Patents

Literature

66results about How to "Increased Diffusion Channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

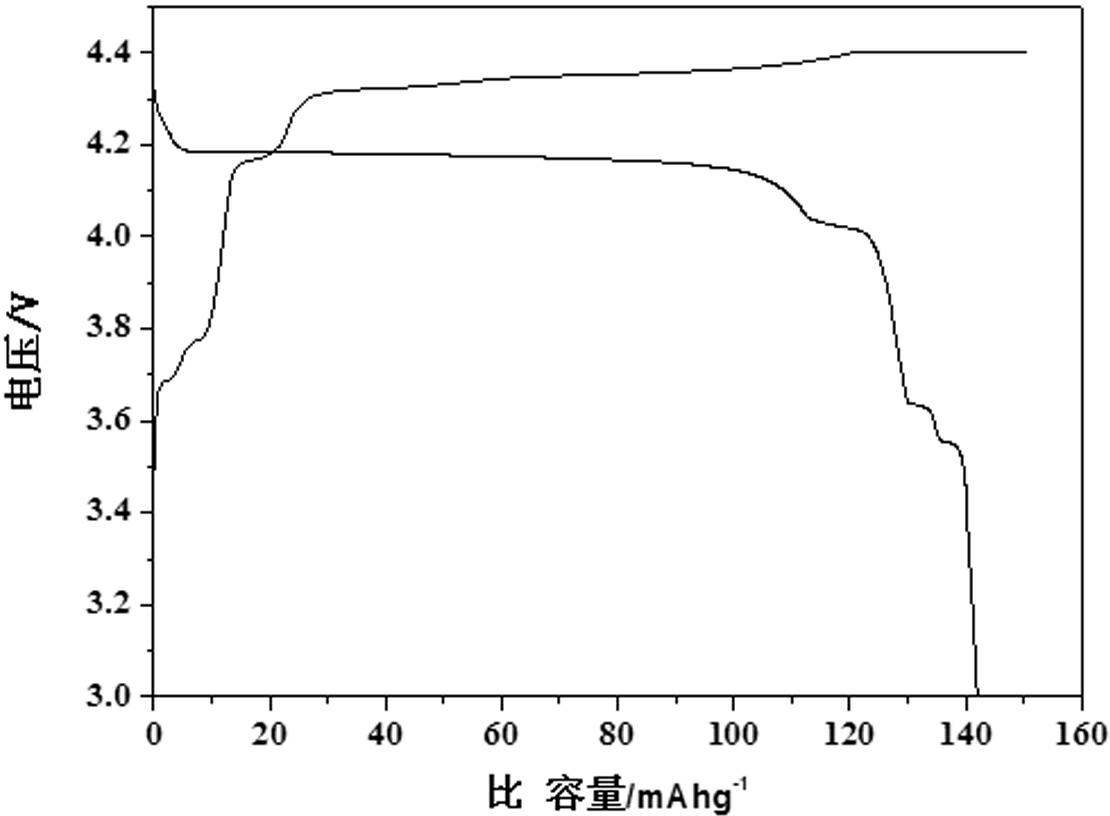

Method for producing high performance lithium ion battery anode material LiFePO4/C

InactiveCN101179124AIncrease the cell volumeIncreased Diffusion ChannelElectrode manufacturing processesPhosphorus compoundsHigh rateCharge discharge

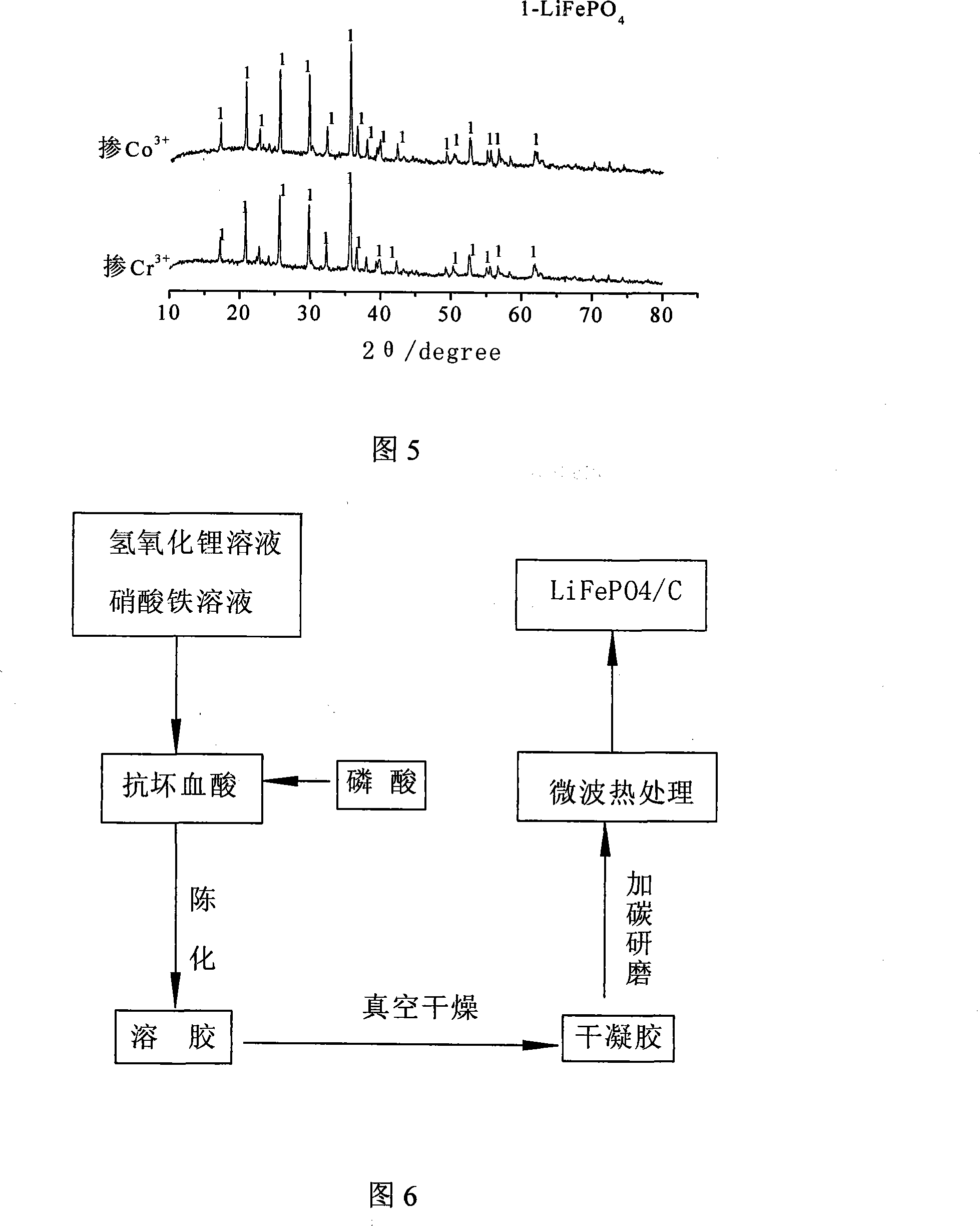

The invention relates to a preparation method for making lithium ion battery cathode materials of LiFePO4 / C by using the reducing agent and inorganic salts of iron source, phosphorus source, lithium source, carbon source and so on as raw materials. Adopt the combining method of sol-gel and microwave treatment and prepare ultrafine particles of LiFePO4 and carbon coat the particles at the same time. On this basis, change the property of LiFePO4 / C by metal doping of Cr3 plus , Co3 plus . By processing with industrial microwave oven of high power, the invention shortens processing time greatly, increases the yield remarkably, reduces material cost and energy loss, simplifies the processes, improves the efficiency of industrial production of lithium ion battery and is convenient for implementation in industry. Take it as cathode materials of lithium ion battery with high-rate discharge. The invention raises conductivity of lithium iron phosphate and at the same time improves charge discharge capacity and cycle numbers by carbon coating and metal element doping.

Owner:江苏君明高新科技有限公司

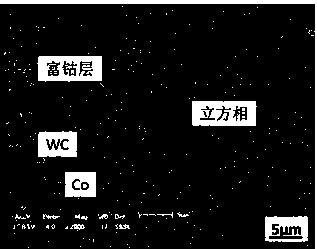

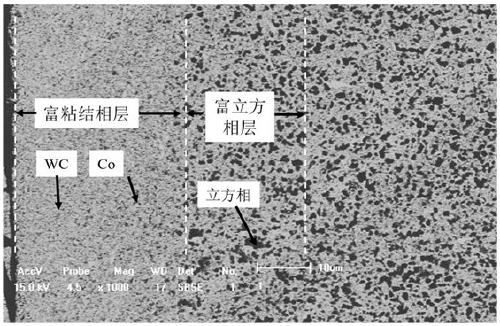

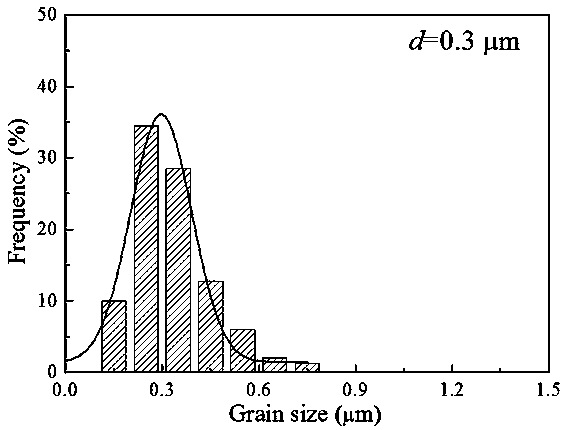

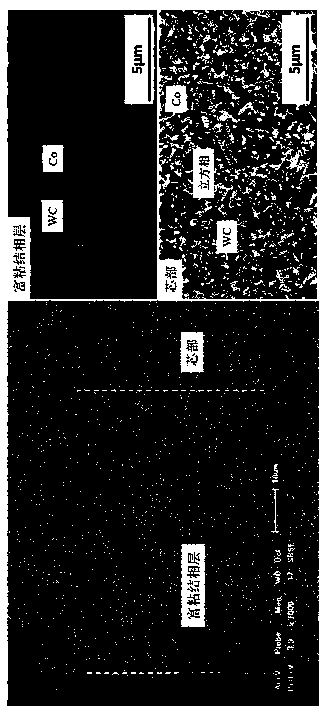

Ultra-fine crystal gradient alloy with rich-cobalt surface and preparation method thereof

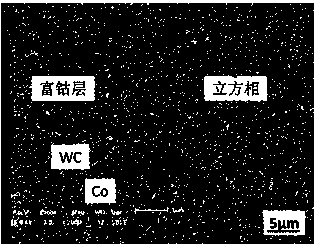

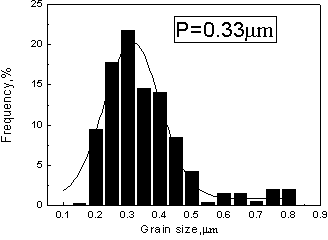

The invention belongs to the field of hard alloy preparation, and in particular relates to an ultra-fine crystal gradient alloy with a rich-cobalt surface and a preparation method of the alloy. According to the ultra-fine crystal gradient alloy with the rich-cobalt surface, a gradient layer with the rich-cobalt surface, which is 10-40mu m thick, is formed by taking WC (Wolfram Carbide) and cubic phase carbonitride as a core part hard phase and cobalt as the binding phase, wherein the average size of the crystal particles of WC in the hard phase and the gradient layer is 0.2-0.4mu m, the content of cobalt in the gradient layer with the rich-cobalt surface is 1.2-2 times of the standard content of cobalt of hard alloys, and the gradient layer with the rich-cobalt surface is free of the cubic phase carbonitride. The preparation method comprises the following steps: firstly, preparing the materials, wet-grinding and pressing into a material blank, and supplying an inert gas with the pressure of 5-10MPa before reaching a liquid phase sintering temperature, wherein the liquid phase sintering temperature is 1,350-1,500 DEG C. By charging the gas with certain pressure in the liquid phase sintering period, the ultra-fine crystal gradient alloy with the rich-cobalt surface is prepared, the WC crystal grains are refined, a rich-cobalt surface layer of certain thickness is obtained, the sintering period is shortened, and the production cost is lowered.

