Patents

Literature

40results about How to "Increasing interlamellar spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

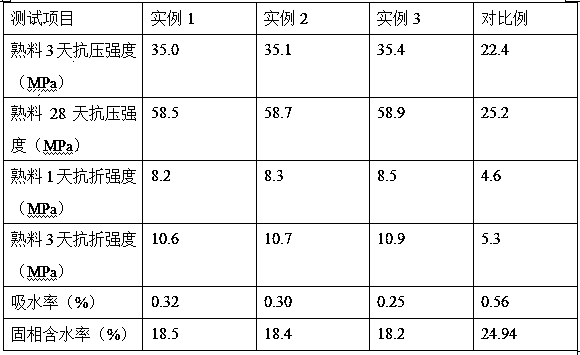

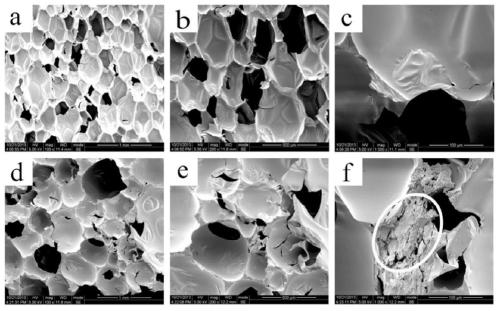

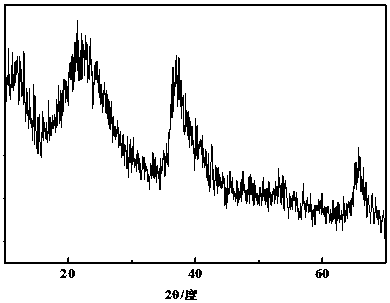

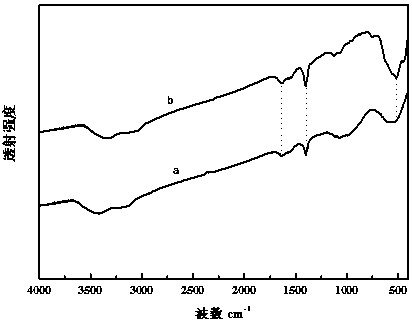

Preparation method and application of montmorillonite-graphene composite powder

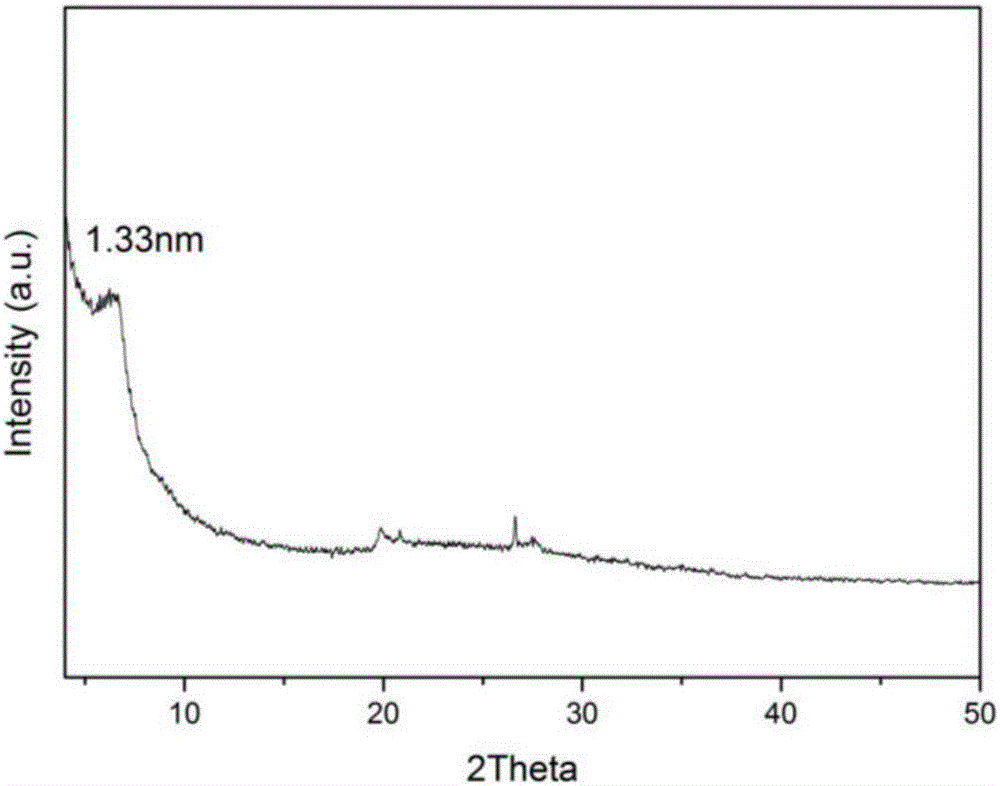

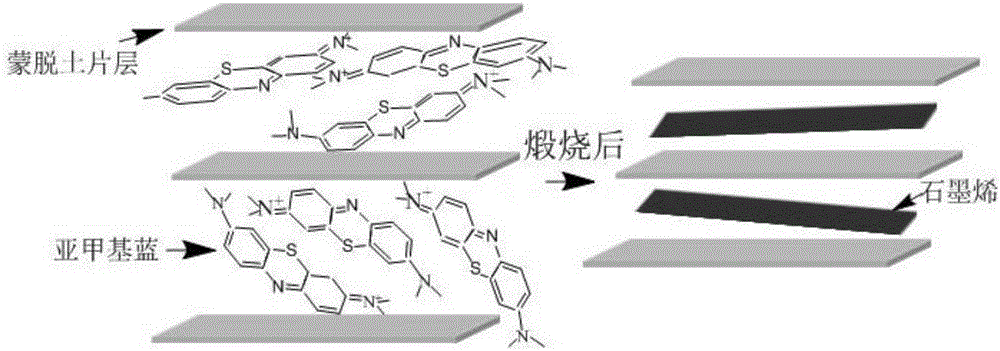

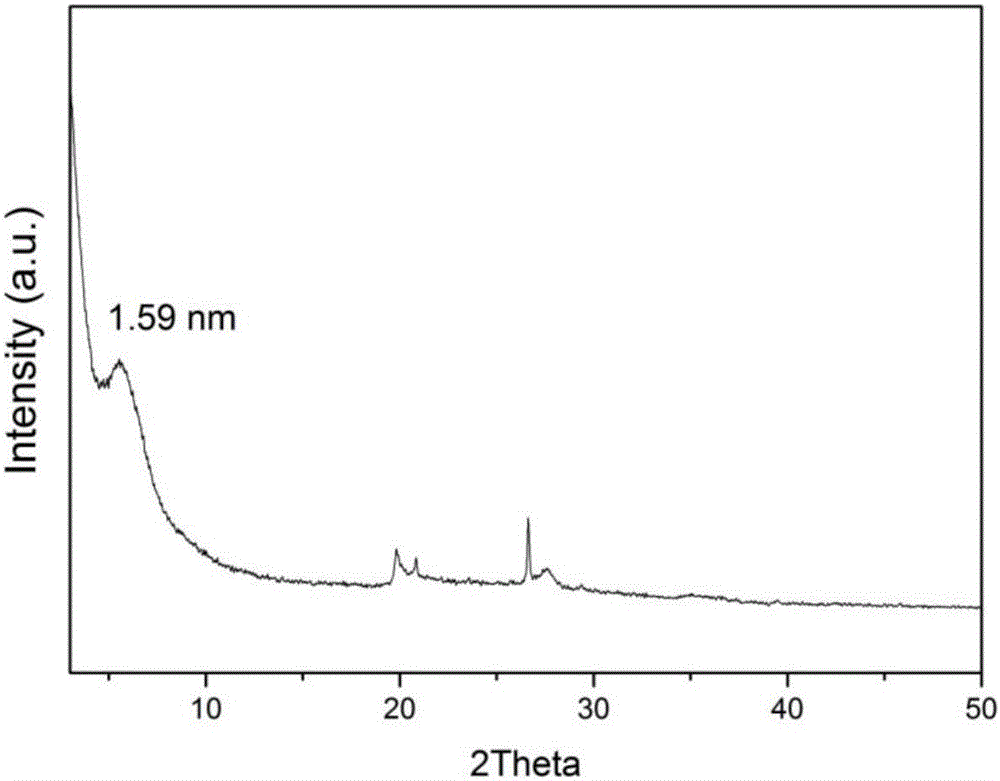

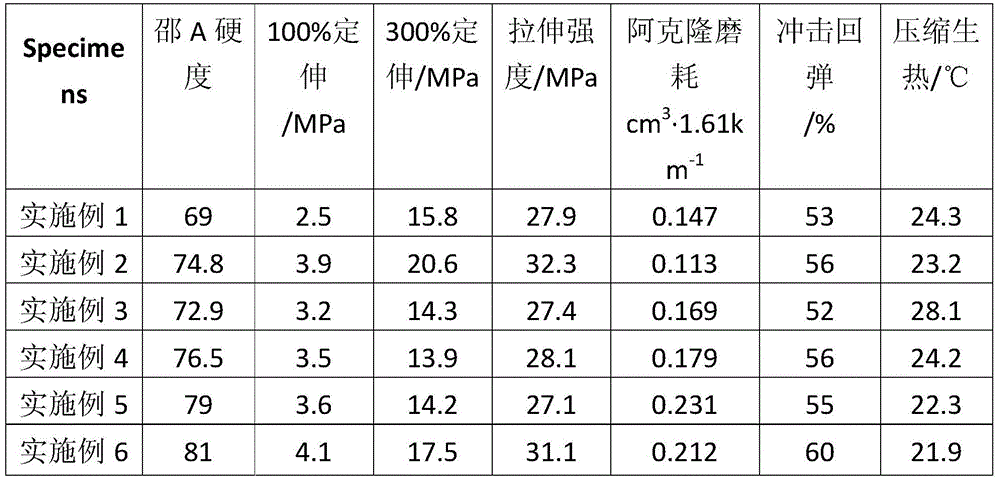

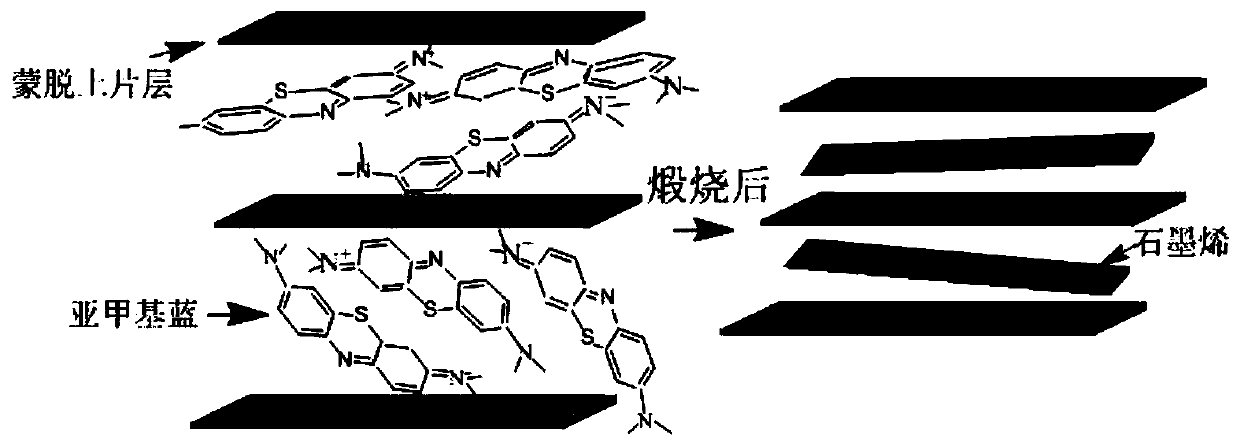

The invention provides a preparation method and application of montmorillonite-graphene composite powder. The preparation method of the montmorillonite-graphene composite powder comprises the following steps: (1) letting montmorillonite adsorb an organic dye to be saturated, centrifuging and washing, and drying to obtain organic dye-adsorbed waste montmorillonite, wherein the mass ratio of montmorillonite to the organic dye is 1: (0.3-1); and (2) calcining the organic dye-adsorbed waste montmorillonite at 600-700 DEG C for 2-4 h under the inert atmosphere protection so as to obtain the montmorillonite-graphene composite powder. By using waste montmorillonite as a raw material, the montmorillonite-graphene composite powder with montmorillonite and graphene uniformly intercalated is prepared by a one-step method. After the montmorillonite-graphene composite powder is modified with a silane coupling agent, the modified product is used as a filling material to prepare a polymer composite material. Then, properties of the polymer composite material, such as tensile strength and impact strength, etc., are effectively enhanced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing high-filling composite masterbatch through semi-open type superheated steam spray-drying method

The invention provides a method for preparing high-filling composite masterbatch through a semi-open type superheated steam spray-drying method, and relates to the field of preparation of high-filling composite rubber masterbatch. Modification treatment is conducted on inorganic filler through a modifying agent, the modified inorganic filler is ground and uniformly dispersed into a rubber emulsion, and then the technology of using a spray-drying technology to prepare the high-filling composite masterbatch is adopted. The technology comprises the steps that inorganic suspension liquid is prepared by adding water, the modifying agent is added for treatment, the fully-ground inorganic suspension liquid is added to the rubber emulsion and stirred to be uniform, spray drying is conducted under the condition without demulsification, and a powder or microbead-shaped composite masterbatch product is obtained. According to the method for preparing the high-filling composite masterbatch through the semi-open type superheated steam spray-drying method, the technology is simple, the rubber component is completely reserved, the problem of high-filling masterbatch is solved, no flocculant is added, pollution does not exist, the drying time is short, human factors are few, continuous production can be achieved, the product quality is stable, and industrialization is easy. By means of the nano composite masterbatch, the inorganic filler can be uniformly dispersed in a rubber matrix in a nano-scaled mode, and the nano composite masterbatch can be applied to the fields such as saloon car tires and engineering tread rubber.

