Polyurethane inorganic flame-retardant heat-insulation material for solar water tanks and method for preparing polyurethane inorganic flame-retardant heat-insulation material

A solar water tank and inorganic flame retardant technology, applied in the field of thermal insulation materials, can solve the problems of short-circuit fire, no flame retardancy, and reduced thermal insulation performance of polyurethane, and achieve the effects of improving thermal insulation effect, improving interface bonding strength, and improving expansion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

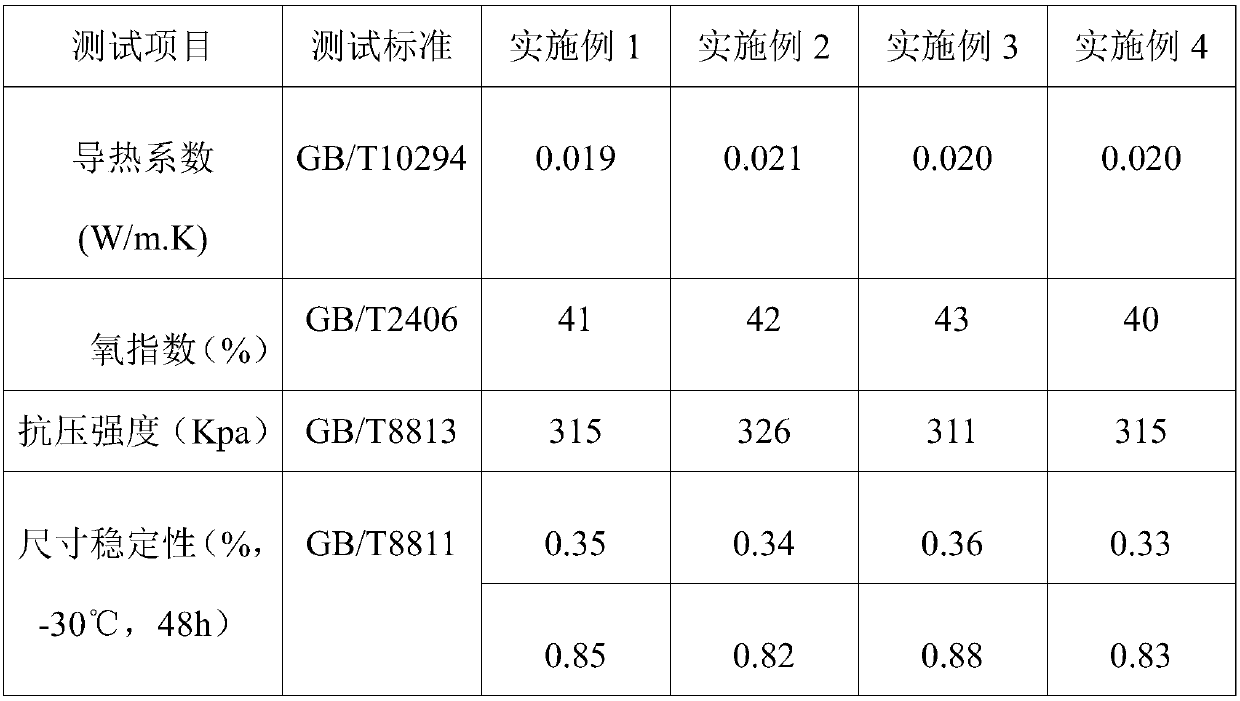

Examples

Embodiment 1

[0018] A polyurethane inorganic flame-retardant insulation material for solar water tanks, made of the following raw materials in parts by weight: 80 parts of polyether polyol, 130 parts of isocyanate, 3 parts of nano-silica, 10 parts of modified expanded vermiculite, 1 part of chitosan grafted modified silane, 5 parts of foaming agent, 0.1 part of foam stabilizer, 2 parts of catalyst, 0.5 part of crosslinking agent;

[0019] Wherein, said polyether polyol comprises sorbitol polyether polyol, glycerol polyether polyol and polyoxypropylene glycol, and the weight ratio of sorbitan polyether polyol, glycerol polyether polyol and polyoxypropylene glycol is 5: 4:1; the isocyanate is toluene diisocyanate; the blowing agent is dichlorofluoroethane, and the foam stabilizer is a silicone foam stabilizer, such as 3-(polyethylene glycol monomethyl ether) Propyltrialkoxysilane; the catalyst is diethanol monoisopropanolamine; the crosslinking agent is glycerin;

[0020] The modified expan...

Embodiment 2

[0024] A polyurethane inorganic flame-retardant insulation material for solar water tanks, made of the following raw materials in parts by weight: 100 parts of polyether polyol, 110 parts of isocyanate, 8 parts of nano-silica, 5 parts of modified expanded vermiculite, 3 parts of chitosan grafted modified silane, 2 parts of foaming agent, 0.5 part of foam stabilizer, 0.5 part of catalyst, 1 part of crosslinking agent;

[0025] Wherein, said polyether polyol comprises sorbitol polyether polyol, glycerol polyether polyol and polyoxypropylene glycol, and the weight ratio of sorbitan polyether polyol, glycerol polyether polyol and polyoxypropylene glycol is 7: 2:1; the isocyanate is diphenylmethane diisocyanate; the blowing agent is trans-1-chloro-3,3,3-trifluoropropene, and the foam stabilizer is a silicone foam stabilizer , such as 3-[poly(ethylene glycol-co-propylene glycol) monomethyl ether]propyltrialkoxysilane; the catalyst is hydroxyethylethylenediamine; the crosslinking age...

Embodiment 3

[0030] A polyurethane inorganic flame-retardant insulation material for solar water tanks, made of the following raw materials in parts by weight: 90 parts of polyether polyol, 120 parts of isocyanate, 5 parts of nano-silica, 7 parts of modified expanded vermiculite, 2 parts of chitosan grafted modified silane, 3 parts of foaming agent, 0.3 part of foam stabilizer, 1 part of catalyst, 0.8 part of crosslinking agent;

[0031] Wherein, said polyether polyol comprises sorbitol polyether polyol, glycerol polyether polyol and polyoxypropylene glycol, and the weight ratio of sorbitan polyether polyol, glycerol polyether polyol and polyoxypropylene glycol is 6: 3:1; the isocyanate is toluene diisocyanate; the blowing agent is dichlorofluoroethane, and the foam stabilizer is a silicone foam stabilizer, such as 3-(polyethylene glycol monomethyl ether) Propyltrialkoxysilane; the catalyst is diethanol monoisopropanolamine; the crosslinking agent is 1,2,6-trihydroxyhexane, pentaerythritol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com