Owner:NORTHEASTERN UNIV LIAONING

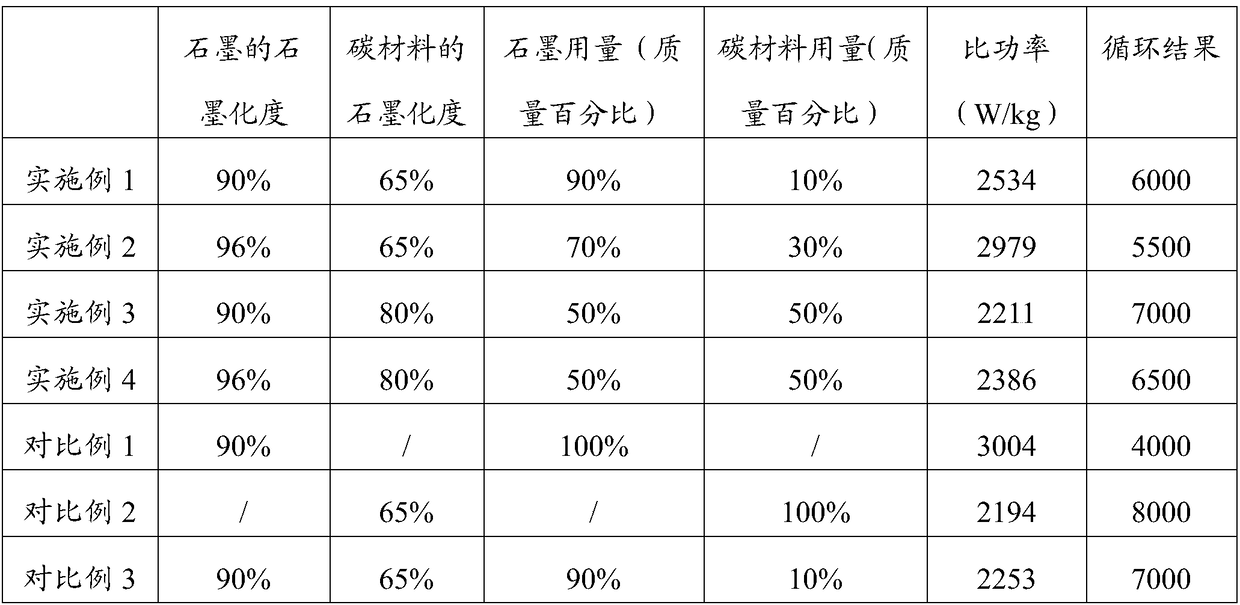

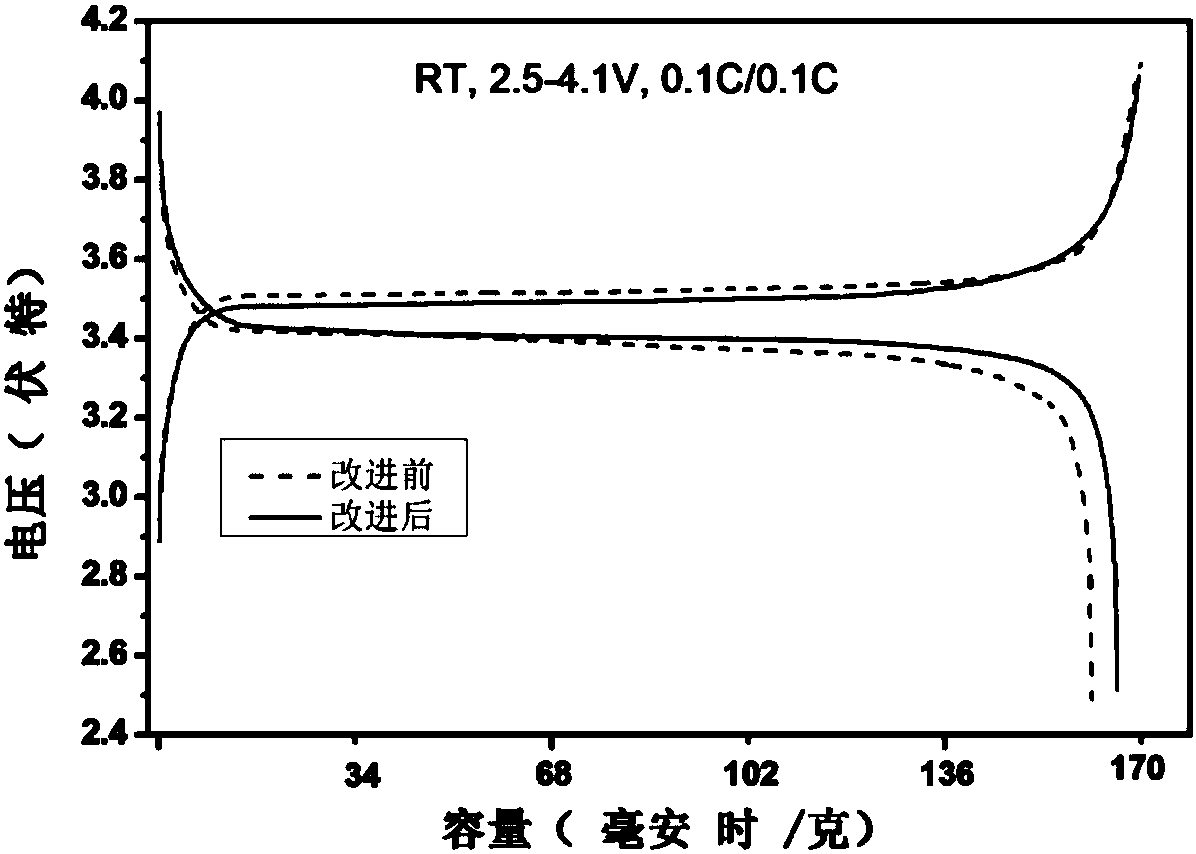

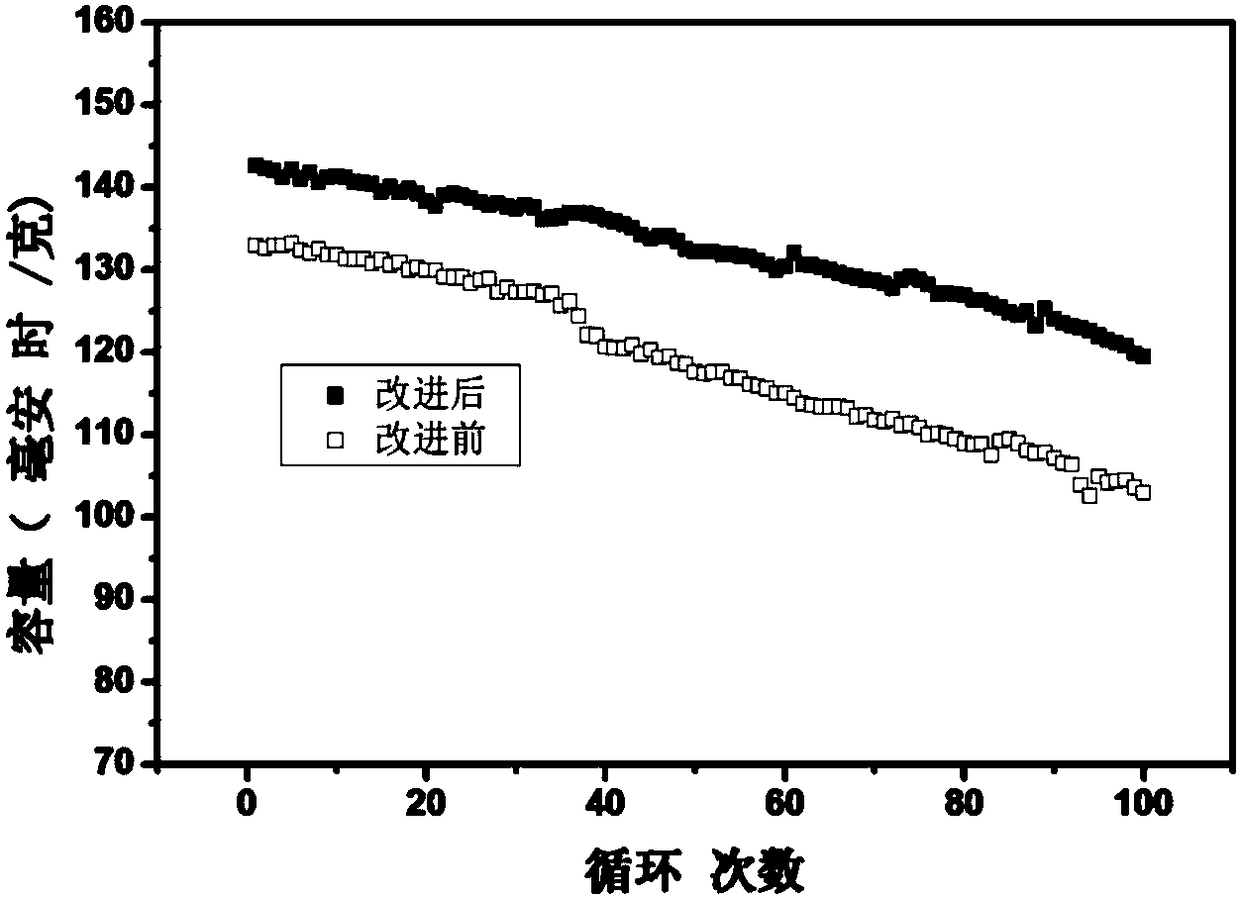

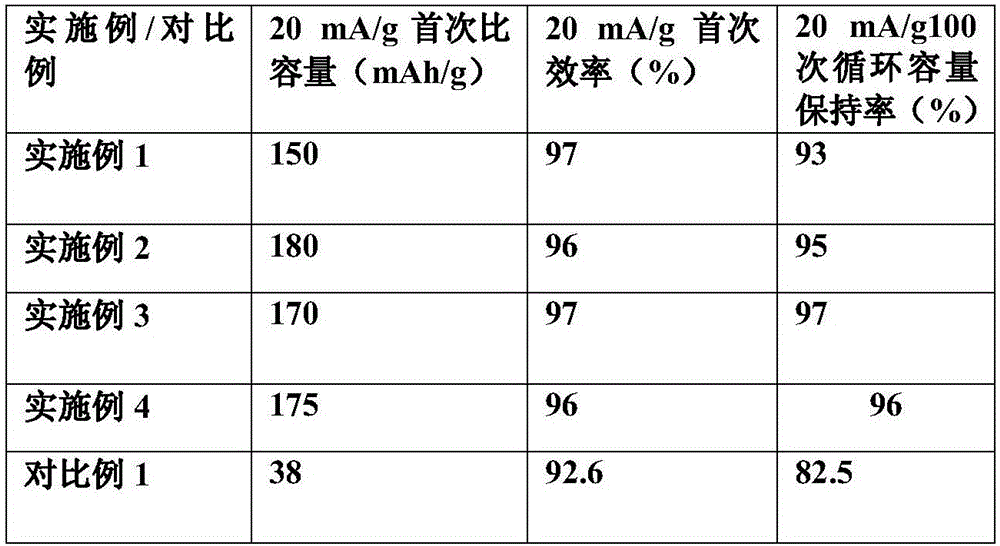

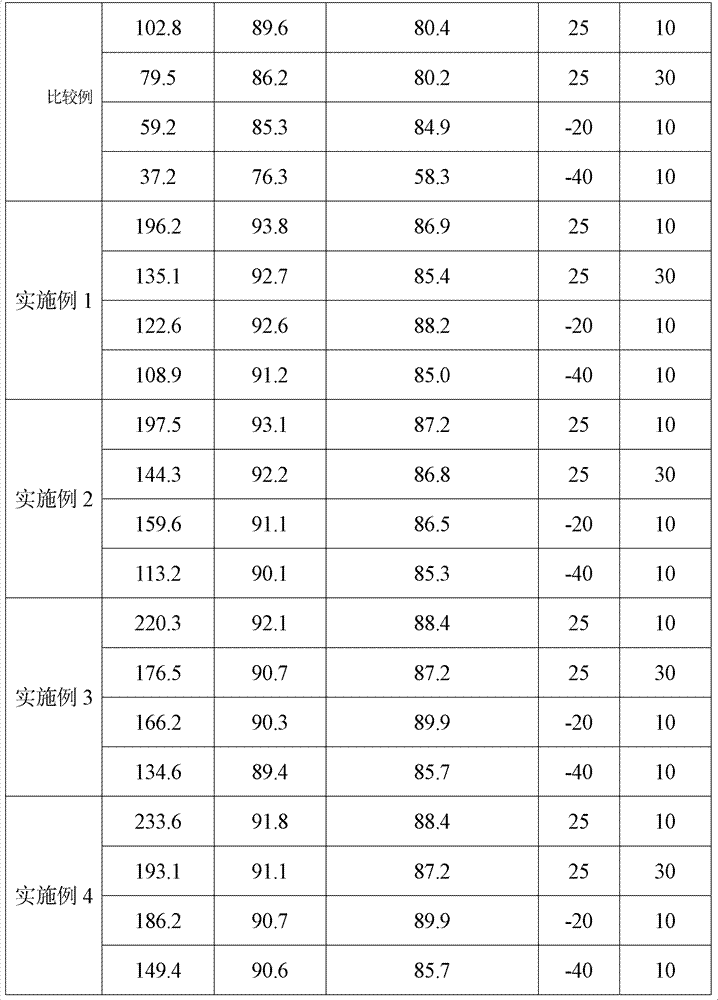

Lithium ion battery and cathode material thereof

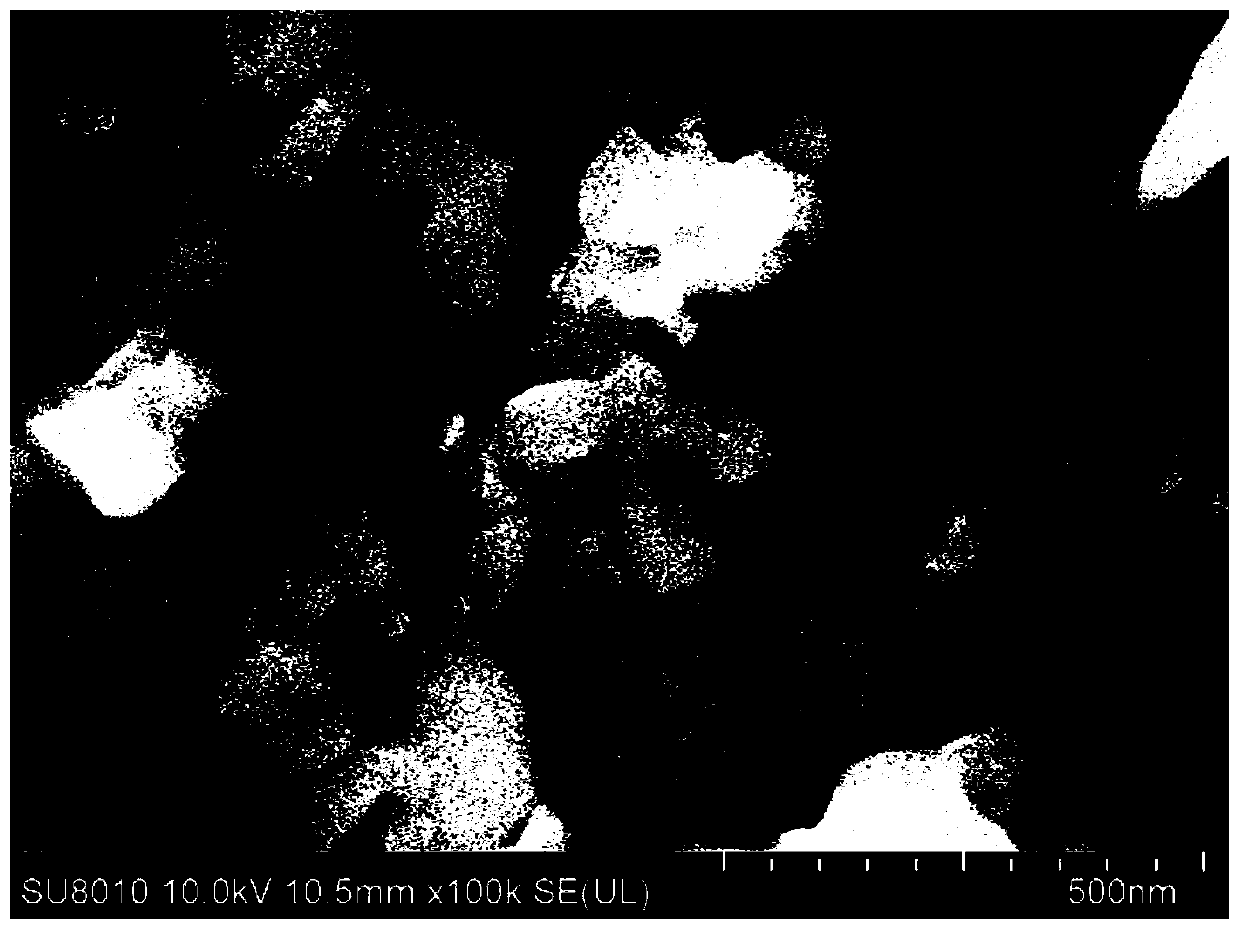

ActiveCN108155351AIncreased Diffusion ChannelImprove lithium intercalation spaceGraphiteNegative electrodesGraphiteMaterials science

The invention discloses a lithium ion battery and a cathode material thereof. The lithium ion battery cathode material comprises graphite and amorphous carbon, wherein the graphitization degree of thegraphite is 90-96%; the average particle size D50 of the graphite is 2-25 [mu]m; the graphitization degree of the amorphous carbon is 65-80%; the average particle size D50 of the amorphous carbon is2-25 [mu]m. Compared with the prior art, the lithium ion battery cathode material prepared by mixing graphite and amorphous carbon which are relatively small in particle size is excellent in dynamic property, circulation property and storage property. The invention further discloses a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO LTD

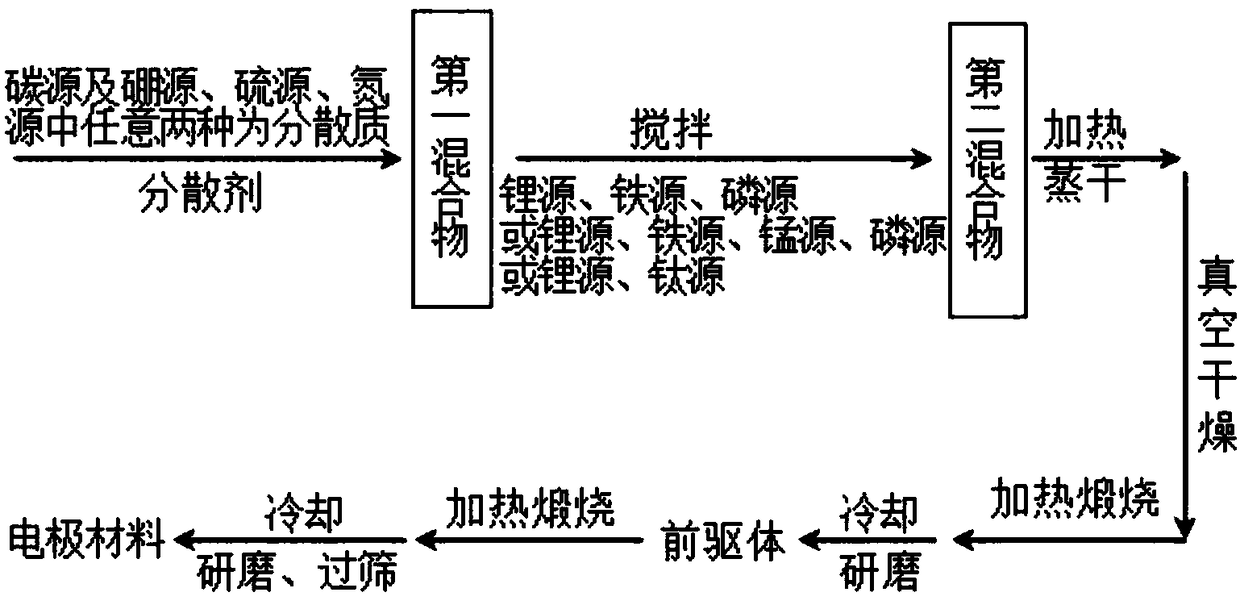

Preparation method of lithium ion battery electrode material

ActiveCN108461707ARaise the ratioImprove cycle stabilityNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

The invention provides a preparation method of a lithium ion battery electrode material. The preparation method comprises the following steps: adding a carbon source and any two of a boron source, a sulfur source and a nitrogen source of a nonmetallic doping raw material as dispersoids into a dispersant, and uniformly stirring the materials to form a first mixture; adding a lithium source, an ironsource and a phosphorus source to the first mixture, or adding a lithium source, an iron source, a manganese source and a phosphorus source, or adding a lithium source and a titanium source to form asecond mixture; stirring and heating the second mixture until the solution is evaporated to form a solid to obtain a precursor of a nonmetallic co-doped carbon-coated electrode material; drying the solid in vacuum, heating the solid to 250-450 DEG C under an inert gas atmosphere, heating the solid at a constant temperature for 3-5h, and cooling and grinding the solid to obtain a reaction precursor; and heating the reaction precursor to 700-1000 DEG C under an inert gas atmosphere, calcining the reaction precursor at a constant temperature for 8-30h, and carrying out grinding and sieving aftercooling to obtain the lithium ion battery electrode material.

Owner:PULEAD TECH IND

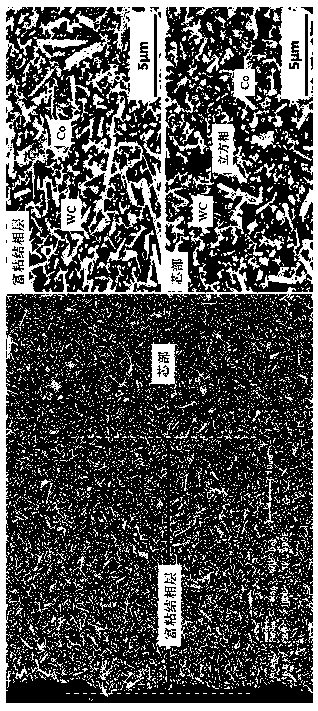

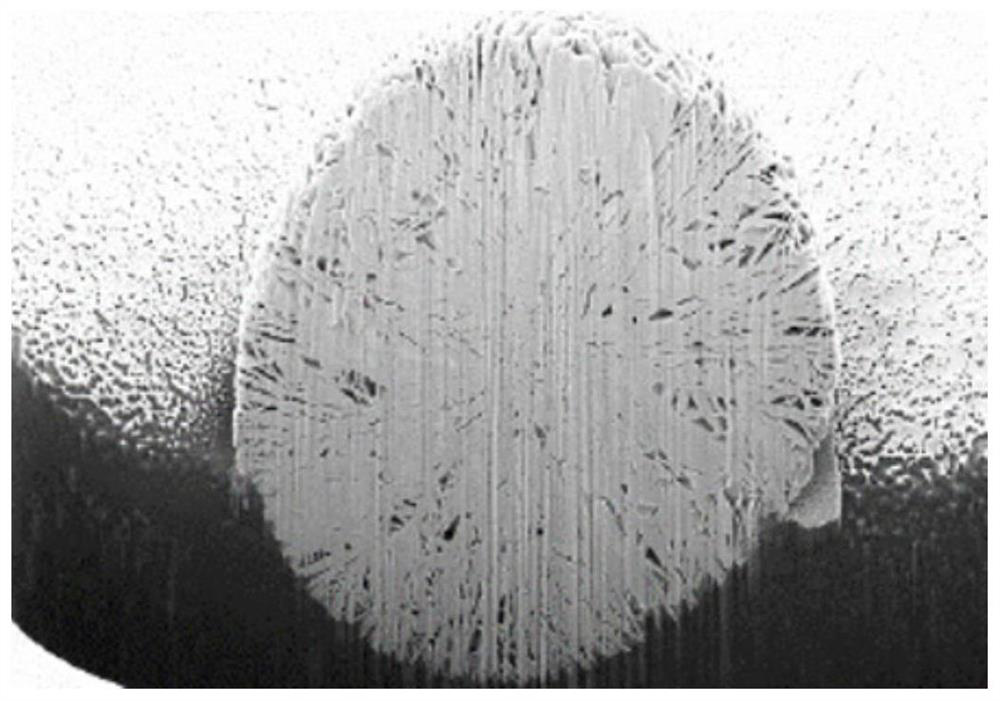

Ultrafine crystal gradient hard alloy with double-gradient-layer structure on surface as well as preparation method thereof

The invention belongs to the field of hard alloy manufacturing and particularly relates to ultrafine crystal gradient hard alloy with a double-gradient-layer structure on the surface as well as a preparation method thereof. The hard alloy takes WC and carbon nitride as a core hard phase; the double-gradient-layer structure comprises a cobalt-enriched layer with the thickness of 20 to 50 um which is formed on the surface by taking the cobalt as the adhesion phase as well as a cubic-phase-enriched layer with the thickness of 10 to 30 um which is formed on the inner side by taking the carbon nitride as a cubic phase; the average size of the WC crystal grains is 0.1 to 0.5 um; the surface cobalt-enriched gradient layer does not contain the cubic phase and the cobalt content is 1 to 2 times ofthe nominal content; and the cubic phase element content of the inner side cubic-phase-enriched layer is 1 to 1.5 times of the nominal content. The preparation method comprises the following steps: after batching, performing wet grinding and performing pressing formation; and sintering by combining low-pressure sintering with gradient sintering to obtain the ultrafine crystal gradient hard alloy with the double-gradient-layer structure. The ultrafine crystal gradient hard alloy with the double-gradient-layer structure is reasonable in structural design, simple and controllable in preparation process and low in production cost and can realize large-scale industrialized production and application.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

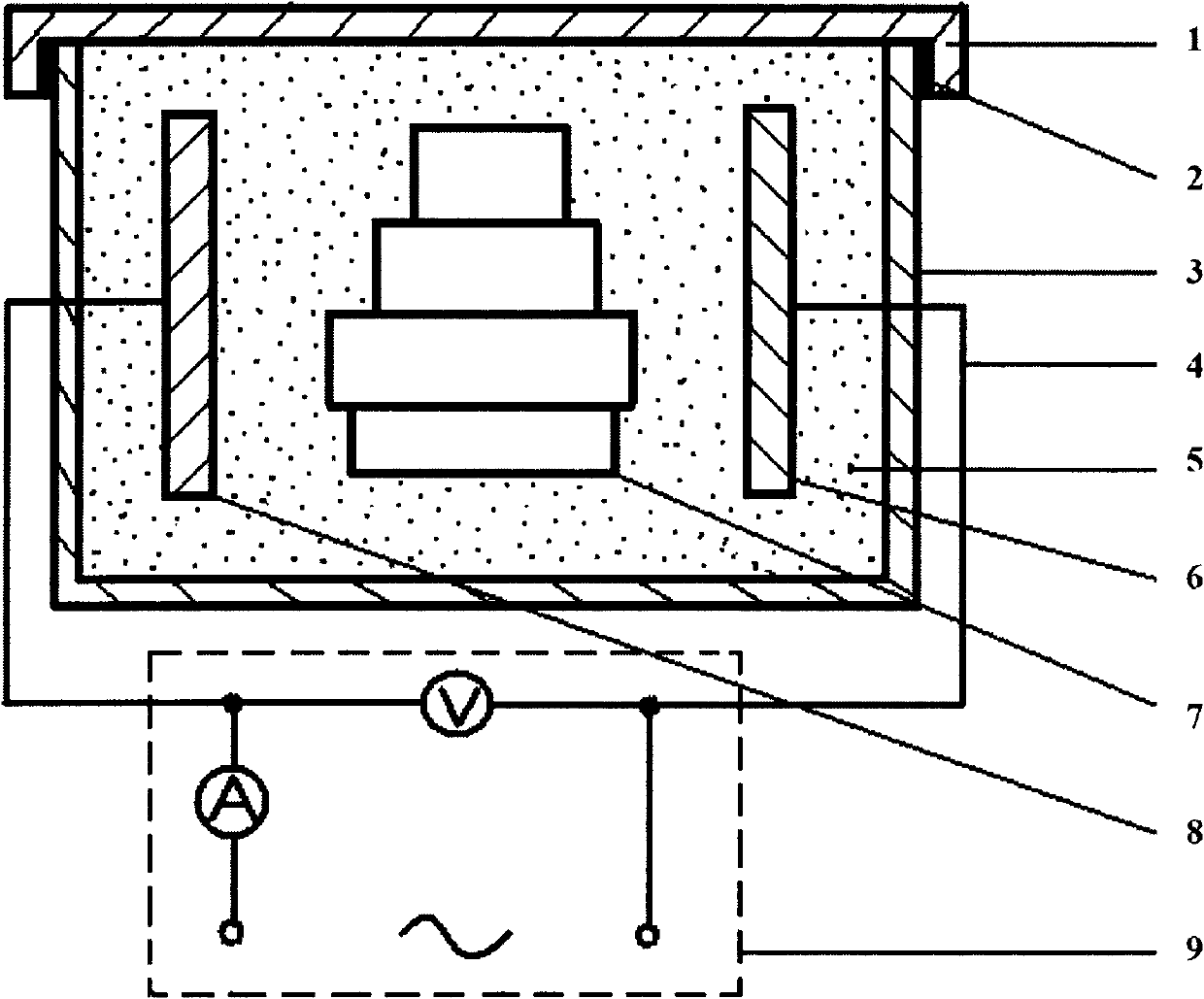

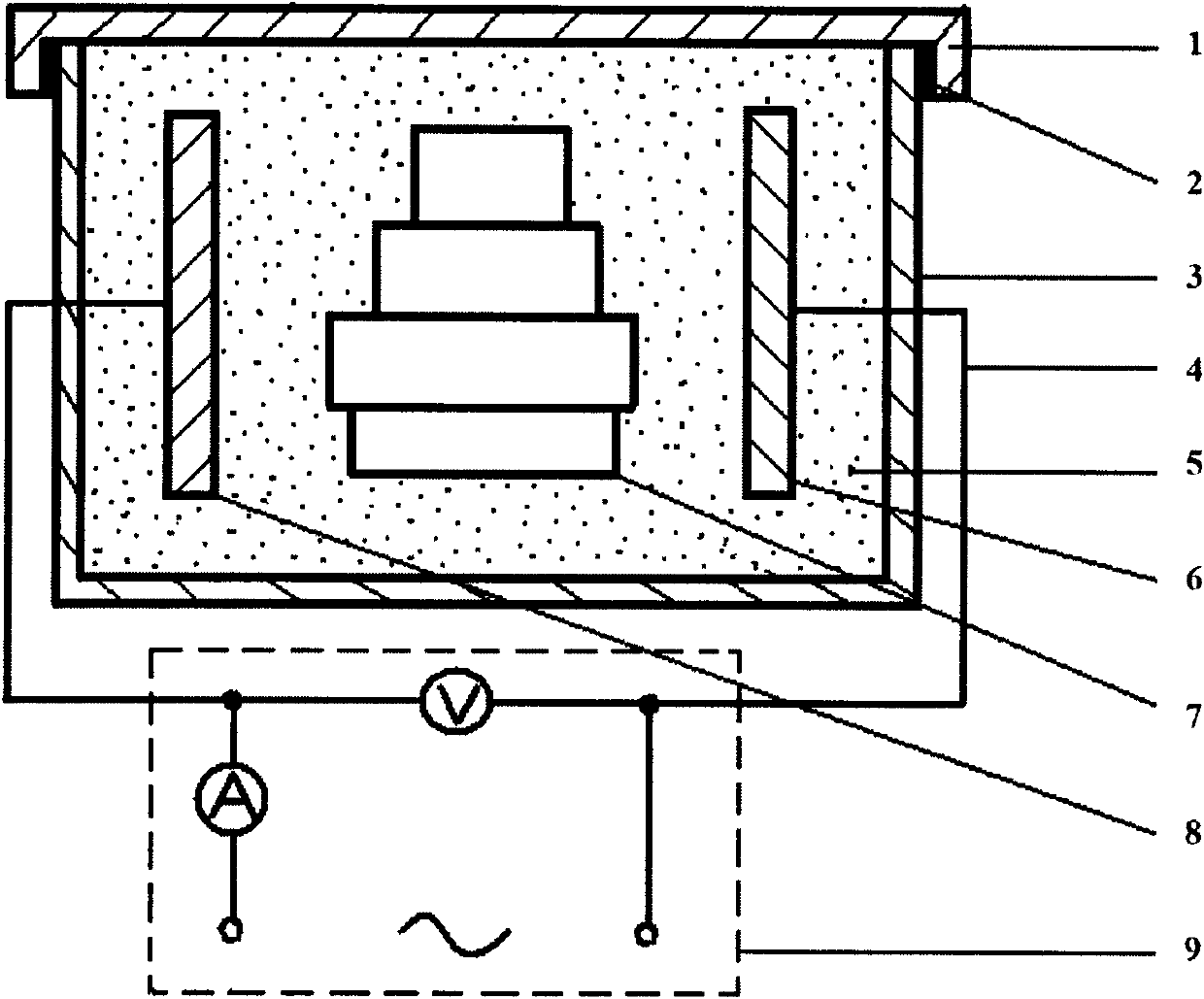

Method and device for accelerating powder method boronisation by alternating-current filed