Owner:BEIJING UNIV OF CHEM TECH

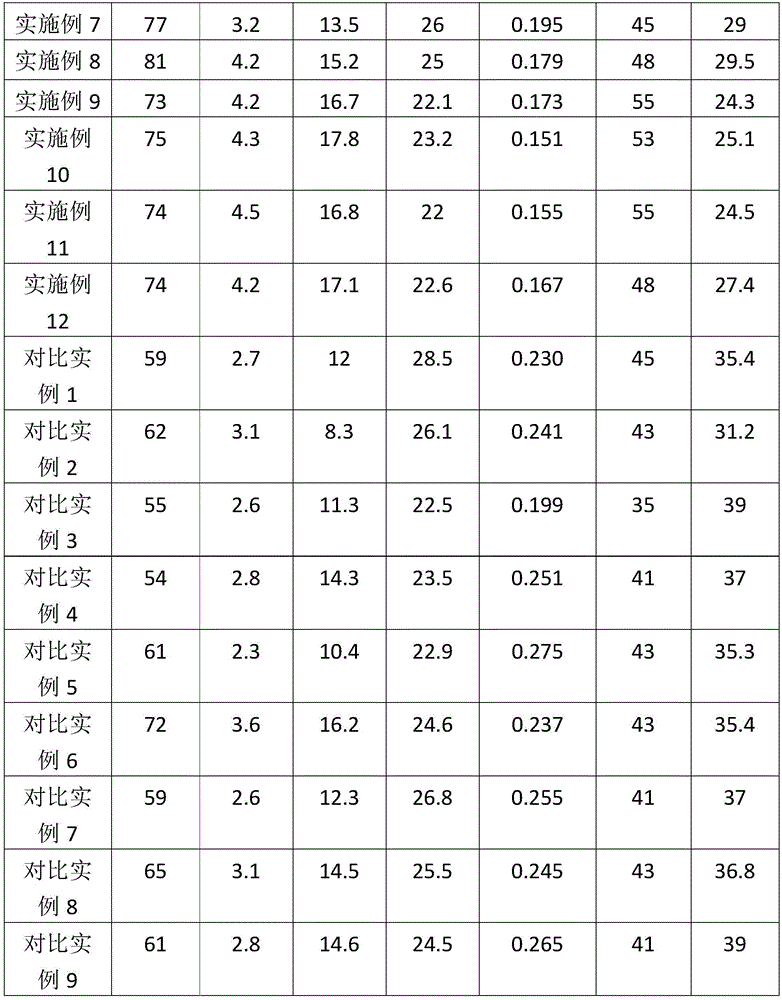

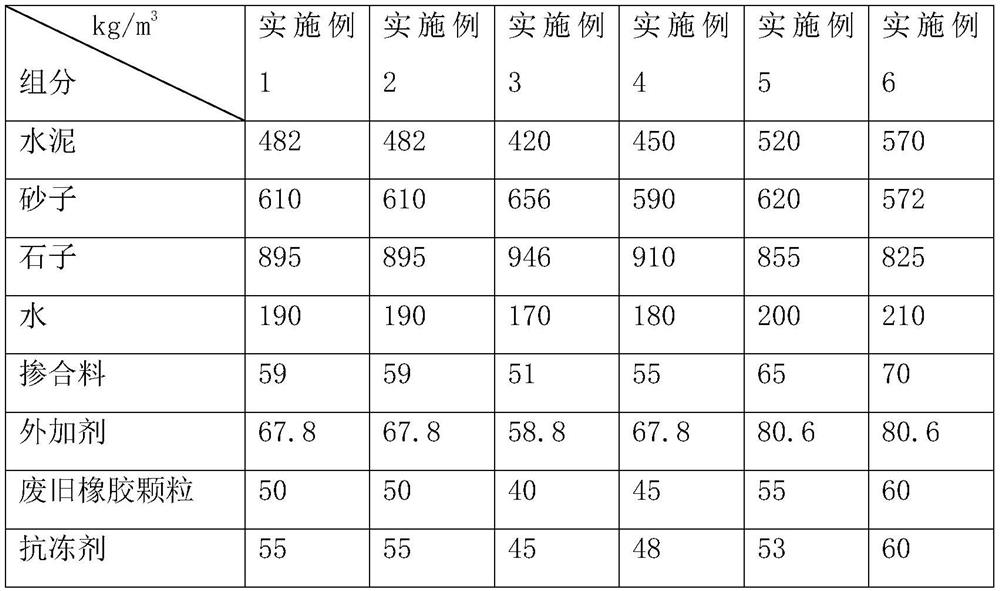

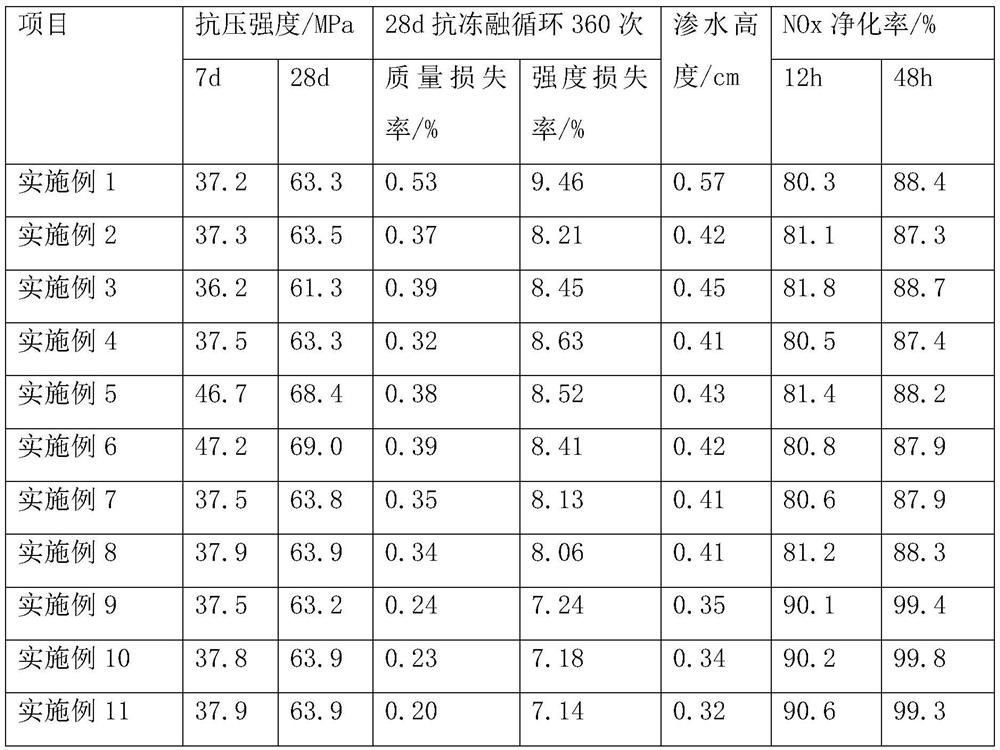

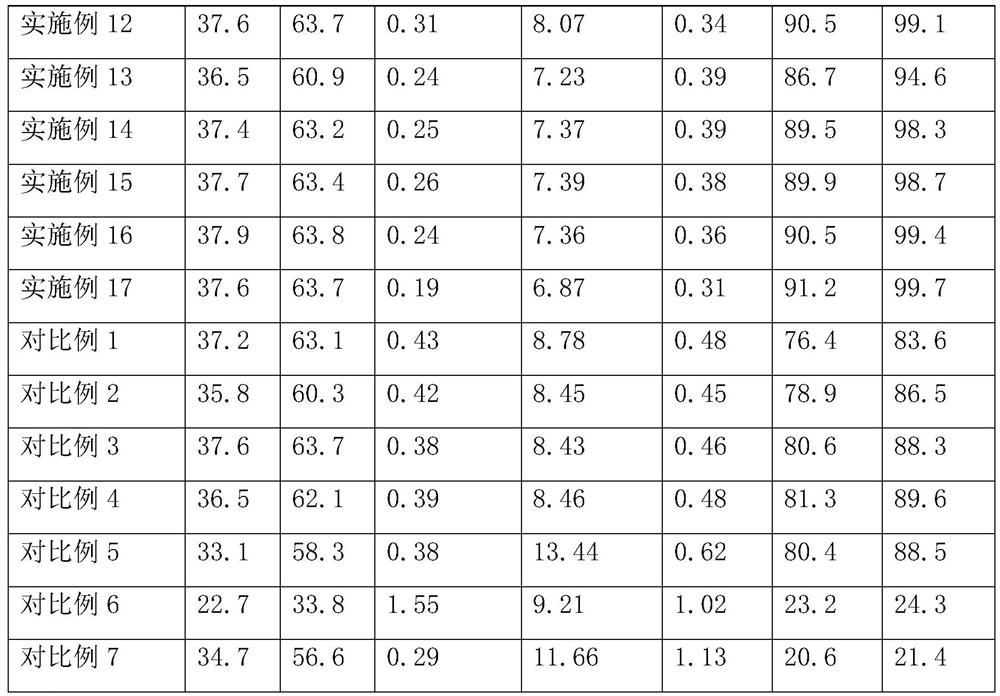

Environment-friendly anti-freezing concrete and preparation method thereof

InactiveCN113149541AImprove frost resistancePrevent expansion crackingSolid waste managementWaste rubberGraphene

The invention relates to the technical field of building materials, and particularly discloses environment-friendly anti-freezing concrete and a preparation method thereof. The environment-friendly anti-freezing concrete is prepared from the following components in parts by weight: 420 to 570 parts of cement, 572 to 656 parts of sand, 825 to 940 parts of stone, 170 to 210 parts of water, 51 to 70 parts of admixture, 58.8 to 80.6 parts of admixture, 40 to 60 parts of waste rubber particles and 45 to 60 parts of anti-freezing agent, the anti-freezing agent comprises the following components: modified starch, graphene oxide, iron tailing powder, eggshell membrane, sodium hydroxide, urea and cellulose; the preparation method comprises the following steps: adding the admixture and the antifreeze agent into water, and uniformly mixing to obtain a premix; mixing the cement, the sand, the stones, the admixture and the waste rubber particles, adding the premix, and uniformly mixing to obtain the environment-friendly anti-freezing concrete. The environment-friendly anti-freezing concrete has the advantages that waste rubber is recycled, the anti-freezing performance and the anti-seepage performance are high, and automobile exhaust can be purified.

Owner:青岛圣丰智能自动化设备有限公司

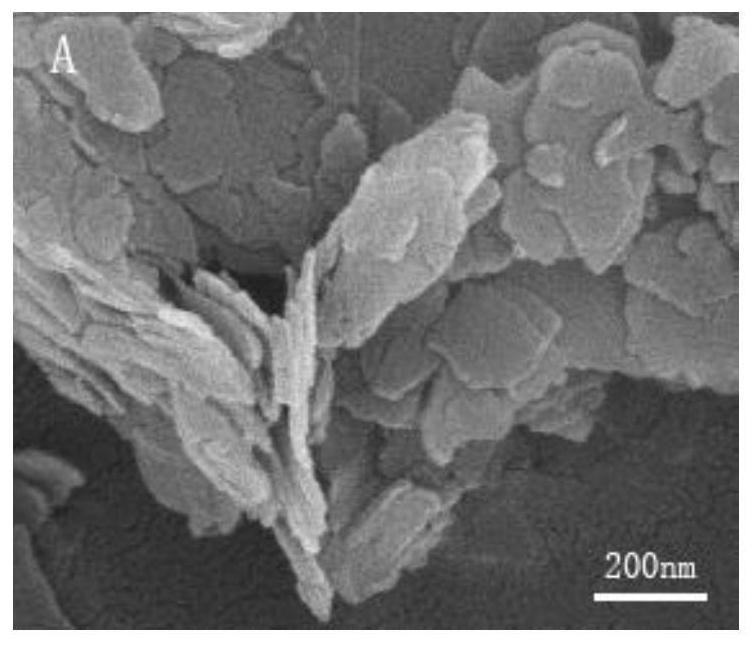

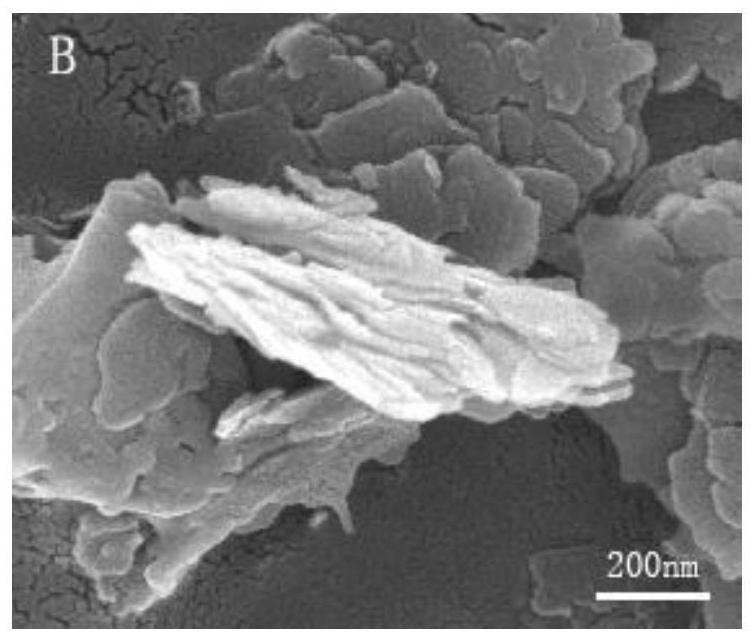

Method for preparing manganese dioxide nanosheet in low-temperature hydrothermal mode

InactiveCN106006746AIncrease contact areaRealize direct insertion/extractionManganese oxides/hydroxidesCapacitanceActive agent

The invention discloses a method for preparing a manganese dioxide nanosheet in a low-temperature hydrothermal mode. The method comprises the steps that potassium permanganate is used as a raw material, ethanediol is used as a reducing agent, SDS is used as a surfactant, and the manganese dioxide nanosheet is integrated in one step in the low-temperature hydrothermal mode. The manganese dioxide nanosheet is loose in layer, large in gap, large in specific area and good in electrical conductivity and super capacitive performance. The raw materials are easy to obtain, the cost is low, practicability is strong, environmental friendliness is achieved, and the method has the good application prospect in the aspect of supercapacitor electrode materials.

Owner:NORTHWEST NORMAL UNIVERSITY

Graphene antibacterial master batch, fiber and preparation method of master batch

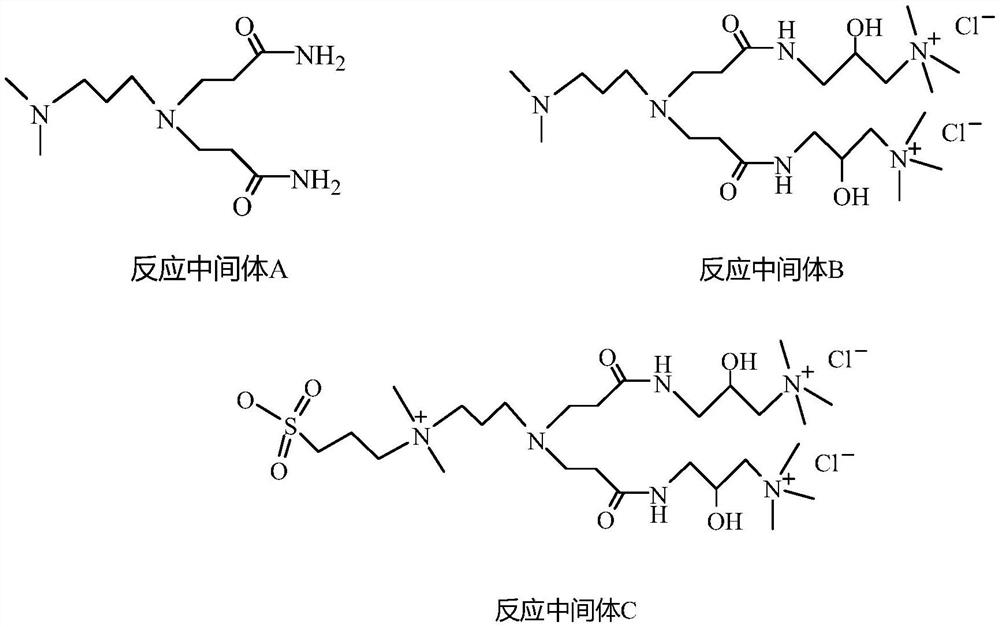

ActiveCN108047709AEvenly dispersedIncreasing interlamellar spacingArtifical filament manufactureMonocomponent polyamides artificial filamentFiberNylon 6

A preparation method of graphene antibacterial master batch comprises the following steps of first powder preparation, second powder preparation and master batch preparation. According to the technical scheme, water-soluble polyquaternary ammonium salt serves as an intercalation agent and an antibacterial agent, gaps between layers of a graphene oxide sheet are increased, then the water-soluble polyquaternary ammonium salt and nylon 6 are prepared into a microcapsule, and a core-shell structure is formed. According to the antibacterial master batch prepared through the method, polyquaternary ammonium salt and graphene oxide are used for preventing bacteria together, so that the master batch is good in antibacterial property; meanwhile, graphene is uniform in dispersion, and the physical and mechanical properties are enhanced; the graphene and nylon 6 can be fused and blended for preparing antibacterial textile silk.

Owner:福建烯石新材料科技有限公司

Thermoplastic polar polymer/laminated clay nanometer composite material and its preparation method

The invention provides a process for preparing thermoplastic polar polymer / laminated clay nano composite material which comprises, using thermoplastic polar polymer, laminated clay, intercalator, and disperse medium as raw material, reacting the laminated clay with intercalator (I) and intercalator (II), obtaining modified laminated clay, then mixing the modified laminated clay with thermoplastic polar polymer. The prepared nano composite material has good combination property.

