Modified asphalt and application thereof

A technology of modified asphalt and asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of poor compatibility of asphalt, achieve the effects of reducing surface energy, improving adhesion, and improving anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

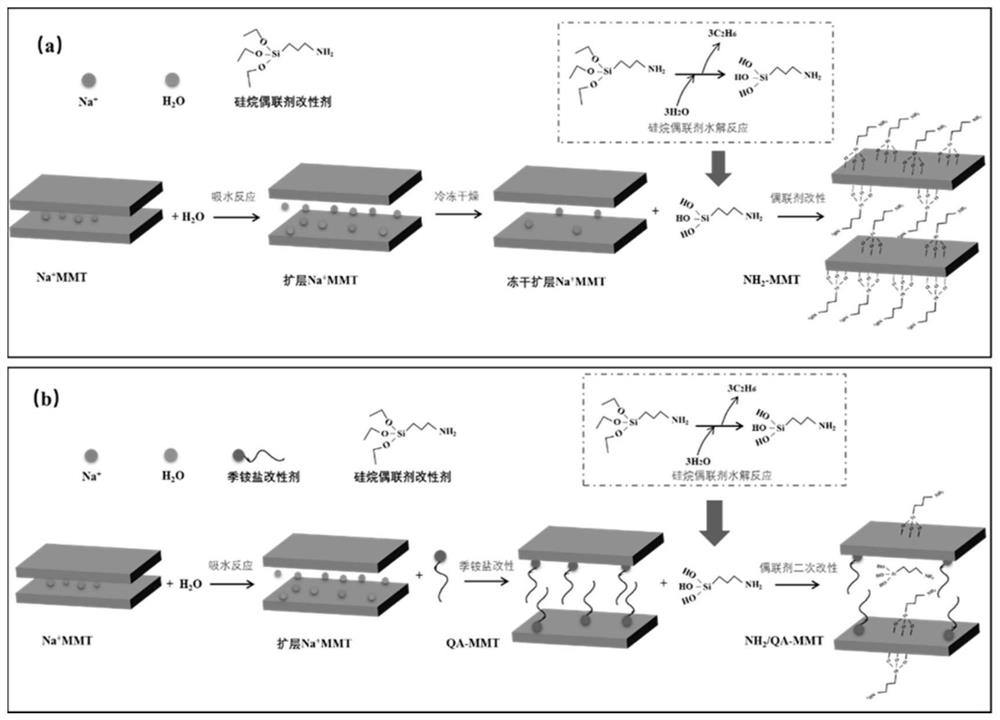

[0059] Evenly disperse 10g NMMT in 1000ml ultrapure water at a high speed (the concentration of NMMT is 0.01g / ml), mechanical stirring is 500rpm, remove the lower layer of particles after standing, and get the upper layer suspension; the montmorillonite suspension is pre-frozen, pre- The freezing temperature is -20°C, and the pre-freezing time is 6 hours to fully freeze the suspension; vacuum freeze-dry the pre-frozen montmorillonite suspension to obtain freeze-dried NMMT.