InactiveCN102168243AIncrease concentrationHigh activitySolid state diffusion coatingPowder methodParallel plate

The invention discloses a method and a device for accelerating powder method boronisation by an alternating-current filed and used for strengthening the surface of a metal part. Two parallel plate-shaped electrodes are placed in powdered boronizing agent and by leads, the two electrodes are respectively connected on a 50Hz alternating current power supply of which the voltage is continuously adjustable within the range of 0-250V; a treated part is positioned between the two electrodes; the electrodes and the part are sealed together with the boronizing agent in a boronisation box and placed in a heat treatment furnace to heat; after the temperature of the furnace achieves a set value, appropriate alternating voltage is applied between the two electrodes; and then the rapid boronisation of the part can be realized. Compared with the existing method, the method of the invention has the advantages that the boronisation can be accelerated by at least 0.3-3 times and the usage amount of the boronizing agent is reduced by above 70%. Therefore, the method and the device can accelerate the powder method boronisation of the metal part, improve the utilization rate of the boronizing agent, lower the temperature of boronisation and reduce deformation of the part.

Owner:CHANGZHOU UNIV

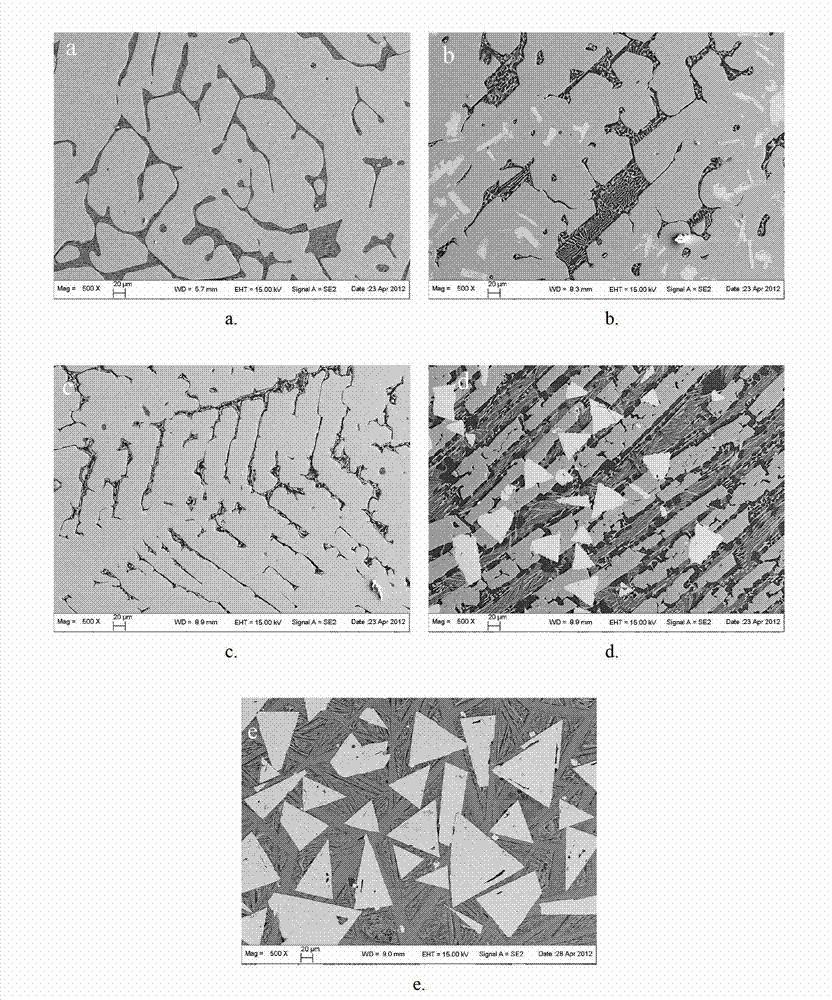

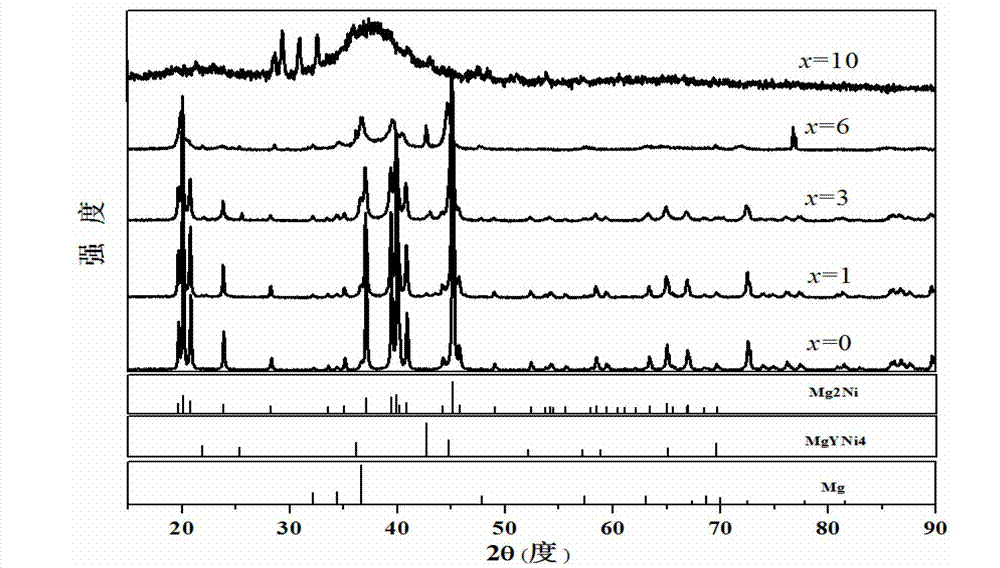

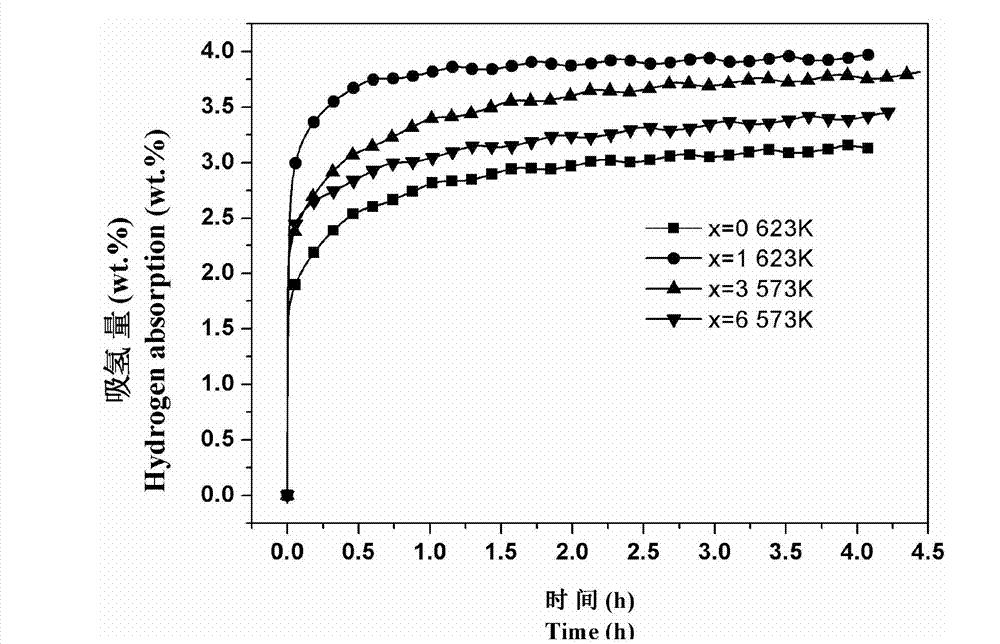

Magnesium-nickel-yttria hydrogen storage alloy thin belt and preparation method thereof

A magnesium-nickel-yttria hydrogen storage alloy thin belt and a preparation method thereof. The hydrogen storage material contains 67at.% of Mg, and 33at.% of nickel and yttrium, wherein yttrium accounts for 0-10at.%, and the rest is nickel. Yttrium is added in a form of a magnesium yttrium intermediate alloy; nickel is added in a form of briquetted nickel powder; a two-step method is adopted to prepare a mother alloy by smelting; and the prepared alloy is remelted and quenched in a single roller melt quenching furnace to obtain a thin belt namely the finished hydrogen storage material. The material provided by the invention improves the hydrogen storage capacity and hydrogen absorption-desorption kinetic properties of a Mg2Ni type hydrogen storage alloy, and overcomes the contradiction that hydrogen storage capacity and dynamic property of Mg base alloy can not be improved at the same time. The invention has the characteristics of simple preparation method, low cost, and low requirement on equipment and environment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Polymer network preparation method for hexagonal boron nitride ceramic powder with high specific surface area

The invention relates to a polymer network preparation method for high-specific-surface hexagonal boron nitride ceramic powder, and the method comprises the following steps: (1) proportioning; (2) preparing precursor powder; (3) synthesizing hexagonal boron nitride; and (4) carrying out purification treatment. The obtained hexagonal boron nitride ceramic powder has the advantages of low cost, high purity and large specific surface area.

Owner:SHENYANG UNIV

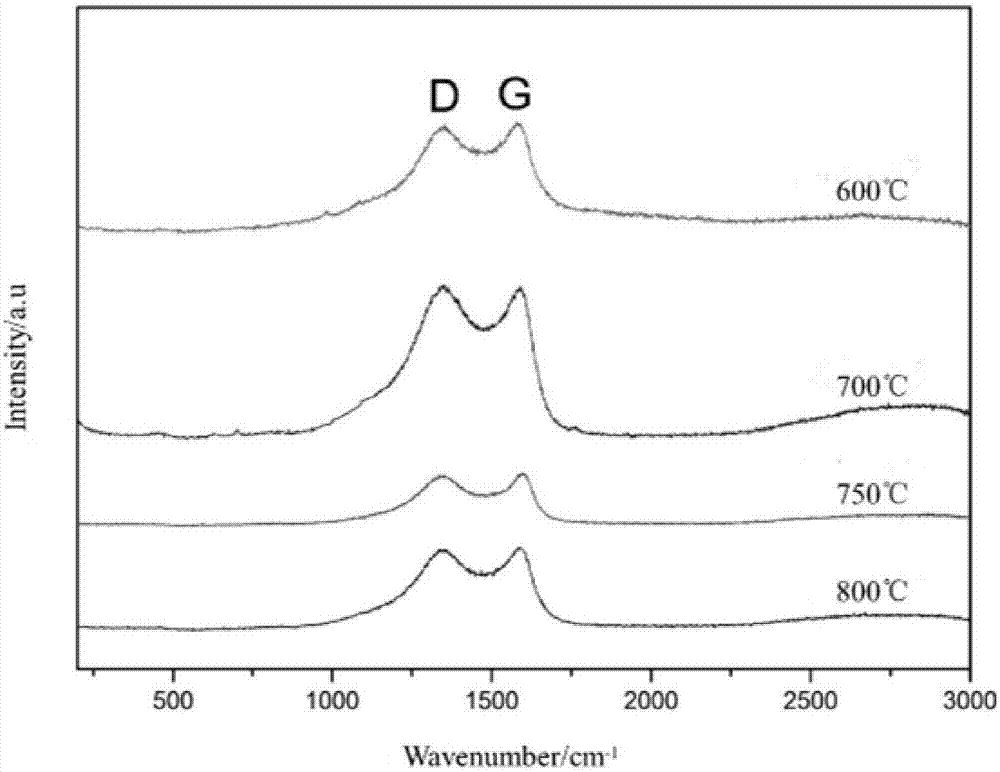

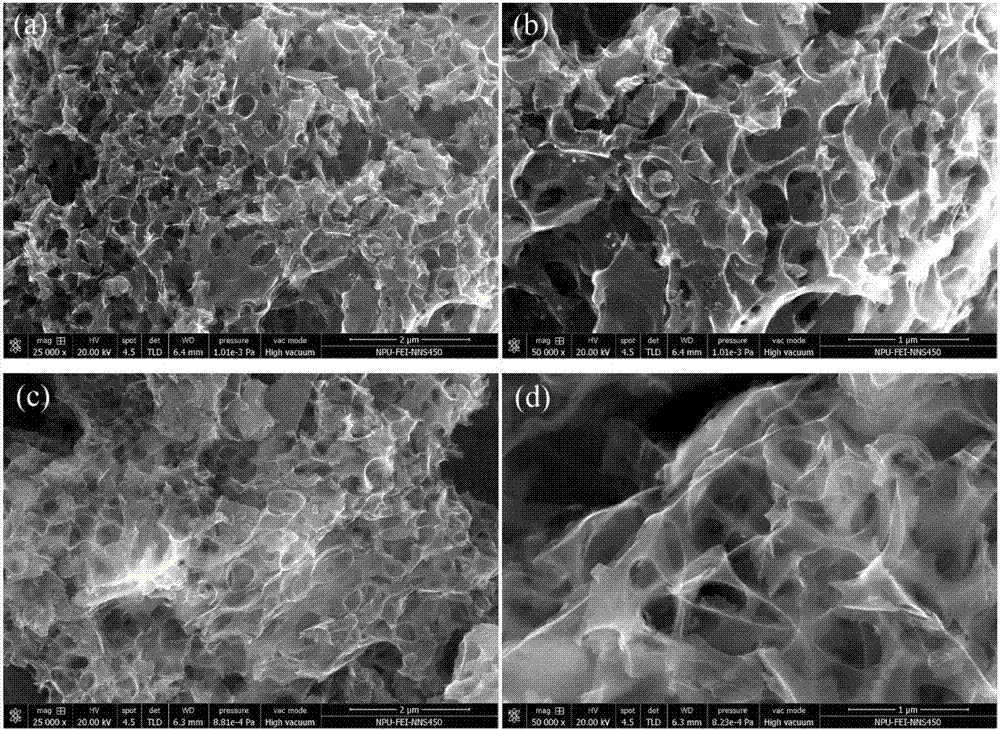

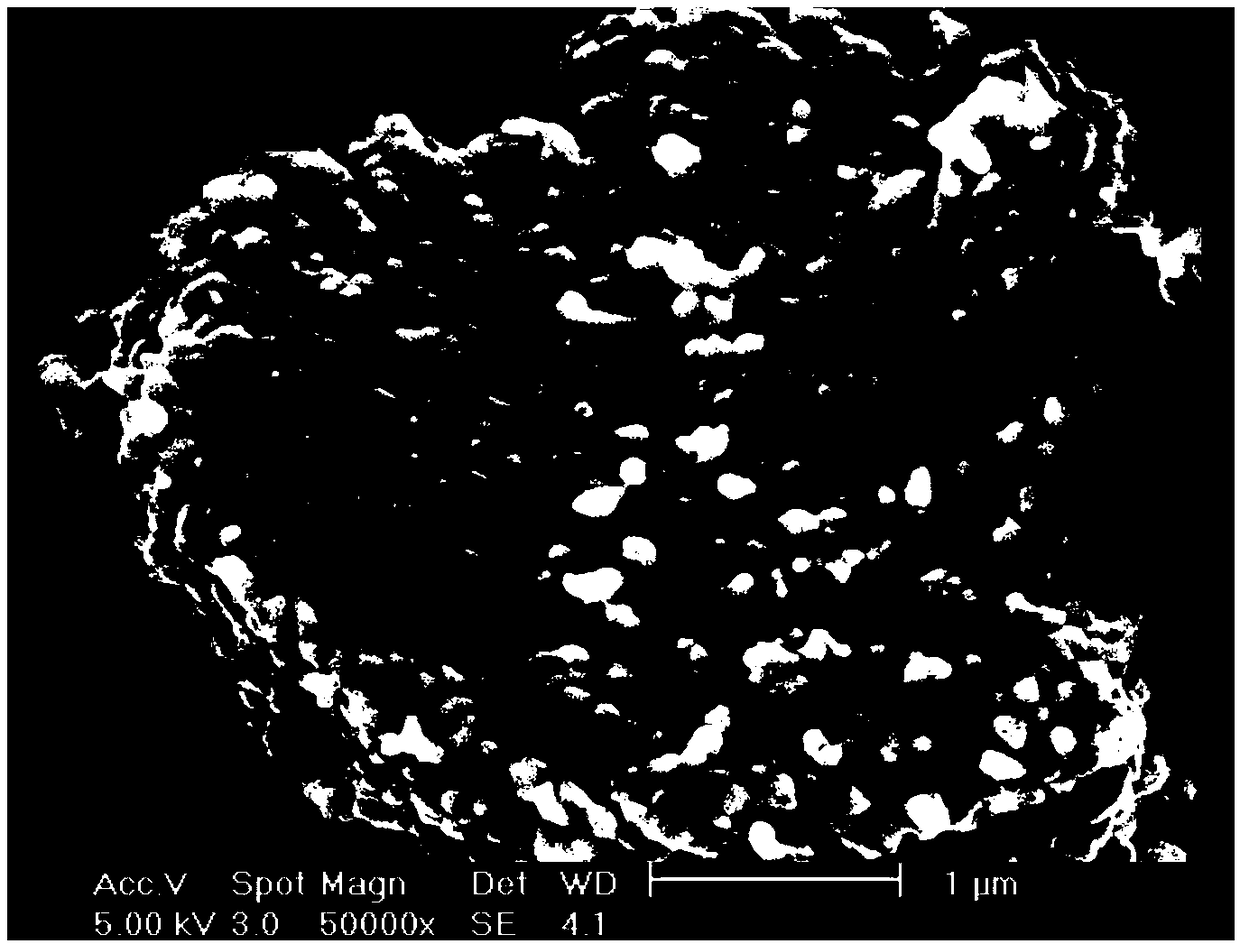

Preparation method for papermaking black liquid-transferred porous carbon negative electrode material for sodium ion battery

InactiveCN107452960AReduce pollutionPollution realizedCell electrodesSecondary cellsFiberPorous carbon

Disclosed is a preparation method for a papermaking black liquid-transferred porous carbon negative electrode material for a sodium ion battery. The preparation method comprises the steps of firstly, putting a papermaking black liquid into a drying oven to be dried at a temperature of 50-90 DEG C; next, putting the dried product into a tubular furnace, pumping argon as the protective gas and heating from the room temperature to 600-800 DEG C at the heating rate of 2-10 DEG C / min to perform heat treatment to obtain a porous carbon material; and finally, putting the obtained porous carbon material into a muffle furnace to perform activation treatment at a temperature of 200-350 DEG C, and performing cooling to obtain the porous carbon negative electrode material for the sodium ion battery. According to the preparation method, the papermaking black liquid is used as the raw material, so that the waste which refers to the ''papermaking black liquid'' in the papermaking production process is recycled and reused, wherein lignin and plant fibers and the like are subjected to thermal treatment to be converted into carbon; alkali included in the black liquid can etch the carbon material at a high temperature, so that the obtained product can obtain a three-dimensional porous structure; and next, by combination with activation treatment, the nanometer porous carbon material with the graded structure can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