Owner:ZHENGZHOU UNIV

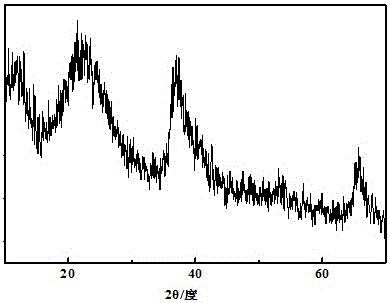

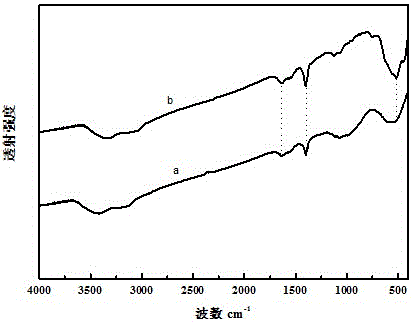

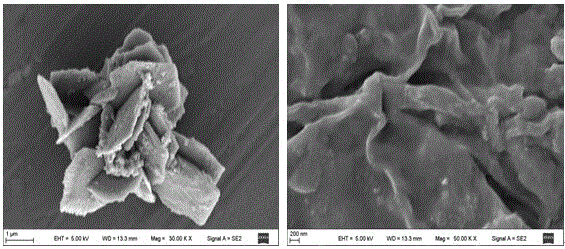

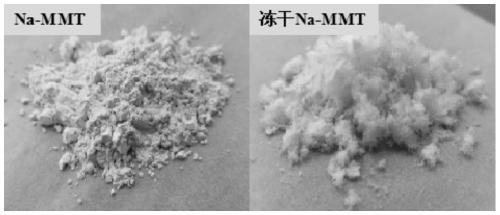

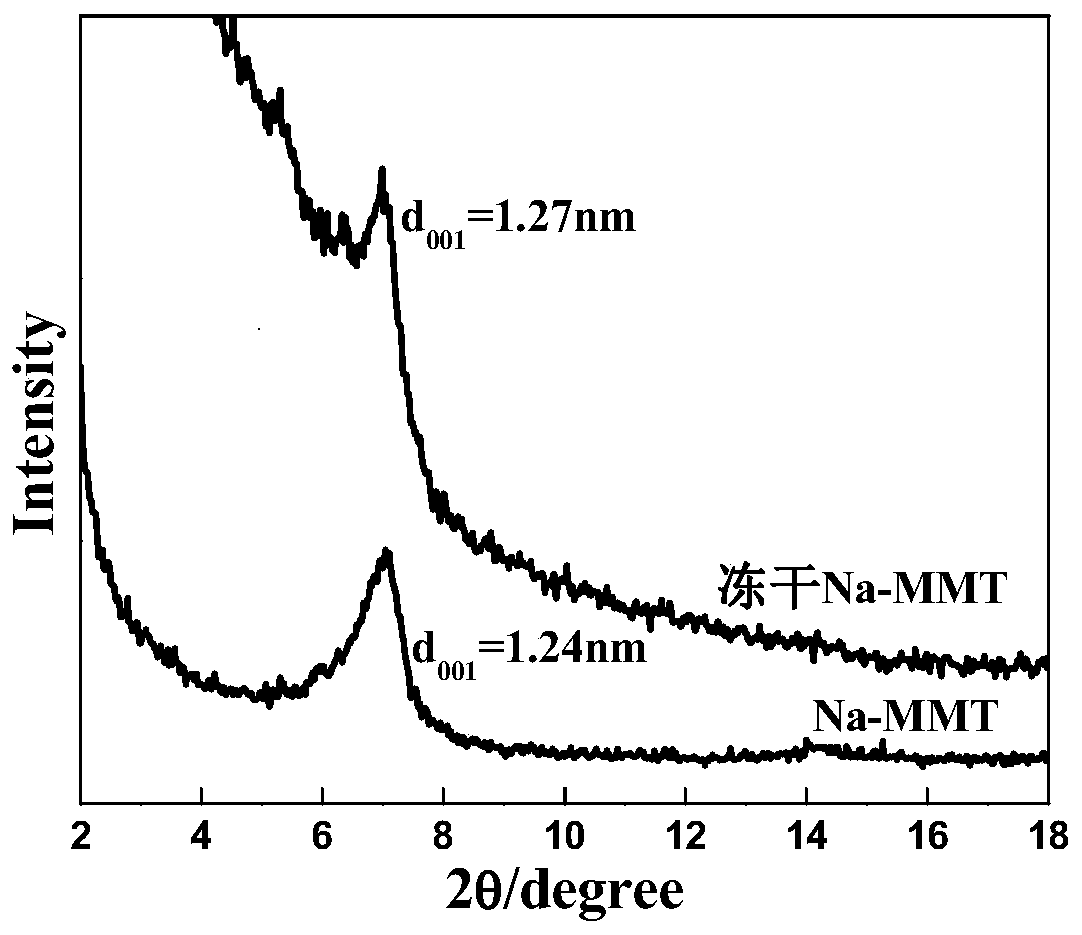

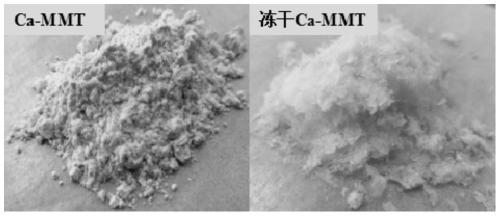

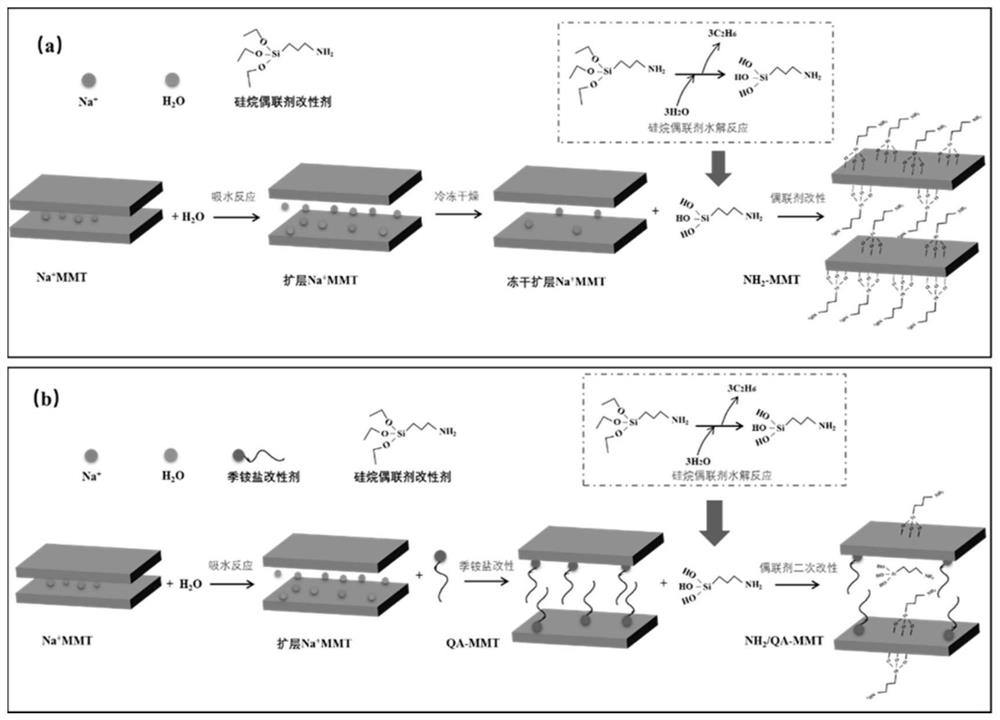

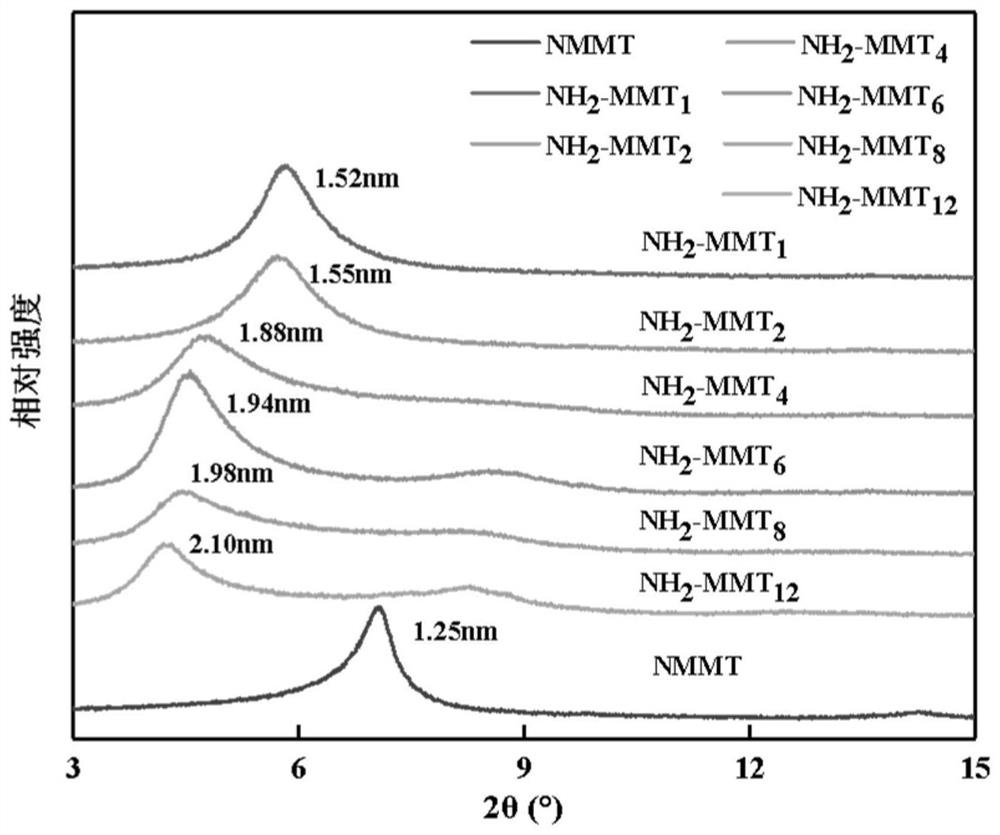

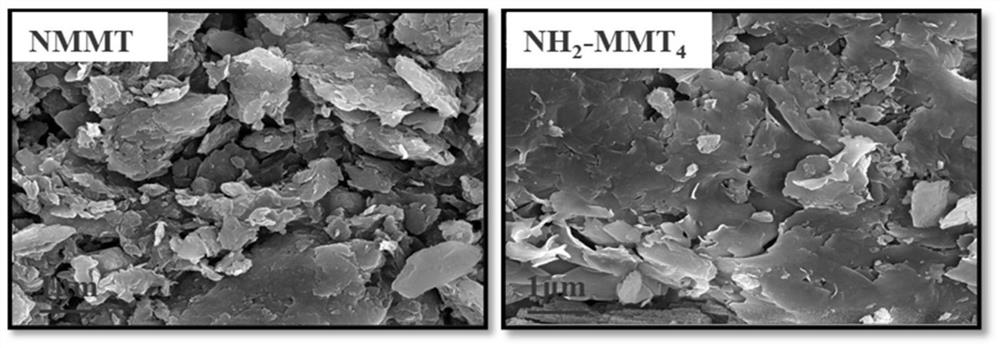

Method for enhancing surface property of montmorillonite by freeze-drying technology

PendingCN109824057AIncrease spacingNo lossNanotechnologySilicon compoundsFreeze-dryingMontmorillonite

The invention discloses a method for enhancing the surface property of montmorillonite by a freeze-drying technology. According to the method, the dispersing property of the montmorillonite is improved by utilizing the freeze-drying technology, and then surface modification is carried out to enhance the surface property of the layered montmorillonite. The montmorillonite with good dispersibility is obtained by vacuum freeze-drying. The freeze-dried montmorillonite dispersed under optimized conditions is obtained by controlling the stirring speed, the dispersing degree and the freeze-drying time of the montmorillonite in water. The freeze-dried montmorillonite is subjected to dopamine surface modification to obtain modified montmorillonite. The method disclosed by the invention has the characteristics of simplicity in operation, good test reproducibility, high efficiency and the like; the layered montmorillonite with functional groups on the surface can be obtained, and a new way for solving the dispersibility and functionalization of inorganic montmorillonite and improving the compatibility of the montmorillonite and organic matters is provided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

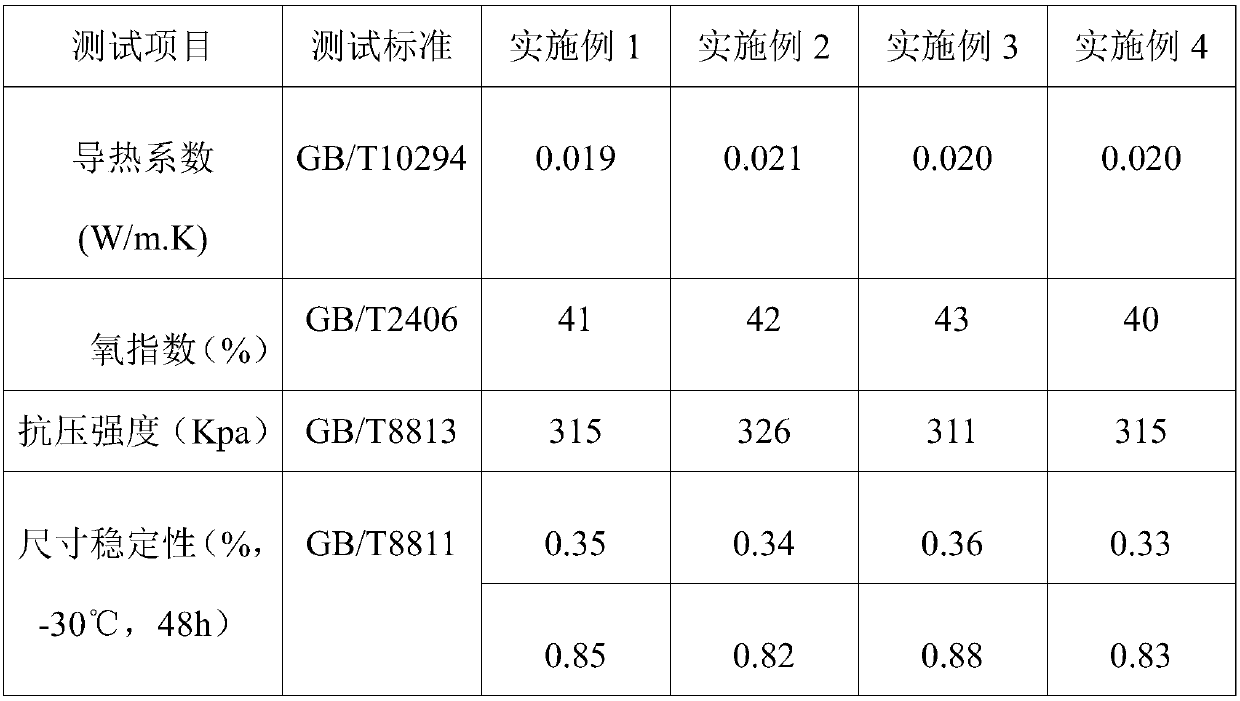

Polyurethane inorganic flame-retardant heat-insulation material for solar water tanks and method for preparing polyurethane inorganic flame-retardant heat-insulation material

The invention provides a polyurethane inorganic flame-retardant heat-insulation material for solar water tanks and a method for preparing the polyurethane inorganic flame-retardant heat-insulation material. The polyurethane inorganic flame-retardant heat-insulation material for the solar water tanks is prepared from raw materials including, by weight, 80-100 parts of polyether polyol, 110-130 parts of isocyanate, 3-8 parts of nanometer silicon dioxide, 5-10 parts of modified expanded vermiculite, 1-3 parts of chitosan grafted modified silane, 2-5 parts of foaming agents, 0.1-0.5 part of foam stabilizers, 0.5-2 parts of catalysts and 0.5-1 part of cross-linking agents. The polyurethane inorganic flame-retardant heat-insulation material and the method have the advantages that the polyurethane inorganic flame-retardant heat-insulation material prepared by the aid of the method is excellent in mechanical property such as compressive strength, the shortcoming of flammability of polyurethaneheat-insulation materials can be overcome by the aid of the polyurethane inorganic flame-retardant heat-insulation material and the method, and the heat-insulation performance of the solar water tanks can be guaranteed.

