Preparation method of titanium carbide loaded platinum-palladium nanoflower electrode catalyst

An electrode catalyst, titanium carbide technology, applied in battery electrodes, circuits, fuel cells, etc., can solve problems such as unreported research on new two-dimensional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

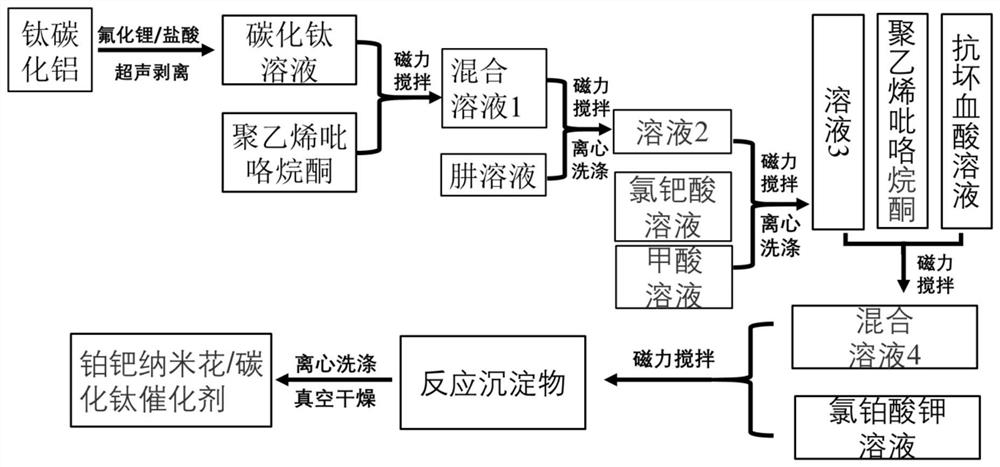

[0043] Such as figure 1 , a preparation method of titanium carbide supported platinum palladium nano flower electrode catalyst, comprising the following steps:

[0044] S1, preparing a titanium carbide nanosheet dispersion;

[0045] S2. Add polyvinylpyrrolidone to the titanium carbide nanosheet dispersion in step S1, stir at a temperature of 0-50°C for 0.5-5h, and mix well to obtain a mixed solution I containing polyvinylpyrrolidone / titanium carbide nanosheet precursor. The mass ratio of titanium carbide to polyvinylpyrrolidone is 1:10-30;

[0046] S3. Add hydrazine solution to the mixed solution I in step S2, stir and react at 0-50°C for 0.5-2h to obtain a black product, then centrifuge and wash 4-8 times at a centrifugal speed of 6000-10000rpm, then use ultra-pure Resuspension in water to obtain a mixed solution II containing hydrazine / polyvinylpyrrolidone / titanium carbide nanosheet precursor; the mass ratio of the hydrazine to the precursor contained in the mixed solution...

Embodiment 1

[0056] A preparation method of titanium carbide supported platinum palladium nano flower electrode catalyst, comprising the following steps:

[0057] S1, preparing a titanium carbide nanosheet dispersion;

[0058] S2. Add polyvinylpyrrolidone to the titanium carbide nanosheet dispersion in step S1, stir at 25°C for 3h, and mix well to obtain a mixed solution I containing polyvinylpyrrolidone / titanium carbide nanosheet precursor. The titanium carbide and The mass ratio of polyvinylpyrrolidone is 1:20;

[0059] S3. Add hydrazine solution to the mixed solution I in step S2, stir and react at 25°C for 1h to obtain a black product, then centrifuge and wash 6 times at a centrifugal speed of 8000rpm, and then resuspend with ultrapure water to obtain hydrazine / The mixed solution II of polyvinylpyrrolidone / titanium carbide nanosheet precursor; the mass ratio of the precursor contained in the hydrazine and the mixed solution I is 0.00008: 1;

[0060] S4. Add chloropalladium acid solu...

Embodiment 2

[0064] The difference between Example 2 and Example 1 is that in step S4, the mass ratio of palladium element in the chloropalladium acid solution, the formic acid and the precursor contained in the mixed solution II is 3.5:0.35:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com