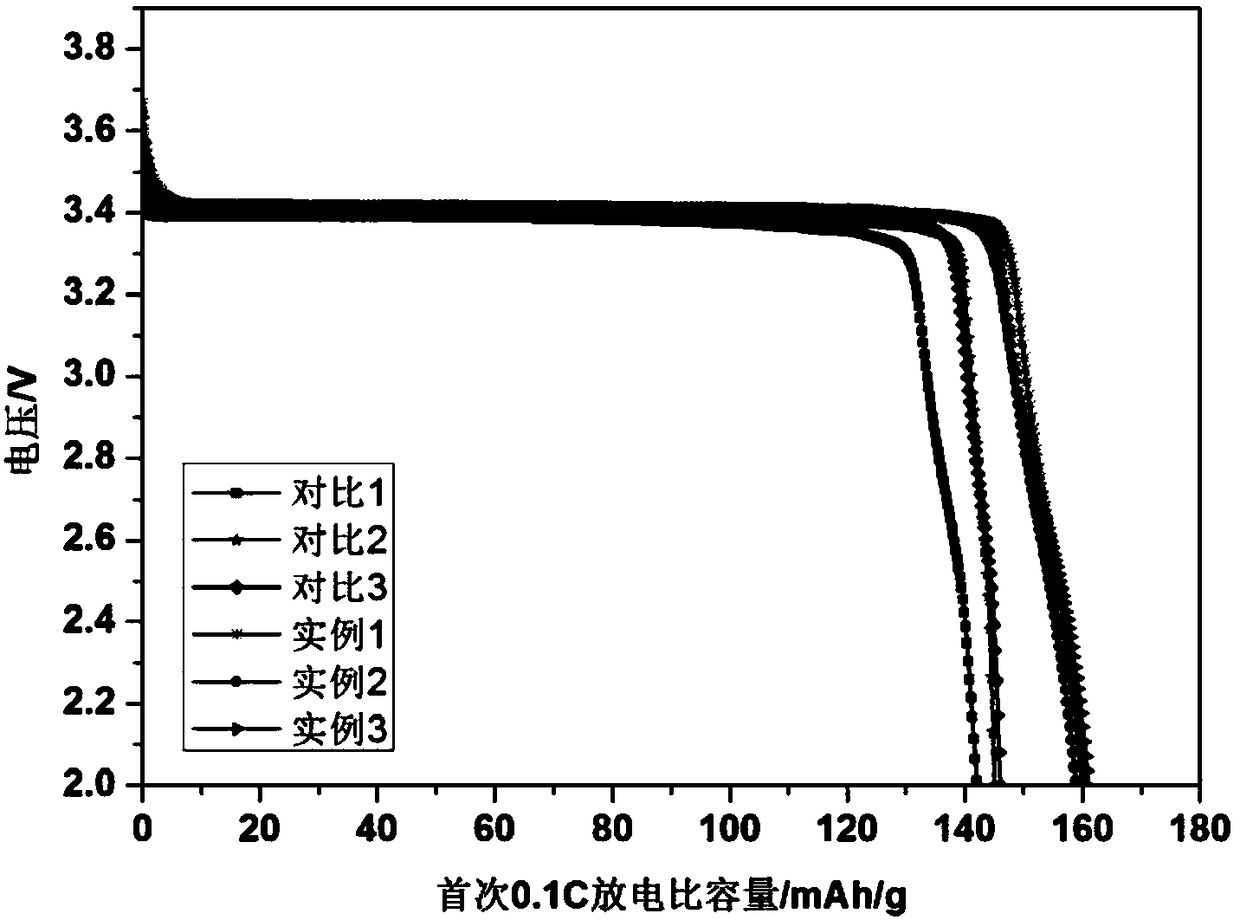

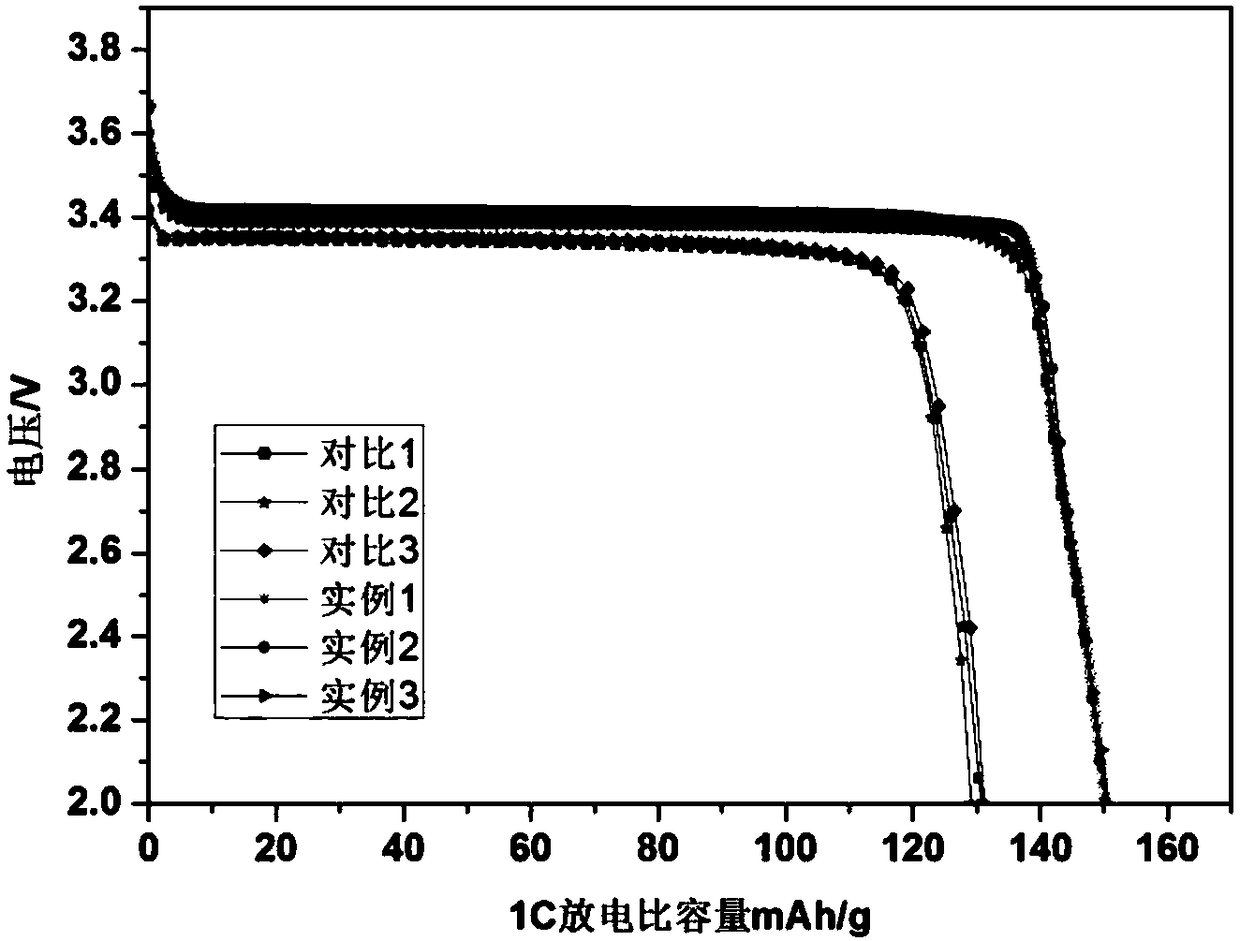

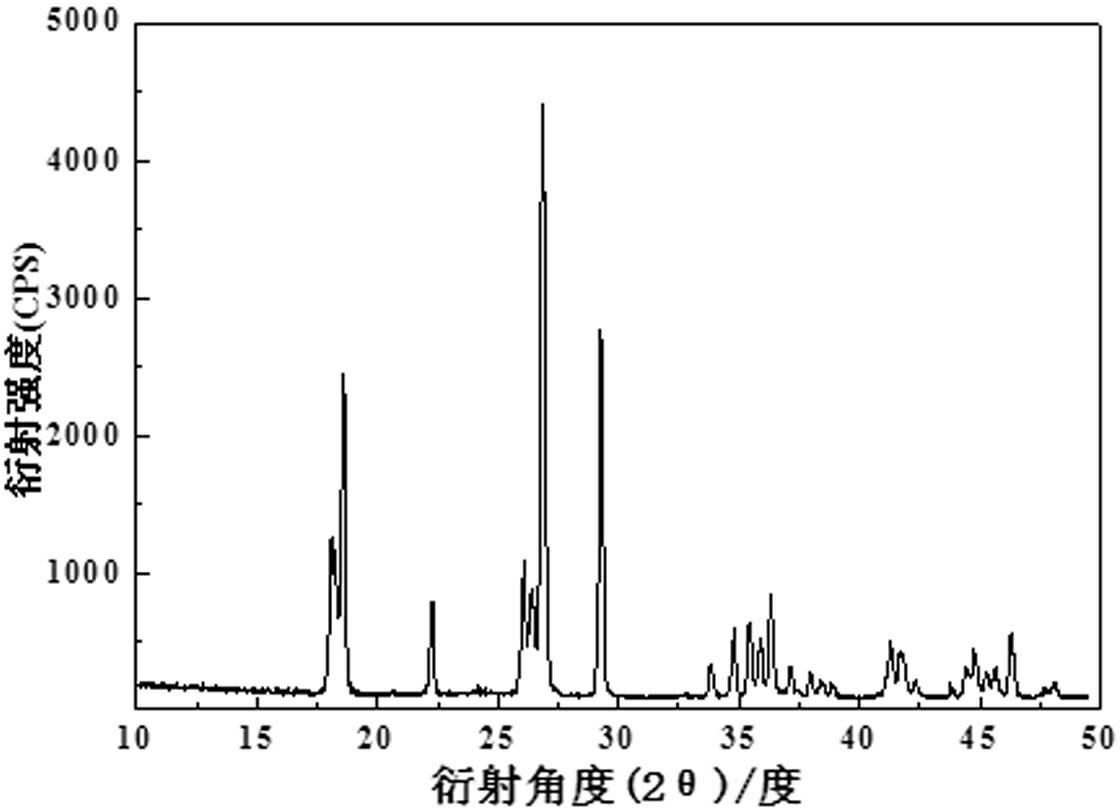

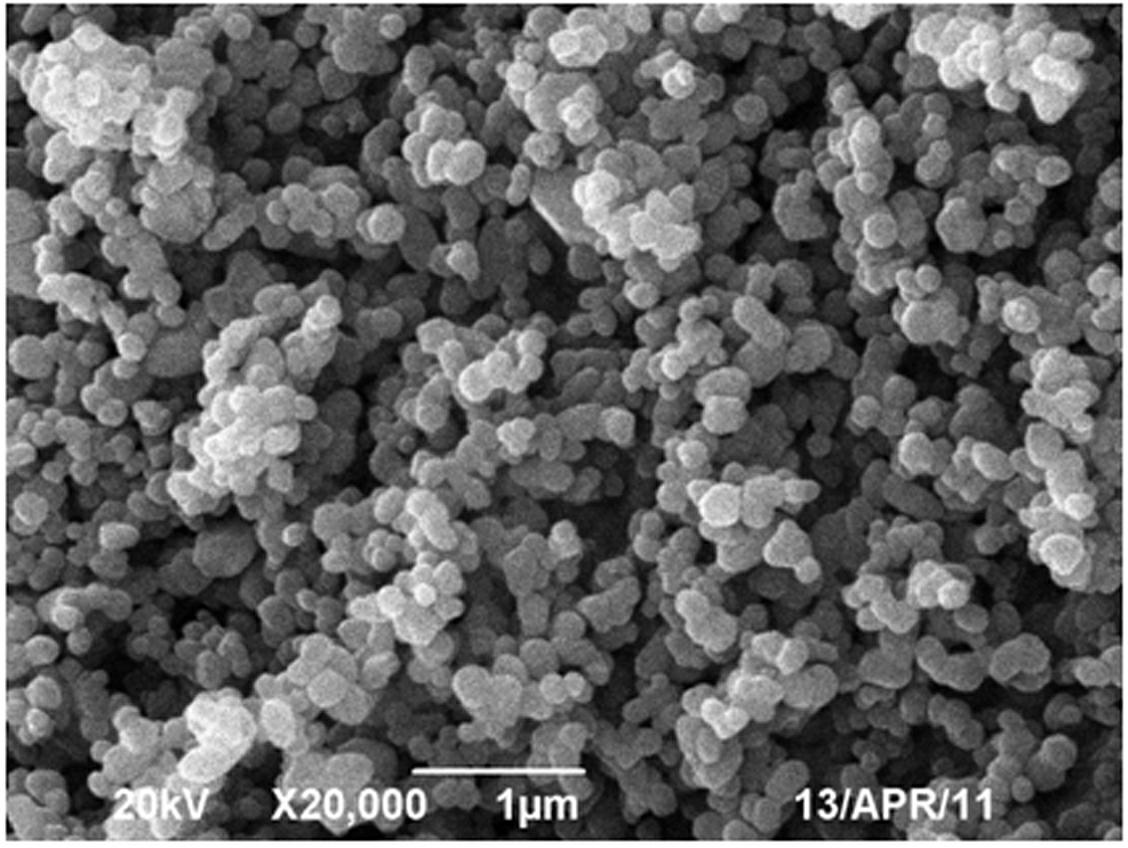

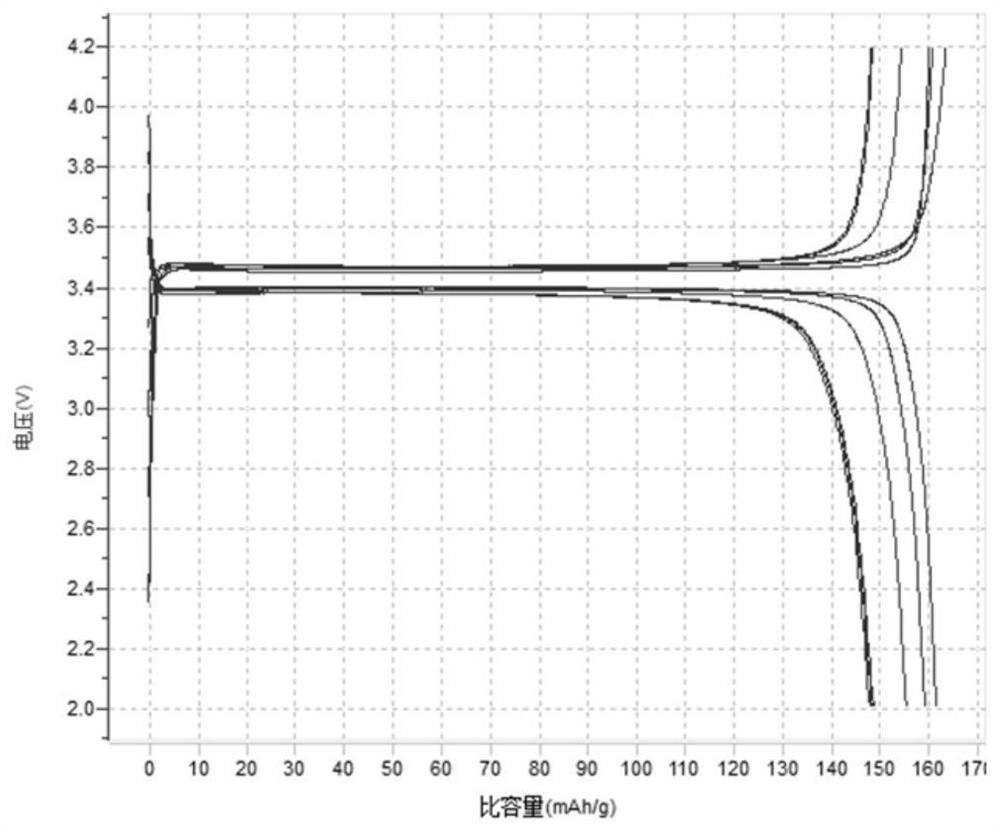

Lithium iron phosphate positive electrode material, preparation method thereof, and lithium ion battery

ActiveCN108063248AIncrease energy densityIncreased Diffusion ChannelMaterial nanotechnologyCell electrodesLithium electrodeElectrode material

The invention provides a lithium iron phosphate positive electrode material. The lithium iron phosphate positive electrode material comprises a lithium iron phosphate array formed by a plurality of lithium iron phosphate cylinders which are arranged in an array manner and granular lithium iron phosphate distributed in the lithium iron phosphate array, wherein a gap exists in two adjacent lithium iron phosphate cylinders in the lithium iron phosphate array, and every gap is filled with the granular lithium iron phosphate. The lithium iron phosphate positive electrode material having a specificmorphology has a high compacted density and a high lithium ion conductivity. The invention also provides a preparation method of the lithium iron phosphate positive electrode material, and a lithium ion battery.

Owner:FOSHAN DYNANONIC +1

Anode material for lithium-ion battery and preparation method

ActiveCN101931077AImprove lithium intercalation spaceHigh reversible specific capacityCell electrodesCarbon compositesPore diameter

The invention provides an anode material for a lithium-ion battery and a preparation method thereof. The anode material is characterized in that the material is a composite of graphite and mesoporous carbons; the mesoporous carbons account for 1-60% of the composite by mass; the graphitization degree of the graphite ranges from 78% to 88%; the pore diameters of the mesoporous carbons are 2-50nm; and the through porosity is not lower than 85%. The carbon composite anode material is prepared by chemically compounding the graphite with low graphitization degree and the mesoporous carbons with high through porosity. The anode material is suitable for low-temperature power lithium-ion batteries, has mild preparation conditions and is beneficial to industrialization.

Owner:HUNAN SHINZOOM TECH

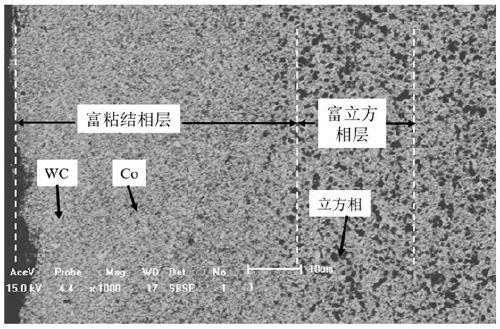

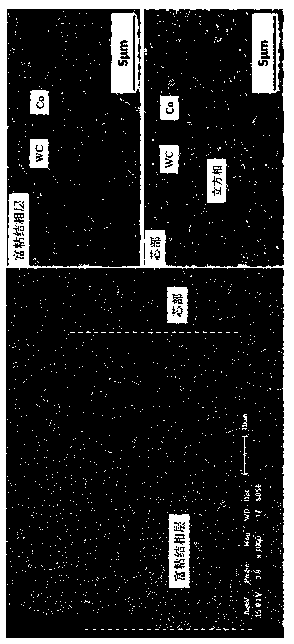

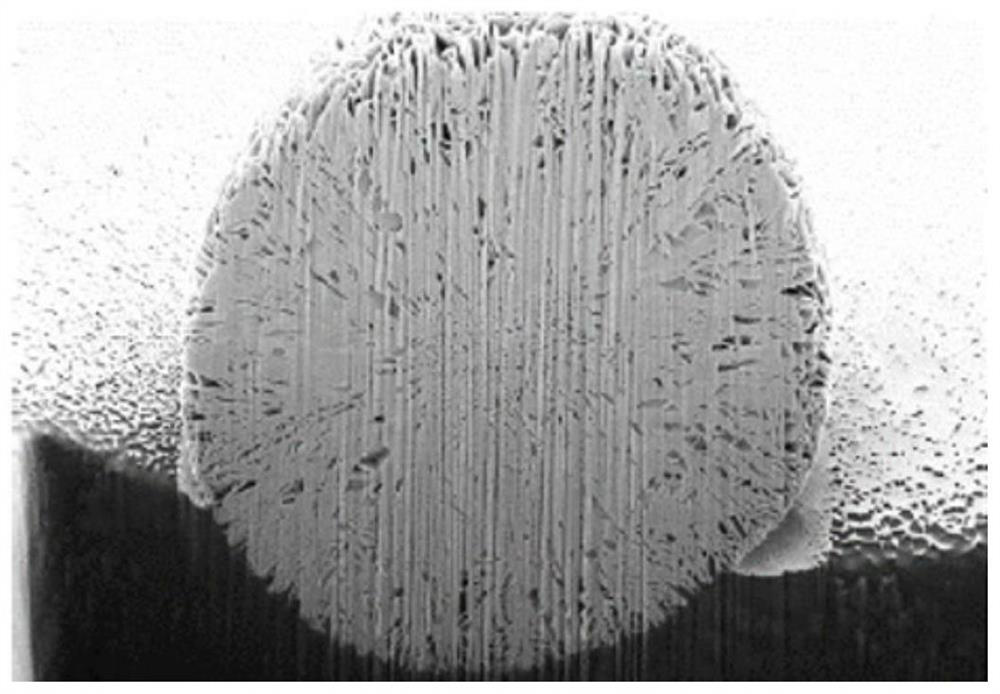

Ultra-fine gradient hard alloy with WC grains in surface rich binding-phase layer arrayed in regular shape and preparation method of ultra-fine gradient hard alloy