Owner:ANHUI MINGGUANG ZHONGXING SUNLIGHT NEW ENERGY TECH CO LTD

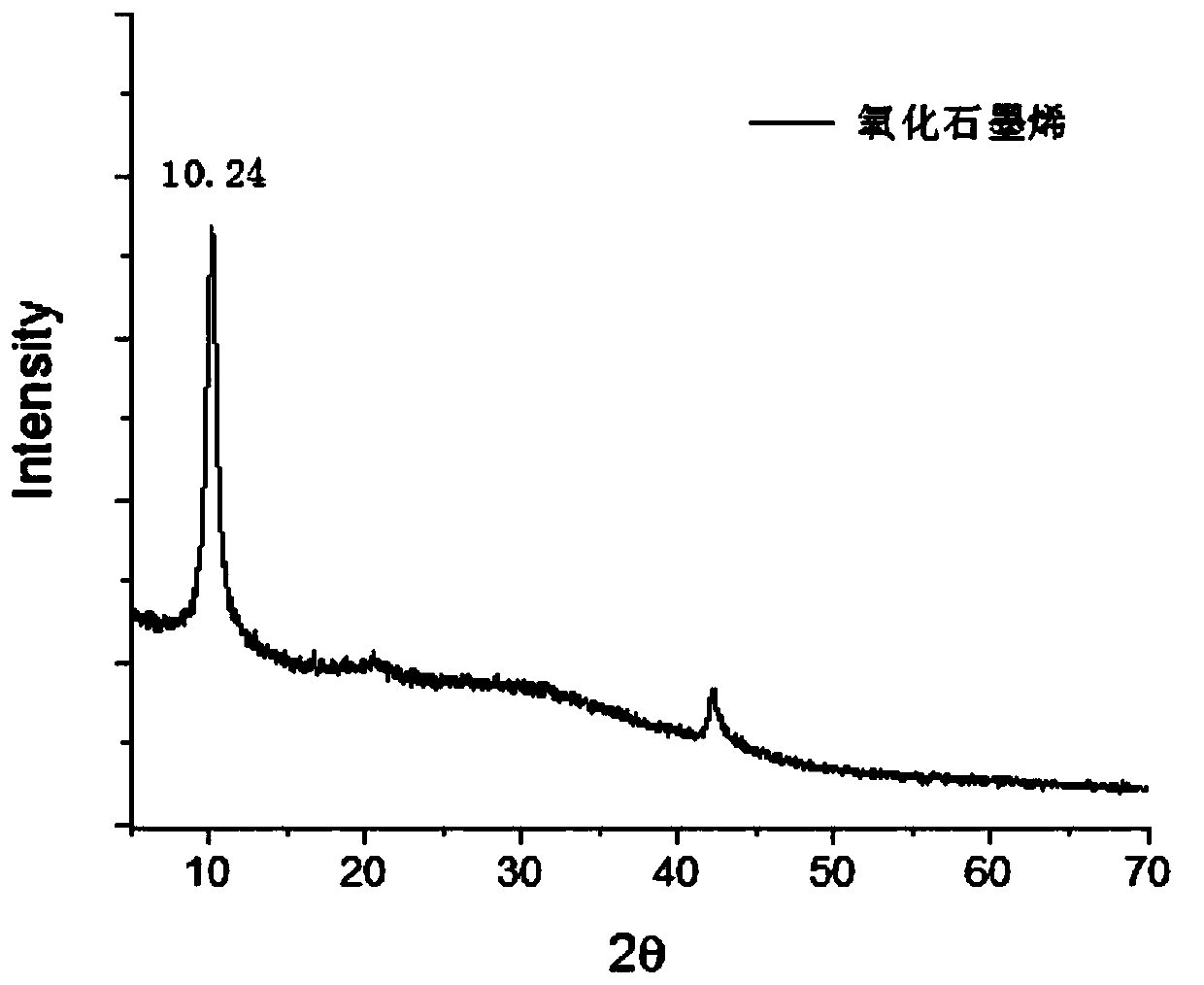

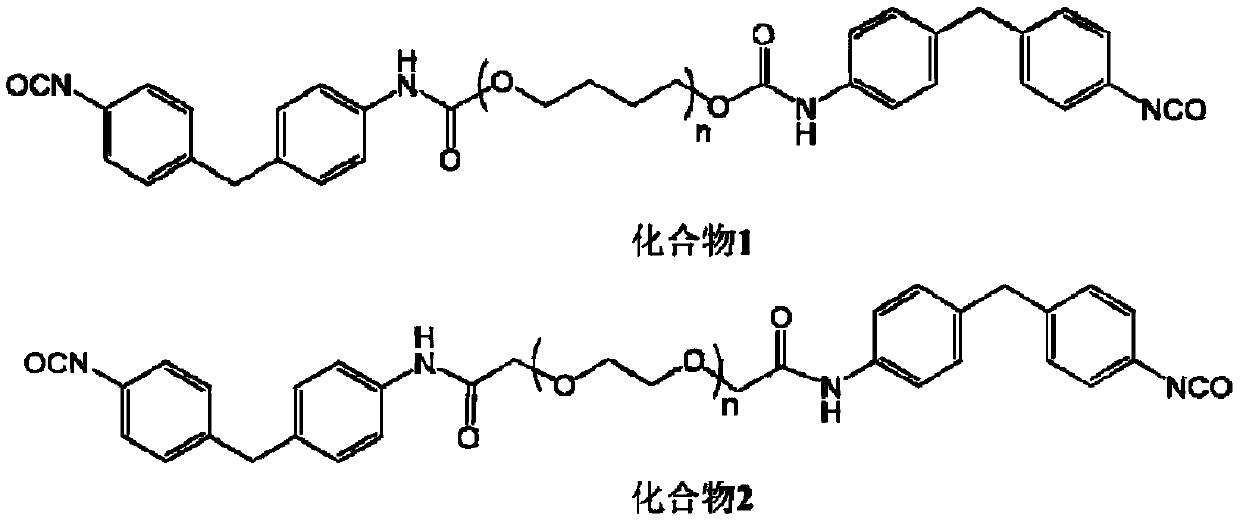

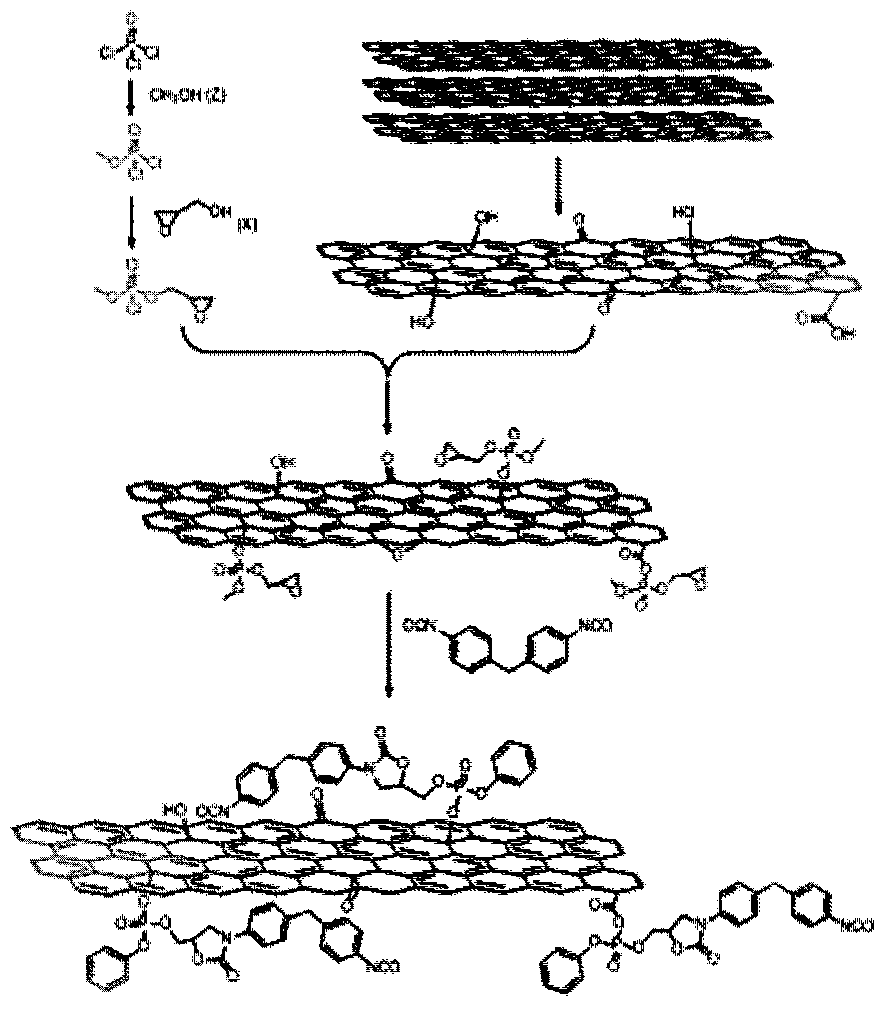

Modified graphene oxide and preparation method thereof

ActiveCN111484757ARetain reactivityEliminate the effects of chain extensionElectroconductive/antistatic filament manufacturePigment physical treatmentPolymer scienceOrganic chemistry

The invention discloses modified graphene oxide and a preparation method thereof. The modified graphene oxide is prepared from, by weight, 10 parts of graphene oxide, 10-50 parts of polyamine, 20-200parts of a mixture composed of polyisocyanate and monoisocyanate and 500-2000 parts of a solvent by dissolving and dispersing the graphene oxide in the solvent for preparing a dispersion liquid, adding the polyamine into the dispersion liquid, raising the temperature to 90-120 DEG C after the polyamine is added, carrying out reduction modification on the graphene oxide, reacting for 4-48 hours, adjusting the temperature to 50-100 DEG C, adding the mixture of polyisocyanate and monoisocyanate, and reacting for 4-48 hours to obtain a modified dispersion liquid. According to the preparation method, the principle that the graphene oxide is reduced by amido is utilized, and the graphene oxide is modified and reduced by the polyamine in the solvent, the mixture of polyisocyanate and monoisocyanate is added to terminate the amido, so that the influence of the amido on spandex chain extension is eliminated, the interlayer spacing of lamellas is further increased, and the crosslinking between the graphene lamellas is greatly reduced.

