A kind of preparation method of composite positive electrode material for lithium battery

A positive electrode material and composite technology, which is applied in the field of preparation of composite positive electrode materials for lithium batteries, can solve problems such as uneven composition and unstable performance, achieve low equipment requirements, good coating or doping, and increase lamellae The effect of spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

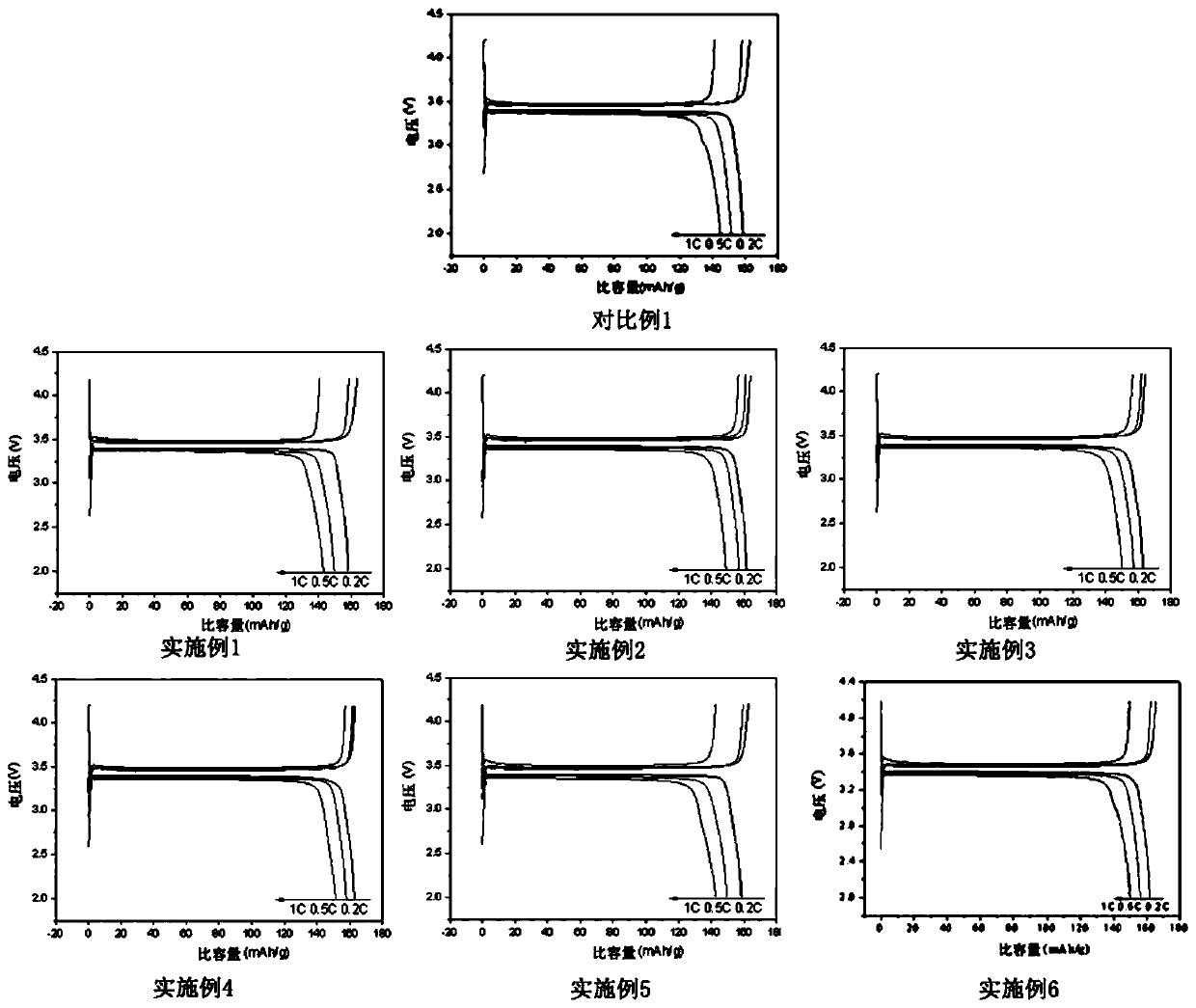

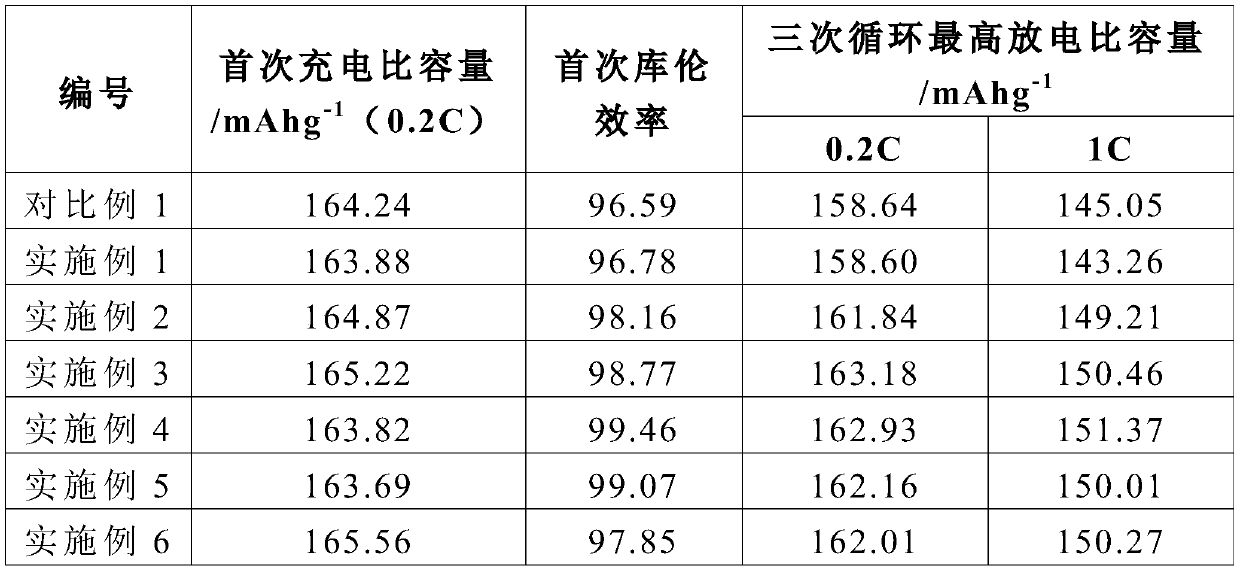

Examples

Embodiment 1

[0034] (1) Add 1g graphene oxide and 500g deionized water into the reaction vessel, form a suspension after ultrasonic dispersion for 45 minutes, then add 2.5g cerium acetate, 0.625g potassium acetate, 0.75g urea to it, and continue ultrasonication for 1 Hours later, add ammonia water to the reaction vessel, adjust the pH to 8.0, and continue ultrasonication for 1 hour, then seal the reaction vessel, place it in an oven, react at 200°C for 24 hours, cool to room temperature, and rinse with deionized water After washing twice and drying, put it into a microwave oven and microwave at full power for 45 seconds to obtain a cerium oxide / graphene composite;

[0035] (2) 5.0g lithium hydroxide, 25.0g iron phosphate, 45.0g oxalic acid, 2.5g glucose, and 7.5g deionized water were added to the three-necked flask together, and then 0.775g cerium oxide was added to it, and under rapid stirring, Heated in a water bath to 80°C and kept for 3 hours, then lowered to room temperature, then vac...

Embodiment 2

