Modified montmorillonite-based cement clinker preparation method

A technology of cement clinker and montmorillonite, applied in cement production and other directions, can solve the problems of low strength, unable to meet the requirements of the material market, poor hydrophobicity, etc., to improve the strength and hydrophobicity, improve the interface binding ability, and enhance the binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

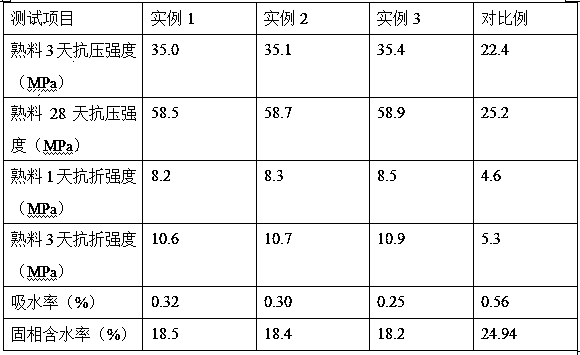

Examples

Embodiment Construction

[0022] In parts by weight, weigh 68 to 72 parts of limestone, 8 to 10 parts of sandstone, 4 to 6 parts of fly ash and 3 to 5 parts of steel slag to mix and grind for 18 to 21 minutes to obtain cement raw meal; Put 80g of montmorillonite into a muffle furnace, and calcined at a temperature of 950-980°C for 24-32 minutes to obtain a calcined product. After cooling, mix and stir the calcined product and deionized water at a mass ratio of 1:3 for 6 ~9min to obtain a suspension; according to the volume ratio of 6:1, mix the suspension and 24% sodium bicarbonate solution with mass fraction and stir for 45~60min to obtain a reaction solution, and adjust the reaction with hydrochloric acid with a concentration of 0.5mol / L The pH of the solution is 5.2-5.6. After adjustment, pour it into a centrifuge and centrifuge for 8-11 minutes. Separate and remove the upper layer to obtain the lower layer of sediment. Finally, put the lower layer of sediment in an oven at a temperature of 85-90°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com