Owner:LIANYUNGANG DUZHONG NEW AOSHEN SPANDEX

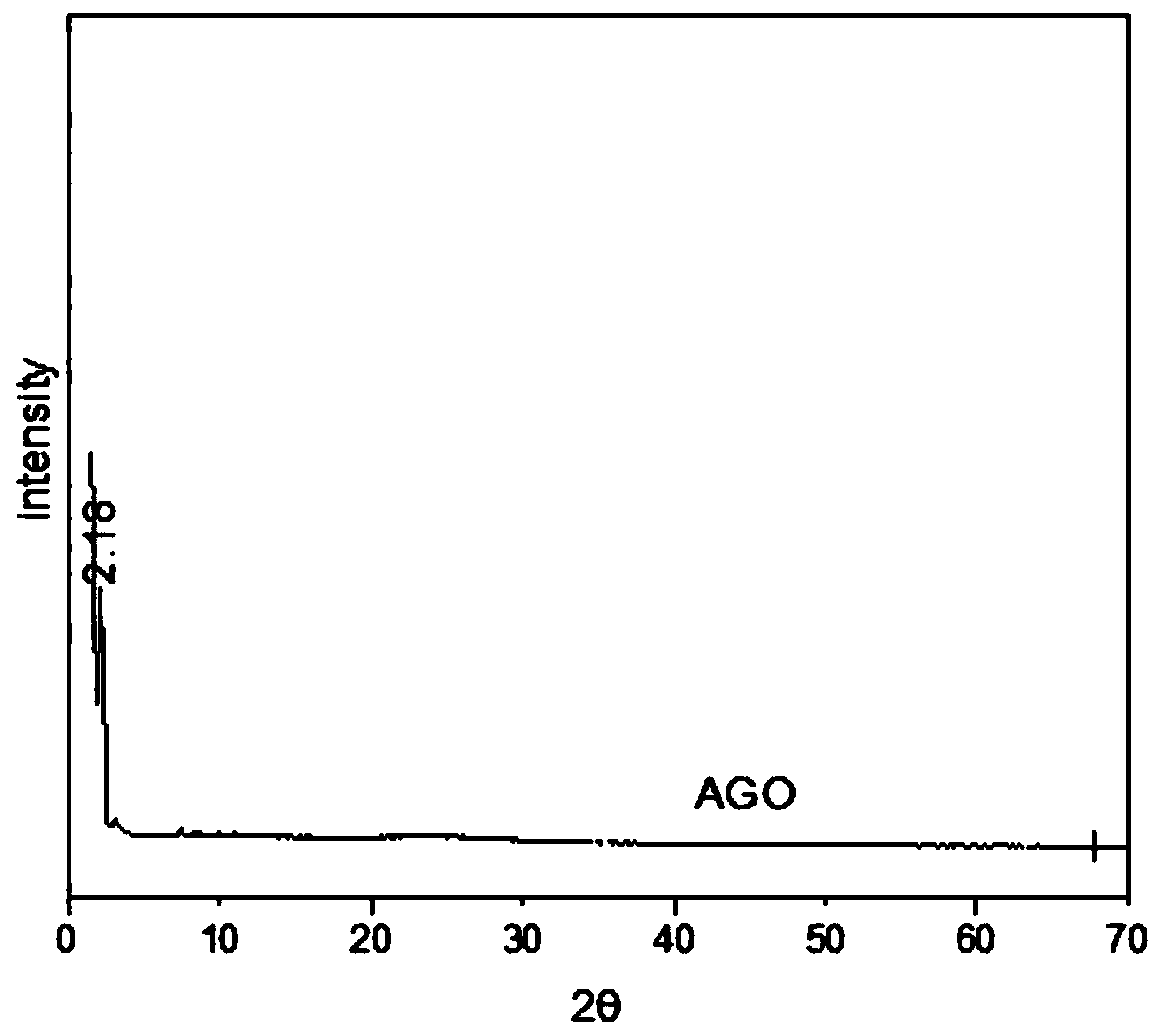

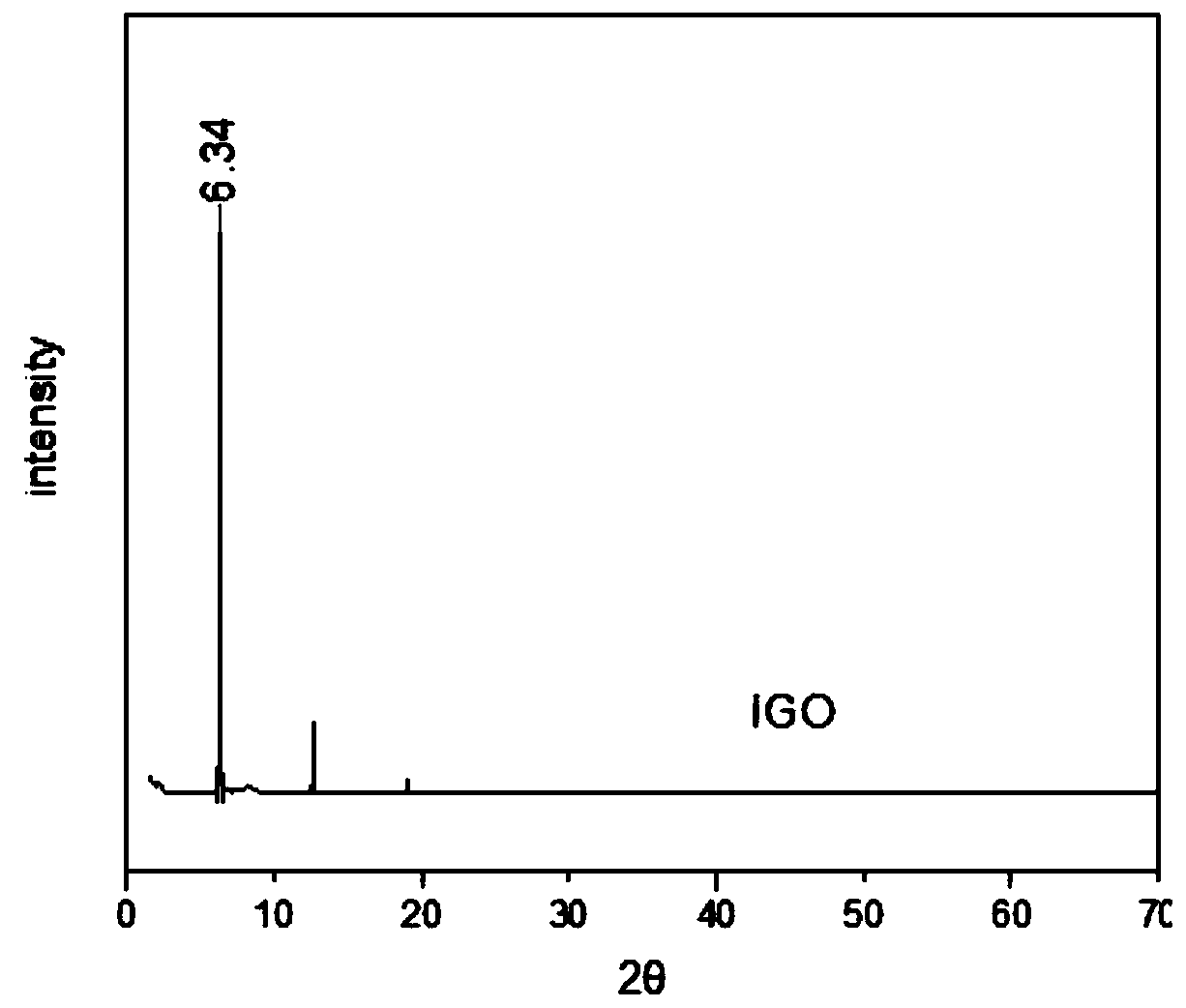

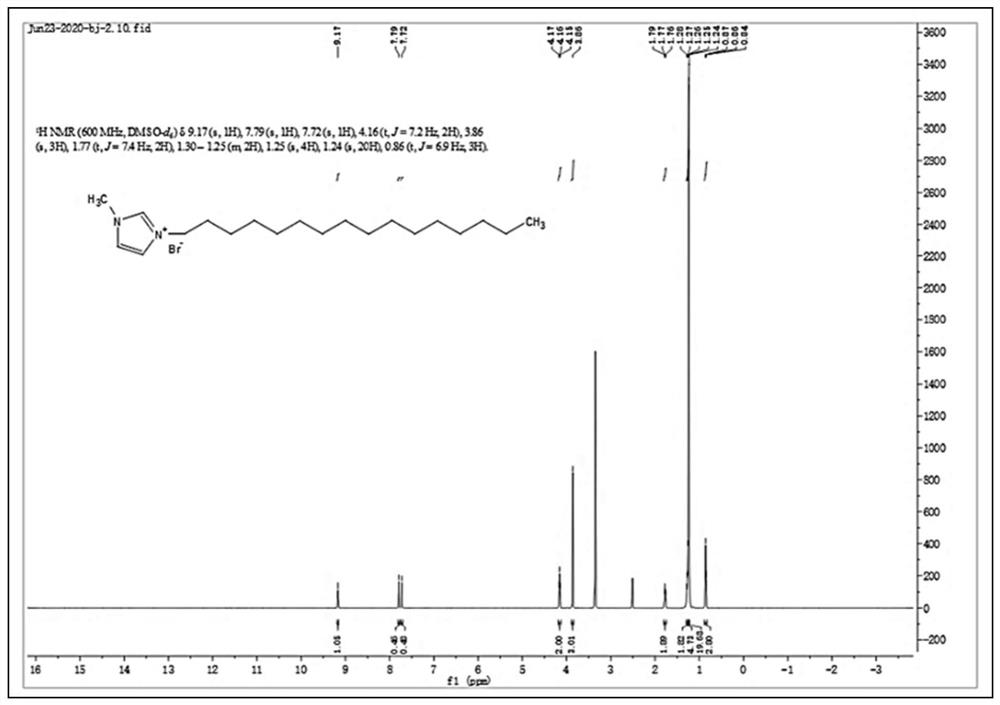

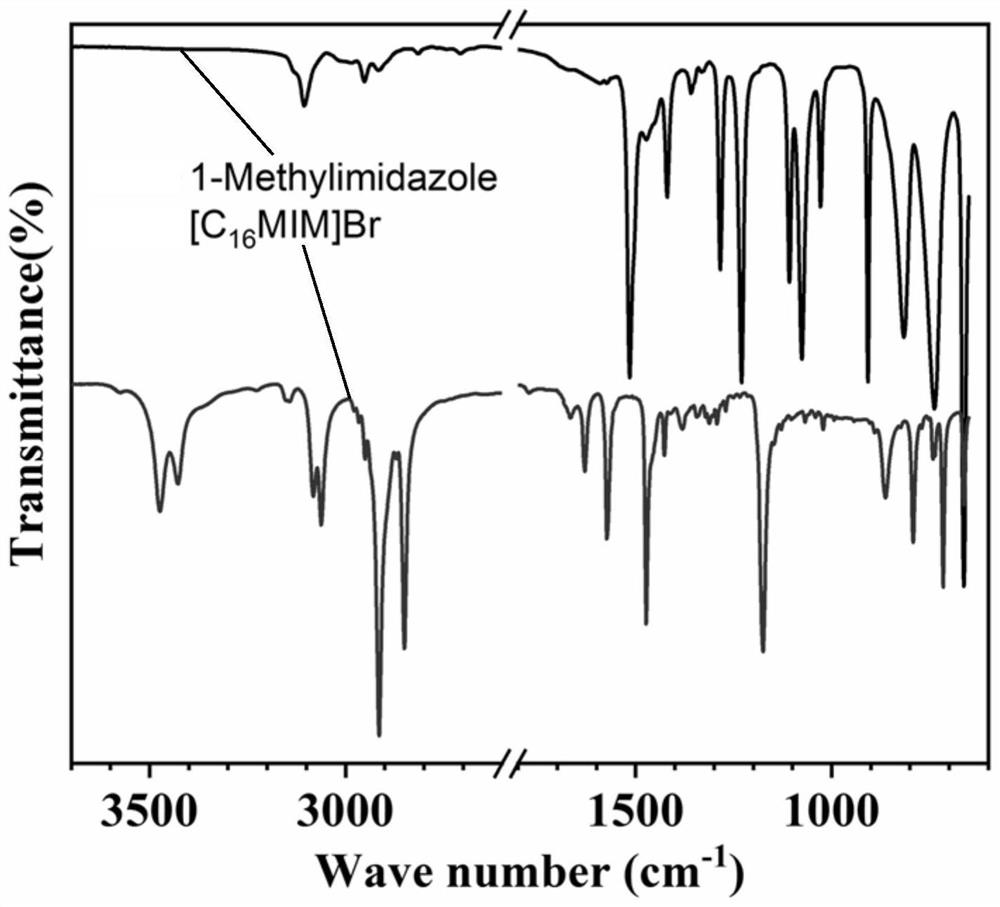

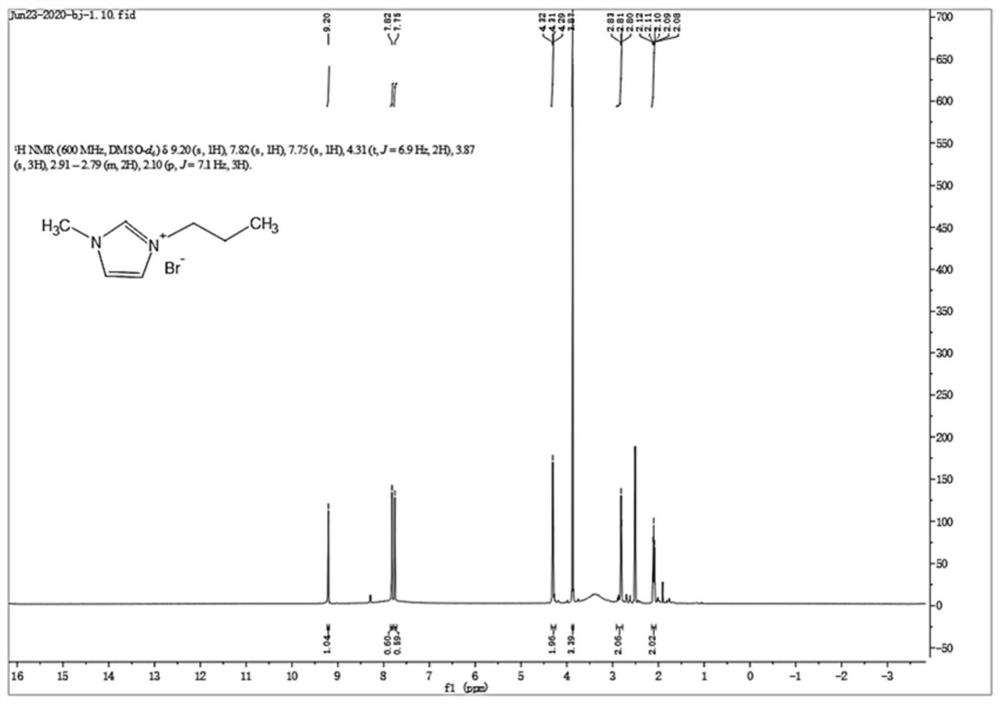

Heat-conduction-enhanced ionic liquid composite phase-change heat-storage material based on modified graphene, and preparation method thereof

PendingCN113072916AHigh purityPhase transition temperature is suitableHeat-exchange elementsPhase-change materialLatent heating

The invention discloses a heat-conduction-enhanced ionic liquid composite phase-change heat-storage material based on modified graphene and a preparation method thereof. The preparation method comprises the steps that firstly, covalent functional modification is conducted on graphene oxide through amino-terminated ionic liquid, and the modified graphene oxide reacts with hydrazine hydrate to be reduced, so the dispersity and interfacial compatibility of a graphene filler in an ionic liquid phase-change material matrix are improved, and the heat conduction characteristic of the composite material is improved; and furthermore, the modified graphene is mixed with the imidazolium ionic liquid phase-change material matrix, and conditions such as rotary evaporation and drying are controlled to obtain a mixture of the modified graphene with different loading capacities and the ionic liquid matrix phase-change material. The material provided by the invention has the characteristics of large phase change latent heat and good thermal stability; and meanwhile, the thermal conductivity is increased by 4.4%-127.9% compared with ionic liquid without modified graphene, and the thermal energy storage and conduction characteristics of the material are remarkably improved.

Owner:XI AN JIAOTONG UNIV

Preparation method of high-strength anti-aging sodium polyacrylate water-absorbing resin

The invention relates to the field of synthesis of polymer materials and discloses a preparation method of high-strength anti-aging sodium polyacrylate water-absorbing resin. The preparation method comprises: A) preparation of organically modified vermiculite powder: adding lactose and dodecyl dimethyl benzyl ammonium chloride into water, carrying out heating for a reaction, carrying out reduced pressure distillation, cleaning the product, drying the product to obtain modified lactose, calcining and grinding vermiculite, preparing a suspension liquid, heating the suspension liquid, adding themodified lactose into the suspension liquid, carrying out stirring for a heat preservation reaction, and carrying out centrifugation, filtration and drying, B) neutralization: adding acrylic acid andacrylamide into water and then neutralizing the solution with sodium hydroxide until the pH is 5-5.5, C) polymerization: adding organically modified vermiculite and bacterial cellulose, adding triallyl ammonium chloride and an initiator and carrying out a reaction process to obtain a viscous liquid, and D) drying and pulverization for forming a sodium polyacrylate water-absorbent resin. The sodiumpolyacrylate resin contains organically modified vermiculite powder so that the strength and aging resistance of the resin are effectively improved.

Owner:深圳市新拓普新材料有限公司

Modified montmorillonite-based cement clinker preparation method

The invention discloses a modified montmorillonite-based cement clinker preparation method, and belongs to the technical field of cement clinker preparation. According to the method, limestone, clay,sandstone, fly ash and steel slag are mixed, grinded and crushed to obtain a cement raw material; montmorillonite is subjected to an activation reaction, an acidification reaction and a sodium modification reaction to obtain modified montmorillonite; aluminate cement is grinded and crushed to obtain aluminate cement powder; and the aluminate cement powder is subjected to surface modification witha polyvinyl alcohol solution, wherein the group in the polyvinyl alcohol solution and the surface of the aluminate cement powder are subjected to a hydroxyl reaction, the partial covalent bond is formed through drying dewatering, the tricalcium aluminate and the tetracalcium aluminoferrite in the aluminate cement powder chemically react with the phosphogypsum in a filler to form hydrated calcium sulphoaluminate and hydrated calcium sulphoferrate, and the hydrated products are attached to the surface of the substrate, seal the surface of the hydrated component, block the diffusion of water molecules and ions, and improve the strength and the hydrophobicity of the cement clinker so as to achieve broad application prospects.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

Method for reinforcing polypropylene composite material by coupling modified short carbon fiber and pyridinium-modified montmorillonite

The invention discloses a method for reinforcing polypropylene composite material by coupling modified short carbon fiber and pyridinium-modified montmorillonite. The method comprises the following steps of putting a polypropylene plastic thin sheet, a thermoplastic elastomer and a compatilizer into an air blowing drying box to dry; uniformly mixing with the short carbon fiber treated by a silanecoupling agent, the surface-modified basalt fiber and a montmorillonite-reinforced flame-retardant system; melting, mixing and extruding at the setting processing temperature; cooling the extruded strip material, blow-drying and cutting into particles; putting the particle material into a constant-temperature drying box to dry; feeding into an injection molding machine to perform injection molding. The method has the advantages that by using the pyridinium-modified montmorillonite as a reinforcing material, and using the decabromodiphenyl ethane / antimony trioxide as a flame-retardant system, after the flame-retardant agent is added, the interlayer spacing of the montmorillonite in the polypropylene composite material is increased, and the dispersivity of the montmorillonite is improved; the thermal stability and flame-retardant property of the composite material are obviously improved, and the montmorillonite and the flame-retardant system can reach better flame-retardant synergistic effect in the polypropylene material.

