Organic-inorganic composite silicon-based negative electrode material, and preparation method and application thereof

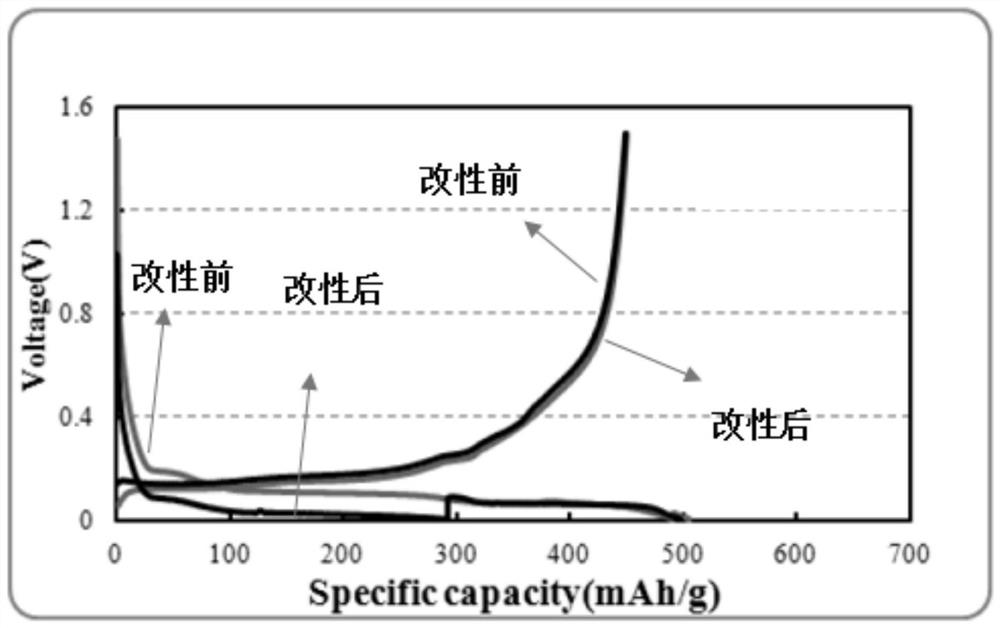

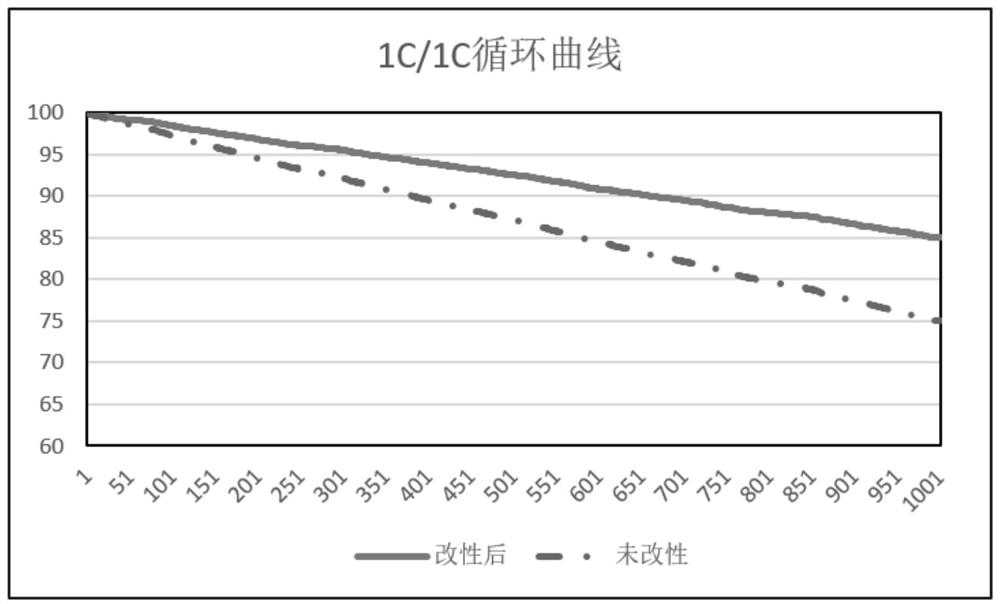

A composite silicon-based and negative electrode material technology, applied in the field of lithium-ion batteries, can solve the problems of limiting the endurance of instruments or tools, the loss of active materials, and the deterioration of cycle performance, so as to improve the first-time efficiency, low cost, and improve the infiltration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing an organic-inorganic composite silicon-based negative electrode material, comprising the steps of:

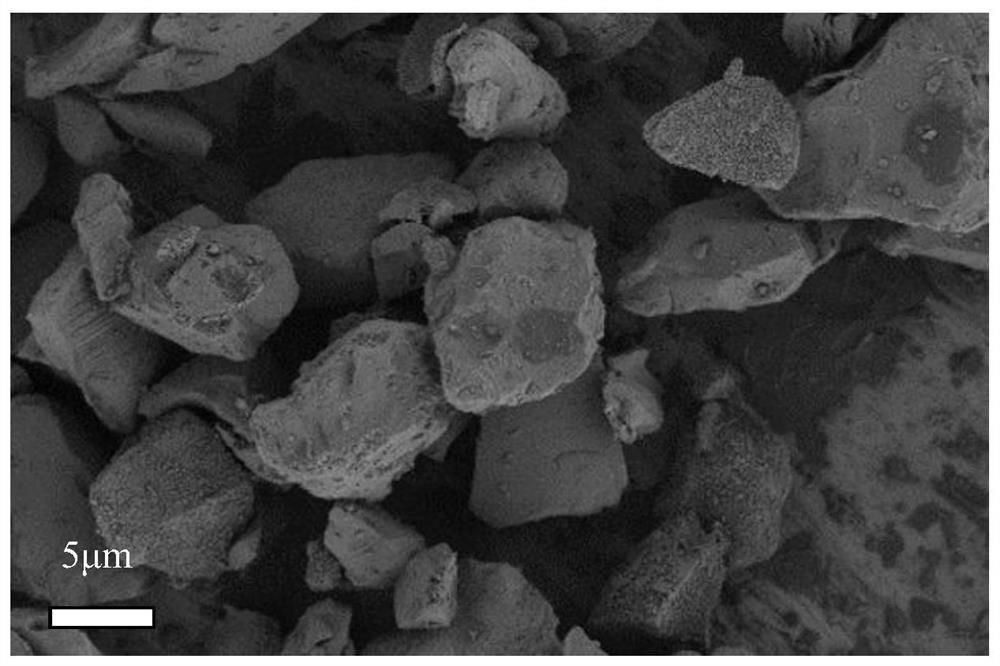

[0031] S1. Taking 1000g, the median particle size is 12.5μm, and the tap density is 1.02g / m 3 , the specific surface area is 1.08m 2 / g, capacity of 430mAh / g silicon-based material (composite material of silicon and graphite) put into 3kg acidic aqueous solution (acidic aqueous solution is hydrochloric acid with concentration of 1mol / L, sulfuric acid of 1mol / L, hydrogen of 1mol / L mixed aqueous solution of hydrofluoric acid) for acid etching for 3 hours, and then cleaned with deionized water for 5 times; then 80 g of pitch was fully mixed with the acid-etched silicon-based material, and carbonized at 900 ° C for 3 hours under the protection of N2 to obtain carbon Coated acid etched silicon-based materials;

[0032] S2. Soak the carbon-coated acid-etched silicon-based material in a mixed aqueous solution of sodium dodecylbenzenesulfonate and a sila...

Embodiment 2

[0034] A method for preparing an organic-inorganic composite silicon-based negative electrode material, comprising the steps of:

[0035] S1. Take 1000g, the median particle size is 6.3μm, and the tap density is 0.98g / m 3 , the specific surface area is 1.15m 2 The silicon-based material (composite material of silicon oxide and graphite) with a capacity of 420mAh / g is put into 3 kg of acidic aqueous solution (the acidic aqueous solution is hydrochloric acid with a concentration of 1mol / L, sulfuric acid with a concentration of 1mol / L, and 1mol / L mixed aqueous solution of hydrofluoric acid) for acid etching for 5 hours, and then cleaned with deionized water for 5 times; then fully mixed 100g of asphalt with the silicon-based material after acid etching, and carbonized at 900°C for 3 hours under the protection of N2 Obtain carbon-coated acid-etched silicon-based materials;

[0036] S2. Soak the carbon-coated acid-etched silicon-based material in a mixed aqueous solution of sodiu...

Embodiment 3

[0038] A method for preparing an organic-inorganic composite silicon-based negative electrode material, comprising the steps of:

[0039] S1, take 1000g of median particle size of 8.4μm, tap density of 1.0g / m 3 , the specific surface area is 1.10m 2 / g, capacity of 420mAh / g silicon-based material (composite material of silicon and graphite) put into 3kg acidic aqueous solution (acidic aqueous solution is hydrochloric acid with concentration of 1mol / L, sulfuric acid of 1mol / L, hydrogen of 1mol / L mixed aqueous solution of hydrofluoric acid) for acid etching for 5 hours, and then cleaned with deionized water for 5 times; then fully mixed 90 g of asphalt with the silicon-based material after acid etching, and carbonized at 900 ° C for 3 hours under the protection of N2 to obtain carbon Coated acid etched silicon-based materials;

[0040] S2. Soak the carbon-coated acid-etched silicon-based material in a mixed aqueous solution of sodium dodecylbenzenesulfonate and a silane coupli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com