A kind of ultraviolet light irradiation cross-linked chlorinated polyethylene cable material and preparation method thereof

A technology of chlorinated polyethylene and ultraviolet light, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of high price of irradiation cross-linked electron accelerator equipment, exhaust gas pollution, and radiation that is not conducive to environmental protection, etc. problem, to achieve a good flame retardant synergistic effect, good flame retardant performance, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

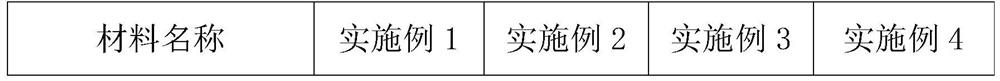

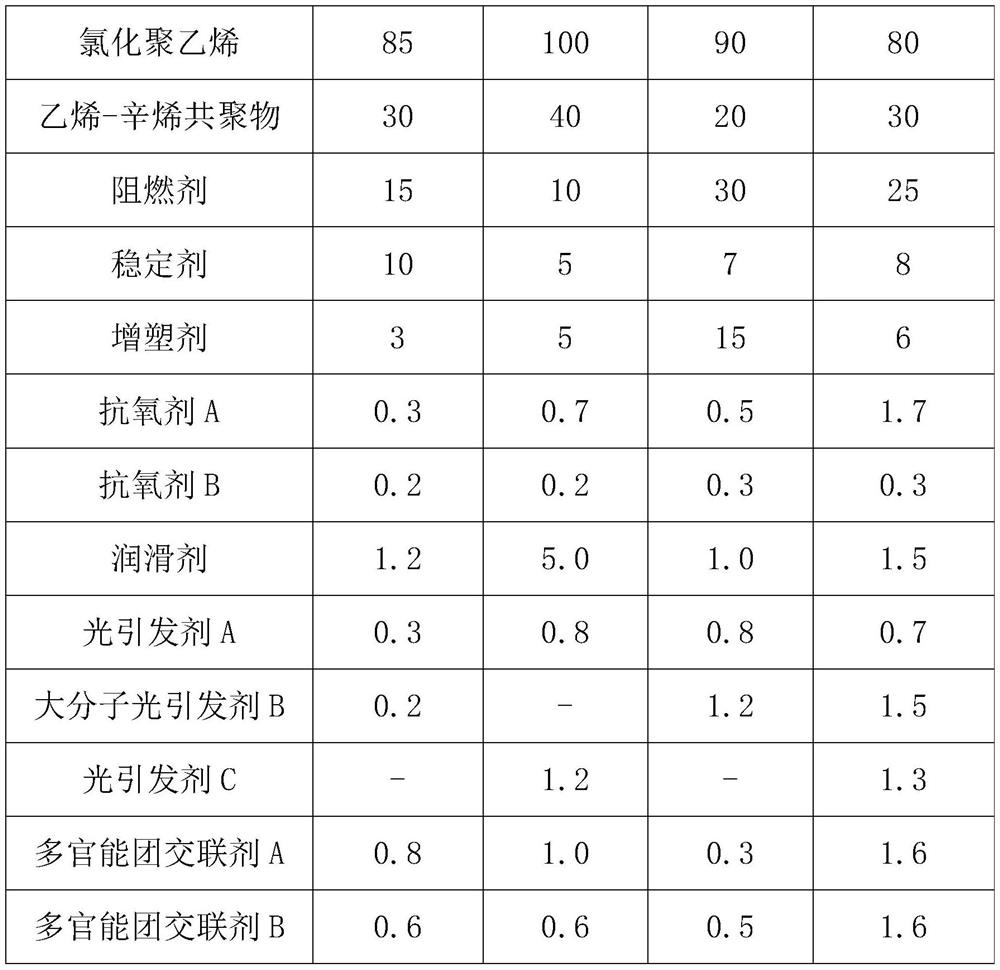

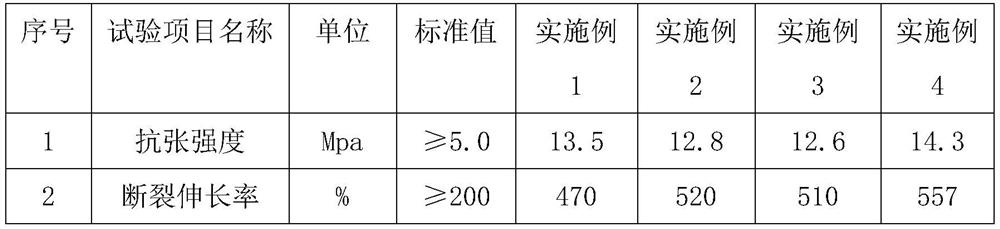

[0037] An ultraviolet-irradiated cross-linked chlorinated polyethylene cable material, the raw material components and parts by weight are shown in Table 1, wherein the flame retardant is compounded by a halogen-based flame retardant and a phosphorus-based flame retardant, and the stabilizer is It is calcium-zinc composite stabilizer, plasticizer is dibutyl phthalate, antioxidant A is hindered phenol antioxidant, antioxidant B is phosphite antioxidant, and lubricant is silicone mother Granules, photoinitiator A is benzophenone and its derivatives, macromolecular photoinitiator B is macromolecular thioxanthone photoinitiator, multifunctional crosslinking agent A is triallyl isocyanurate, The multifunctional crosslinking agent B is tris(2-hydroxyethyl)isocyanurate triacrylate.

[0038] The preparation method is as follows:

[0039] S1, put into Banbury mixer after mixing each raw material components weighed by formula weight and carry out melt blending, Banbury temperature 160-...

Embodiment 2

[0044] An ultraviolet-irradiated cross-linked chlorinated polyethylene cable material, the raw material components and parts by weight are shown in Table 1, wherein the flame retardant is compounded by a phosphorus-based flame retardant and an intumescent flame retardant, and the stabilizer is It is organotin stabilizer, plasticizer is dioctyl sebacate, antioxidant A is phosphite antioxidant, antioxidant B is phosphite antioxidant, and lubricant is ethylene bisulfite Stearamide, photoinitiator A is benzoin and its derivatives, photoinitiator C is thioxanthone, multifunctional crosslinking agent A is triallyl cyanurate, and multifunctional crosslinking agent B is Propoxylated neopentyl glycol diacrylate.

[0045] The preparation method is as follows:

[0046] S1, put into Banbury mixer after mixing each raw material components weighed by formula weight and carry out melt blending, Banbury temperature 160-180 ℃, Banbury time is 15-20 minutes, obtains mixture;

[0047] S2. Add th...

Embodiment 3

[0051] An ultraviolet-irradiated cross-linked chlorinated polyethylene cable material, the raw material components and parts by weight are shown in Table 1, wherein the flame retardant is compounded by a halogen-based flame retardant, a phosphorus-based flame retardant and an inorganic flame retardant The stabilizer is an organic tin stabilizer and a rare earth stabilizer, the plasticizer is epoxidized soybean oil, the antioxidant A is a hindered phenol antioxidant, and the antioxidant B is a thioester antioxidant. The lubricant is ethylene bis-stearamide, the photoinitiator A is a triazine type initiator, the macromolecular photoinitiator B is a macromolecular thioxanthone type photoinitiator, and the multifunctional crosslinking agent A is triacrylic acid propane trimethanol ester, the multifunctional crosslinking agent B is dipentaerythritol hexaacrylate.

[0052] The preparation method is as follows:

[0053] S1, put into Banbury mixer after mixing each raw material compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com