Owner:QUANJIAO XIANGRUI PLASTIC

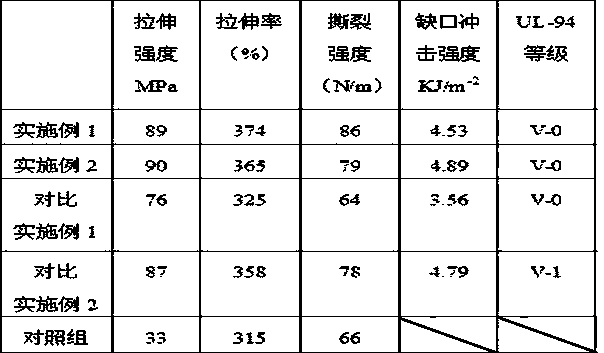

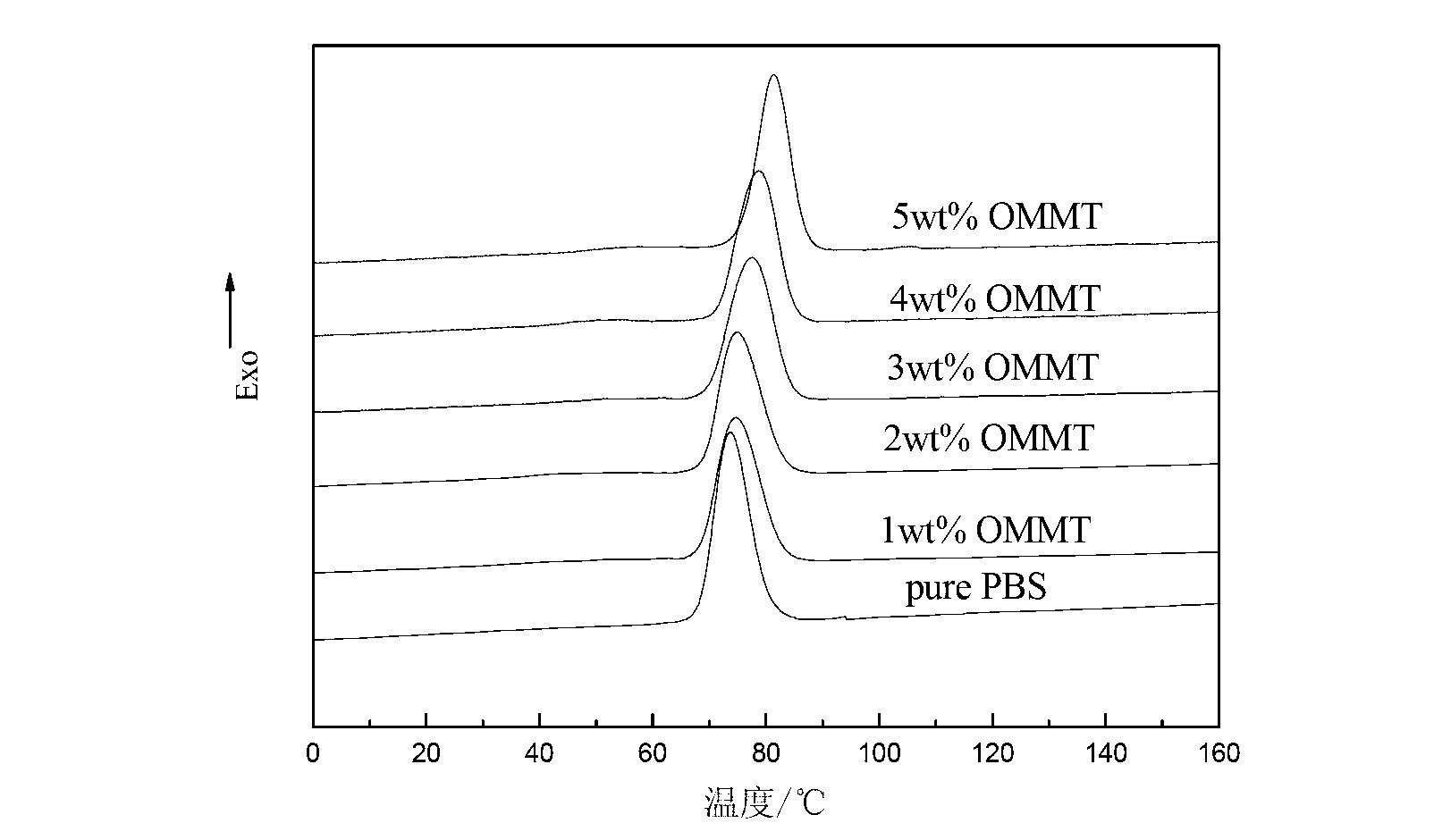

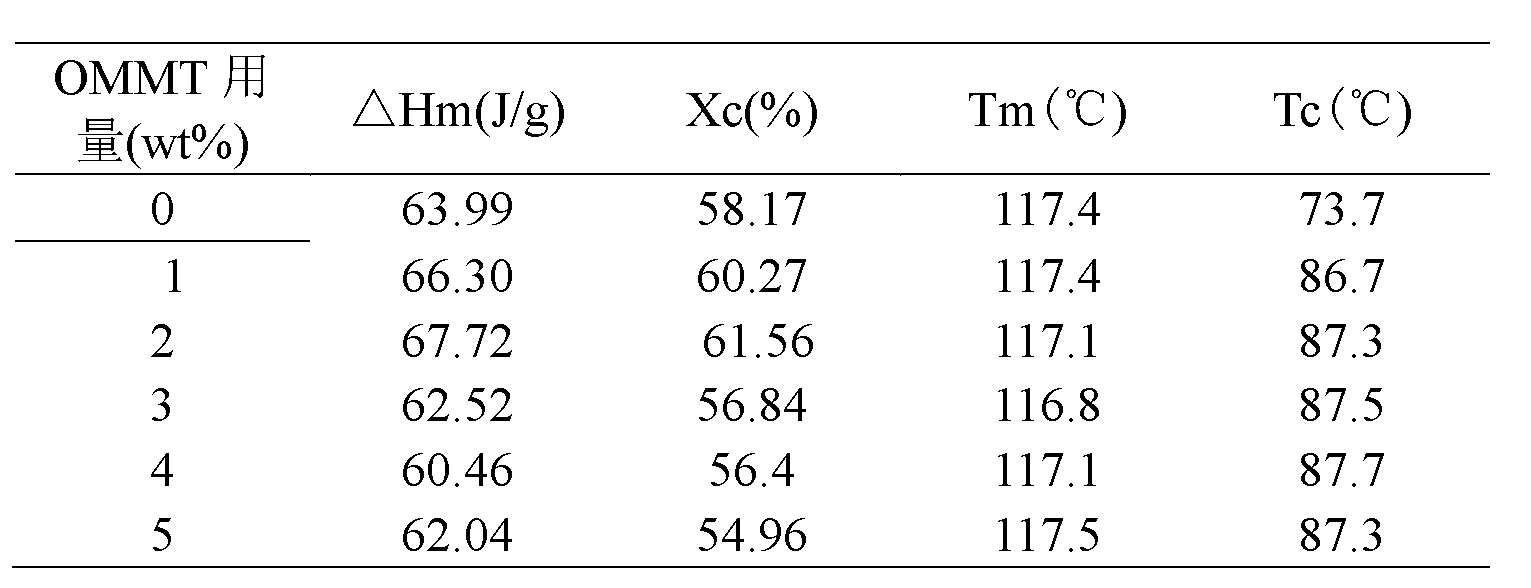

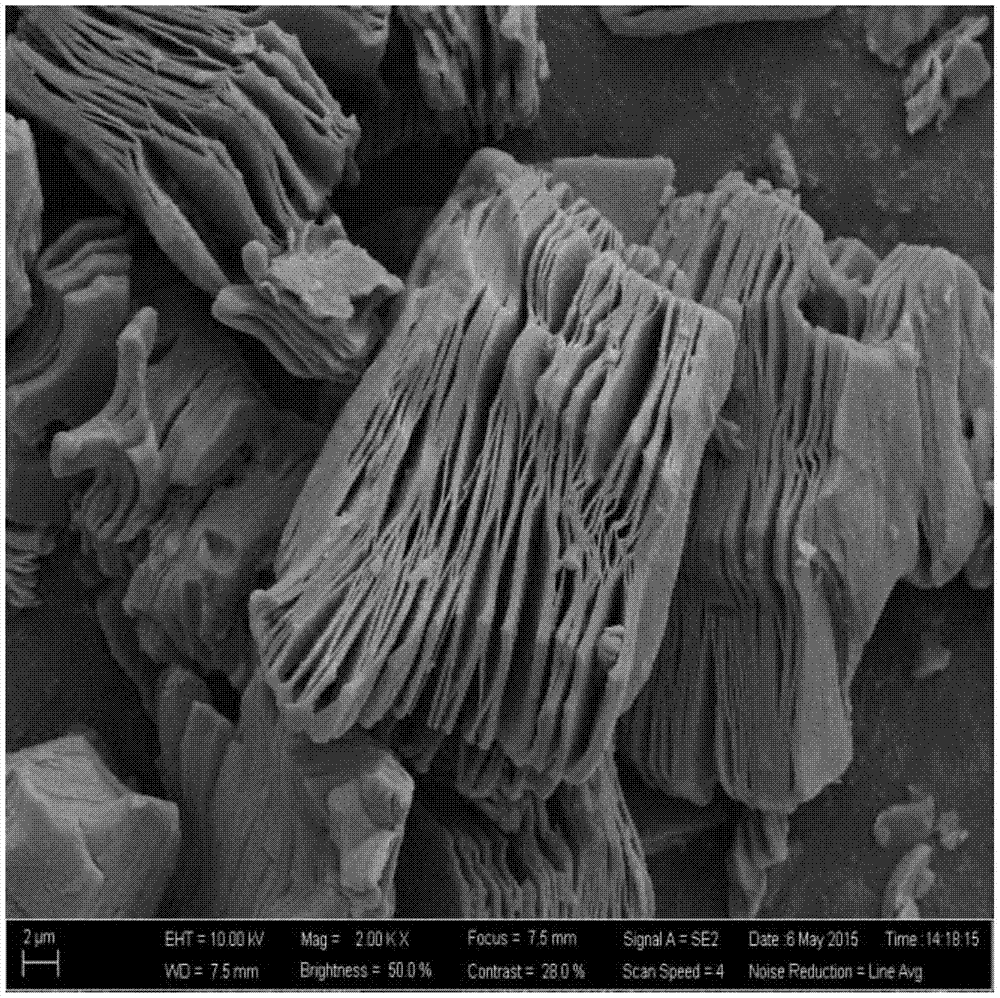

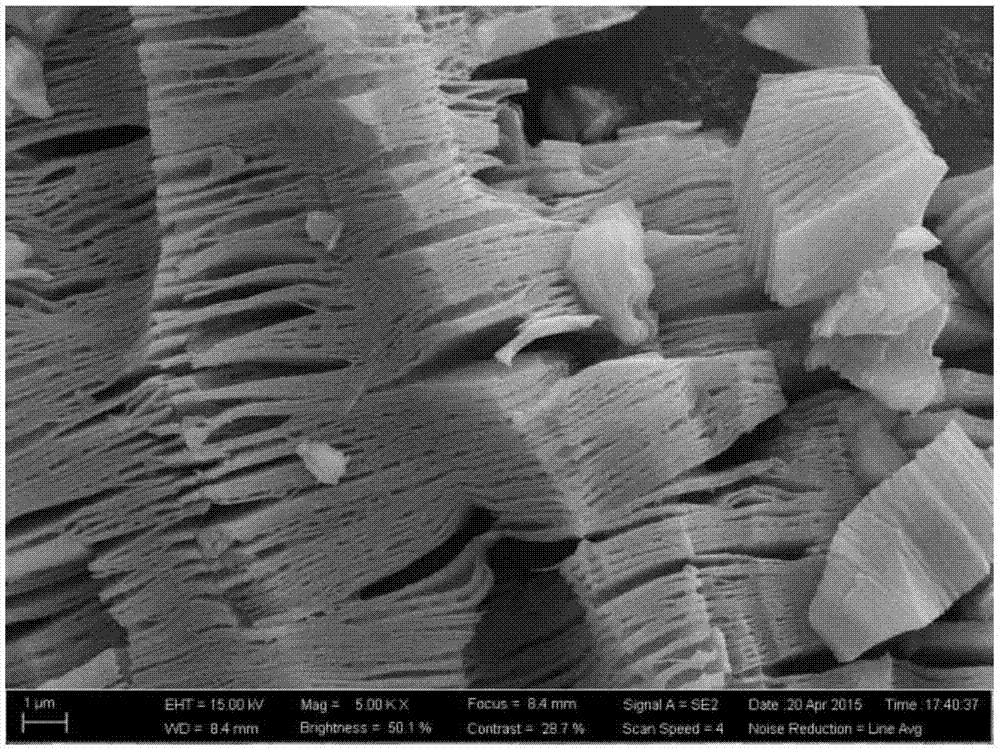

Preparation method of poly(butylene succinate)/organic montmorillonite nano-composite material

InactiveCN103013059AMaintain the characteristics of full biodegradationImprove toughnessMontmorilloniteWater cooling

The invention discloses a preparation method of a poly(butylene succinate) / organic montmorillonite nano-composite material The preparation method comprises the following steps of: (1) adding organic montmorillonite into dried poly(butylene succinate), wherein feeding amount of the organic montmorillonite (OMMT) is 1-5wt% of the poly(butylene succinate) (PBS); uniformly mixing to obtain a mixture of the poly(butylene succinate) and the organic montmorillonite; and (2) adding the mixture of the poly(butylene succinate) and the organic montmorillonite into a screw extruder, and extruding; setting the rotating sped of a screw at 25-35rpm; and after extruding, water-cooling and slicing to obtain a product. The PBS / organic montmorillonite nano-composite material disclosed by the invention keeps the property of complete biodegradation of the poly(butylene succinate), and the added catalyst and other materials are biodegradable materials, so that the final product is completely degraded by the microorganisms in the soil.

Owner:CHINA PACKAGING RES & TEST CENT

A preparation method of titanium carbide nanosheet/graphene composite material that can be used for lithium-ion battery negative electrode

InactiveCN105098162BImprove performanceShort cycleCell electrodesSecondary cellsFiltrationTitanium carbide

Owner:HARBIN INST OF TECH

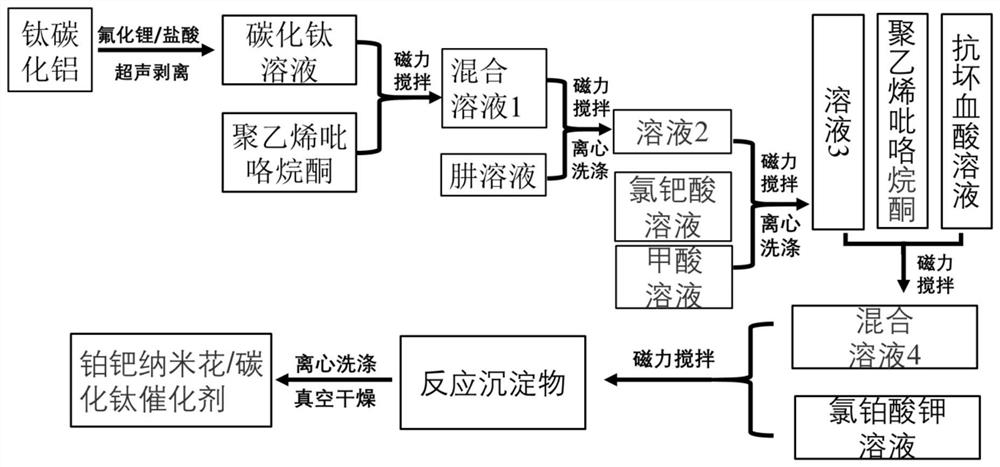

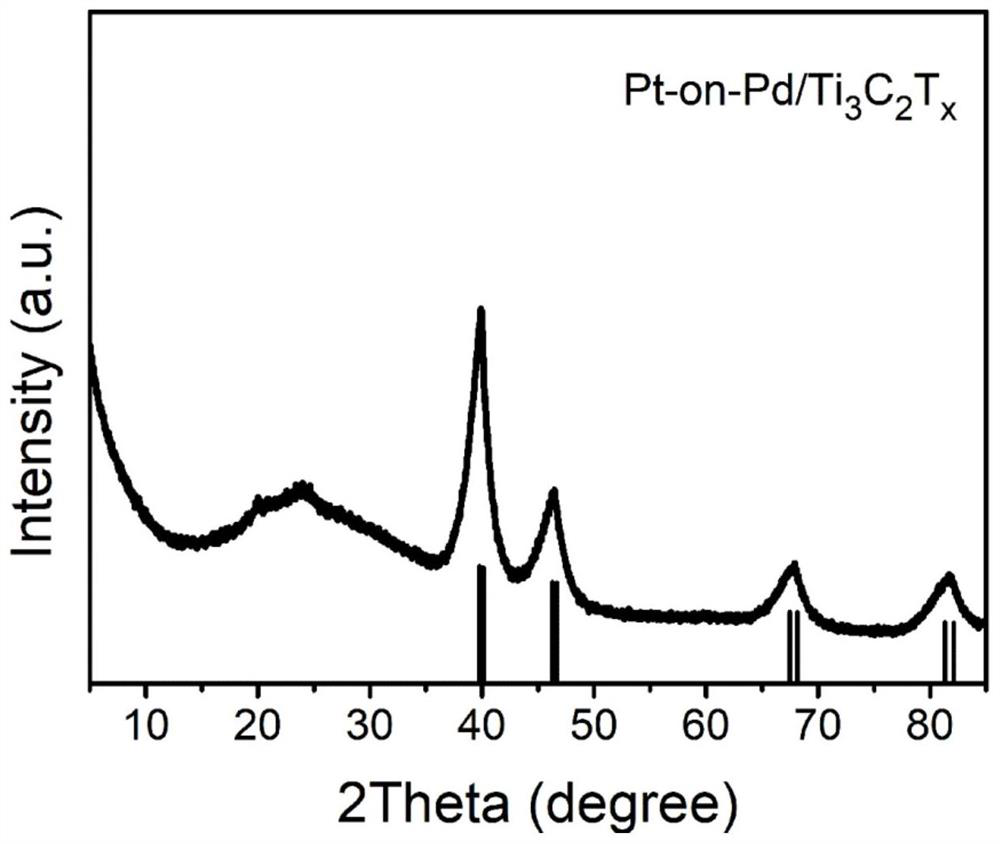

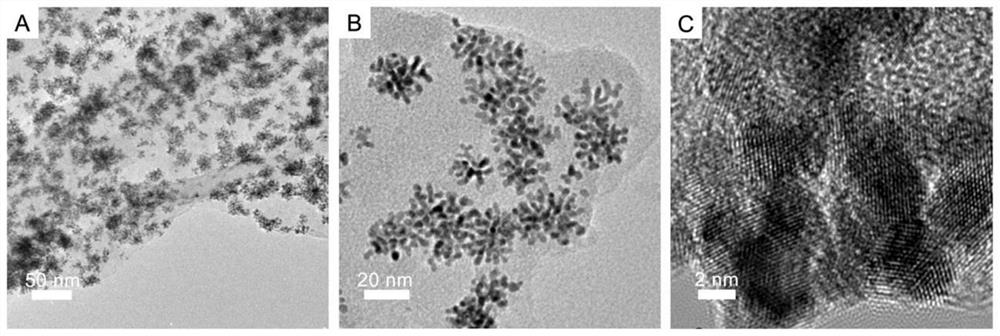

Preparation method of titanium carbide loaded platinum-palladium nanoflower electrode catalyst

ActiveCN113363507AIncrease profitGood dispersionCell electrodesFuel cellsPtru catalystPlatinum salts

The invention provides a preparation method of a titanium carbide-loaded platinum-palladium nanoflower electrode catalyst, and relates to the field of electrode catalysts. The preparation method comprises the steps of adding a polyvinylpyrrolidone solution into a titanium carbide nanosheet, then adding a hydrazine solution, uniformly mixing, centrifugally washing and re-dispersing to obtain a polyvinylpyrrolidone / titanium carbide nanosheet precursor, then adding a palladium salt solution and a formic acid solution, uniformly mixing, centrifugally washing and re-dispersing to obtain a palladium-modified titanium carbide nanosheet precursor; and then sequentially adding a polyvinylpyrrolidone solution and an ascorbic acid solution, stirring, adding a platinum salt solution, reacting, and finally centrifugally washing and freeze-drying the obtained black precipitate to obtain the titanium carbide loaded platinum-palladium nanoflower electrode catalyst. The titanium carbide nanosheet is used as a template, palladium and platinum are sequentially grown on the surface of the titanium carbide nanosheet in situ, and the prepared electrode catalyst has the advantages of being stable in structure, high in catalytic activity and high in poison resistance.

Owner:北京三川烯能科技有限公司

Polyformaldehyde composite material and preparation method thereof

The invention relates to a polyformaldehyde composite material and a preparation method thereof. The preparation method comprises the following steps: respectively uniformly stirring nanometer aluminum oxide, micron aluminum oxide and 2wt%-3wt% of coupling agent, treating the surfaces of nanometer aluminum oxide and micron aluminum oxide, and then drying after treating; preparing 0.3-1 part by weight of sulfonated graphene into a sulfonated graphene aqueous solution; dispersing 3-10 parts by weight of nanometer aluminum oxide treated with the coupling agent into deionized water, dropwise adding the sulfonated graphene solution into a nanometer aluminum oxide dispersion liquid under stirring state, stopping stirring after the ending of dropwise adding, filtering after the layering of liquid, and drying filter residue, thereby acquiring a sulfonated graphene / nanometer aluminum oxide compound; mixing 80-93 parts by weight of polyformaldehyde, 3-7 parts by weight of sulfonated graphene / nanometer aluminum oxide compound, parts by 3.5-9 weight of micron aluminum oxide treated with the coupling agent and a defined amount of additives, and then drying; mixing for 3-4 hours in a blender mixer; extruding, chopping and drying after mixing, thereby acquiring the polyformaldehyde composite material.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of nano modified polyester material

The invention discloses a preparation method of a nano modified polyester material and belongs to the technical field of polyester material preparation. The preparation method comprises: activating montmorillonite, acidifying the activation resultant, performing sodication, grinding to obtain modified montmorillonite powder so that lamellar spacing is increased for the powder, allowing lamellar inorganic interlayers to bind base molecular bundles such that both motion of base chain segments and translation or rotation of molecular chains are hindered greatly, mixing sodium carbonate solution and zinc chloride solution to allow reacting, and calcining at a high temperature to obtain nano zinc oxide grains, and using stearic acid and anhydrous ethyl alcohol to surface-modify the nano zinc oxide grains such that the nano zinc oxide grains are dispersed evenly in a base with rarity of clustering; the surface of the nano zinc oxide grains is modified such that the nano zinc oxide grains andthe base experience chemical bonding and molecular entangling, the strength and rigidity of the base are improved, the tensile strength of the nano modified polyester material is further improved, and the nano modified polyester material is widely applicable.