[0039] (1) Add 1g of graphene oxide and 800g of deionized water into the reaction vessel, form a suspension after ultrasonic dispersion for 50 minutes, then add 3.0g of cerium acetate, 0.75g of potassium acetate, and 0.75g of urea to it, and continue ultrasonication for 1.5 Hours later, add ammonia water to the reaction vessel, adjust the pH to 8.5, and continue ultrasonication for 1.5 hours, then seal the reaction vessel, place it in an oven, react at 300°C for 36 hours, cool to room temperature, and rinse with deionized water After washing twice and drying, put it into a microwave oven and microwave at full power for 50 seconds to obtain a cerium oxide / graphene composite;

[0040] (2) Add 5.0g of lithium hydroxide, 25g of iron phosphate, 45g of oxalic acid, 3.0g of glucose, and 8g of deionized water into a three-necked flask, and then add 1.56g of Tm 2 o 3 , under rapid stirring, the water bath was heated to 80°C and kept for 4 hours, then lowered to room temperature, then ...

Embodiment 3

[0044] (1) Add 1g of graphene oxide and 1000g of deionized water into the reaction vessel, form a suspension after ultrasonic dispersion for 60 minutes, then add 5g of cerium acetate, 1.25g of potassium acetate, and 0.75g of urea to it, and continue ultrasonication for 2 hours Finally, add ammonia water to the reaction vessel, adjust the pH to 9.0, and continue ultrasonication for 2 hours, then seal the reaction vessel, place it in an oven, react at 250°C for 24 hours, cool to room temperature, and wash with deionized water 3 times, after drying, put it into a microwave oven, microwave at full power for 60 seconds, and obtain a cerium oxide / graphene composite;

[0045] (2) Add 5.0g of lithium hydroxide, 30.0g of iron phosphate, 50.0g of oxalic acid, 5.0g of glucose, and 10.0g of deionized water into a three-necked flask, and then add 4.5g of Sm 2 o 3 , under rapid stirring, the water bath was heated to 90°C and kept for 5 hours, then lowered to room temperature, and then vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com