The invention provides an ultra-fine gradient hard alloy with WC grains in a surface rich binding-phase layer arrayed in a regular shape and a preparation method of the ultra-fine gradient hard alloy,belongs to the field of hard alloy manufacturing, and particularly relates to an ultra-fine gradient hard alloy with WC grains in a surface rich binding-phase area arrayed regularly and distributed in an oriented mode and a preparation method of the ultra-fine gradient hard alloy. The surface of the gradient hard alloy is the rich binding-phase layer only containing WC and Co and having the thickness of 40-80 [mu]m, and the WC grains in a rich binding phase are approximately in a rectangular shape and are regularly arrayed and distributed in order; and WC, Co and a cubic phase are uniformly distributed in a core part, and the WC grains are distributed in an irregular and disordered shape. The preparation method comprises the steps that ingredients are ball-milled and then pressed into a hard alloy block, and the hard alloy block is sintered under pressure first and then sintered in a gradient manner under a vacuum nitrogen-free atmosphere to be subjected to heat treatment, so that theultra-fine gradient hard alloy with the WC grains in the surface rich binding-phase area distributed in the oriented mode is obtained. The ultra-fine gradient hard alloy is reasonable in structural design, the preparation process is controllable, the production cost is low, and the ultra-fine gradient hard alloy can be industrially produced and used to a large scale.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

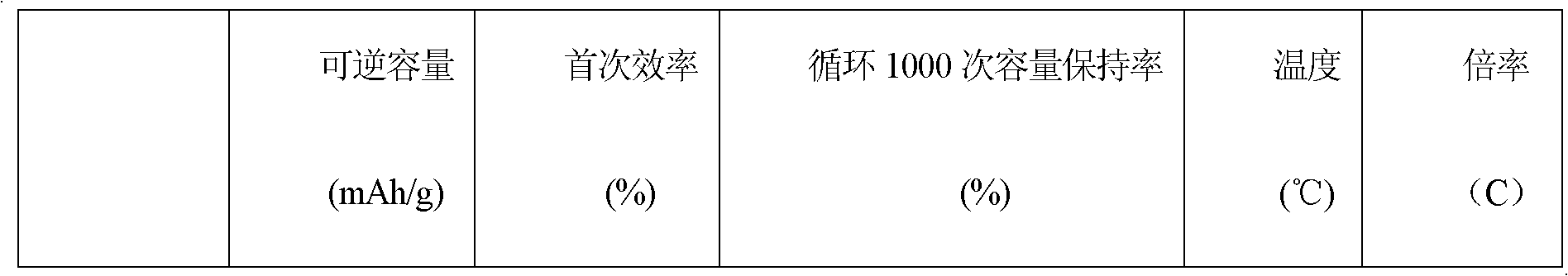

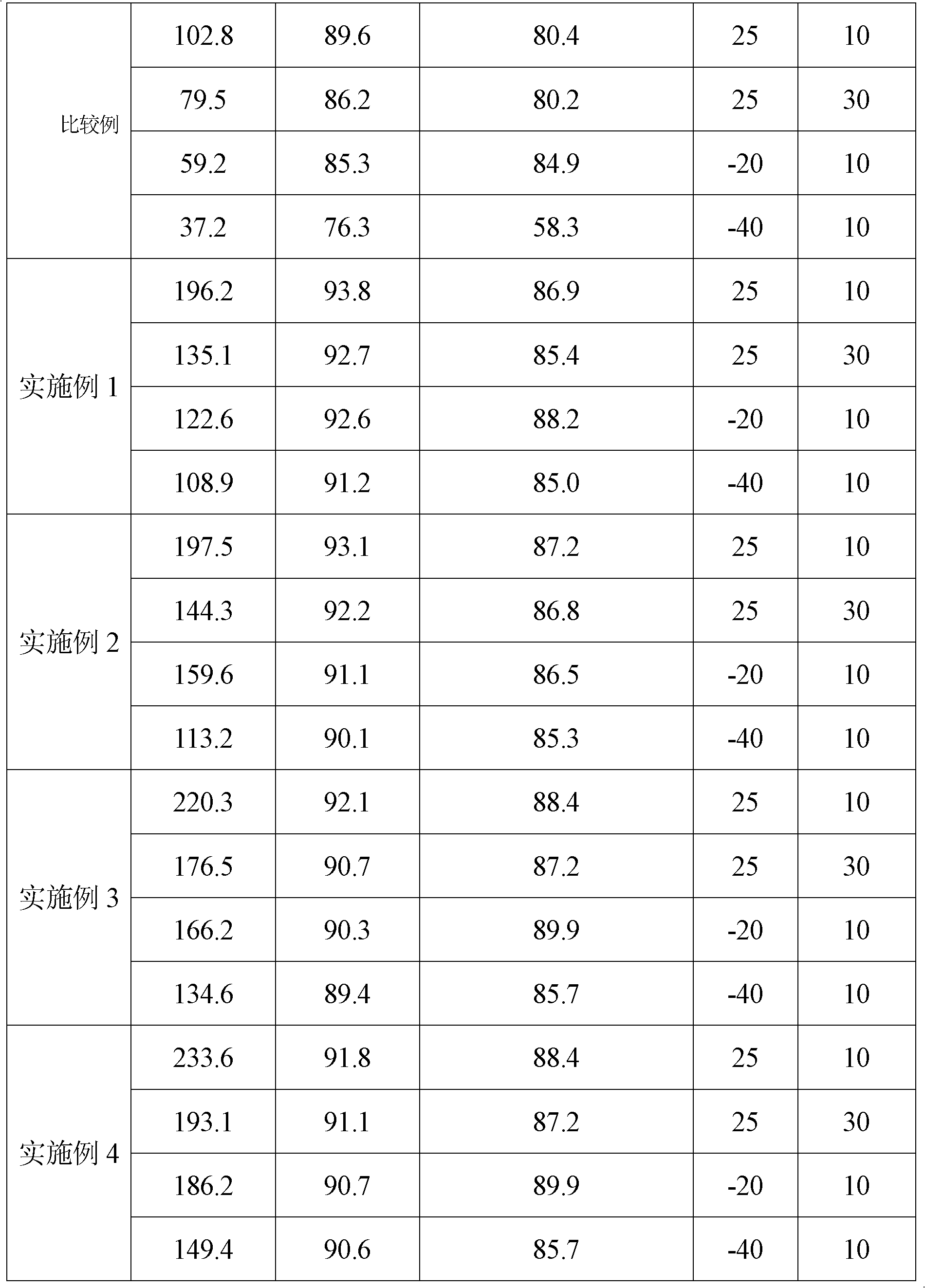

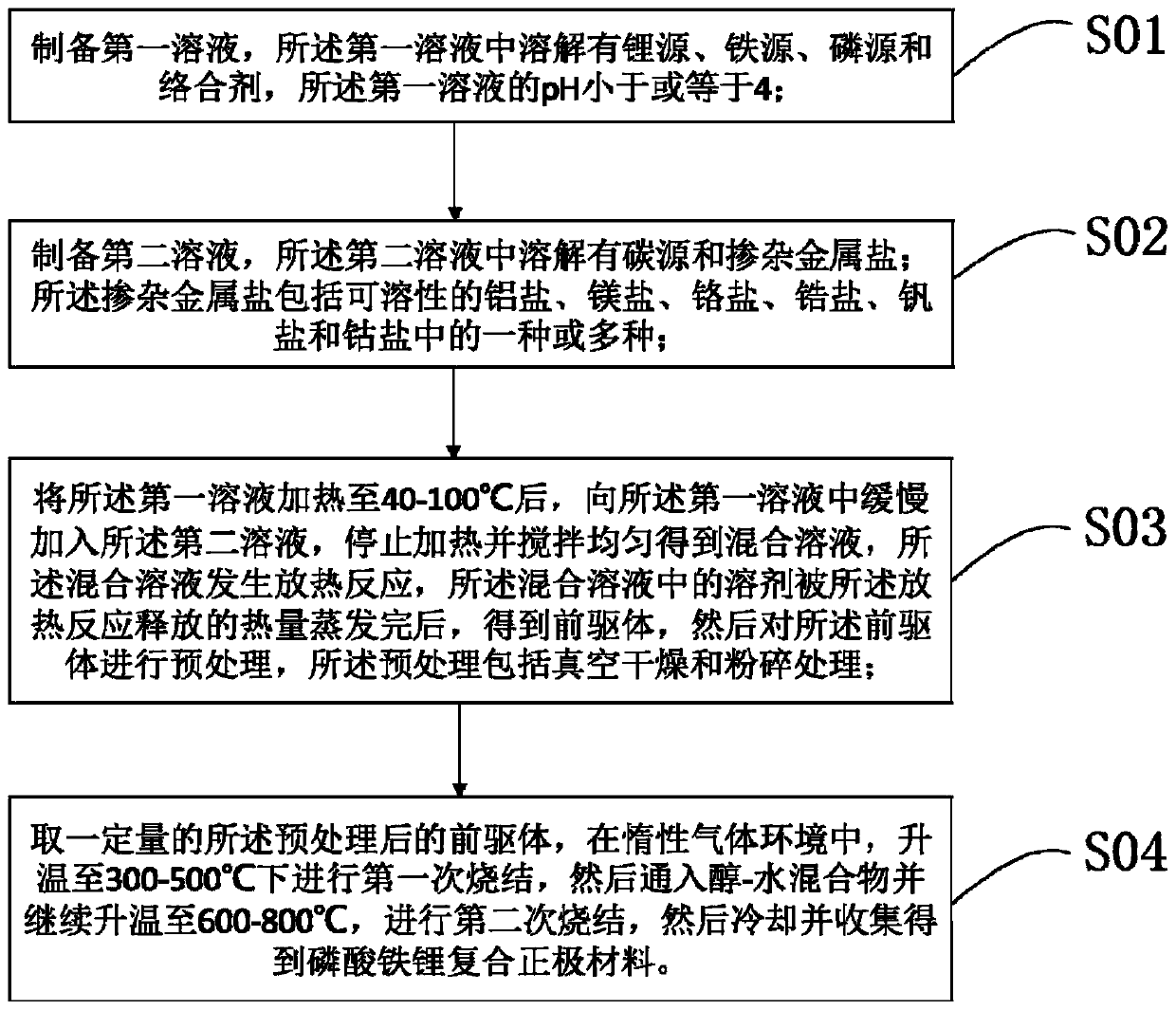

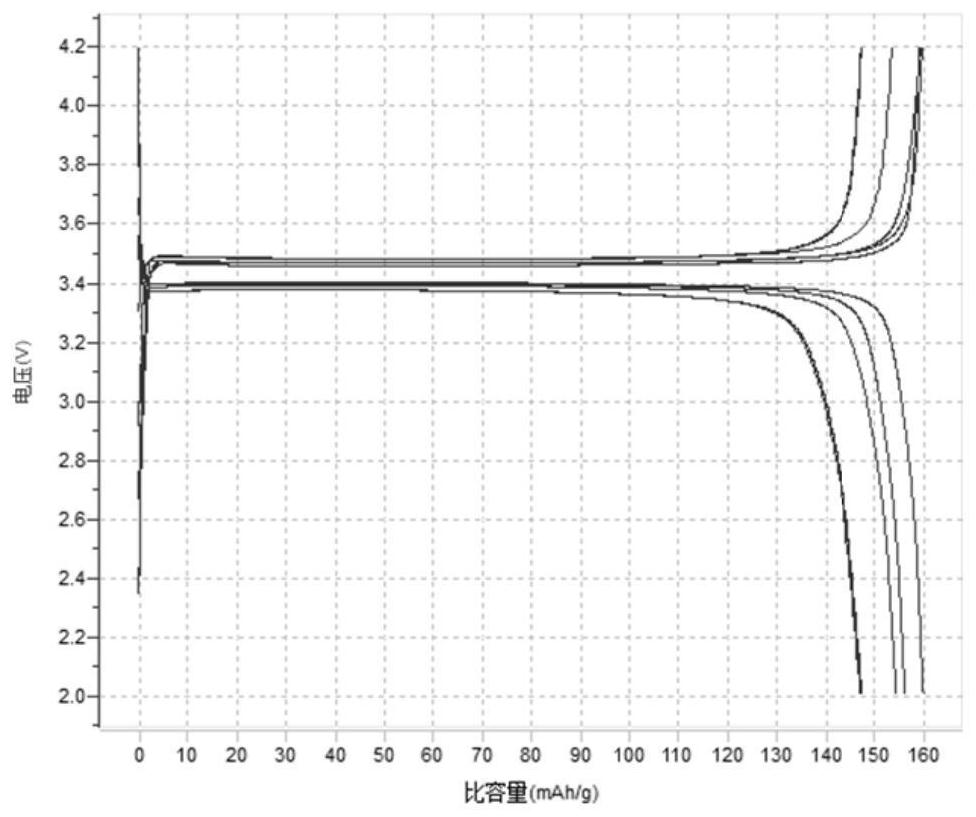

Lithium iron phosphate composite positive electrode material and preparation method and application thereof

ActiveCN110085839AThe crystal phases are closely arrangedImprove diffusion abilityMaterial nanotechnologySecondary cellsCarbon coatingConcentration polarization

The invention provides a lithium iron phosphate composite positive electrode material, which comprises lithium iron phosphate composite nanoparticles and a carbon coating coated on the surfaces of thelithium iron phosphate composite nanoparticles, wherein doping metal elements are evenly distributed in the lithium iron phosphate composite nanoparticles, and the doping metal elements include one or more of aluminum, magnesium, chromium, zirconium, vanadium and cobalt. In the lithium iron phosphate composite positive electrode material, the mass percentage content of the carbon element is 0.5%-4.0%, and the particle size of the lithium iron phosphate composite positive electrode material is 50nm-120nm. The lithium iron phosphate composite positive electrode material can greatly improve thediffusion ability of lithium ions, reduce the concentration polarization of the lithium ions during the charging and discharging process and has outstanding rate performance. The invention further provides a preparation method and an application of the lithium iron phosphate composite positive electrode material.

Owner:FOSHAN DYNANONIC

Cathode paste of rapidly discharged/charged high power lithium ion battery and manufacturing method thereof

InactiveCN108305989AHigh tap densityIncrease compaction densityElectrode manufacturing processesSecondary cellsPolystyreneSodium-ion battery

The invention discloses a cathode paste of a rapidly discharged / charged high power lithium ion battery. The cathode paste comprises following components in parts by weight: 55 to 75 parts of active substance C, 20.5 to 36 parts of active substance D, 1 to 2 parts of thickening agent, 2 to 4 parts of conductive agent C, and 1.5 to 3 parts of binder B; wherein the active substance C is artificial graphite or meso-phase carbon micro beads; the active substance D is soft carbon or hard carbon; the conductive agent C is Super-P; the thickening agent is sodium carboxymethyl cellulose CMC; and the binder B is styrene butadiene rubber SBR or polystyrene-acrylate. The provided lithium ion battery can be rapidly charged and discharged, has high power and a long service life, and can be continuouslydischarged or charged (30C). The 30C constant current charge capacity can account for 70% or more of 1C capacity, and the 30C discharge capacity can account for 90% or more of 1C capacity. Compared with a conventional power type lithium ion battery, the charge performance is improved by 20% or more, and the discharge performance is improved by 10% or more.

Owner:FENGFAN

High-voltage nickel-cobalt-manganese ternary precursor and preparation method thereof

ActiveCN113603154AHold capacityImprove high pressure performanceCell electrodesSecondary cellsPhysical chemistryManganese

The invention relates to the field of nickel-cobalt-manganese ternary precursor manufacturing, and in particular, relates to a high-voltage nickel-cobalt-manganese ternary precursor and a preparation method thereof. The preparation method comprises the steps: mixing a nickel-cobalt-manganese ternary metal salt solution, a carbonate solution, a complexing agent solution and a first base solution, carrying out a co-precipitation reaction, and carrying out solid-liquid separation after precipitate reaches a required particle size range to obtain a nickel-cobalt-manganese composite basic carbonate seed crystal; and mixing the nickel-cobalt-manganese ternary metal salt solution, a precipitant solution, the ammonia water solution and a second base solution containing the nickel-cobalt-manganese composite basic carbonate seed crystal, enabling the nickel-cobalt-manganese composite basic carbonate seed crystal to continuously grow, and after the seed crystal reaches the required particle size range, carrying out solid-liquid separation, drying, batch mixing, sieving and demagnetizing to obtain the ternary precursor, wherein the core of the ternary precursor is nickel-cobalt-manganese composite basic carbonate, and the shell of the ternary precursor is nickel-cobalt-manganese composite hydroxide. A battery assembled by a ternary positive electrode material prepared from the precursor shows high discharge capacity, high first coulombic efficiency and excellent rate capability under 4.5 V high cut-off voltage.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