Owner:许水仙

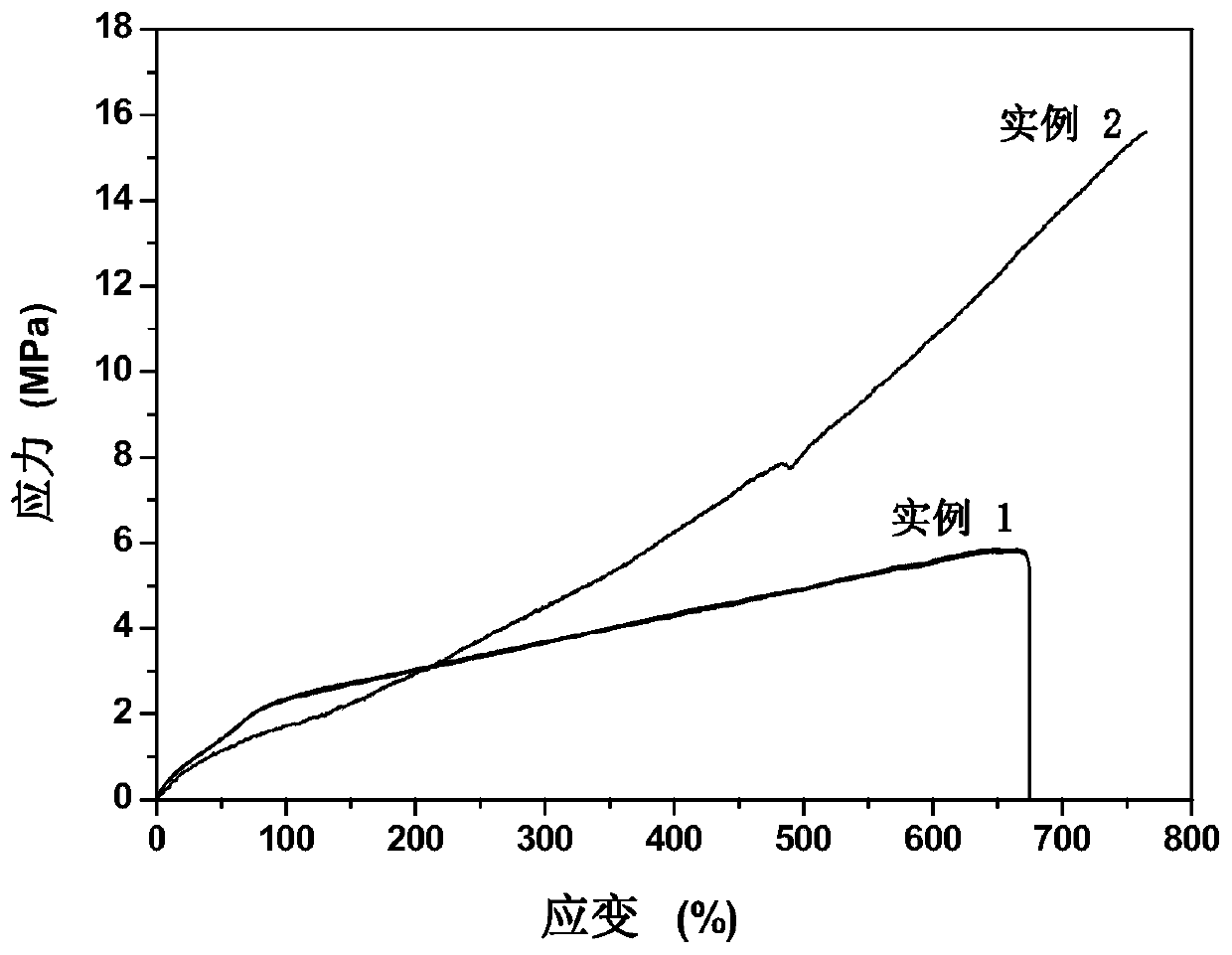

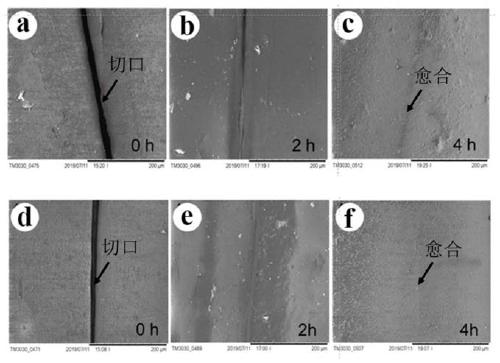

Self-healing flexible composite material and preparation method thereof

InactiveCN111592655AImprove self-healing abilityImprove mechanical propertiesOrganic chemistry methodsFuranGraphene flake

The invention discloses a self-healing flexible composite material and a preparation method thereof, and belongs to the field of material preparation. According to the preparation method of the self-healing flexible material, furan functionalized graphene oxide is prepared, so that the interlayer spacing of graphene is increased, the problem of dispersity of graphene is solved, and the mechanicalproperty of the material is remarkably improved; a Diels-Alder reaction is carried out on the furan functionalized graphene oxide and maleimide derivatives to generate the flexible material with a dynamic covalent bond; and the reaction conditions are mild, the generated flexible material has excellent self-healing performance, external stimulation is not needed in the healing process, and self-repairing can be achieved at the room temperature. The problems that graphene is poor in dispersity in a polymer matrix and a polymer composite material is low in self-repairing efficiency are solved.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of sodium polyacrylate water-absorbing fibers

ActiveCN109023583AImprove water retentionHigh strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureViscous liquidFiber

The invention relates to the field of synthesis of polymer materials and discloses a preparation method of sodium polyacrylate water-absorbing fibers. The preparation method comprises: A) preparationof organically modified vermiculite powder: adding lactose and dodecyl dimethyl benzyl ammonium chloride into water, carrying out heating for a reaction, carrying out reduced pressure distillation, cleaning the product, drying the product to obtain modified lactose, calcining and grinding vermiculite, preparing a suspension liquid, carrying out heating, adding the modified lactose into the suspension liquid, carrying out stirring under thermal insulation for a reaction, and carrying out centrifugation, filtration and drying, B) neutralization: adding acrylic acid and acrylamide into water, andthen neutralizing the solution with sodium hydroxide until the pH is 5-5.5, C) polymerization: adding organically modified vermiculite and bacterial cellulose into the solution, and adding a triallylammonium chloride and an initiator into the solution for a reaction so that a viscous liquid is obtained, and D) wet spinning: preparing sodium polyacrylate fibers. The organically modified vermiculite powder in the sodium polyacrylate fibers can effectively improve the strength and aging resistance of fibers.

Owner:深圳市金利源绝缘材料有限公司

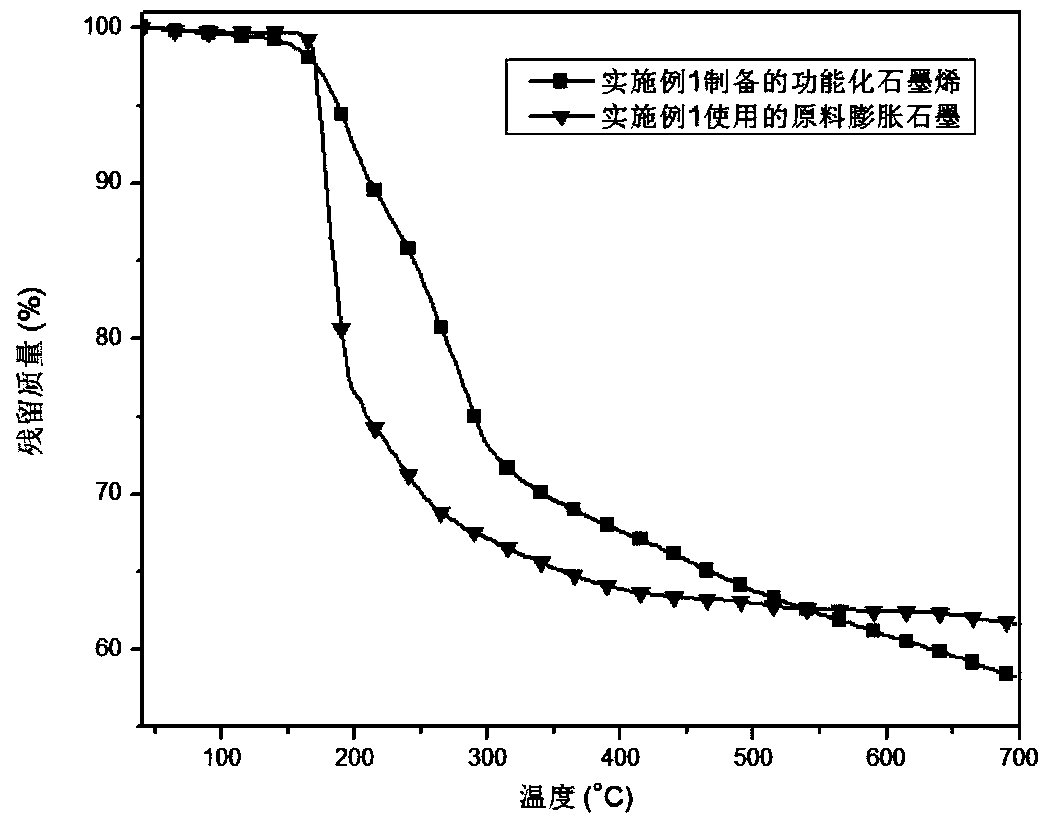

Functionalized graphene and its preparation method and its flame-retardant crosslinked polyurethane rigid foam

The invention discloses functionalized graphene. A general structural formula of the functionalized graphene is represented in the specification, wherein X is an epoxy group, Y is graphene, Z is any one of alkyl groups of C1-C6, and the functionalized graphene is prepared by grafting graphene oxide onto a product obtained through reaction of a phosphorus and chlorine compound, epoxy structure containing monomers and phenol monomers in an environment without water. After the functionalized graphene is added to rigid polyurethane foam, the functionalized graphene as an intrinsic type flame retardant can better perform functions on the basis of good dispersibility, flame retardancy and compressibility of the rigid polyurethane foam are greatly improved, the density and the heat insulating performance of the rigid polyurethane foam can be equivalent to those of common rigid polyurethane foam, besides, a preparation technology of the functionalized graphene and the rigid polyurethane foam is simple and easy, and large-scale popularization and application can be performed conveniently.

Owner:SICHUAN UNIV

A kind of graphene antibacterial masterbatch, fiber and preparation method thereof

ActiveCN108047709BEvenly dispersedIncreasing interlamellar spacingArtifical filament manufactureMonocomponent polyamides artificial filamentFiberNylon 6

A preparation method of graphene antibacterial master batch comprises the following steps of first powder preparation, second powder preparation and master batch preparation. According to the technical scheme, water-soluble polyquaternary ammonium salt serves as an intercalation agent and an antibacterial agent, gaps between layers of a graphene oxide sheet are increased, then the water-soluble polyquaternary ammonium salt and nylon 6 are prepared into a microcapsule, and a core-shell structure is formed. According to the antibacterial master batch prepared through the method, polyquaternary ammonium salt and graphene oxide are used for preventing bacteria together, so that the master batch is good in antibacterial property; meanwhile, graphene is uniform in dispersion, and the physical and mechanical properties are enhanced; the graphene and nylon 6 can be fused and blended for preparing antibacterial textile silk.

Owner:福建烯石新材料科技有限公司

Method for preparing manganese dioxide nanosheets by low-temperature hydrothermal method

InactiveCN106006746BIncrease contact areaRealize direct insertion/extractionManganese oxides/hydroxidesSupercapacitorSURFACTANT BLEND

The invention discloses a method for preparing a manganese dioxide nanosheet in a low-temperature hydrothermal mode. The method comprises the steps that potassium permanganate is used as a raw material, ethanediol is used as a reducing agent, SDS is used as a surfactant, and the manganese dioxide nanosheet is integrated in one step in the low-temperature hydrothermal mode. The manganese dioxide nanosheet is loose in layer, large in gap, large in specific area and good in electrical conductivity and super capacitive performance. The raw materials are easy to obtain, the cost is low, practicability is strong, environmental friendliness is achieved, and the method has the good application prospect in the aspect of supercapacitor electrode materials.

Owner:NORTHWEST NORMAL UNIVERSITY

A kind of preparation method and application of montmorillonite-graphene composite powder

The invention provides a preparation method and application of montmorillonite-graphene composite powder. The preparation method of the montmorillonite-graphene composite powder comprises the following steps: (1) letting montmorillonite adsorb an organic dye to be saturated, centrifuging and washing, and drying to obtain organic dye-adsorbed waste montmorillonite, wherein the mass ratio of montmorillonite to the organic dye is 1: (0.3-1); and (2) calcining the organic dye-adsorbed waste montmorillonite at 600-700 DEG C for 2-4 h under the inert atmosphere protection so as to obtain the montmorillonite-graphene composite powder. By using waste montmorillonite as a raw material, the montmorillonite-graphene composite powder with montmorillonite and graphene uniformly intercalated is prepared by a one-step method. After the montmorillonite-graphene composite powder is modified with a silane coupling agent, the modified product is used as a filling material to prepare a polymer composite material. Then, properties of the polymer composite material, such as tensile strength and impact strength, etc., are effectively enhanced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

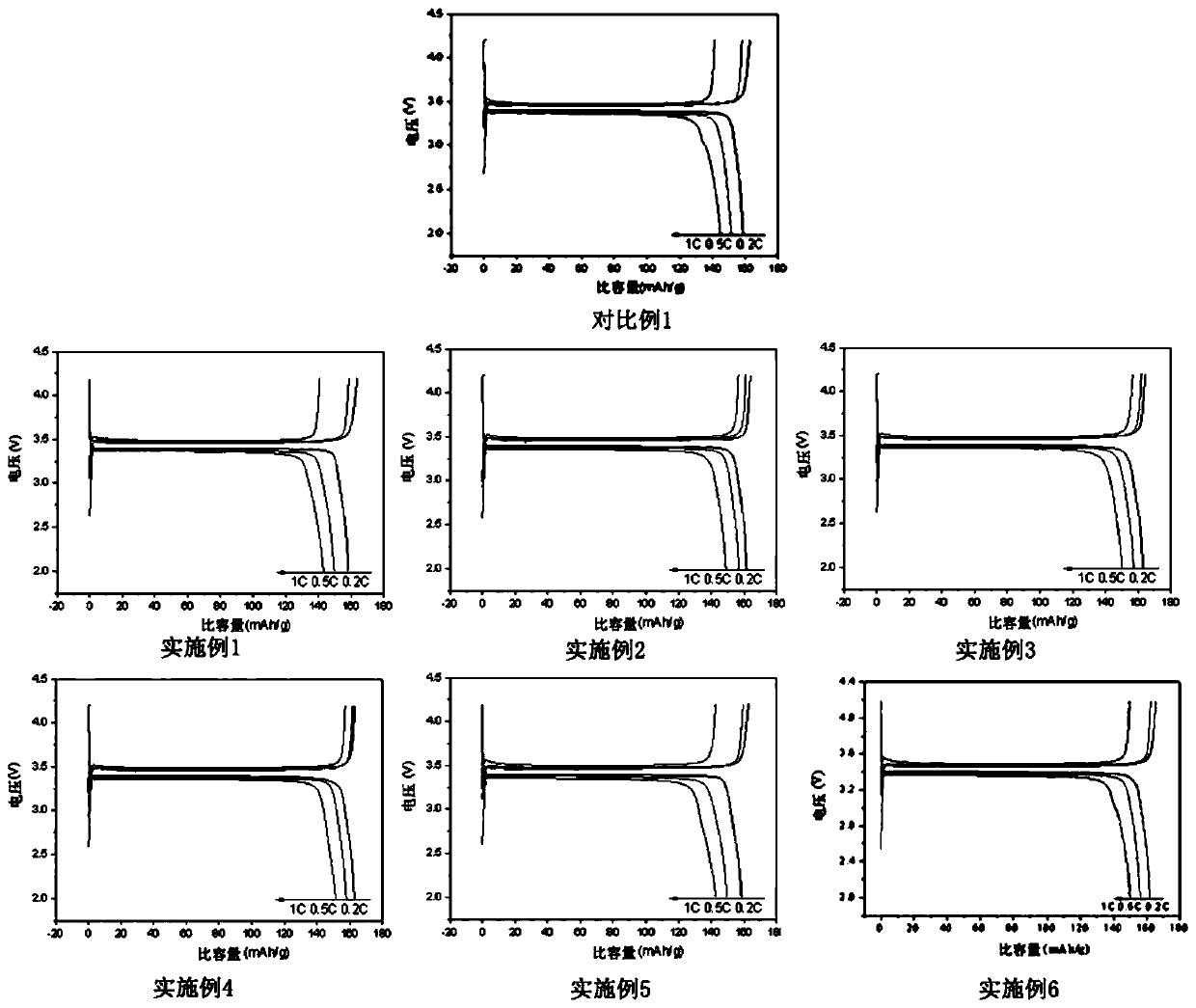

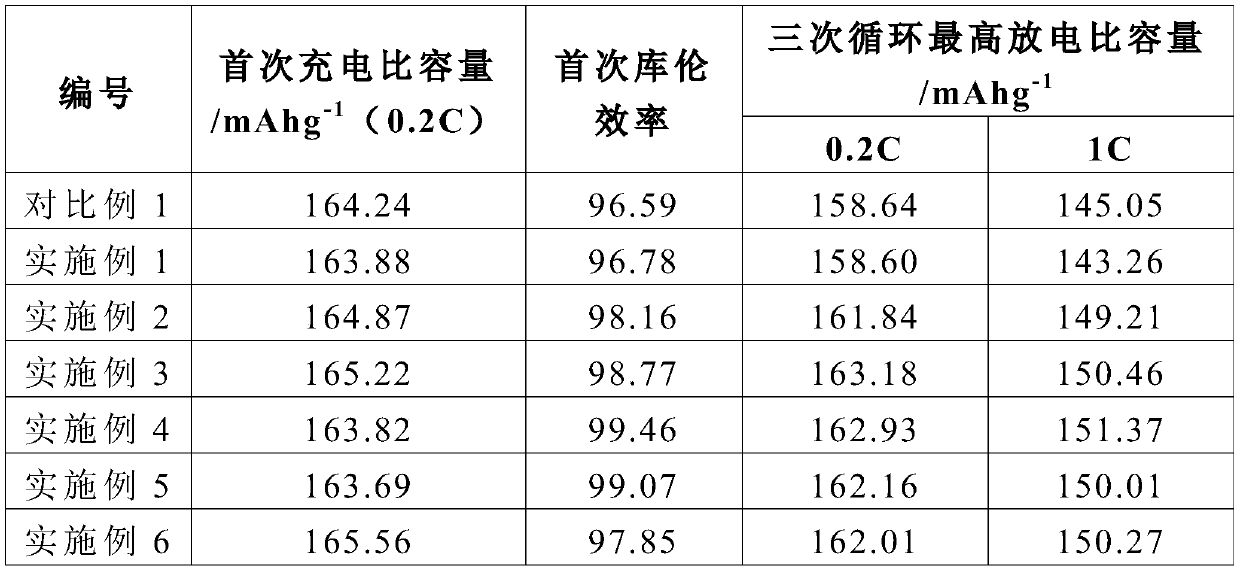

A kind of preparation method of composite positive electrode material for lithium battery

