High-voltage nickel-cobalt-manganese ternary precursor and preparation method thereof

A nickel-cobalt-manganese, high-voltage technology, applied in high-voltage nickel-cobalt-manganese ternary precursor and its preparation, lithium-ion battery cathode material, high-voltage lithium-ion battery nickel-cobalt-manganese ternary cathode material precursor and its preparation , In the field of lithium-ion batteries, it can solve problems such as powdering of agglomerated particles, structural collapse, and poor structural stability, and achieve the effects of reducing particle agglomeration and adhesion, low requirements for production equipment, and improving high-voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

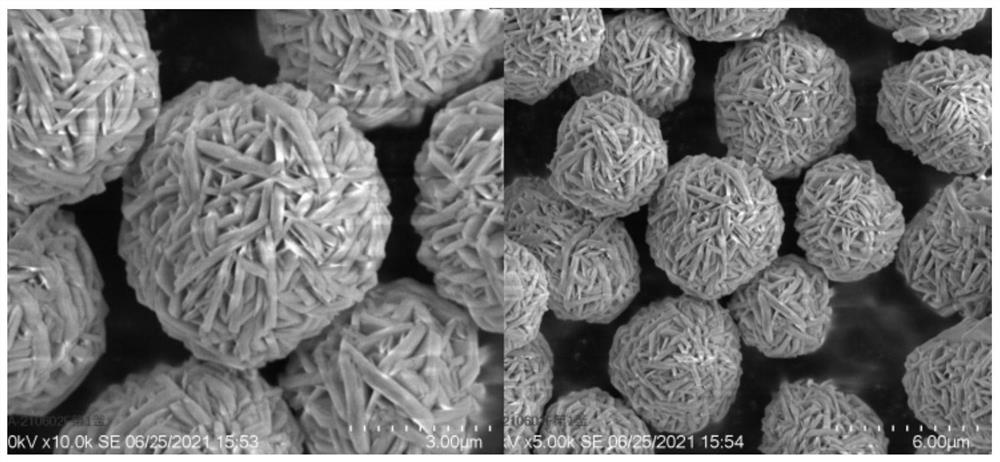

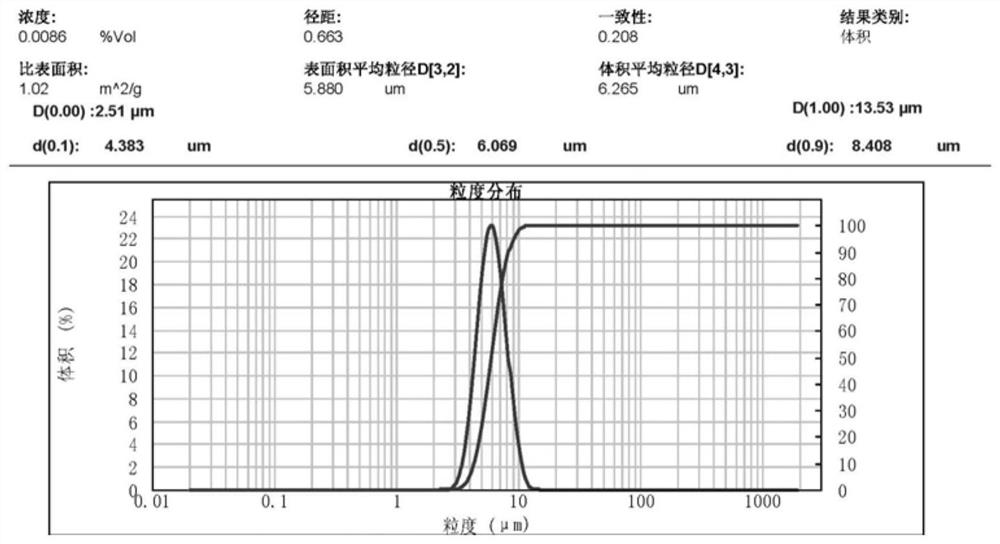

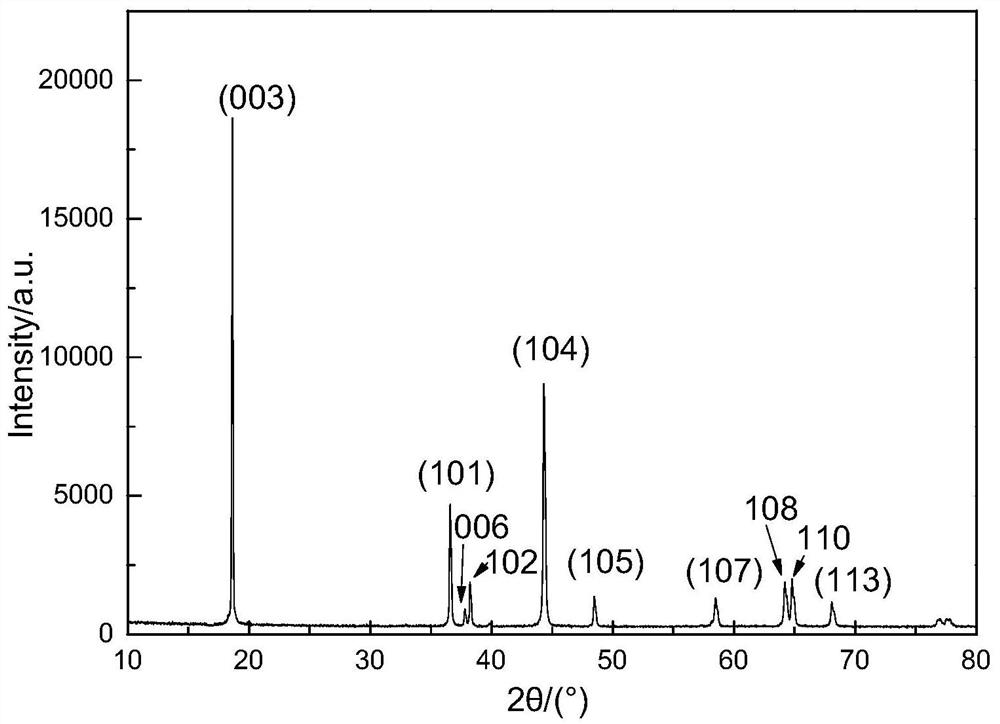

Embodiment 1

[0081] The high-voltage nickel-cobalt-manganese ternary precursor Ni provided by this embodiment 0.60 co 0.20 mn 0.20 (OH) 2 The preparation method comprises the following steps:

[0082] (a), the mixed solution of nickel sulfate, cobalt sulfate and manganese sulfate (the total molar concentration of nickel-cobalt-manganese metal ions is 1.2mol / L, and the mol ratio of nickel element, cobalt element and manganese element is 6:2:2), The aqueous solution of sodium carbonate (the molar concentration is 1.5mol / L) and EDTA (ethylenediaminetetraacetic acid) are fed at a constant speed through the metering pump to be respectively transported to the first bottom liquid (pH is 7.5 sodium hydroxide solution), rich In the reactor A containing nitrogen, carry out co-precipitation reaction; In the process of reaction, the temperature of control solution system is at 40 ℃, and pH is at 7.5, and the feed rate of complexing agent solution (mass concentration is 1.0g / L) is 0.02 times of the...

Embodiment 2

