Flame-retardant molecular chain grafted mesoporous silica modified epoxy resin coating and preparation method thereof

A technology of mesoporous silica and epoxy resin coatings, which is applied in the direction of epoxy resin coatings, fireproof coatings, coatings, etc., can solve the problems of weak flame retardancy of inorganic compounds, increase thermal stability, and suppress toxic smoke gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

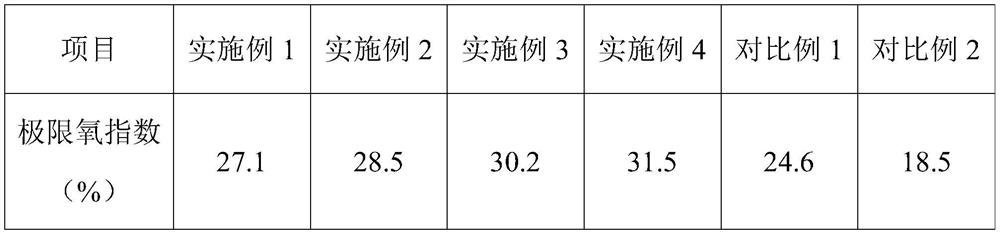

Examples

Embodiment 1

[0035] This embodiment provides the following technical solution: the preparation of a flame-retardant molecular chain grafted mesoporous silica-modified epoxy resin coating, the specific preparation process is as follows:

[0036] Add 100g of epoxy resin, 10g of flame retardant molecular chain grafted mesoporous silica, 1.5g of monoglyceride stearate, 2.1g of organic micro-wax powder, and 0.8g of simethicone into deionized water, stir and mix evenly, The flame retardant molecular chain grafted mesoporous silica modified epoxy resin coating is obtained.

[0037] The preparation of flame retardant molecular chain grafted mesoporous silica, the specific preparation process is as follows:

[0038] (a1) Mix 5 g of mesoporous silica and 4.5 g of 3-aminopropyltriethoxysilane, reflux at 80° C. for 22 h, filter, wash and dry overnight to obtain aminated mesoporous silica.

[0039] (b1) Add 7.5g of aminated mesoporous silica and 9g of flame-retardant molecular chains prepared in step ...

Embodiment 2

[0044] This embodiment provides the following technical solution: the preparation of a flame-retardant molecular chain grafted mesoporous silica-modified epoxy resin coating, the specific preparation process is as follows:

[0045]Add 100g of epoxy resin, 11.5g of flame retardant molecular chain grafted mesoporous silica, 1.5g of monoglyceride stearate, 2.1g of organic micro-wax powder, and 0.8g of simethicone into deionized water, stir and mix evenly , to obtain the flame retardant molecular chain grafted mesoporous silica modified epoxy resin coating.

[0046] The preparation of flame retardant molecular chain grafted mesoporous silica, the specific preparation process is as follows:

[0047] (a1) Mix 5 g of mesoporous silica and 4.5 g of 3-aminopropyltriethoxysilane, reflux at 80° C. for 22 h, filter, wash and dry overnight to obtain aminated mesoporous silica.

[0048] (b1) Add 7.5g of aminated mesoporous silica and 9g of flame-retardant molecular chains prepared in step ...

Embodiment 3

[0053] This embodiment provides the following technical solution: the preparation of a flame-retardant molecular chain grafted mesoporous silica-modified epoxy resin coating, the specific preparation process is as follows:

[0054] Add 100g of epoxy resin, 13g of flame retardant molecular chain grafted mesoporous silica, 1.5g of monoglyceride stearate, 2.1g of organic micro wax powder, and 0.8g of simethicone into deionized water, stir and mix evenly, The flame retardant molecular chain grafted mesoporous silica modified epoxy resin coating is obtained.

[0055] The preparation of flame retardant molecular chain grafted mesoporous silica, the specific preparation process is as follows:

[0056] (a1) Mix 5 g of mesoporous silica and 4.5 g of 3-aminopropyltriethoxysilane, reflux at 80° C. for 22 h, filter, wash and dry overnight to obtain aminated mesoporous silica.

[0057] (b1) Add 7.5g of aminated mesoporous silica and 9g of flame-retardant molecular chains prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com