High-strength lightweight antibacterial plastic film and preparation method thereof

A plastic film, lightweight technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of limitation, reduced packaging performance, limited use scope, etc., to expand the scope of application, excellent Antibacterial properties, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

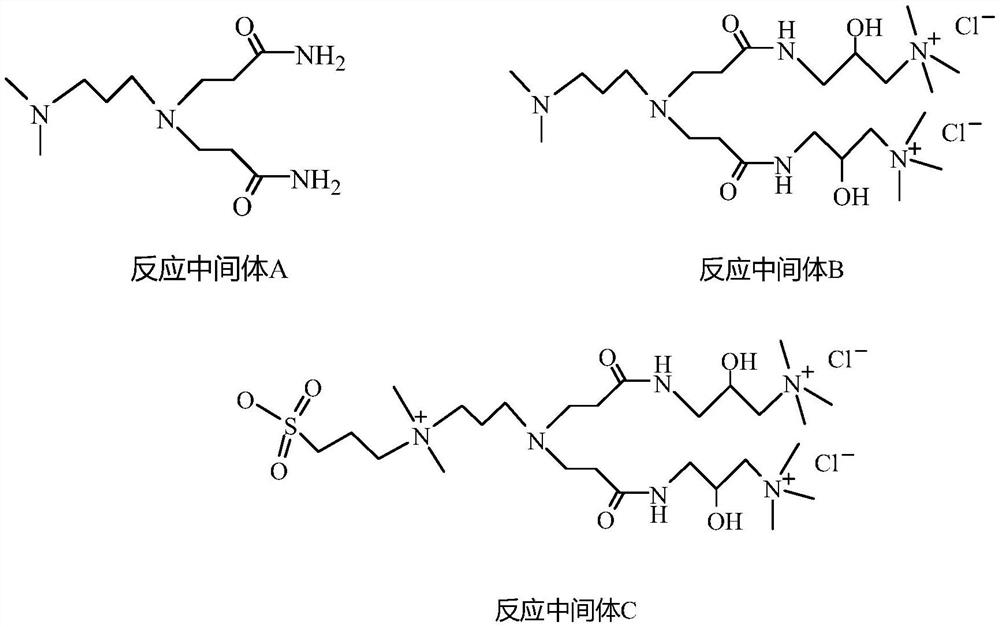

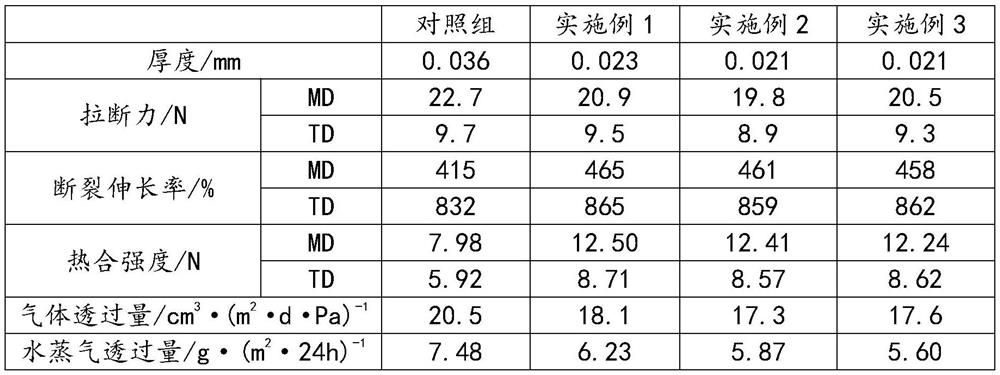

[0031] A high-strength and lightweight antibacterial plastic film, which is made by co-extrusion blow molding of an upper surface layer, a middle layer, and a lower surface layer, and the upper surface layer and the lower surface layer are made of the following components by weight: 15 parts of metal polyethylene, 80 parts of low-density polyethylene, 5 parts of nano-calcium carbonate, 2 parts of fluoropolymer PPA, 0.15 parts of talcum powder, 0.1 part of erucamide, 2 parts of antibacterial masterbatch (Sanafor PO-5 antibacterial agent), the middle layer is made of the following components by weight: 90 parts of low density polyethylene, 5 parts of nanometer calcium carbonate, 2 parts of fluoropolymer PPA, 0.15 part of talcum powder, erucamide 0.1 part, 15 parts of barrier masterbatch (EVAL barrier masterbatch produced by Japan Kuraray, brand name is L171B), 15 parts of organically modified montmorillonite, 3 parts of maleic anhydride grafted polyethylene. Among them, organica...

Embodiment 2

[0043] A high-strength and lightweight antibacterial plastic film, which is made by co-extrusion blow molding of an upper surface layer, a middle layer, and a lower surface layer, and the upper surface layer and the lower surface layer are made of the following components by weight: 20 parts of metal polyethylene, 80 parts of low-density polyethylene, 10 parts of nano-calcium carbonate, 2 parts of fluoropolymer PPA, 0.6 part of talcum powder, 0.4 part of erucamide, 4 parts of antibacterial masterbatch, the middle layer is composed of the following Components in parts by weight: 95 parts of low-density polyethylene, 10 parts of nano-calcium carbonate, 2 parts of fluoropolymer PPA, 0.6 part of talcum powder, 0.4 part of erucamide, 20 parts of barrier masterbatch, organically modified Mongolian 20 parts of soil removal, 6 parts of maleic anhydride grafted polyethylene. Wherein, the preparation process of organically modified montmorillonite is as follows:

[0044] S1. Add 3-dime...

Embodiment 3

[0055] A high-strength and lightweight antibacterial plastic film, which is made by co-extrusion blow molding of an upper surface layer, a middle layer, and a lower surface layer, and the upper surface layer and the lower surface layer are made of the following components by weight: 18 parts of metal polyethylene, 80 parts of low-density polyethylene, 8 parts of nano-calcium carbonate, 2 parts of fluoropolymer PPA, 0.4 part of talcum powder, 0.25 part of erucamide, 3 parts of antibacterial masterbatch, the middle layer is composed of the following Components in parts by weight: 92 parts of low-density polyethylene, 8 parts of nano-calcium carbonate, 2 parts of fluoropolymer PPA, 0.35 parts of talc, 0.3 parts of erucamide, 18 parts of barrier masterbatch, organically modified Mongolian 17 parts of soil removal, 5 parts of maleic anhydride grafted polyethylene. Wherein, the preparation process of organically modified montmorillonite is as follows:

[0056] S1. Add 3-dimethylami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com