Environment-friendly anti-freezing concrete and preparation method thereof

A concrete and environmentally friendly technology, applied in the field of building materials, can solve the problems affecting the safety and durability of concrete structures, and accelerate the deterioration of concrete structure performance, strength and impermeability, so as to improve impermeability and frost resistance, improve Antifreeze performance, effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

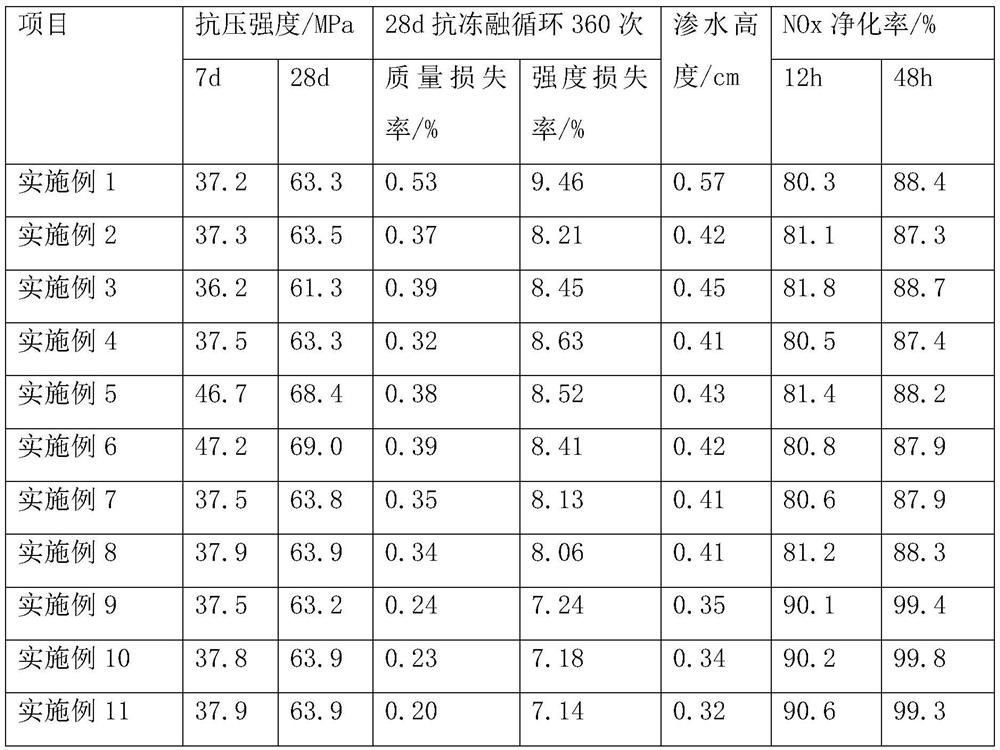

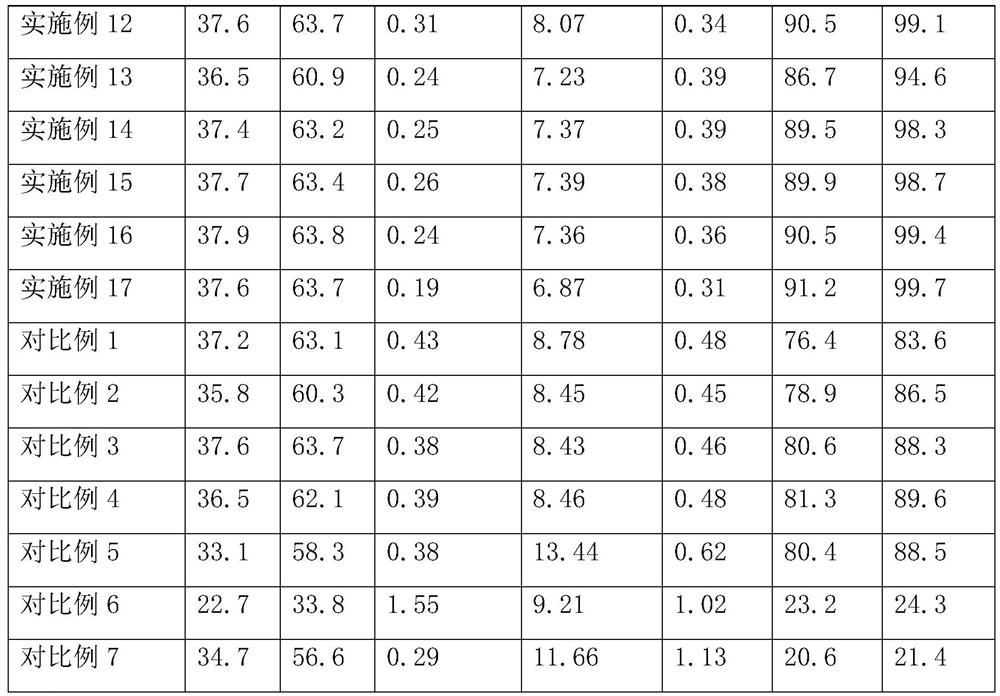

Examples

preparation example 1

[0039] Preparation example 1: Crush 10kg of egg shells, add 240L of water with a concentration of 36%, then add 24L of acetic acid with a concentration of 36%, keep it at 45°C for 1.5h, then let it stand at room temperature for 24h, filter, wash with water, and dry at 60°C for 1.5h , chopped, added 10L of sulfuric acid with a concentration of 20%, heated to 80° C. for reflux extraction for 5 hours, added 3 kg of calcium carbonate, filtered, spray-dried, and crushed to 1 μm to obtain eggshell membranes.

preparation example

[0041] In Preparation Example 1-4, the modified carboxymethyl starch was selected from Renqiu Haochun Chemical Co., Ltd., model 021, the graphene oxide was selected from Hangzhou Zhiti Purification Technology Co., Ltd., and the urea was selected from Beijing Kangpu Huiwei Technology Co., Ltd. Co., Ltd., the model is 012, and the cellulose is carboxymethyl cellulose selected from Renqiu Jinyu Chemical Co., Ltd., the model is jy-006.

[0042] Preparation example 1: (1) Mix 10kg of graphene oxide and 5kg of modified starch, and disperse it ultrasonically for 1.5h at a power of 600W to obtain a graphene oxide / modified starch intercalation composite material. The modified starch is modified carboxylated starch methyl starch;

[0043] (2) Dissolve 2.5kg urea and 2.5kg sodium hydroxide in water respectively to form a 12% urea solution and a 7% sodium hydroxide solution, mix the urea solution and the sodium hydroxide solution, and add graphene oxide / Modified starch intercalation com...

preparation example 2

[0046] Preparation example 2: (1) Mix 13kg graphene oxide and 8kg modified starch, and disperse it ultrasonically for 1.8h at a power of 550W to obtain a graphene oxide / modified starch intercalation composite material. The modified starch is modified carboxylated starch methyl starch;

[0047] (2) Dissolve 3.7kg urea and 3.2kg sodium hydroxide in water respectively to form a urea solution with a concentration of 12% and a sodium hydroxide solution with a concentration of 7%, mix the urea solution and the sodium hydroxide solution, and add graphene oxide / Modified starch intercalation composite material, ultrasonic 1.5h under the power of 450W, cooled to -13 ℃, add 6.5kg cellulose and 0.8kg 2-epoxy-3 chloropropane, stir well at room temperature, add 5.4kg egg Shell film and 3.7kg of iron tailings powder are added in a water bath at 28°C for 44 hours, dried at 65°C for 1.5 hours, and crushed to make antifreeze. The eggshell film is selected from Preparation Example 1 of eggshell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com