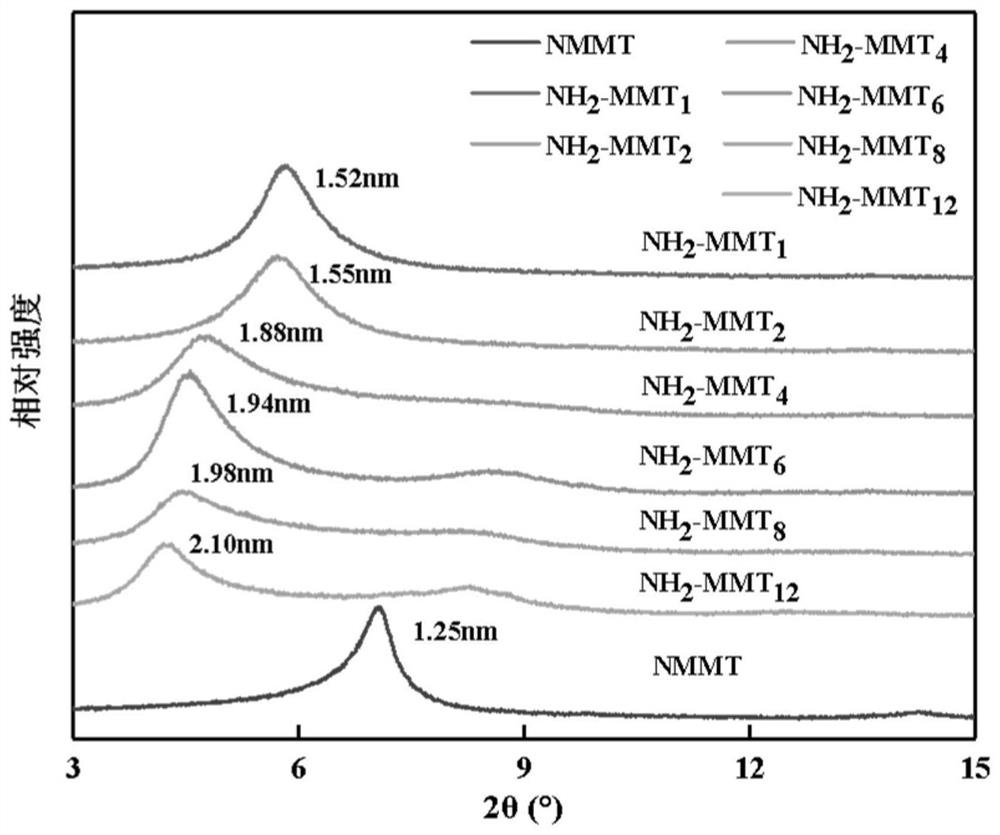

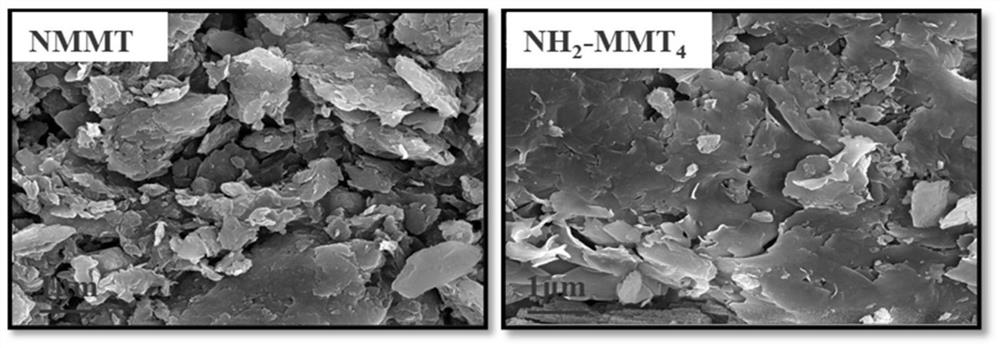

[0060] Take 10 g of freeze-dried NMMT and add it to 200 mL of ultrapure water, and stir at room temperature for 1 h to fully destroy the clays in the dispersion medium. Use dilute hydrochloric acid solution to adjust the pH value of the suspension to 4-4.5, and continue stirring for 1 h. According to the aminosilane KH-550: NMMT mass ratio of 1:10, 2:10, 4:10, 6:10, 8:10, 12:10, add KH550 to the suspension, and the suspension is at 80 Under the condition of water bath at ℃, stir for 4h. The suspension wa...

Embodiment 2

[0067] (1) using the NH prepared in Example 1 2 -MMT 4 , Take 100 parts of asphalt and heat it to about 160 ° C ~ 180 ° C, and use melt blending method to mix 3 parts of NMMT or NH 2 -MMT 4 Add to the molten asphalt in several times, shear 120min at a shear rate of 5000r / min, make NMMT or NH 2 -MMT 4 Fully dispersed in molten asphalt. Then develop at 600r / min stirring speed for 90min to obtain NMMT-A and NH 2 -MMT 4 -A.

[0068] (2) Select Gr aggregates with a particle size of 13.2mm-19mm, ultrasonically clean the surface with water, and dry at 100°C for 9-10h until the quality does not change.

[0069] (3) Evaluate NMMT-A and NH according to the boiling method of T0616-1993 in "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" 2 -MMT 4 -A grade of adhesion to Gr aggregates.

[0070] The results of the boiling test showed that if Figure 5 (a), after the Gr aggregate was wrapped in NMMT-A, the asphalt film on the aggregate surface partially f...

Embodiment 3

[0080] (1) Take 100 parts of asphalt and heat it to about 160 ℃ ~ 180 ℃, and use melt blending method to mix 3 parts of NMMT or NH 2 -MMT 4 Add to the molten asphalt in several times, shear 120min at a shear rate of 5000r / min, make NMMT or NH 2 -MMT 4 Fully dispersed in molten asphalt. Then develop at 600r / min stirring speed for 90min to obtain NMMT-A, NH 2 -MMT 4 -A. According to the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" JTG E20-2011, the above two kinds of asphalts were respectively subjected to rotating film heating tests to obtain NMMT-A-RTFO, NH 2 -MMT 4 -A-RTFO.

[0081] (2) Select Gr aggregates with a particle size of 13.2mm-19mm, ultrasonically clean the surface with water, and dry at 100°C for 9-10h until the quality does not change.

[0082] (3) Evaluate NMMT-A-RTFO, NH 2 -MMT 4 - Adhesion rating of A-RTFO to Gr aggregates.

[0083] The results of the water boiling test showed that after the Gr aggregate was wrapped in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com