A preparation method of titanium carbide nanosheet/graphene composite material that can be used for lithium-ion battery negative electrode

A technology for lithium ion batteries and composite materials, which is applied in the field of synthesis and preparation of nano-ceramic materials, can solve problems such as low efficiency and complex preparation process, and achieves the effects of high efficiency, wide application range and expanded application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment 1: This embodiment can be used for the preparation method of the titanium carbide nanosheet / graphene composite material of lithium-ion battery negative pole, realizes according to the following steps:

[0024] 1. Mix Ti, Al, and C powders according to the molar ratio of 3:(1.1~1.3):2, and synthesize Ti by pressureless sintering at 1400°C~1500°C 3 AlC 2 phase ceramics, and then pulverized to obtain Ti 3 AlC 2 powder;

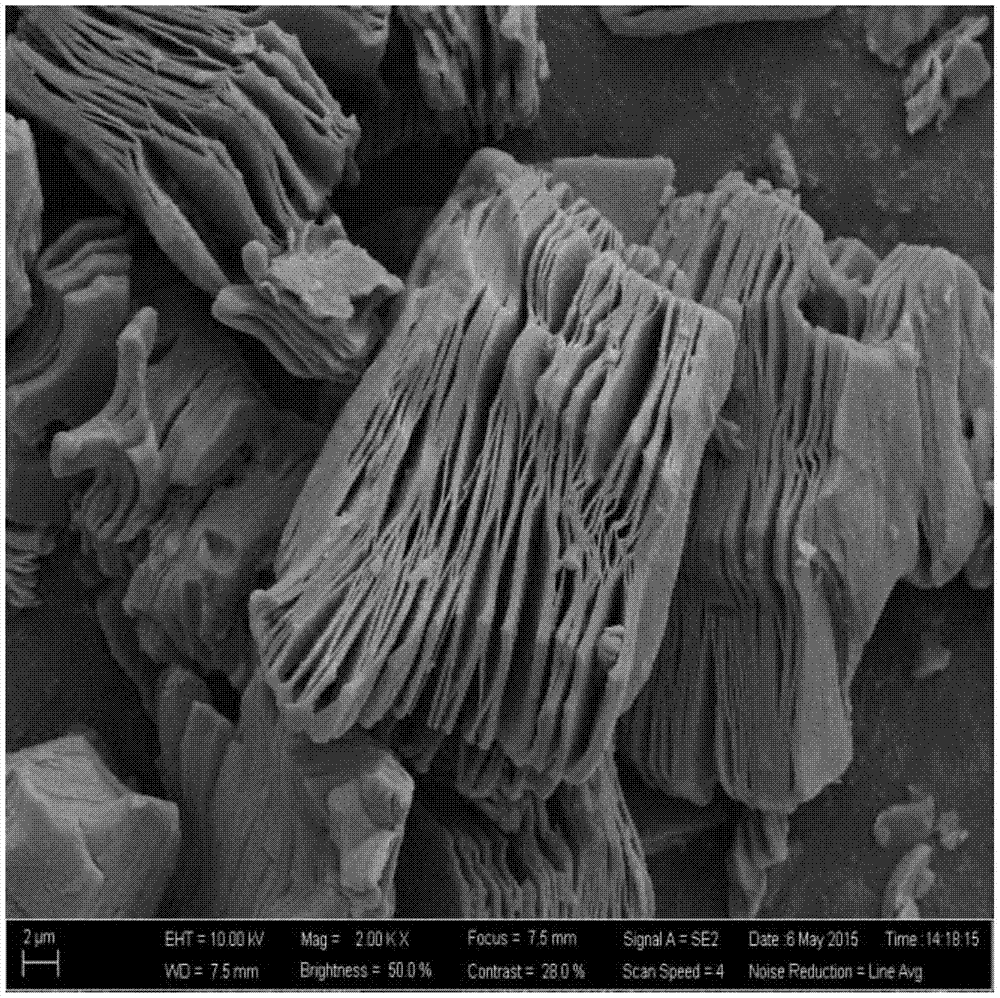

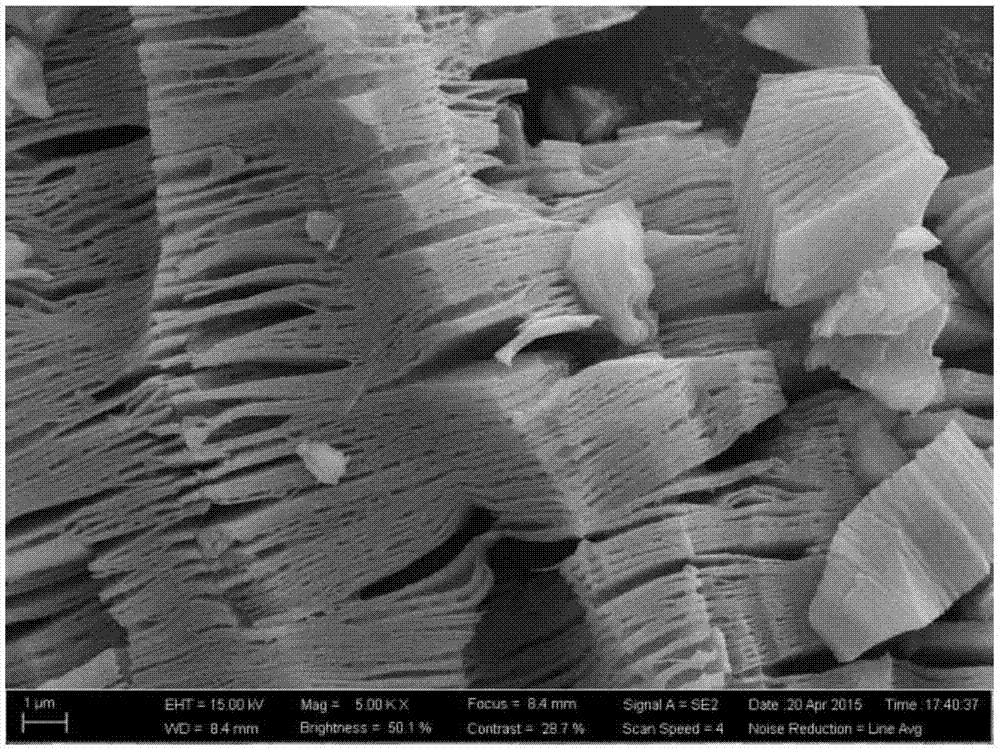

[0025] Second, the Ti 3 AlC 2 The powder is corroded in hydrofluoric acid with a concentration of 20wt.% to 50wt.% for 4 to 24 hours. After corrosion, the solution is added to deionized water for centrifugation, and then the precipitate is dried to obtain stacked layered Ti 3 C 2 T x Powder;

[0026] 3. The layered Ti layer that will be stacked 3 C 2 T x The powder and the organic solvent are mixed according to the mass ratio of 1: (10-100), and then centrifuged to obtain a suspension;

[0027] 4. Take the supernatant of the...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, Ti, Al, and C powders are mixed according to the molar ratio of 3:1.2:2, and Ti is synthesized by pressureless sintering at 1450°C. 3 AlC 2 phase ceramics. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, Ti 3 AlC 2 The powder was corroded in 40wt.% hydrofluoric acid for 12 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com