300 rpm for 0.5h, age the suspension obtained from the reaction for 24h, vacuum filter, dry the filtered product in an oven at 100°C for 12h, crush and sieve to obtain melamine-mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com