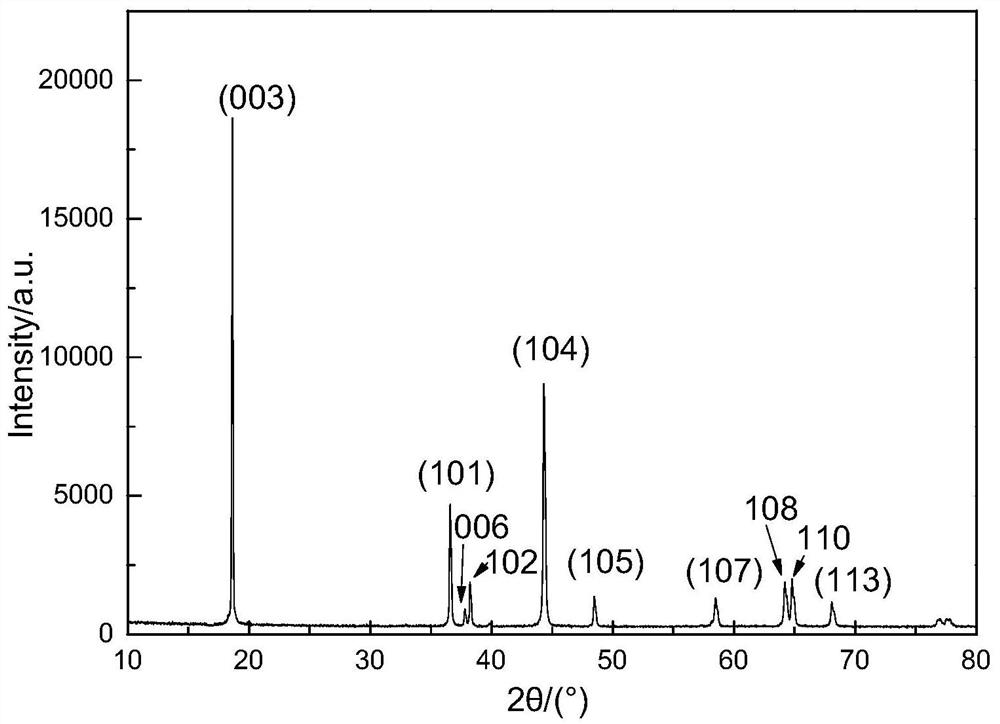

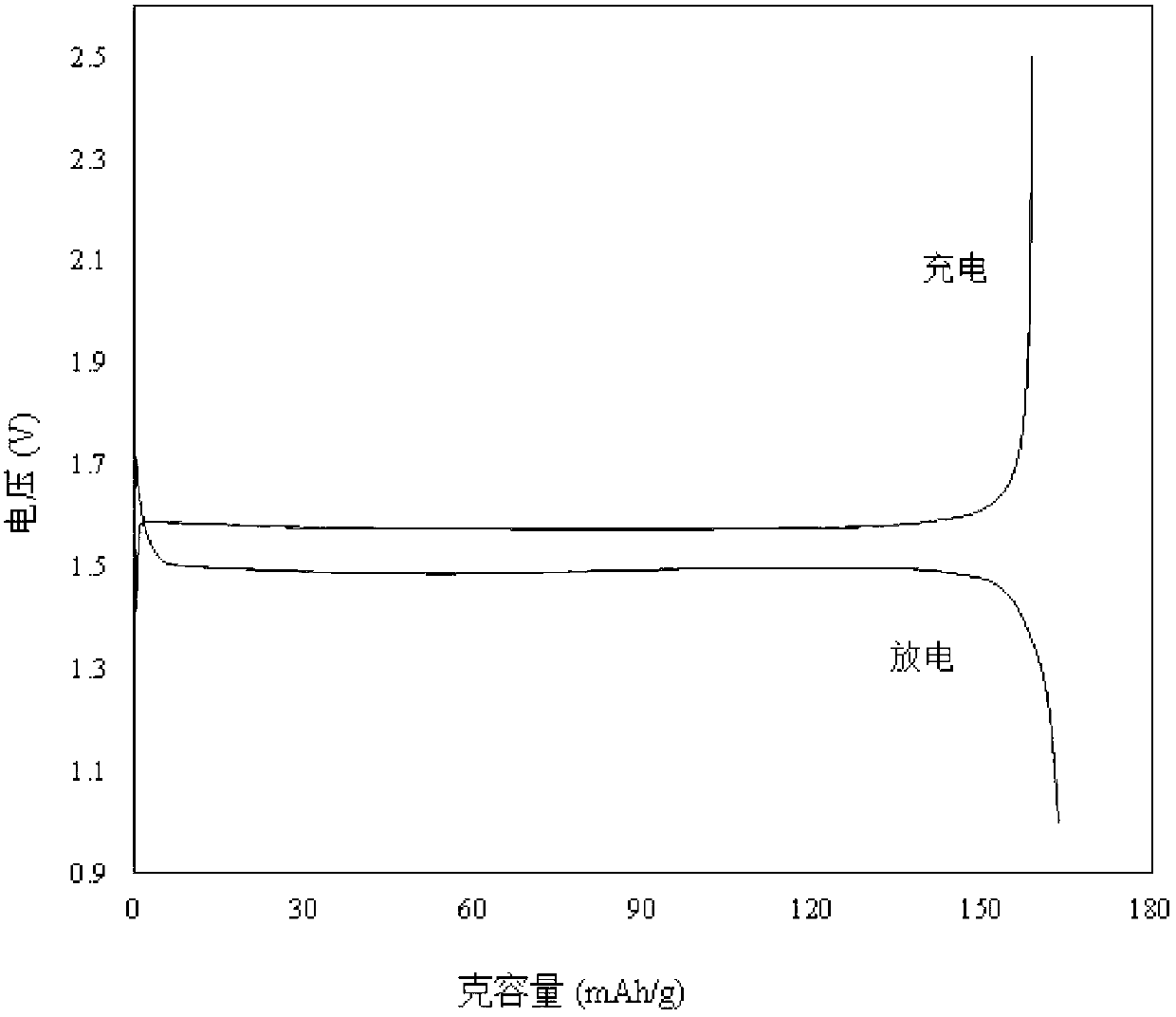

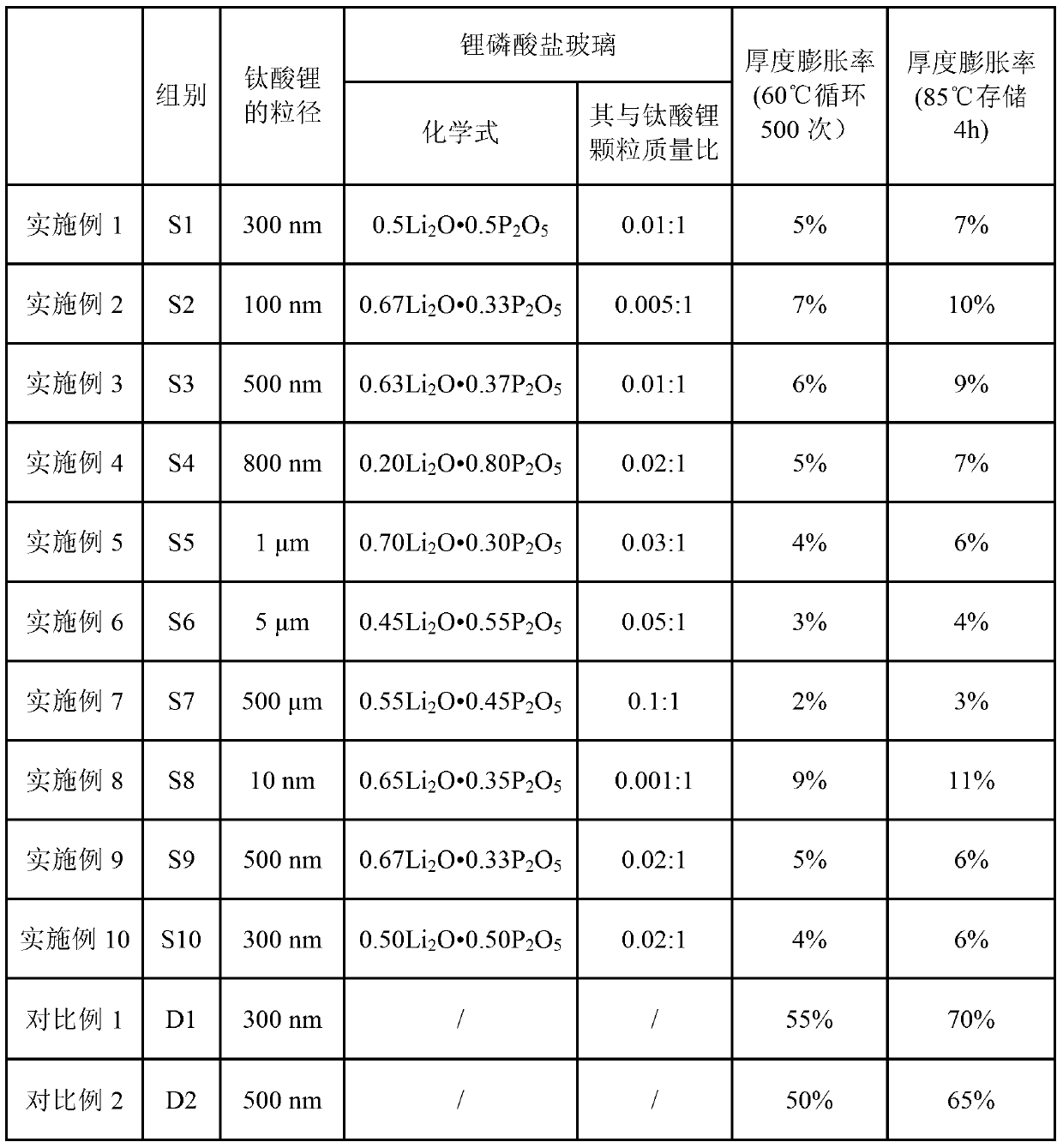

Lithium titanate composite material and preparation method and application thereof

ActiveCN103280568AAvoid direct contactInhibitory responseCell electrodesHigh temperature storageSlurry

The invention provides a lithium titanate composite material and a preparation method and application thereof. The lithium titanate composite material comprises lithium titanate particles and lithium phosphate glass coated on the surface of the lithium titanate particles. The preparation method comprises the following steps of: uniformly mixing the lithium titanate particles and the mixture of a lithium source and a phosphorus source in a liquid system solvent to obtain uniformly-mixed liquid; performing ball milling on the uniformly-mixed liquid to form slurry; taking out the slurry and drying to obtain the precursor powder of the composite material; calcining the precursor powder of the composite material; and cooling and breaking to obtain the lithium titanate composite material of which the lithium phosphate glass is coated by the lithium titanate on the surface. The lithium titanate composite material is used as an active substance of a lithium ion battery or an electrode material of a capacitor. The lithium titanate composite material can suppress expansion of a lithium ion battery when applied to the lithium ion battery, improves the high-temperature storage and cycle performance of the lithium ion battery, increases the diffusion coefficient of lithium ions in the active substance, and is favorable for improving the rate capability of lithium titanate.

Owner:NINGDE AMPEREX TECH

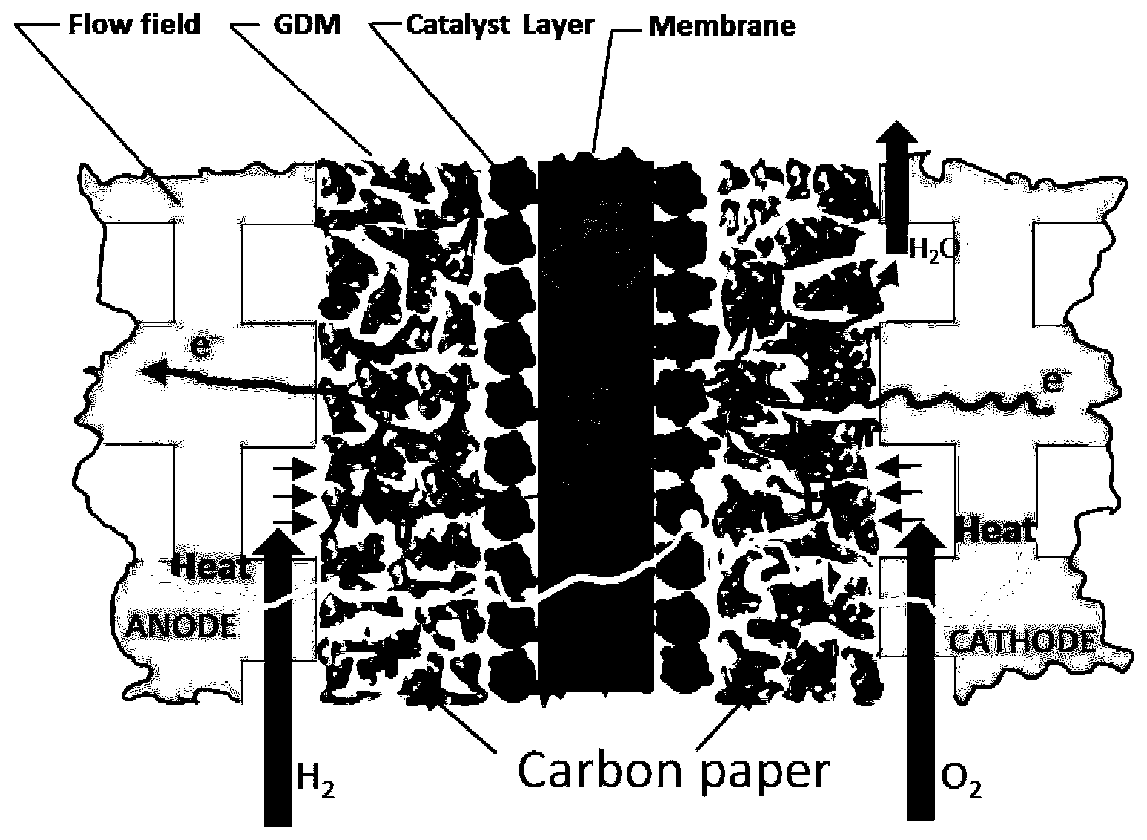

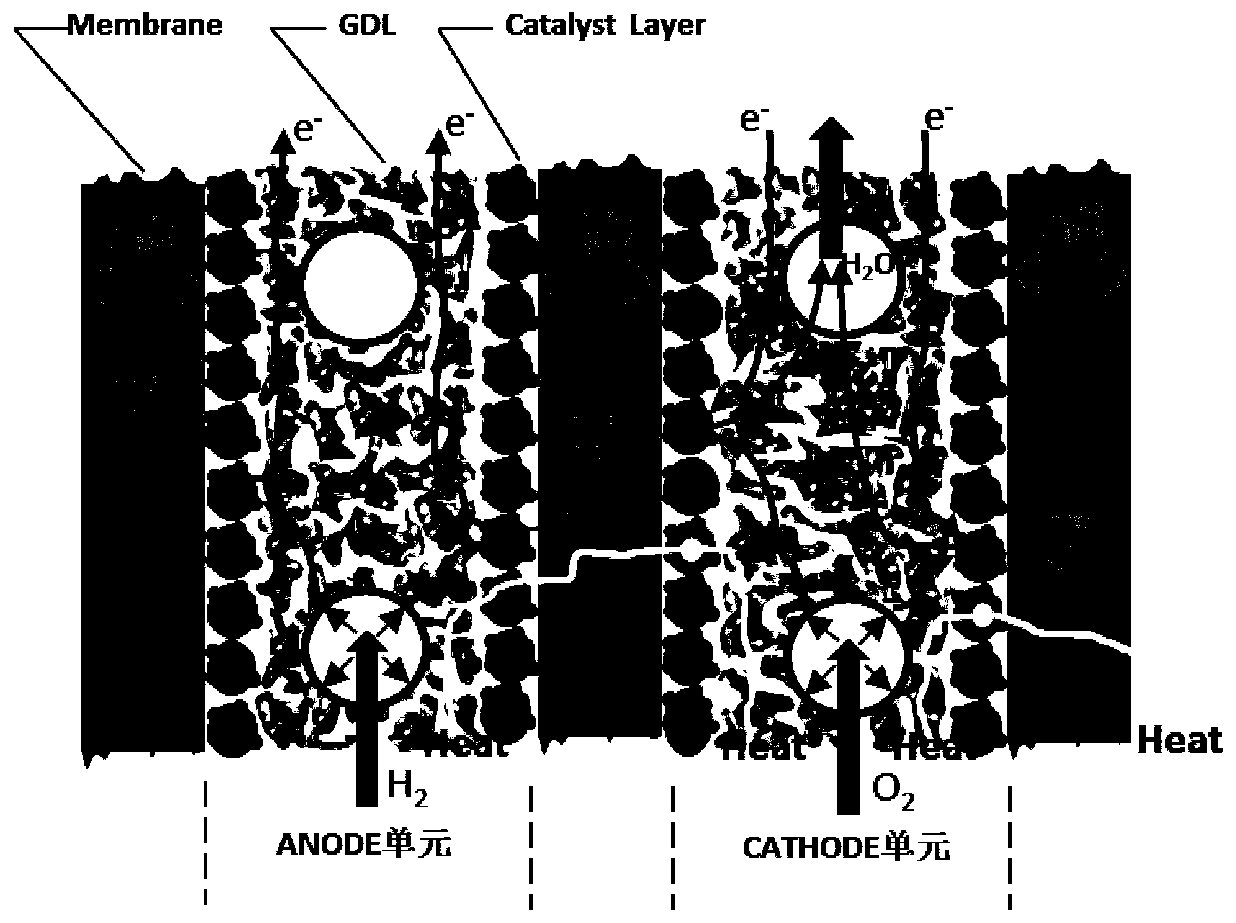

High-flux carbon paper for fuel cell and preparation method of high-flux carbon paper

PendingCN113135000ASimple designIncreased Diffusion ChannelLamination ancillary operationsLaminationPaper sheetSurface resistivity

The invention discloses high-flux carbon paper for a fuel cell, which is characterized in that the thickness of the carbon fiber paper is 0.12-0.2 mm, the volume density is 0.25-0.40 g / cm3, the porosity is 78-85%, and the air permeability is greater than or equal to 2200ml*mm / (cm2.hr*mmAq); the surface resistivity is less than or equal to 100m [omega]cm; and the heat conductivity is greater than or equal to 1.5 W / (m.K). The invention also discloses a preparation scheme of the carbon fiber paper, wherein the carbon fiber paper is formed by superposing two to six layers of carbon fiber prepreg paper sheets layer by layer, continuously and integrally perforating and then carrying out high-temperature treatment. According to the invention, on the basis of the dry-method carbon paper, the regular perforation design is combined, so that a water vapor rapid channel in the thickness direction of the carbon paper is formed, a high-flux airflow channel is facilitated, and meanwhile, the transverse diffusion capability of irregular pore channels to water vapor is reserved.

Owner:SHANGHAI JAZZ NEW MATERIAL TECH CO LTD

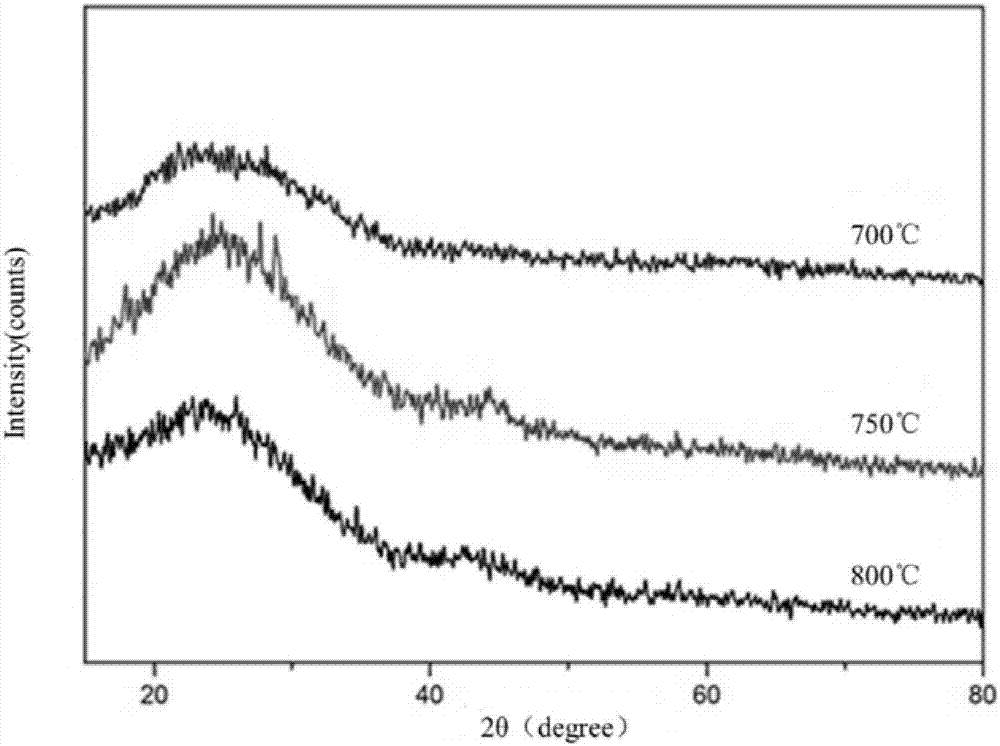

Preparation method of sodium ion battery high capacity graphite negative electrode material

ActiveCN105762359AHigh specific capacityExcellent rate performanceCell electrodesSecondary cellsWater bathsSodium-ion battery

The invention discloses a preparation method of a sodium ion battery high capacity graphite negative electrode material. The method comprises the steps of: (1) adding a certain amount of graphite slowly into sulfuric acid with a concentration of 20-80%, then adding an oxidizing agent and a titanium source in order, carrying out stirring reaction in water bath at a constant temperature of 20-70DEG C for 0.5-4h, then performing washing to a ph of 6.0-7.0, conducting filtering, and then carrying out drying at 80-100DEG C to obtain titanium inserted graphite; and (2) placing the titanium inserted graphite obtained in step (1) in an atmosphere furnace at 500-1000DEG C to carry out high-temperature treatment for 4-10h, thus obtaining the sodium-ion battery high capacity graphite negative electrode material. The method provided by the invention inserts the titanium source to the graphite interlayer to enlarge the interlayer spacing of graphite so as to reserve the contraction and expansion space for intercalation and deintercalation of sodium ions, and at the same time broadens the diffusion channel of sodium ions, thus being conducive to enhancing the specific capacity of graphite and improving its rate performance. At the same time, the titanium oxide generated by the titanium source inserted to the interlayer can greatly increase the embedding capacity of the sodium ions, thereby further increasing the specific capacity.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Preparation method of novel energy battery composite cobalt carbonate negative electrode material

InactiveCN110212179AGood dispersionTemporary isolationMaterial nanotechnologyNegative electrodesNew energyOil phase

The invention discloses a preparation method of a novel energy battery composite cobalt carbonate negative electrode material, and belongs to the technical field of new energy materials. The preparation method comprises the following steps that firstly, graphene oxide is dispersed into water, and sodium polystyrenesulfonate is added to prepare a pretreated graphene oxide dispersion liquid, then stirring and mixing are carried out on the mixture with a cobalt salt solution and a chitosan dispersion liquid to prepare a water phase dispersion liquid; then, oleic acid, silicate ester and absoluteethyl alcohol are used as raw materials to prepare an oil phase dispersion liquid; then in a constant temperature stirring state, a water phase dispersion liquid is dropwise added into the oil phase dispersion liquid slowly, and a precipitant is dropwise added after the water phase dispersion liquid is dropwise added; continuously stirring and reacting are performed at a constant temperature afterthe dropwise addition of the precipitant is finished, and then centrifugal separation, washing and drying are carried out to obtain a precursor; the precursor is slowly heated to 280-300 DEG C in aninert gas protective state, a heat preservation reaction is performed and then cooling is carried out to obtain a pyrolysis material; and the obtained pyrolysis material is soaked in an alkali liquor,and then the pyrolysis material is washed to be neutral, and dried to obtain the composite cobalt carbonate cathode material of the new energy battery.

Owner:易尧芳

Method for preparing anode material lithium vanadium phosphate by adopting quenching

InactiveCN102386407AImprove conductivityImproved magnification performanceCell electrodesHigh energyBall mill

The invention relates to a method for preparing anode material lithium vanadium phosphate by adopting quenching, which comprises the following steps: mixing a lithium source compound, a vanadium source compound, a phosphorus source compound and a fluoride at a molar ratio of lithium : vanadium : phosphorus : fluorine = (1-1.05):1:1:1, adding a carbon source at a molar ratio of the carbon source : the vanadium source compound = 1:1-10:1, performing high-energy ball-milling for uniform mixing to obtain a precursor mixture, drying the precursor mixture, placing the dried precursor mixture in a non-oxidizing atmosphere and heating to 500-1000 DEG C, performing constant-temperature calcination for 0.5-48 h, rapidly transferring the high-temperature powder to a low-temperature medium (-209-40 DEG C), and allowing rapid quenching for a period from 1 min to 1 h to obtain lithium vanadium phosphate powder. The lithium vanadium phosphate powder prepared by using the quenching method provided by the invention has nano size, uniform particle size distribution, and excellent large-multiplying factor charging / discharging performance.

