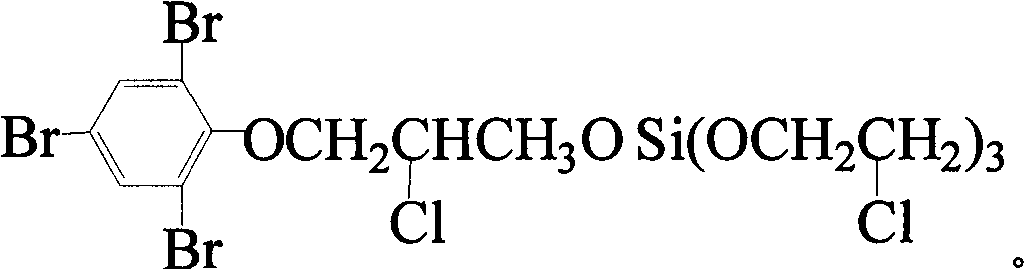

Flame retardant trichloroethyltribromophenoxychloropropylsilicate ester compound and preparation method thereof

A tribromophenoxy and chloroethyl technology, applied in the direction of silicon organic compounds, etc., to achieve good processing performance, stable physical and chemical properties, and good structural plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

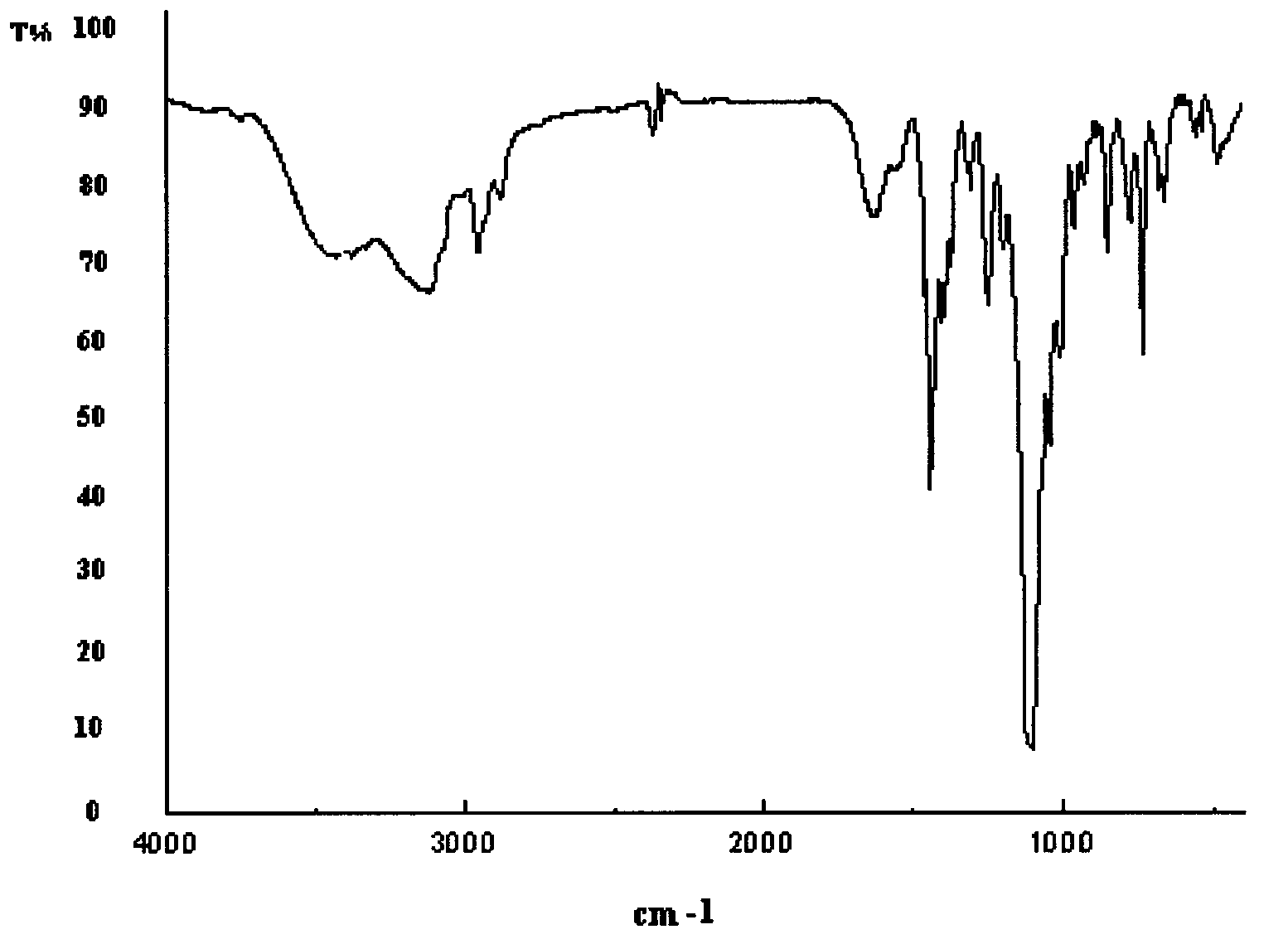

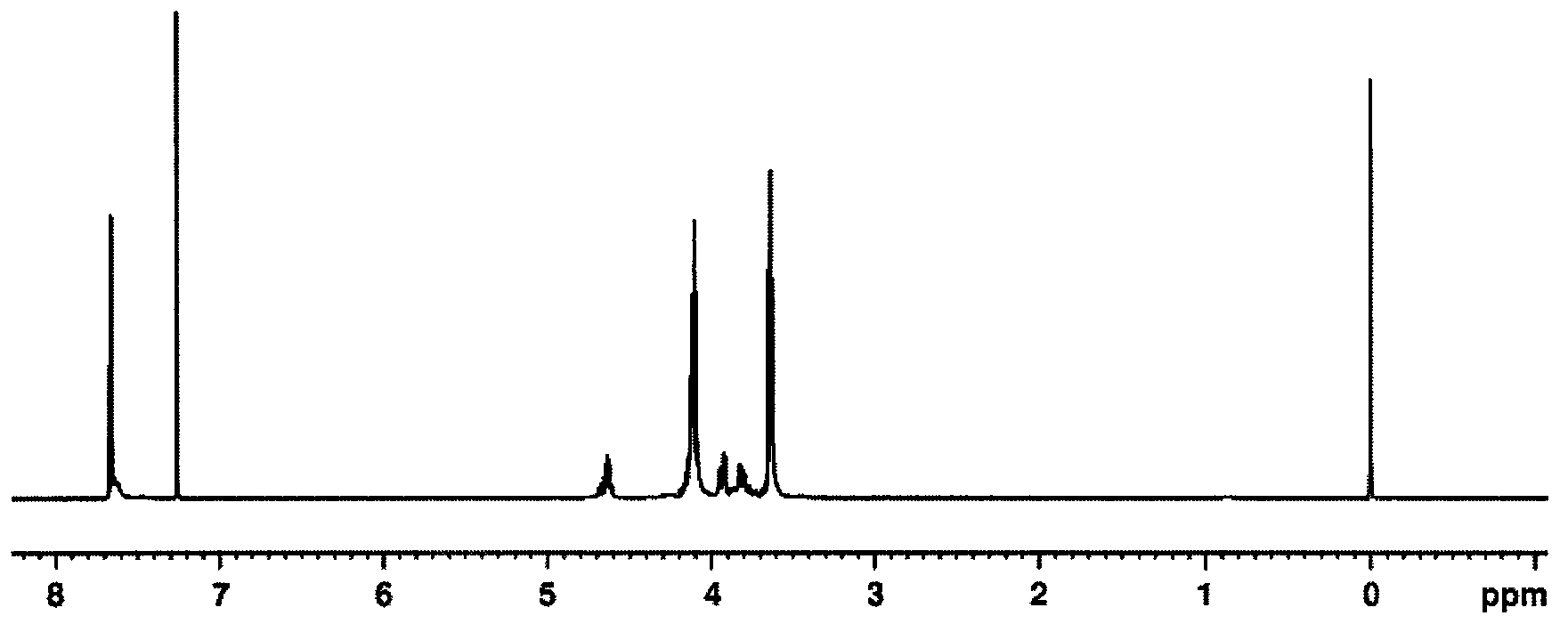

[0026] Example 1 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of tetrahydrofuran, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and add 50ml of it dropwise within 60min at 20°C. A solution of 11.6g (0.03mol) tribromophenyl glycidyl ether dissolved in tetrahydrofuran, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 60°C within 1 hour, kept for 6 hours, and then cooled to 35°C , under cooling, add 7.25g (0.09mol) of chloroethanol dropwise, control the temperature during the dropping process to not exceed 40°C, then raise the temperature to 50°C within 1h and keep it warm for 6h, cool down to 35°C, and add about 0.5g of triethylamine acid-binding agent , adjusted to pH=5-6, stirred for 1 h, filtered, the filtrate was distilled to remove the organic solvent (recycled), and then evaporated a small amount of low-boiling matter u...

Embodiment 2