[0087] The high-voltage nickel-cobalt-manganese ternary precursor Ni provided by this embodiment 0.60 co 0.20 mn 0.20 (OH) 2 The preparation method comprises the following steps:

[0088] (a), the mixed solution of nickel sulfate, cobalt sulfate and manganese sulfate (the total molar concentration of nickel-cobalt-manganese metal ions is 1.5mol / L, and the mol ratio of nickel element, cobalt element and manganese element is 6:2:2), The aqueous solution of sodium carbonate (the molar concentration is 1.5mol / L) and ethylenediaminetetrapropionic acid (EDTP) are simultaneously fed at a constant speed by a metering pump to be transported respectively to the sodium hydroxide solution containing the first bottom liquid (pH is 8.5), In the reactor A rich in nitrogen, carry out coprecipitation reaction; In the process of reaction, control the temperature of solution system at 35 ℃, pH at 8, the feed rate of complexing agent solution (mass concentration is 2.0g / L) It is 0.15 times of...

Embodiment 3

[0093] The high-voltage nickel-cobalt-manganese ternary precursor Ni provided by this embodiment 0.60 co 0.20 mn 0.20 (OH) 2 The preparation method comprises the following steps:

[0094] (a), the mixed solution of nickel sulfate, cobalt sulfate and manganese sulfate (the total molar concentration of nickel-cobalt-manganese metal ions is 1.8mol / L, and the mol ratio of nickel element, cobalt element and manganese element is 6:2:2), The aqueous solution of sodium carbonate (the molar concentration is 1.0mol / L) and EDTA (ethylenediaminetetraacetic acid) are fed at a constant speed through the metering pump to be respectively transported to the sodium hydroxide solution containing the first bottom liquid (pH is 8.0), rich In the reactor A containing nitrogen, carry out co-precipitation reaction; In the process of reaction, the temperature of control solution system is at 40 ℃, and pH is at 7.2, and the feed rate of complexing agent solution (mass concentration is 3.0g / L) is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com