Owner:CENT SOUTH UNIV

Nitrogen-doped carbon nanotube/rare earth metal ion-doped lithium iron phosphate composite cathode material and preparation method thereof

PendingCN112607725ALarge specific surface areaImprove hydrophilicityCarbon compoundsCell electrodesElectrical batteryLithium hydroxide

The invention discloses a nitrogen-doped carbon nanotube / rare earth metal ion-doped lithium iron phosphate composite positive electrode material and a preparation method thereof, and is applied to the field of lithium ion batteries. The preparation method of the material comprises the following steps: mixing hydrazine hydrate and carbon nanotubes, and then carrying out reflux, suction filtration and freeze drying to prepare nitrogen-doped carbon nanotubes; preparing rare earth metal ion doped lithium iron phosphate by taking lithium hydroxide, ferric phosphate, oxalic acid, glucose and rare earth metal oxide as raw materials; and finally, adding the nitrogen-doped carbon nanotube and the rare earth metal ion-doped lithium iron phosphate into dispersion liquid for dispersion, and performing ball milling to obtain a final product. Compared with the traditional lithium iron phosphate, the nitrogen-doped carbon nanotube / rare earth metal ion-doped lithium iron phosphate composite positive electrode material prepared by the method has excellent rate charge-discharge performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

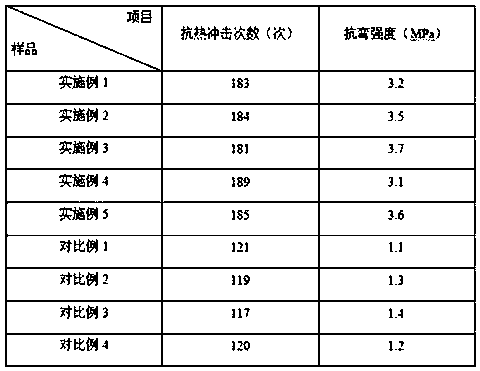

Novel composite ceramic with high thermal shock resistance and processing process thereof

InactiveCN109732088AImprove performanceSolve the problem of prone to agglomeration and uneven distributionComposite ceramicCrystal structure

The invention discloses a novel composite ceramic with high thermal shock resistance and a processing process thereof. The composite ceramic is prepared from the following components of magnesium powder, silicon powder, carbon powder, aluminosilicate mineral and a binder. The processing process includes the following steps of preparing of a first mixture; preparing of a pre-sintered material; preparing of a perform body; preparing of a biscuit; and sintering of the biscuit by discharge plasma to obtain the novel composite ceramic. According to the novel composite ceramic, the atomic level mixing between the magnesium powder and the aluminosilicate mineral is achieved, a highly disordered crystal structure is formed, and the carbon powder and the silicon powder generate silicon carbide whiskers in situ which are uniformly distributed among the highly disordered crystal structure formed by the magnesium powder and the aluminosilicate mineral, so that the problems of agglomeration and uneven distribution caused by directly adding silicon carbide whiskers are solved, and the performance of the composite ceramic is greatly improved. According the experimental result, the novel compositeceramic has good thermal shock resistance and bending resistance.

Owner:徐菡

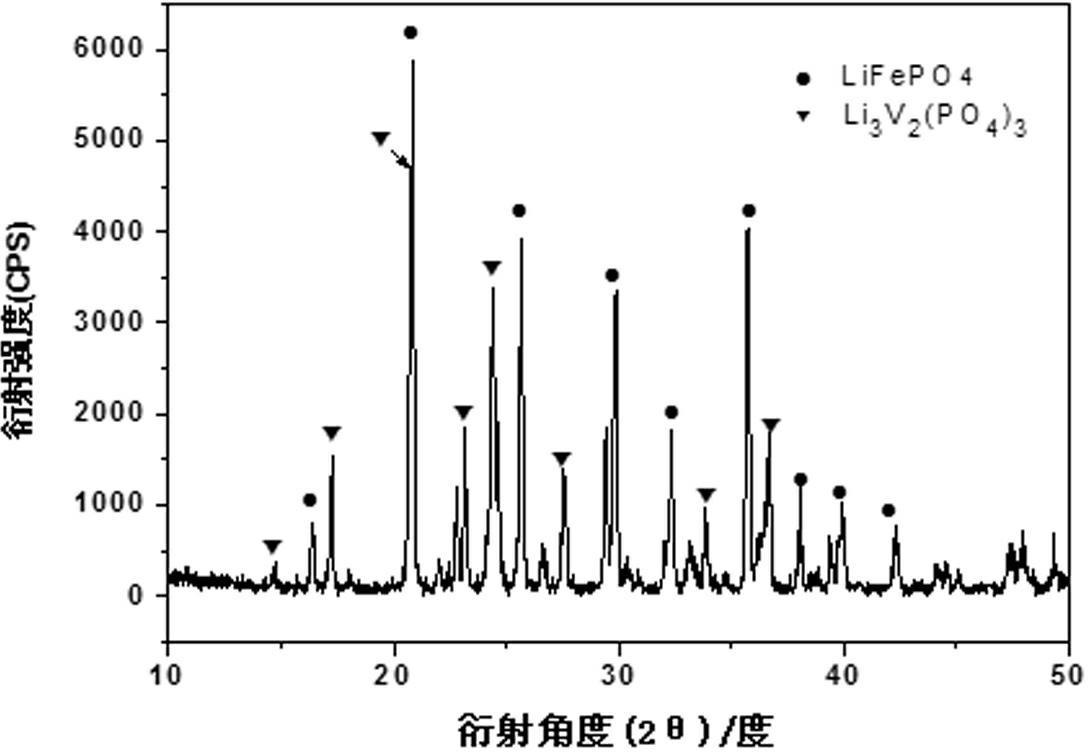

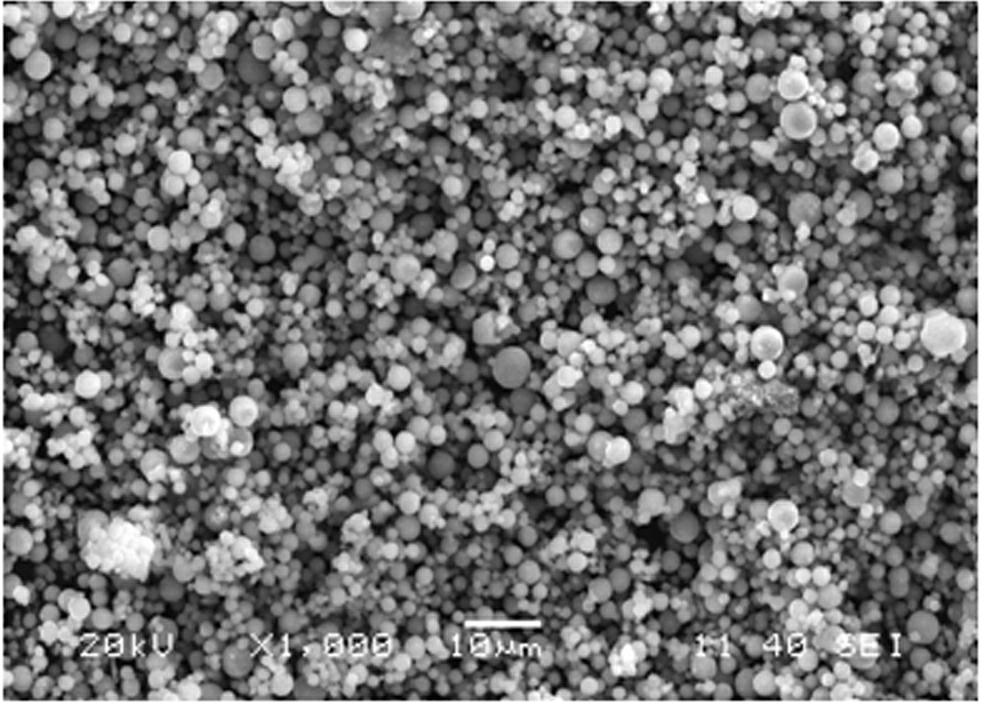

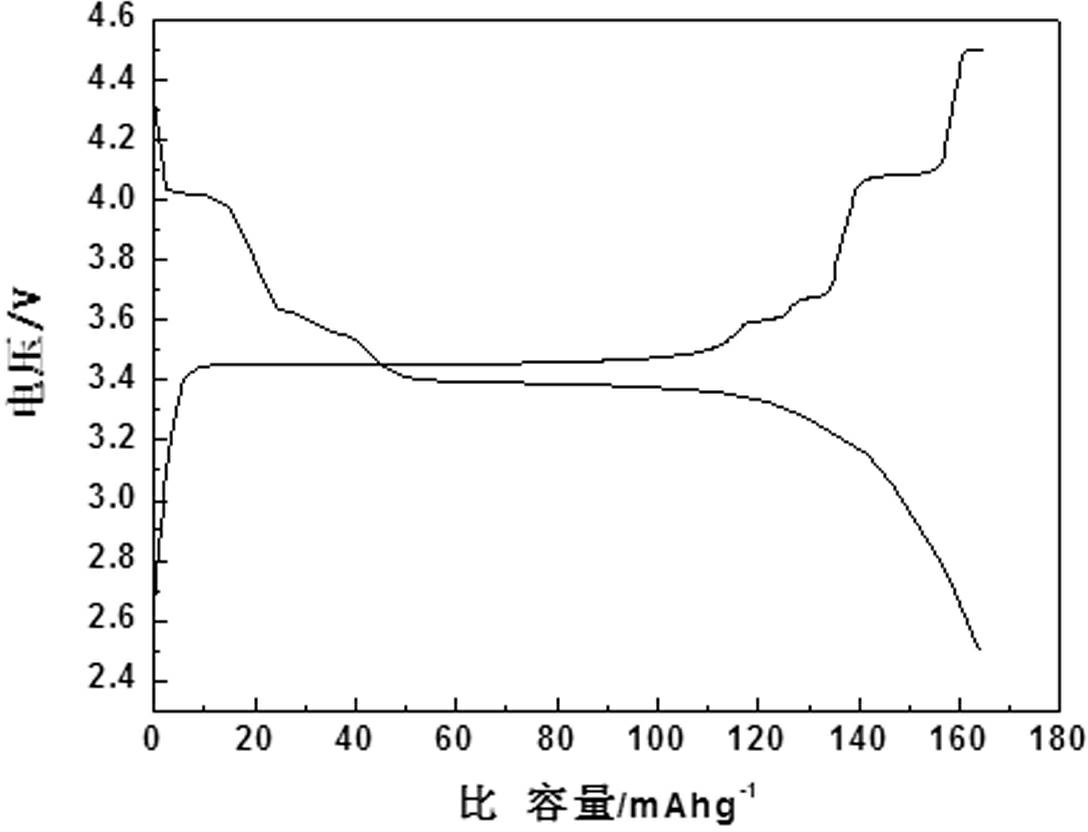

Method for preparing lithium iron phosphate-lithium vanadium phosphate by quenching method

A method for preparing lithium iron phosphate-lithium vanadium phosphate by a quenching method. The method comprises the following steps: well mixing a vanadium source compound, an iron source compound, a lithium source compound and a phosphor source compound according to a stoichiometric ratio of the composite material, adding a carbon source, stirring and mixing, uniformly distributing the mixture in a solvent, performing spray drying to prepare a spherical precursor mixture, calcining the precursor mixture at 500-900 DEG C in nonoxidative atmosphere for 2-48 hours, finally transferring the high-temperature powder to a low-temperature medium with a temperature of -209 DEG C-35 DEG C, quenching for 1 min-2 h so as to prepare the lithium iron phosphate-lithium vanadium phosphate composite material. The invention can prepare a composite cathode material with a high tap density and high magnification performance, and greatly improves the energy density and magnification performance of the material.

Owner:CENT SOUTH UNIV +1

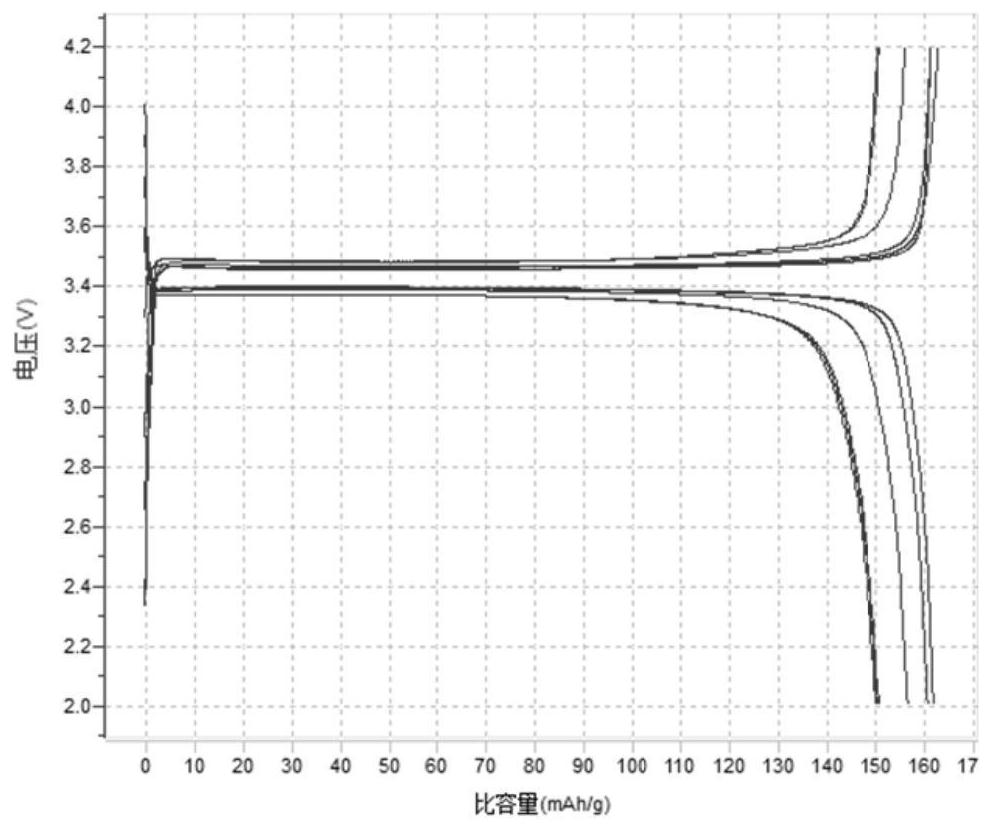

Preparation method of aluminum iron-doped lithium titanate negative electrode material

InactiveCN107799734AImprove ionic conductivityIncreased Diffusion ChannelCell electrodesSecondary cellsCarbon coatingDiffusion resistance

The invention discloses a preparation method of an aluminum iron-doped lithium titanate negative electrode material. According to the method, Al<3+> and Fe<3+> are doped into a lattice structure of lithium titanate according to a certain proportion through a hydrothermal method; the novel negative electrode material synthesized by the method is still of a spinel structure, so that the lithium iondiffusion channel is expanded and lithium ion diffusion resistance is lowered, thereby improving ionic conductivity of the material; and by taking a hard carbon component as a carbon coating agent ofthe negative electrode material, the negative electrode material is high in specific capacity and excellent in cycle performance and rate performance.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

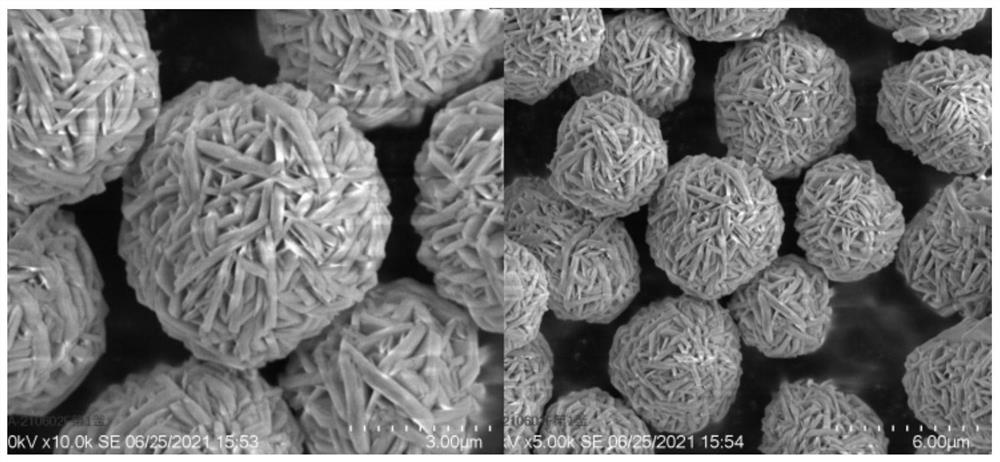

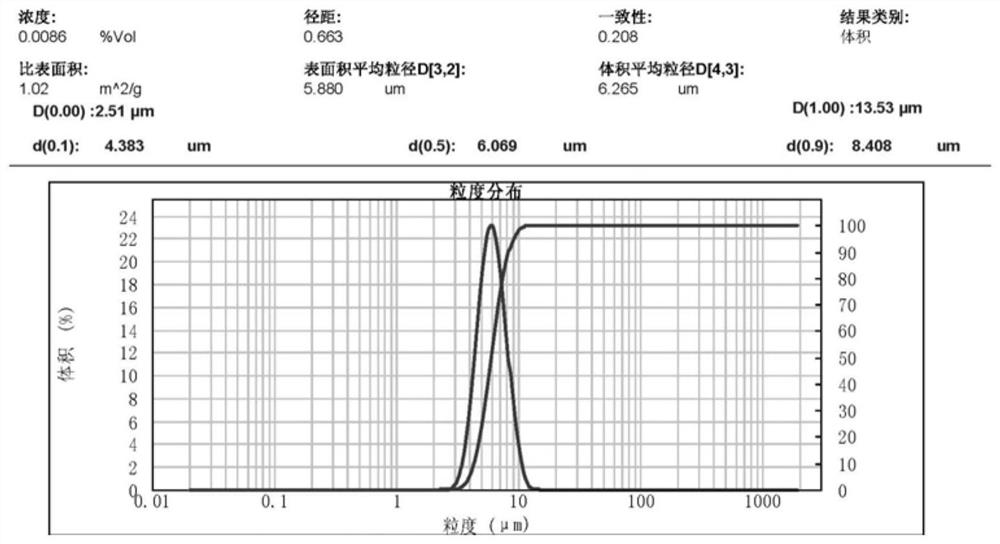

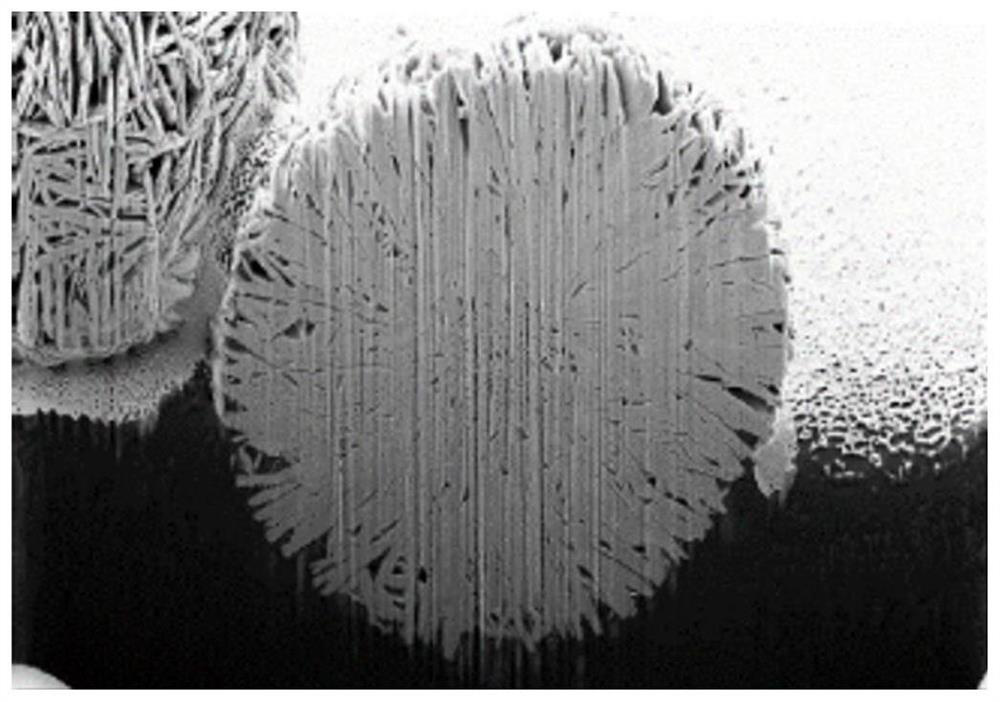

Ternary precursor and preparation method and application thereof

PendingCN114084914AExcellent cycle characteristicsAvoid crackingSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention relates to the technical field of lithium ion batteries, in particular to a ternary precursor and a preparation method and an application thereof. The ternary precursor comprises a compact inner core and a loose radial shell which extends and grows from the inner core. As the obtained ternary precursor shell is loose and radial, stress can be released through the radial shell in the use process, so that cracks caused by particle breakage during circulation are avoided, the circulation characteristic of the ternary precursor is further improved, the loose shell can increase diffusion channels of lithium ions, When the material is used for preparing the positive electrode material of the lithium ion battery, the first charge-discharge performance and the cycle performance of the lithium ion battery can be remarkably improved.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

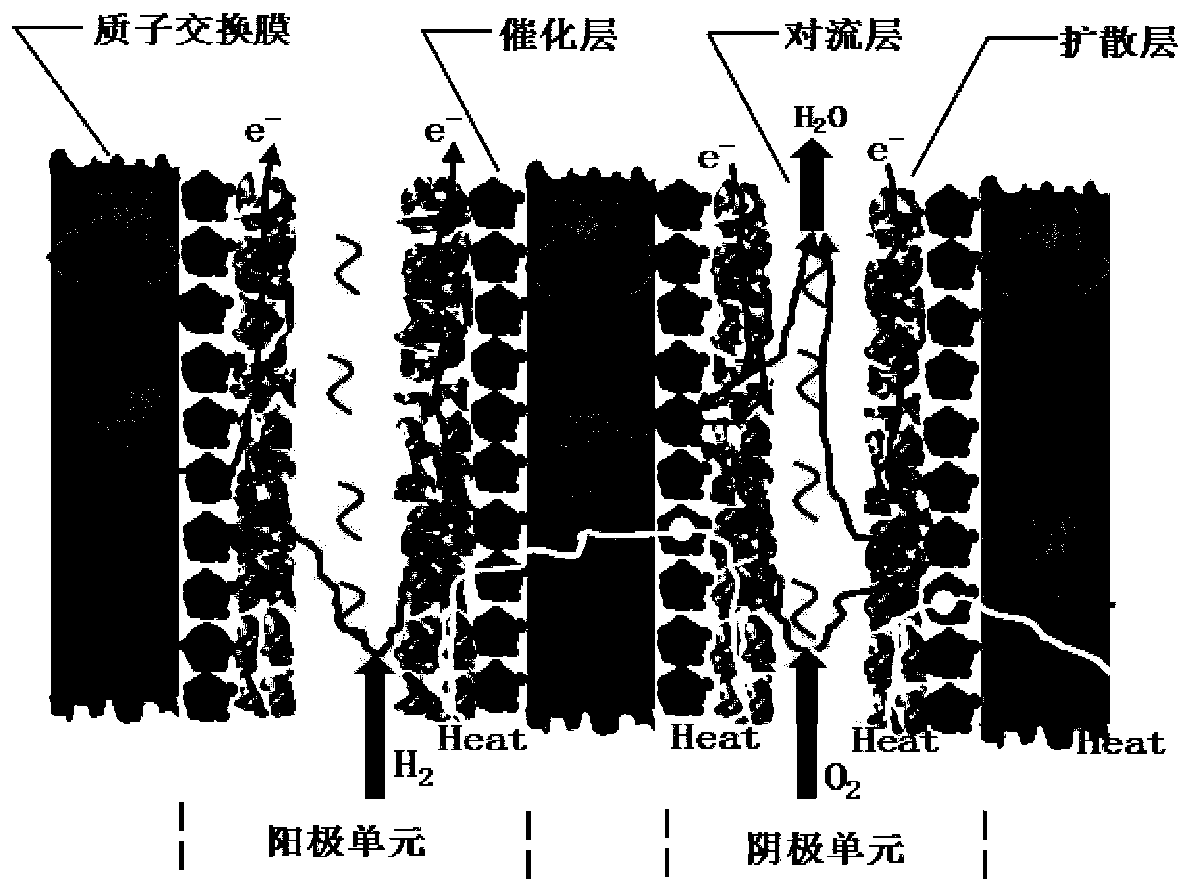

Novel proton exchange membrane fuel cell

ActiveCN109768298AImprove mass transfer efficiency and assembly performanceAvoid stress concentrationFuel cellsElectricityEngineering

The invention discloses a novel proton exchange membrane fuel cell. According to the proton exchange membrane fuel cell, a passage through which water, electricity and gas enter or exit from the cellis realized by designing a flow channel or a special convection zone in a diffusion layer, the phenomenon of 'bipolar plate removal' or 'bipolar plate flow channel removal' can be realized, the contact transmission resistance between the bipolar plates and the diffusion layer in the cell can be obviously reduced, and thus the PEMFC with high efficiency, low cost and long service life can be obtained.