[0027] Example 2 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of chloroform, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and add 50ml of it dropwise within 60min at 20°C. A solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in chloroform, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 60°C within 1 hour, kept for 5 hours, and then cooled to 35°C , under cooling, add 7.97g (0.099mol) of chloroethanol dropwise, and control the temperature during the dropping process to not exceed 40°C, then raise the temperature to 55°C within 1h and keep it for 5h, cool down to 35°C, and add about 0.5g N,N-dimethyl Aniline acid-binding agent, adjusted to pH = 5-6, stirred for 1 h, filtered, the filtrate was distilled to remove the organic solvent (for recycling), and then distilled off excess chloroethanol (for recycling)...

Embodiment 3

[0028]Example 3 In a 100ml four-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of acetonitrile, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and add 50ml of it dropwise within 60min at 20°C. A solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in acetonitrile, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 70°C within 1 hour, kept for 4 hours, and then cooled to 35°C , under cooling, add 8.70g (0.108mol) of chloroethanol dropwise, and control the temperature during the dropping process to not exceed 40°C, then raise the temperature to 60°C within 1h and keep it warm for 4h, cool down to 35°C, add about 0.5g of melamine acid-binding agent, adjust to pH = 5-6, stirred for 1 hour, filtered, the filtrate was distilled to remove the organic solvent (for recycling), and then distilled off excess chloroethanol (for recycling) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com