Ternary precursor and preparation method and application thereof

A precursor and directional growth technology, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve the problems of unfavorable product property stability, microcracks and fragmentation, and complicated preparation process, so as to improve the first charge and discharge performance and Cycle performance, less cracks, and improved cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

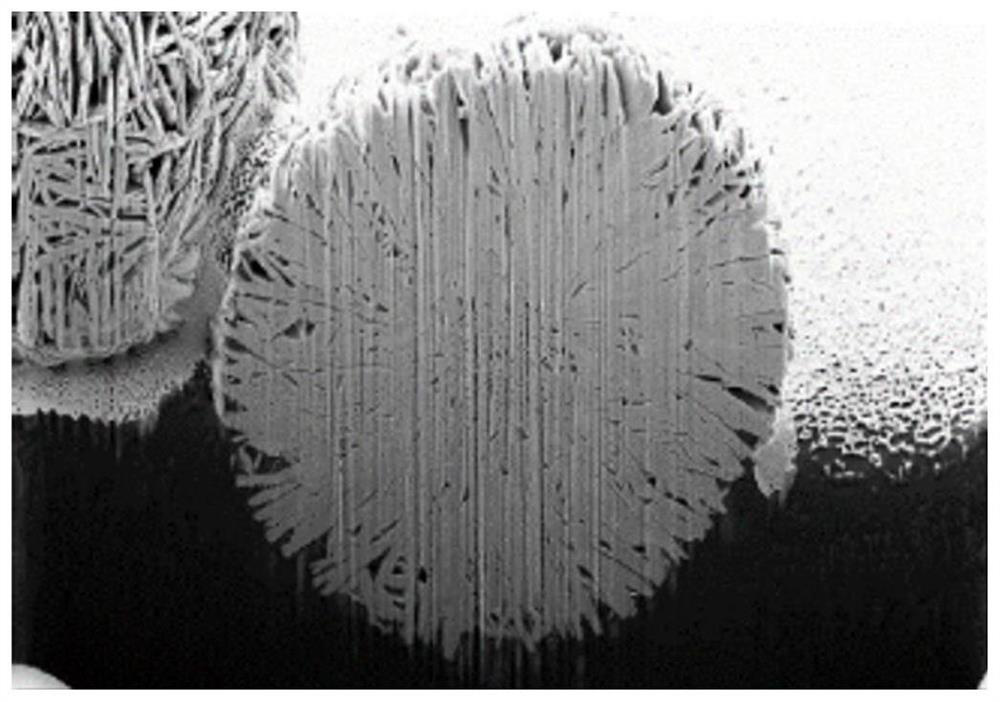

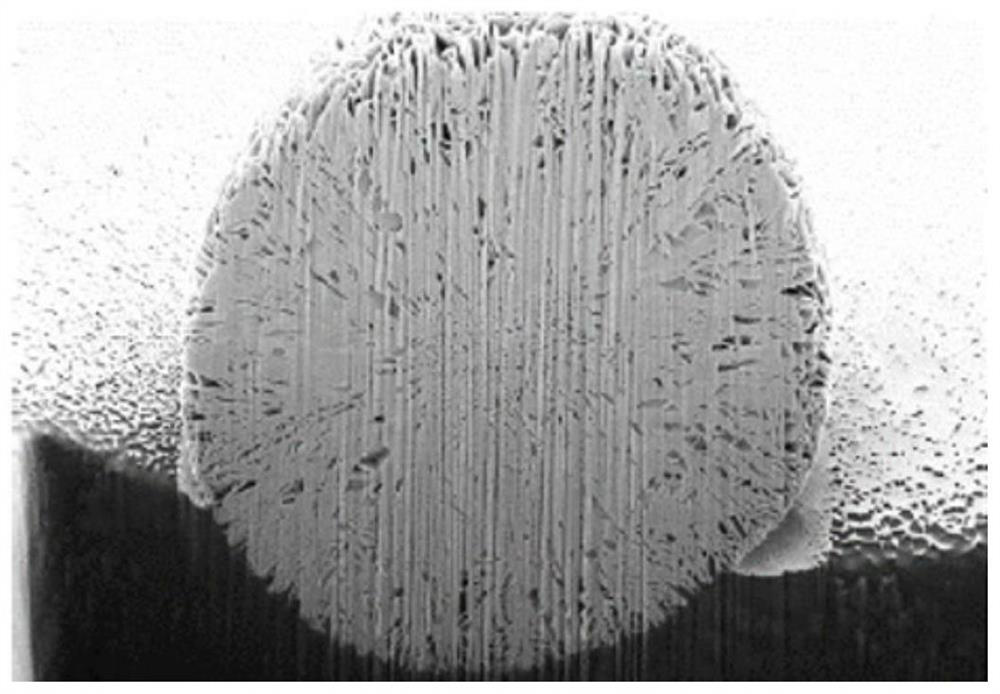

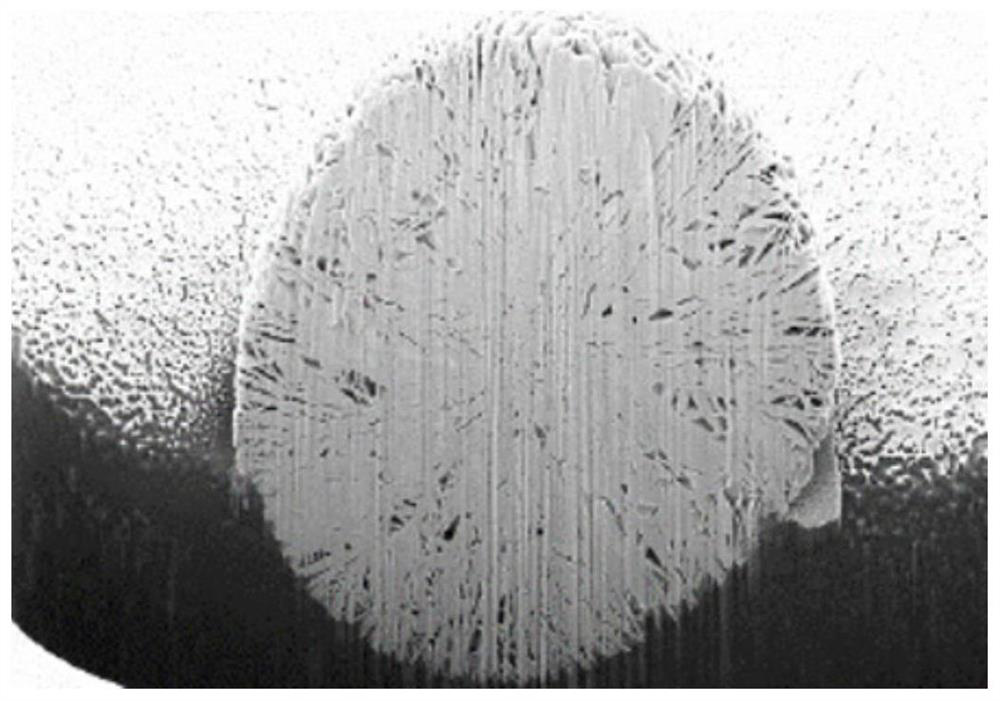

[0040] The second aspect of the embodiment of the present application provides a preparation method for directional growth of a ternary precursor, including the following steps:

[0041] S01. Under inert atmosphere conditions, feed nickel, cobalt, manganese or nickel, cobalt, aluminum soluble salts, the first complexing agent, the first precipitating agent and the bottom liquid to prepare the first mixed solution and carry out the first precipitation reaction, When the median particle size of the first precipitate in the first mixed solution reaches the first target particle size, stop feeding, and perform solid-liquid separation after standing to obtain a ternary precursor crystal nucleus;

[0042] S02. Pure water, the second complexing agent, the second precipitating agent and the ternary precursor crystal nucleus are formulated into the second mixed solution, and the pH and ammonium root concentration conditions of the second mixed solution are adjusted, and then nickel, cob...

Embodiment 1

[0084] A preparation method for directional growth of a ternary precursor, comprising the steps of:

[0085] (1) Provide nickel, cobalt, manganese soluble salt solution, complexing agent solution, precipitant solution and bottom liquid; wherein, the total concentration of nickel, cobalt, manganese soluble salt solution is 1.5mol / L, nickel, cobalt, manganese three The molar ratio of the elements is 96:2:2; the complexing agent solution is selected from the ammonia solution with a concentration of 7mol / L, the precipitant solution is selected from the sodium hydroxide solution with a concentration of 12mol / L, and the bottom liquid is selected from the ammonia solution containing ammonium ions. alkaline aqueous solution;

[0086] (2) Add a bottom solution with a certain pH, temperature, and ammonium root concentration to the reactor, keep feeding nitrogen, control a certain speed, and then add the metal salt solution, precipitant, and complexing agent to the reactor in parallel to...

Embodiment 2

[0091] A preparation method for directional growth of a ternary precursor, comprising the steps of:

[0092] (1) Provide nickel, cobalt, aluminum soluble salt solution, complexing agent solution, precipitant solution and bottom liquid; wherein, the total concentration of nickel, cobalt, aluminum soluble salt solution is 1.5mol / L, nickel, cobalt three elements molar The ratio is 90:10; the complexing agent solution is selected from the ammonia solution with a concentration of 7mol / L, the precipitant solution is selected from the sodium hydroxide solution with a concentration of 12mol / L, and the bottom liquid is selected from the alkaline aqueous solution containing ammonium ions;

[0093] (2) Add a bottom solution with a certain pH, temperature, and ammonium root concentration to the reactor, keep feeding nitrogen, control a certain speed, and then add the metal salt solution, precipitant, and complexing agent to the reactor in parallel to control and stabilize the pH , ammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com