Owner:CENT SOUTH UNIV

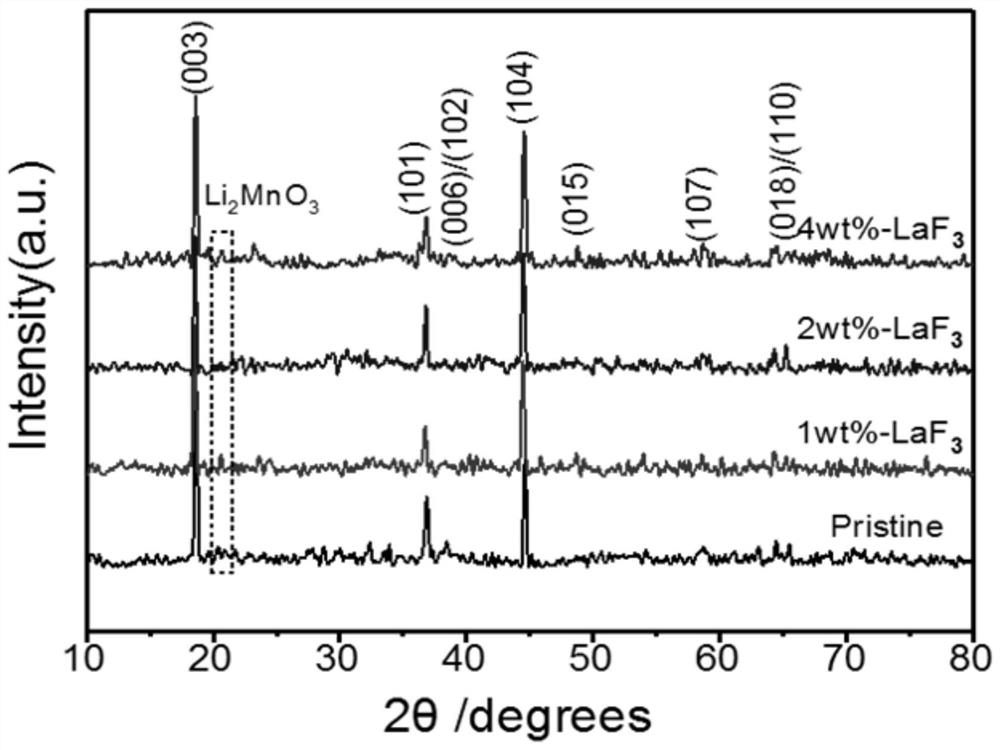

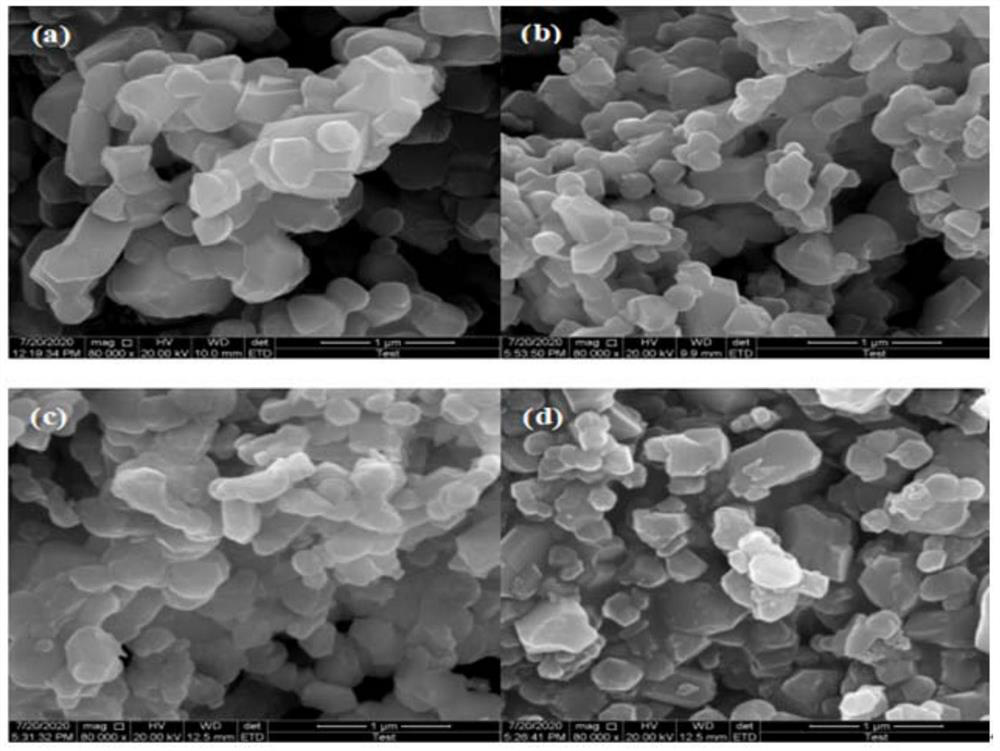

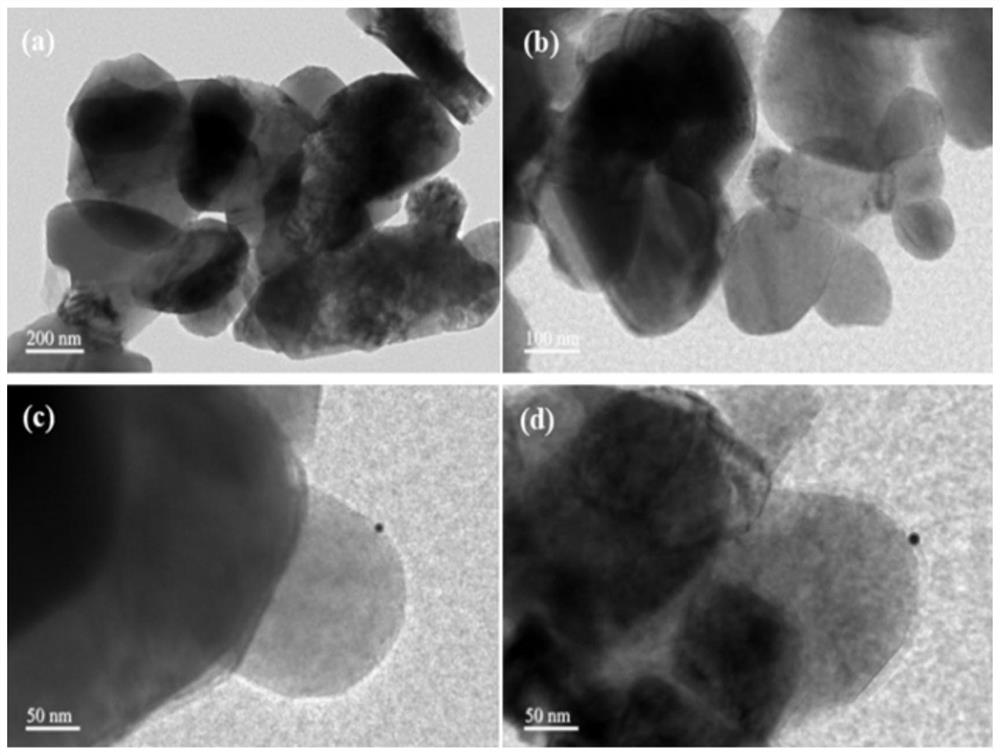

Preparation method of ultrahigh-capacity ternary lithium-rich manganese-based composite electrode material

InactiveCN112635725AIncreased Diffusion ChannelEasy to embedSecondary cellsPositive electrodesComposite electrodeManganese

The invention discloses a preparation method of an ultrahigh-capacity ternary lithium-rich manganese-based composite electrode material. The method comprises the following steps: by taking Li(CH3COO). 2H2O, Ni(CH3COO) 2.4 H2O, Co(CH3COO) 2.4 H2O and Mn (CH3COO)2.4 H2O as raw materials, citric acid as a chelating agent, water as a solvent and ammonia water as a pH regulator, preparing a Li1.2Mn0.54Co0.13Ni0.13O2 cathode material by a sol-gel method; and performing chemical deposition and calcination through a wet coating method to obtain Li1.2Mn0.54Co0.13Ni0.13O2@LaF3 composite electrode material. the method is simple, wide in raw material source and beneficial to large-scale production; the prepared Li1.2Mn0.54Co0.13Ni0.13O2@LaF3Li composite electrode material has the advantages of ultrahigh capacity, good rate capability, good cycling stability and the like.

Owner:NANJING UNIV OF SCI & TECH

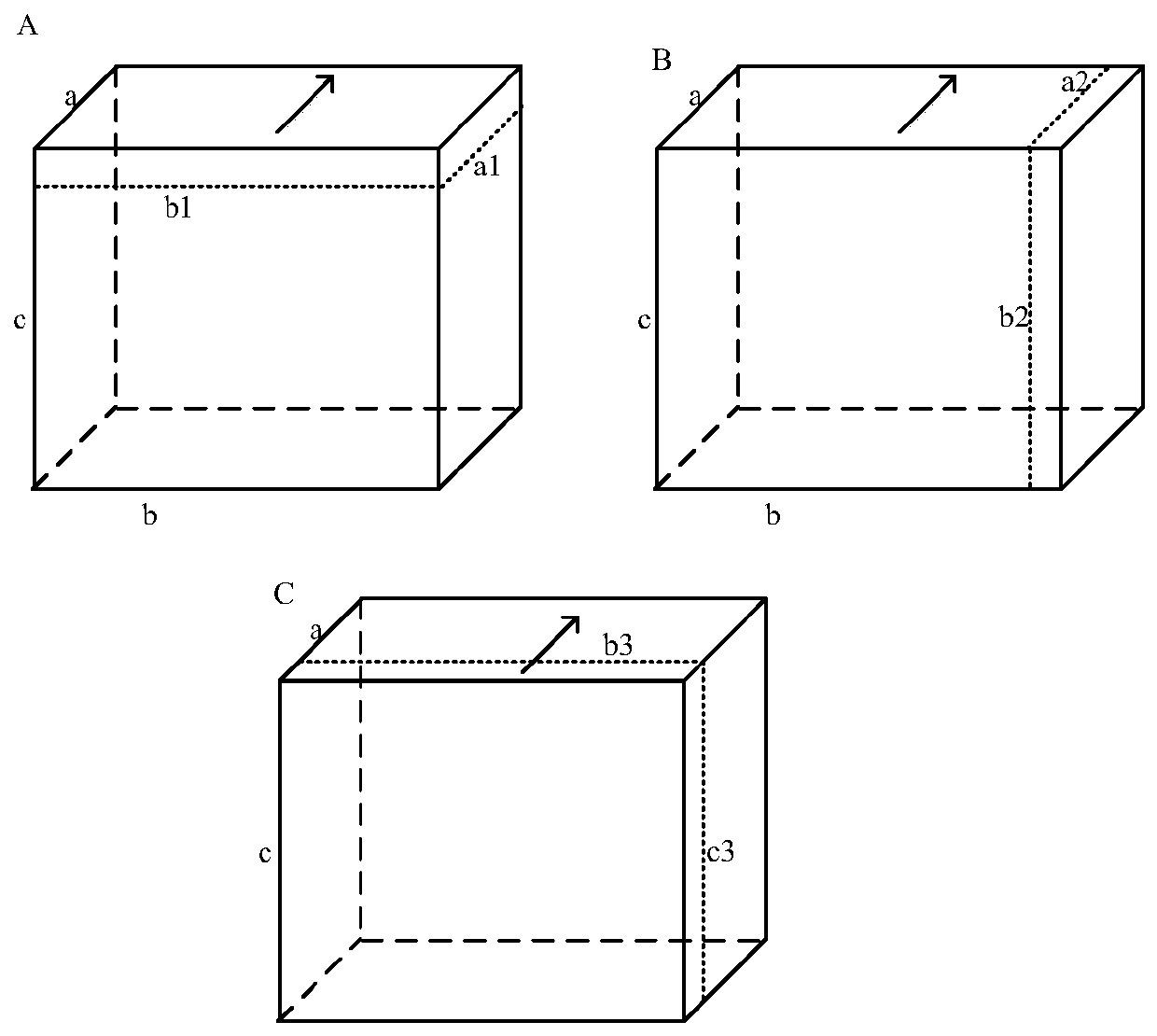

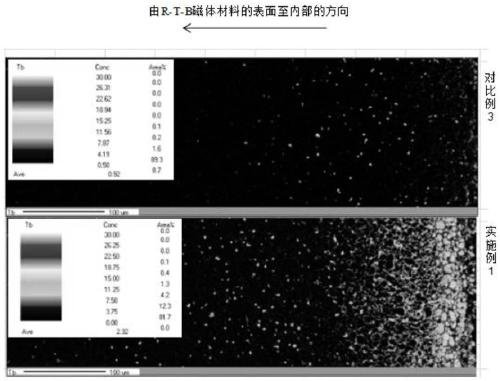

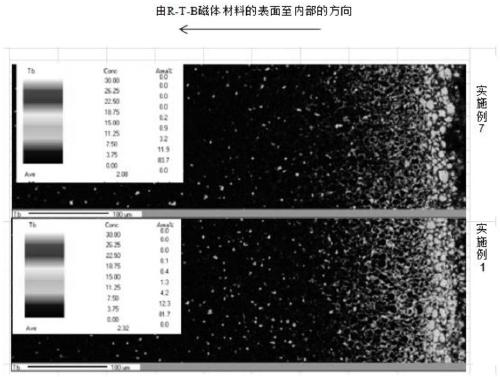

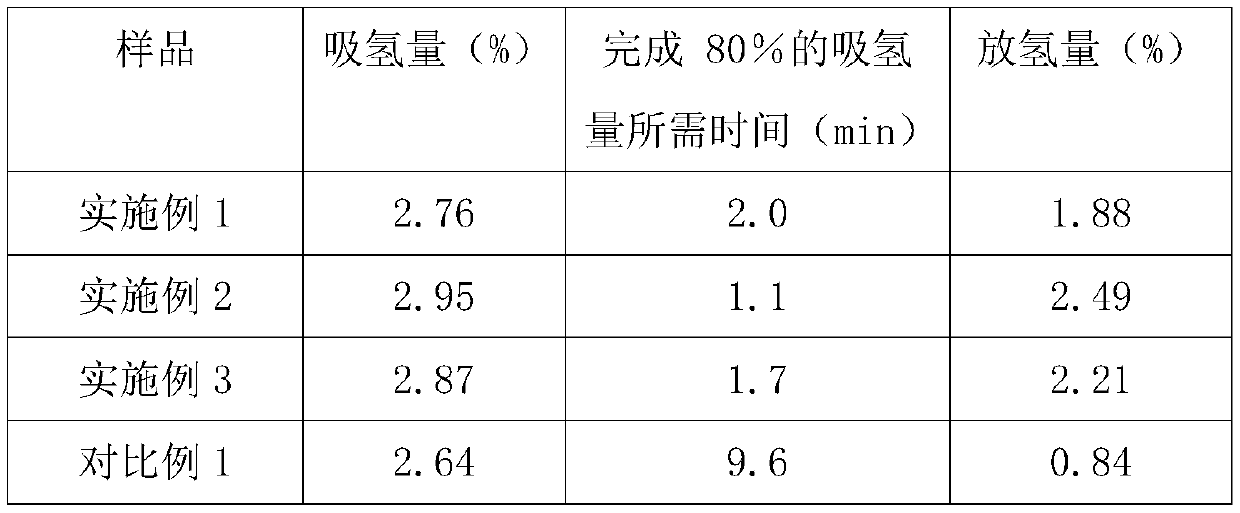

R-T-B magnet material, preparation method and application thereof

ActiveCN111210987AIncrease the amount of diffusionIncreased Diffusion DepthInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementTemperature resistance

The invention discloses an R-T-B magnet material, a preparation method and an application thereof. The preparation method of the R-T-B magnet material comprises the following steps: performing hydrogen activation treatment on a sintered body of the R-T-B magnet material in a gas atmosphere; and then performing grain boundary diffusion, wherein the gas atmosphere includes a mixed gas of an inert gas and hydrogen; a temperature of the hydrogen activation treatment is 100-300 DEG C, and time is more than 10 minutes; a ratio of amass volume concentration of the hydrogen to the mass volume concentration of the sintered body is 0.01-0.1%; and the volume ratio of the hydrogen to the inert gas is 0.1-5%. The R-T-B magnet material disclosed by the invention is relatively good in high-temperature resistance, demagnetization resistance and coercive force; rare earth elements or a large amount of cobalt elements are not added during smelting so that cost is relatively low; grain refinement can beavoided, and production difficulty is low; and the R-T-B magnet material with a length within 1 mm in anorientation direction can be obtained, and the magnet material is good in magnetic performance.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Magnesium-based hydrogen storage alloy and preparation method thereof

ActiveCN109898002AGood dispersionImprove hydrogen absorption and desorption performanceElectronHydrogen absorption

The invention discloses a magnesium-based hydrogen storage alloy and a preparation method thereof. The magnesium-based hydrogen storage alloy is prepared from raw materials of Mg2Ni alloy powder and nickel-plated carbon nano-tubes, wherein the weight ratio of the Mg2Ni alloy powder to the nickel-plated carbon nano-tubes is 100:(0.5-1). The preparation method includes the steps that the Mg2Ni alloypowder and the nickel-plated carbon nano-tubes are subjected to high-current electron beam pulse surface radiation pretreatment, then mechanical alloying is carried out through planet ball-milling, finally, high-current electron beam pulse surface radiation treatment is carried out, and the magnesium-based hydrogen storage alloy is obtained. The poor hydrogen heat absorption and release and dynamics performance of the magnesium-based hydrogen storage alloy is effectively improved, the low-temperature hydrogen absorption and release performance of the magnesium-based hydrogen storage alloy isgreatly improved, the hydrogen absorption and release rate of the magnesium-based hydrogen storage alloy is effectively increased, and thus the magnesium-based hydrogen storage alloy has higher practical application value.

Owner:三桥惠(佛山)新材料有限公司

Anode material for lithium-ion battery and preparation method

ActiveCN101931077BImprove lithium intercalation spaceHigh reversible specific capacityCell electrodesCarbon compositesGraphite

The invention provides an anode material for a lithium-ion battery and a preparation method thereof. The anode material is characterized in that the material is a composite of graphite and mesoporous carbons; the mesoporous carbons account for 1-60% of the composite by mass; the graphitization degree of the graphite ranges from 78% to 88%; the pore diameters of the mesoporous carbons are 2-50nm; and the through porosity is not lower than 85%. The carbon composite anode material is prepared by chemically compounding the graphite with low graphitization degree and the mesoporous carbons with high through porosity. The anode material is suitable for low-temperature power lithium-ion batteries, has mild preparation conditions and is beneficial to industrialization.

Owner:HUNAN SHINZOOM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com