Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

A technology of intumescent flame retardant and composite flame retardant, which is applied in the field of flame retardant materials, can solve the problems of low flame retardant efficiency of a single flame retardant, and achieve the advantages of reducing smoke phenomenon, improving flame retardant efficiency and improving flame retardant efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

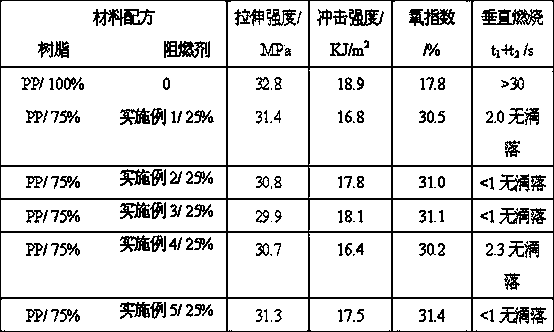

Examples

Embodiment 1

[0024] The composite flame retardant containing microcapsule-coated expansion flame retardant of the present invention, its composition is by mass percentage: microcapsule expansion flame retardant 75%, flame retardant synergist aluminum hydroxide and red phosphorus add up to 15%, ph Smoke agent zinc borate 9%, hindered amine light stabilizer 770 1%.

[0025] Wherein said microcapsule-coated expansion flame retardant uses expansion flame retardant powder as core material and urea-formaldehyde resin as shell material, and said expansion flame retardant powder accounts for 65% of the total mass of expansion flame retardant The acid source material ammonium polyphosphate, the gas source material melamine and dicyandiamide accounting for 25% of the total mass of the intumescent flame retardant, and the carbon source material pentaerythritol accounting for 10% of the total mass of the intumescent flame retardant.

[0026] The specific preparation method is:

[0027] Weigh 650g of am...

Embodiment 2

[0031] The composite flame retardant containing microcapsule-coated intumescent flame retardant of the present invention is composed by mass percentage: 80% of microcapsule intumescent flame retardant, 12% in total of flame retardant synergist magnesium hydroxide and montmorillonite, The smoke suppressant antimony trioxide and ferrocene accounted for 6.8%, and the hindered amine light stabilizers 622 and 944 accounted for 1.2%.

[0032] Wherein said microcapsule-coated intumescent flame retardant uses intumescent flame retardant powder as the core material and urea-formaldehyde resin as the shell material, and the intumescent flame retardant powder accounts for 70% of the total mass of the intumescent flame retardant The acid source material melamine polyphosphate and PNP expansion flame retardant, the gas source material urea accounting for 18% of the total mass of the expansion flame retardant, and the carbon source material dipentaerythritol accounting for 12% of the total m...

Embodiment 3

[0037] The composite flame retardant containing microcapsule-coated expansion flame retardant of the present invention, its composition is by mass percentage: microcapsule expansion flame retardant 60%, flame retardant synergist organosilicon and carbon nanotube total 25%, ph Smoke agent molybdenum trioxide 10%, hindered amine light stabilizer 622 5%.

[0038] Wherein said microcapsule-coated expansion flame retardant uses expansion flame retardant powder as core material and melamine formaldehyde resin as shell material, and said expansion flame retardant powder accounts for the total expansion flame retardant powder The acid source material melamine cyanurate with a mass of 40%, the gas source material urea accounting for 30% of the total mass of the intumescent flame retardant powder, and the carbon source material dipentaerythritol accounting for 30% of the total mass of the intumescent flame retardant powder.

[0039] The specific preparation method is:

[0040] Weigh 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com