Preparation method for papermaking black liquid-transferred porous carbon negative electrode material for sodium ion battery

A sodium-ion battery and porous carbon material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable environmental protection, and achieve the effects of simple preparation process, low reaction temperature, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

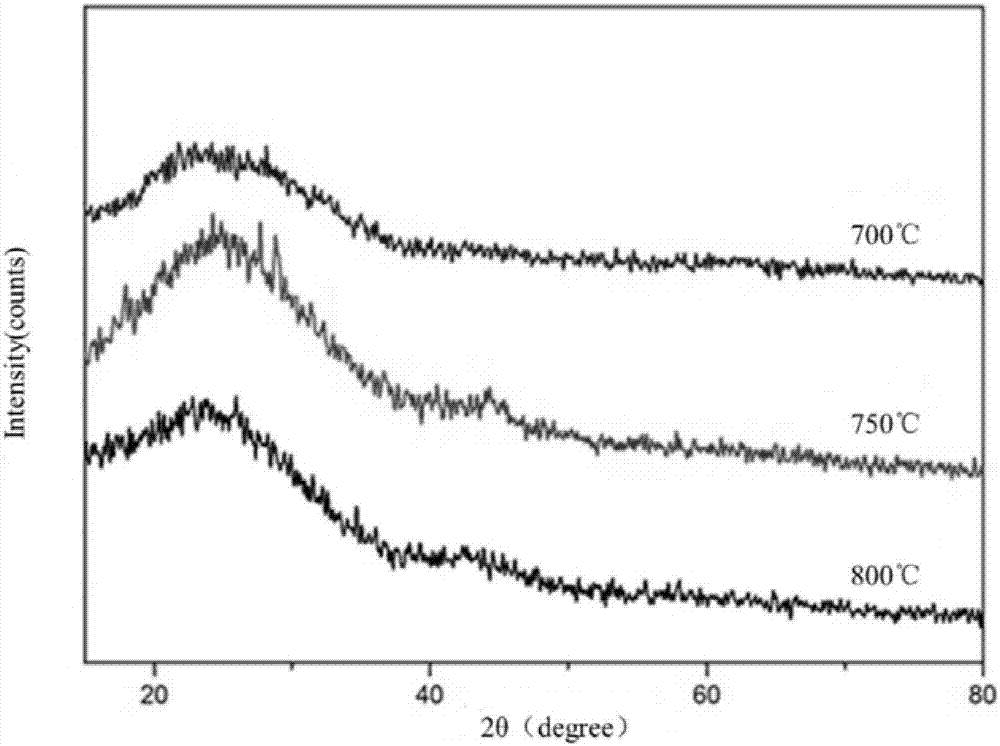

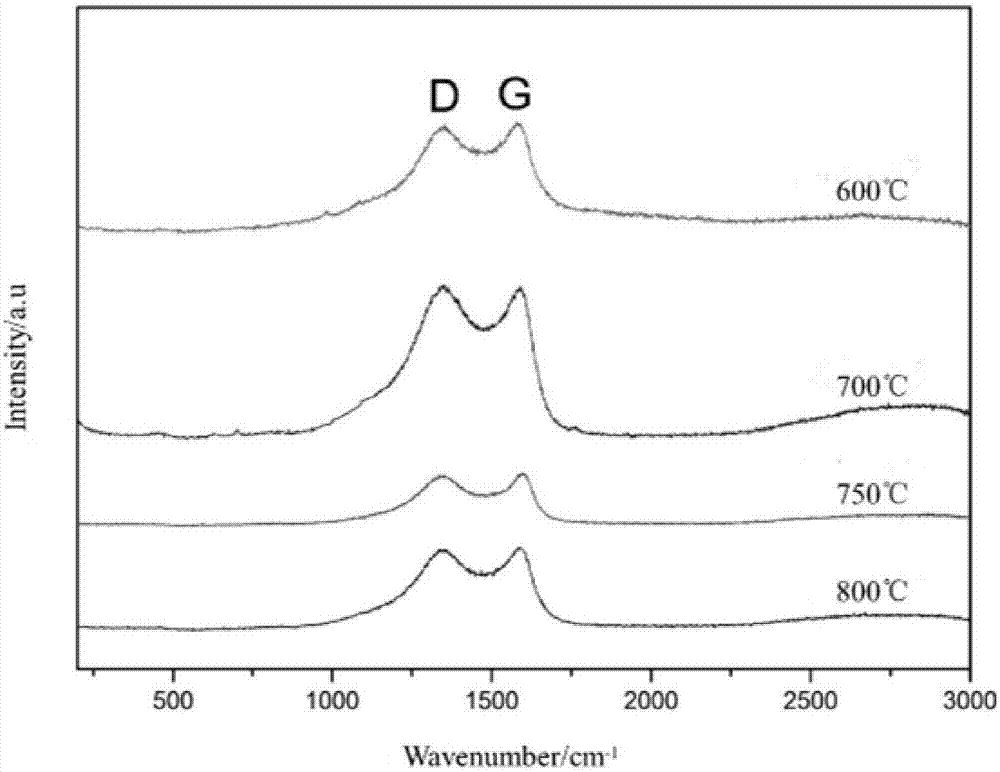

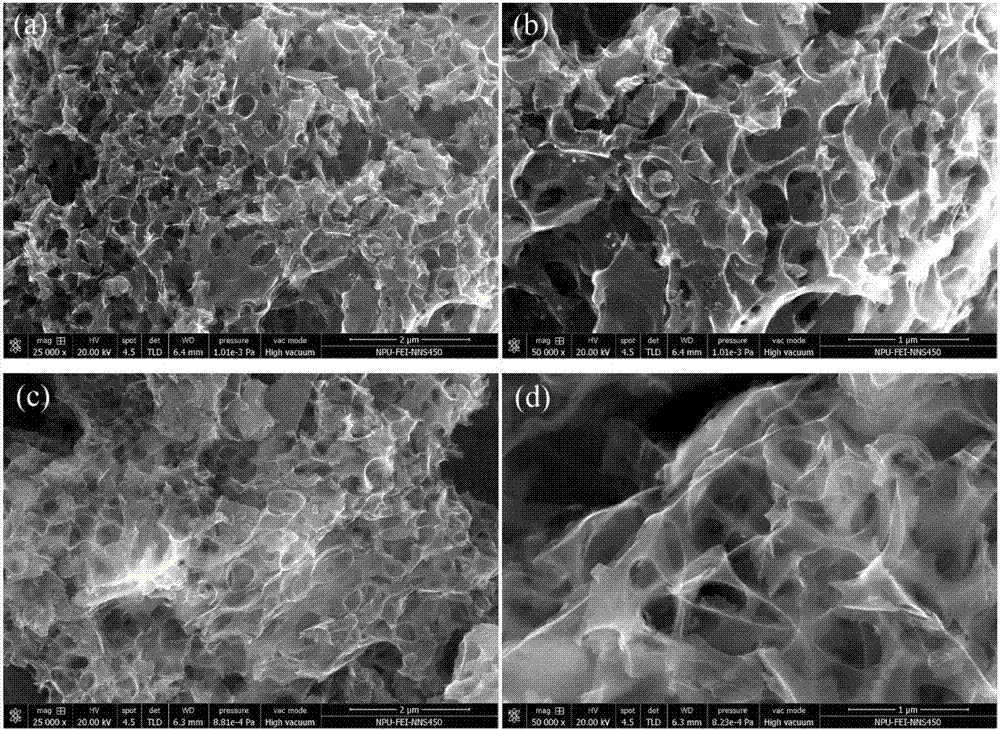

Embodiment 1

[0024] 1) First, put the papermaking black liquor in an oven and dry it at 50°C for 30 hours;

[0025] 2) Then, place the dried product in a tube furnace, pass through argon as a protective gas, and the argon flow rate is 20ml / min, and heat treatment is performed from room temperature to 600°C at a heating rate of 2°C / min 5h, obtain porous carbon material;

[0026] 3) Finally, the obtained porous carbon material was placed in a muffle furnace for activation treatment at 200° C. for 2 hours, and after cooling, a porous carbon-sodium-ion battery negative electrode material was obtained.

Embodiment 2

[0028] 1) First, dry the papermaking black liquor in an oven at 60°C for 25 hours;

[0029] 2) Then, place the dried product in a tube furnace, pass through argon as a protective gas, and the argon flow rate is 50ml / min, and heat treatment is performed from room temperature to 650°C at a heating rate of 5°C / min 3h, obtain porous carbon material;

[0030] 3) Finally, the obtained porous carbon material was placed in a muffle furnace for activation treatment at 250° C. for 2 h, and after cooling, a porous carbon sodium ion battery negative electrode material was obtained.

Embodiment 3

[0032] 1) First, put the papermaking black liquor in an oven and dry it at 70°C for 20 hours;

[0033] 2) Then, place the dried product in a tube furnace, pass through argon as a protective gas, and the argon flow rate is 50ml / min, and heat treatment is performed from room temperature to 700°C at a heating rate of 5°C / min 2h, obtain porous carbon material;

[0034] 3) Finally, the obtained porous carbon material was placed in a muffle furnace for an activation treatment at 300° C. for 1 h, and after cooling, a porous carbon sodium ion battery negative electrode material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com