Method for enhancing surface property of montmorillonite by freeze-drying technology

A surface performance, montmorillonite technology, applied in the field of chemical materials, can solve the problems of uneven ball milling, fragmentation and deformation of montmorillonite sheets, and achieve the effects of simple method, improved dispersion performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of lyophilized Na-MMT:

[0037]Evenly disperse 3gNa-MMT in 300ml deionized water at high speed (the concentration of Na-MMT is 0.01g / ml), the dispersion speed is 6000rpm, remove the particles in the lower layer after standing, and take the upper layer suspension; the suspension is concentrated by rotary evaporation, rotated The temperature of the constant temperature pot of the evaporator is 65°C, and the rotation speed is 150rpm; continue to carry out ultrasonic dispersion to obtain a suspension of montmorillonite; pre-freeze the suspension of montmorillonite, the pre-freezing temperature is -20°C, and the pre-freezing time is 6h. Fully freeze the suspension; vacuum freeze-dry the pre-frozen montmorillonite suspension to obtain freeze-dried Na-MMT.

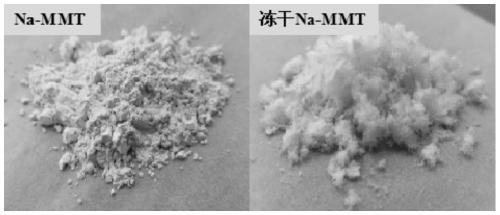

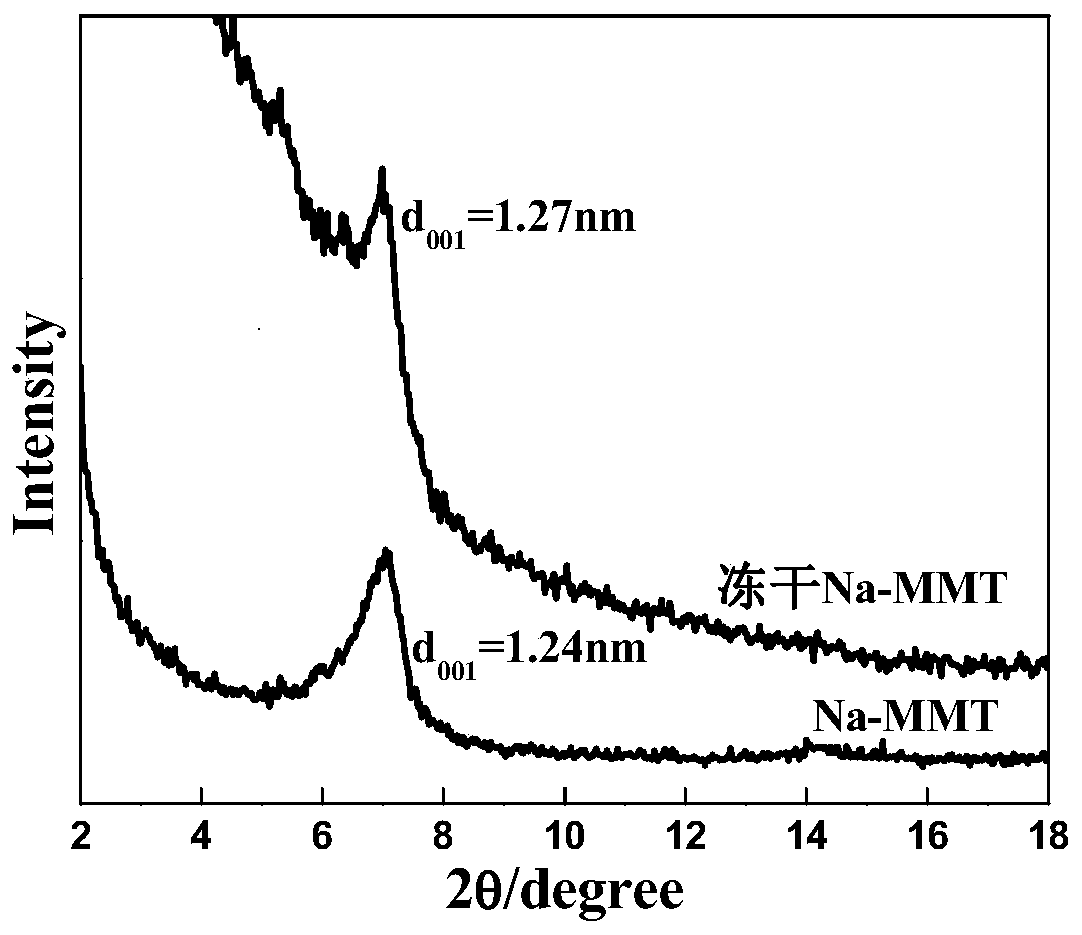

[0038] figure 1 It is the morphological figure of the freeze-dried Na-MMT obtained in this embodiment. It can be seen from the figure that Na-MMT is in the form of powder, while the freeze-dried Na-MMT is in t...

Embodiment 2

[0041] Preparation of lyophilized Ca-MMT:

[0042] Evenly disperse 3g Ca-MMT in 300ml deionized water at high speed (the concentration of Ca-MMT is 0.01g / ml), the dispersion speed is 6000rpm, remove the lower layer of particles after standing, take the upper layer suspension; concentrate the suspension by rotary evaporation, The temperature of the constant temperature pot of the rotary evaporator is 65 ° C, and the rotation speed is 150 rpm; continue to carry out ultrasonic dispersion to obtain a suspension of montmorillonite; pre-freeze the suspension of montmorillonite at -20 ° C, and the pre-freezing time is 6 hours , to fully freeze the suspension; vacuum freeze-dry the pre-frozen montmorillonite suspension to obtain freeze-dried Ca-MMT.

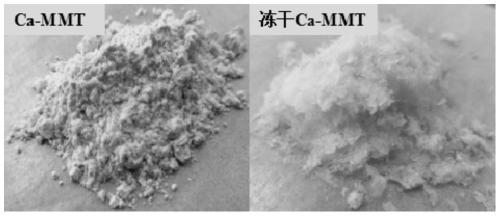

[0043] image 3 It is the appearance diagram of the freeze-dried Ca-MMT obtained in this embodiment. It can be seen from the figure that the Ca-MMT is in the form of powder, while the freeze-dried Ca-MMT is in the form of loose sheets. ...

Embodiment 3

[0046] Lyophilized OMMT preparation

[0047] Evenly disperse 3gOMMT in 300ml deionized water at high speed (the concentration of OMMT is 0.01g / ml), the dispersion speed is 6000rpm, remove the lower layer of particles after standing, and take the upper suspension; the suspension is concentrated by rotary evaporation, and the constant temperature of the rotary evaporator is The temperature of the pot is 65°C, and the rotation speed is 150rpm; continue to carry out ultrasonic dispersion to obtain a suspension of montmorillonite; pre-freeze the suspension of montmorillonite at -20°C, and the pre-freezing time is 6 hours, so that the suspension is fully Freeze; vacuum freeze-dry the pre-frozen montmorillonite suspension to obtain freeze-dried OMMT.

[0048] Figure 5 It is the appearance figure of the freeze-dried OMMT obtained in this embodiment. It can be seen from the figure that the OMMT is in the form of powder, while the freeze-dried OMMT is in the form of loose floc.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com