Method for reinforcing polypropylene composite material by coupling modified short carbon fiber and pyridinium-modified montmorillonite

A technology of chopped carbon fiber and flame retardant polypropylene, which is applied in the field of modified plastics, can solve the problems of destroying the integrity and continuity of materials, limiting the application scope of polypropylene materials, and deteriorating mechanical properties of materials, so as to improve thermal stability and Effects of flame retardancy, rigidity enhancement, and storage modulus increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

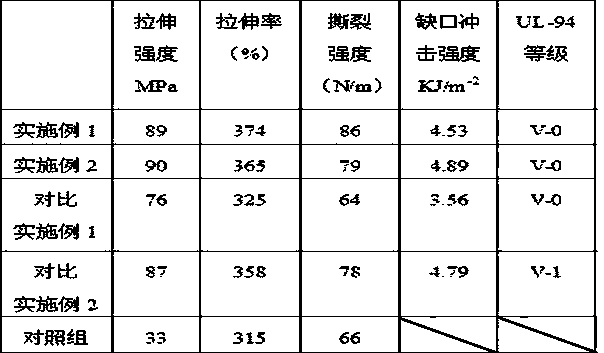

Examples

Embodiment 1

[0029] A method for coupling modified chopped carbon fiber-pyridinium salt modified montmorillonite reinforced flame-retardant polypropylene composite material, comprising the steps of:

[0030] (1) Surface modification of chopped carbon fibers by coupling agent:

[0031] Add ethanol aqueous solution to the oxidized chopped carbon fiber, then add coupling agent solution, after mechanical stirring for 25 minutes, put it in a constant temperature water bath at 60-62°C and let it stand for 3 hours, after rotary evaporation, put it in 80-83°C for vacuum drying 4h in the case, after cooling, the chopped carbon fibers obtained by silane coupling agent treatment;

[0032] (2) Coupling agent treatment of basalt fiber surface modification:

[0033] Stir 0.1 part of silane coupling agent solution on a magnetic stirrer at 80-90 ° C to complete hydrolysis, soak 15 parts of dry basalt coarse sand in it for 1 hour, take it out and dry it naturally, then put it in a constant temperature box...

Embodiment 2

[0046] A method for coupling modified chopped carbon fiber-pyridinium salt modified montmorillonite reinforced flame-retardant polypropylene composite material, comprising the steps of:

[0047] (1) Surface modification of chopped carbon fibers by coupling agent:

[0048]Add ethanol aqueous solution to the oxidized chopped carbon fiber, then add coupling agent solution, after mechanical stirring for 25 minutes, put it in a constant temperature water bath at 60-62°C and let it stand for 3 hours, after rotary evaporation, put it in 80-83°C for vacuum drying 4h in the case, after cooling, the chopped carbon fibers obtained by silane coupling agent treatment;

[0049] (2) Coupling agent treatment of basalt fiber surface modification:

[0050] Stir 0.1 part of silane coupling agent solution on a magnetic stirrer at 80-90°C for complete hydrolysis, soak 15 parts of dry basalt coarse sand in it for 1 hour, take it out and dry it naturally, then put it in a constant temperature box a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com