ActiveCN108110251BLarge specific surface areaIncreasing interlamellar spacingSecondary cellsPositive electrodesLithium hydroxidePhosphoric acid

The invention discloses a preparation method of a composite type positive electrode material for a lithium battery. The preparation method comprises the following steps: ultrasonically dispersing graphene oxide into deionized water, adding cerium acetate, potassium acetate, urea and ammonia water into a container, and performing sealing, baking, drying and microwave treatment to prepare a cerium oxide / graphene compound; preparing rare earth metal ion doped lithium iron phosphate from raw materials such as lithium hydroxide, iron phosphate, oxalic acid, glucose and rare earth metal oxide; performing ultrasonic dispersion and ball milling on the cerium oxide / graphene compound, the rare earth metal ion doped lithium iron phosphate and ethanol to prepare cerium oxide / graphene rare earth metalion doped lithium iron phosphate; and performing stirring, microwave treatment and calcination on the raw materials such as the lithium hydroxide, ferric vanadate, phosphoric acid, deionized water andthe cerium oxide / graphene rare earth metal ion doped lithium iron phosphate to prepare the composite type positive electrode material for the lithium battery. The composite type positive electrode material prepared by the method has excellent electrical performance; moreover, the preparation method is clean and environment-friendly.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

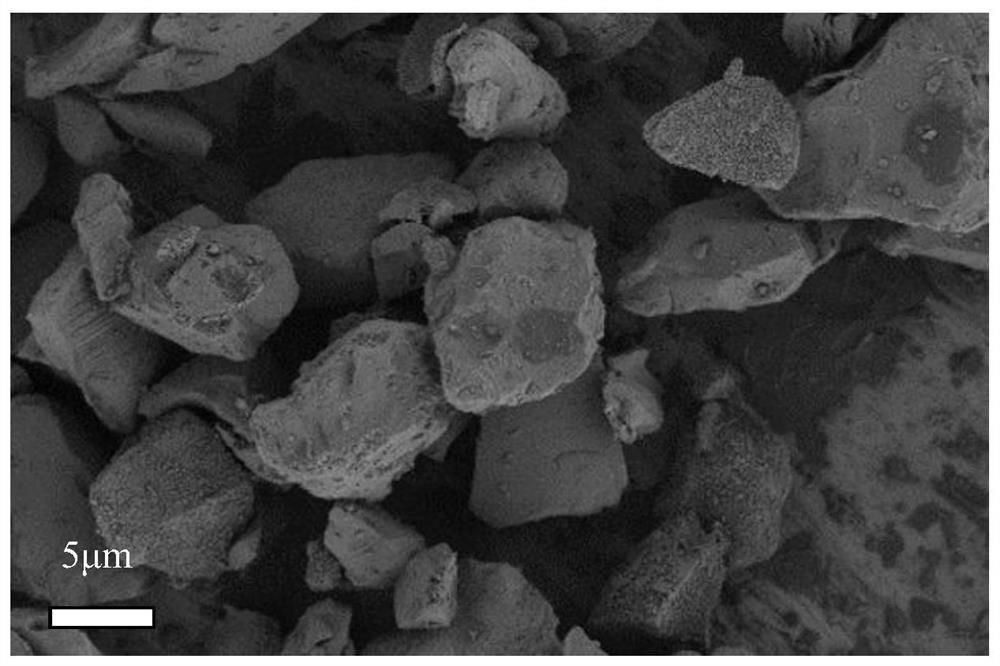

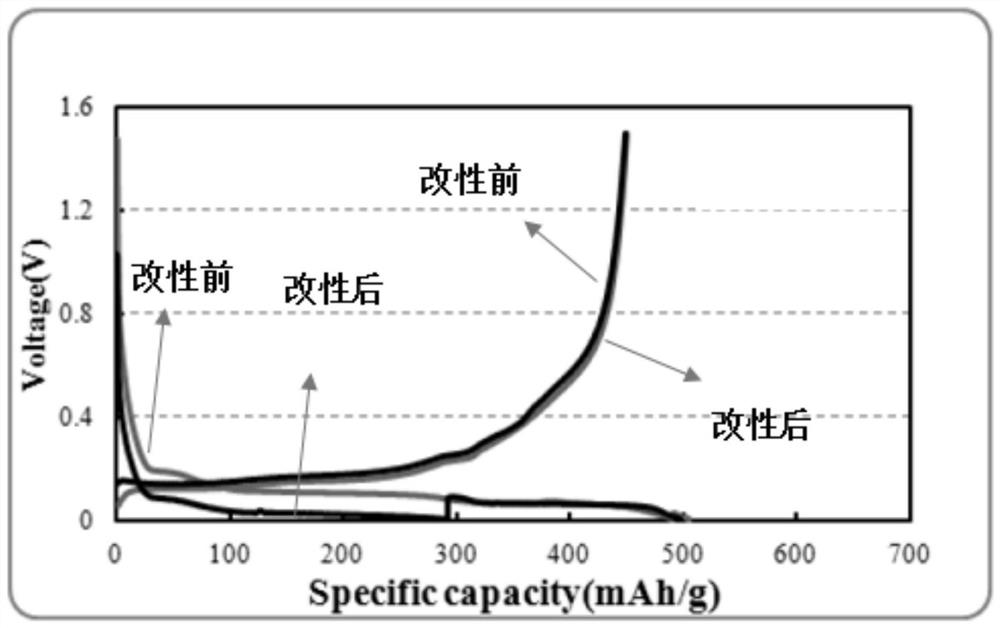

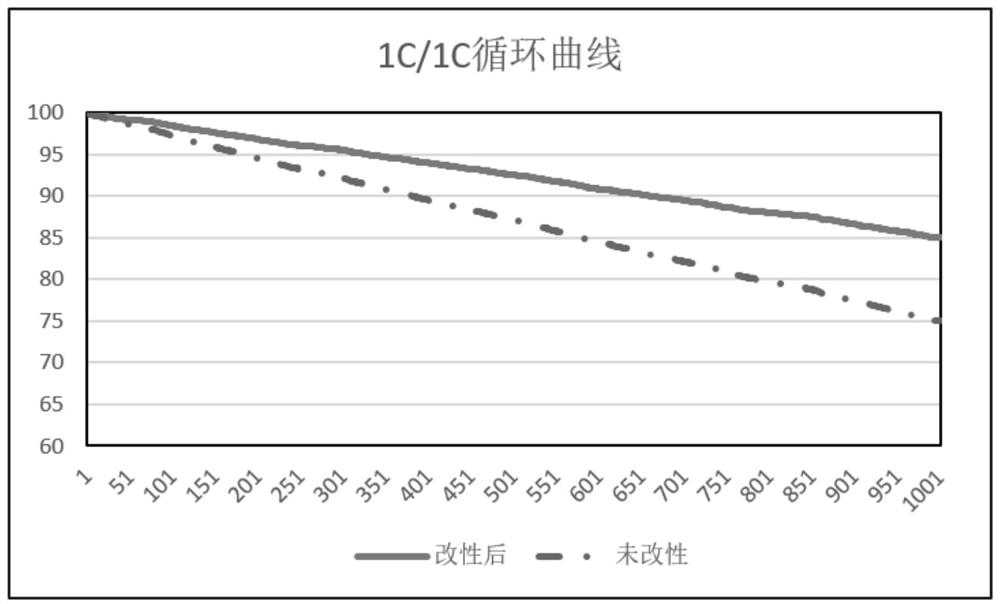

Organic-inorganic composite silicon-based negative electrode material, and preparation method and application thereof

InactiveCN112289987AImprove cycle performanceImprove electronic conductivityCell electrodesSecondary cellsElectrical batteryLithium-ion battery

The invention discloses a preparation method of an organic-inorganic composite silicon-based negative electrode material. The method comprises the following steps: S1, carrying out acid pickling etching on a silicon-based material, uniformly mixing the silicon-based material with a carbon source, and carbonizing in an inert atmosphere to obtain a carbon-coated acid-etched silicon-based material; and S2, uniformly mixing the carbon-coated acid-etched silicon-based material with a mixed aqueous solution, soaking, and carrying out spray drying to obtain the organic-inorganic composite silicon-based negative electrode material, wherein a solute of the mixed aqueous solution is sodium dodecyl benzene sulfonate and a silane coupling agent. The invention also discloses an organic-inorganic composite silicon-based negative electrode material which is prepared according to the preparation method of the organic-inorganic composite silicon-based negative electrode material. The invention also discloses an application of the organic-inorganic composite silicon-based negative electrode material in a lithium ion battery. The method is simple in process, stable in performance, low in cost and excellent in cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

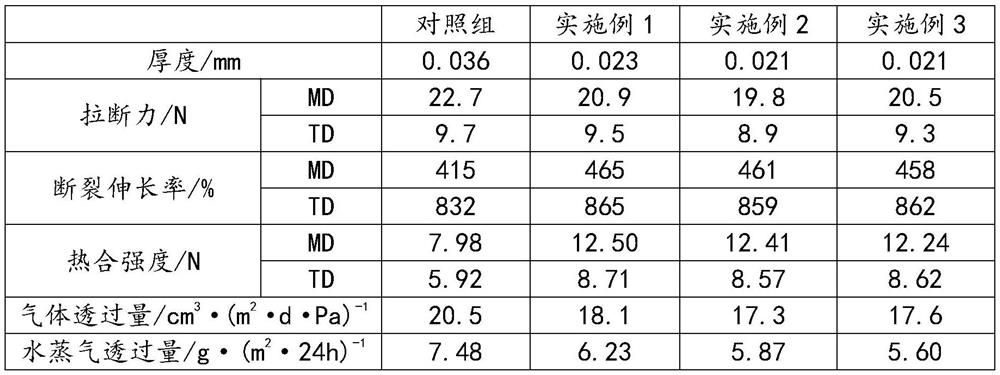

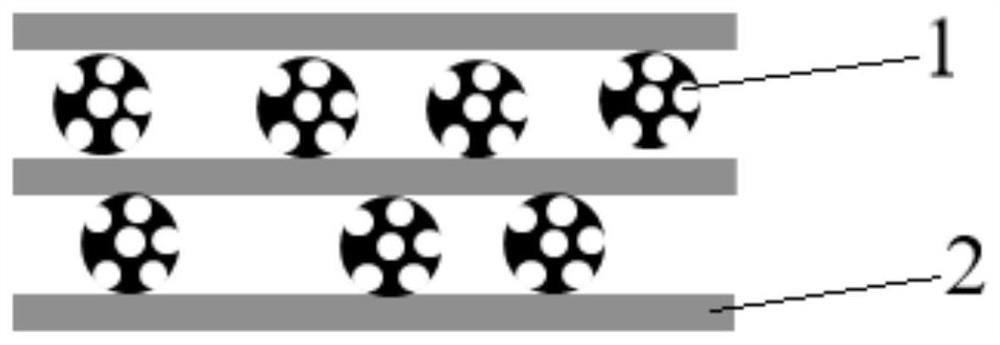

High-strength lightweight antibacterial plastic film and preparation method thereof

PendingCN114193884AImprove antibacterial propertiesReduce usageSynthetic resin layered productsLow-density polyethylenePolymer science

The invention relates to a high-strength lightweight antibacterial plastic film and a preparation method thereof. The antibacterial plastic film is prepared by co-extrusion blow molding of an upper surface layer, a middle layer and a lower surface layer, the upper surface layer and the lower surface layer are prepared from the following components in parts by weight: 15-20 parts of metallocene polyethylene, 80 parts of low-density polyethylene, 5-10 parts of nano calcium carbonate, 2 parts of fluorine-containing polymer PPA, 0.15-0.6 part of talcum powder, 0.1-0.4 part of erucyl amide and 2-4 parts of antibacterial master batch; the middle layer is prepared from the following components in parts by weight: 90 to 95 parts of low-density polyethylene, 5 to 10 parts of nano calcium carbonate, 2 parts of fluorine-containing polymer PPA, 0.15 to 0.6 part of talcum powder, 0.1 to 0.4 part of erucyl amide, 15 to 20 parts of barrier master batch, 15 to 20 parts of organic modified montmorillonite and 3 to 6 parts of maleic anhydride grafted polyethylene. The high-strength and light-weight polyethylene film prepared by the preparation method disclosed by the invention has high-barrier and antibacterial functions at the same time.

Owner:FUJIAN HENGAN HYGIENE MATERIAL

Black talc adsorbent as well as preparation method and application thereof

PendingCN113731364ARealize full component utilizationIncreasing interlamellar spacingOther chemical processesWater contaminantsSorbentPhysical chemistry

The invention provides a black talc adsorbent as well as a preparation method and application thereof. The preparation method of the black talc adsorbent comprises the following steps: 1) homogenization: crushing black talc raw ore to obtain an ultrafine and uniform powder raw material; 2) carbonization: calcining the powder raw material obtained in the step 1) under the protection of nitrogen to obtain a carbonized material; 3) activation: calcining and activating the carbonized material obtained in the step 2) under steam to obtain the black talc adsorbent. The black talc prepared through the preparation method serves as an adsorbent and has the high specific surface area and activity and good adsorption performance; meanwhile, the preparation method is simple in technological process and low in production cost, full-component utilization of the black talc is achieved, and the product adsorption performance is high.

Owner:苏州中材非金属矿工业设计研究院有限公司

Modified asphalt and application thereof

PendingCN111875975AGood modification effectImprove compatibilityBuilding insulationsMontmorilloniteMaterials science

The invention discloses modified asphalt and application thereof. According to the invention, a freeze-drying method and aminosilane are utilized to modify nano montmorillonite, and the nano montmorillonite is added into asphalt as a single asphalt modifier, so that the dispersity and compatibility of montmorillonite and asphalt are effectively improved, and the cohesion of asphalt is enhanced. Inorder to further enhance the adhesive force between asphalt and acidic aggregate, aminosilane is adopted to modify the surface of the acidic aggregate, so that the surface energy of the aggregate isreduced, and the adhesive force between the asphalt and the aggregate is improved. Compared with matrix asphalt and granite aggregate, the method of bidirectional modification of single amino silane modified montmorillonite modified asphalt and modified aggregate has the advantages that the adhesion work is improved by 13%, and the peeling work is reduced by 23%. After the asphalt is aged for a short time, a bidirectional modification method is adopted, so that the adhesion performance of the asphalt and the aggregate is still obviously improved, the adhesion work is improved by 8%, the peeling work is reduced by 21%, and the water damage of an asphalt pavement can be effectively relieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of preparation method of sodium polyacrylate water-absorbent fiber

ActiveCN109023583BImprove water absorptionAbsorbent retentionMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberSpinning

The invention relates to the field of polymer material synthesis, and discloses a method for preparing sodium polyacrylate water-absorbing fibers. The steps are: A) preparation of organically modified vermiculite powder: chlorinating lactose and dodecyldimethylbenzyl Ammonium is added to water for heating reaction, the product is washed under reduced pressure, and dried to obtain modified lactose; vermiculite is calcined and pulverized; prepared into a suspension, heated, added modified lactose, stirred and incubated for reaction, and then centrifuged , filter, dry; B) neutralization: add acrylic acid and acrylamide to water, then neutralize with sodium hydroxide until the pH is 5-5.5; C) polymerization: add organically modified vermiculite and bacterial cellulose first, Then add triallyl ammonium chloride and an initiator, and react to obtain a viscous liquid; D) wet spinning to obtain sodium polyacrylate fiber; the present invention is compounded with organically modified leech in the sodium polyacrylate fiber Stone powder can effectively improve the strength and aging resistance of high fiber.

Owner:SHENZHEN JINLIYUAN INSULATION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com