Lithium titanate composite material and preparation method and application thereof

A composite material, lithium titanate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low lithium ion conductivity, affecting the rate performance of lithium titanate, limited gas production inhibition, etc. Cycling performance, solving gas generation problems, effect of suppressing reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to the preparation method of lithium titanate composite material according to the second aspect of the present invention, it is used to prepare the lithium titanate composite material according to the first aspect of the present invention, comprising the step of: mixing lithium titanate particles with lithium source and phosphorus source The mixture is mixed in a liquid system solvent to obtain a mixed liquid; the mixed liquid is ball-milled to form a slurry, and then the slurry is taken out and dried to obtain the precursor powder of the composite material; the precursor of the composite material The bulk powder is calcined, and after cooling, it is crushed to obtain a lithium titanate composite material whose surface is covered with lithium phosphate glass.

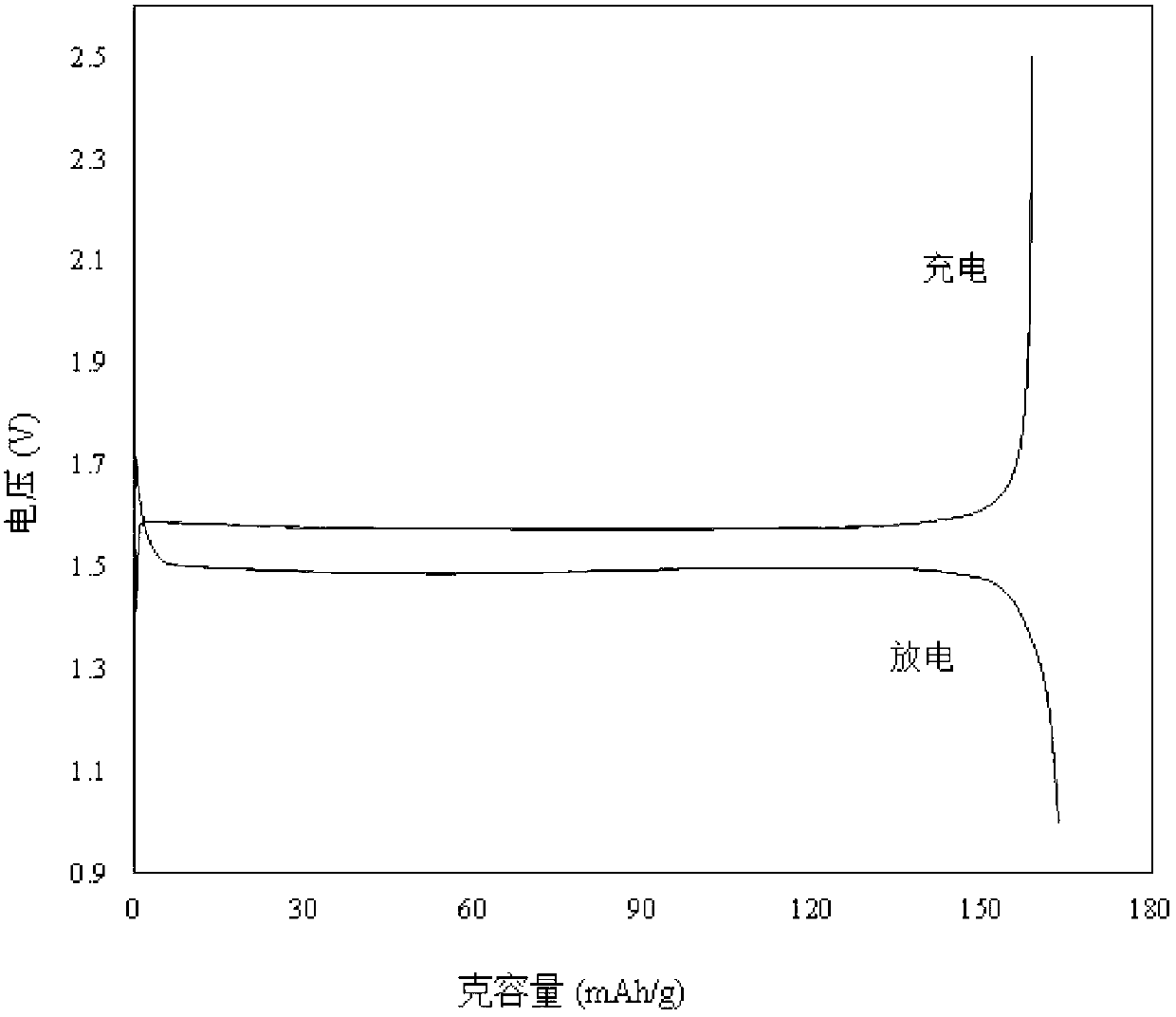

[0024] Lithium titanate particles coated with lithium phosphate glass are used to isolate lithium titanate from the electrolyte. Lithium phosphate glass is a kind of Li 2 O and P 2 o 5 The eutectic me...

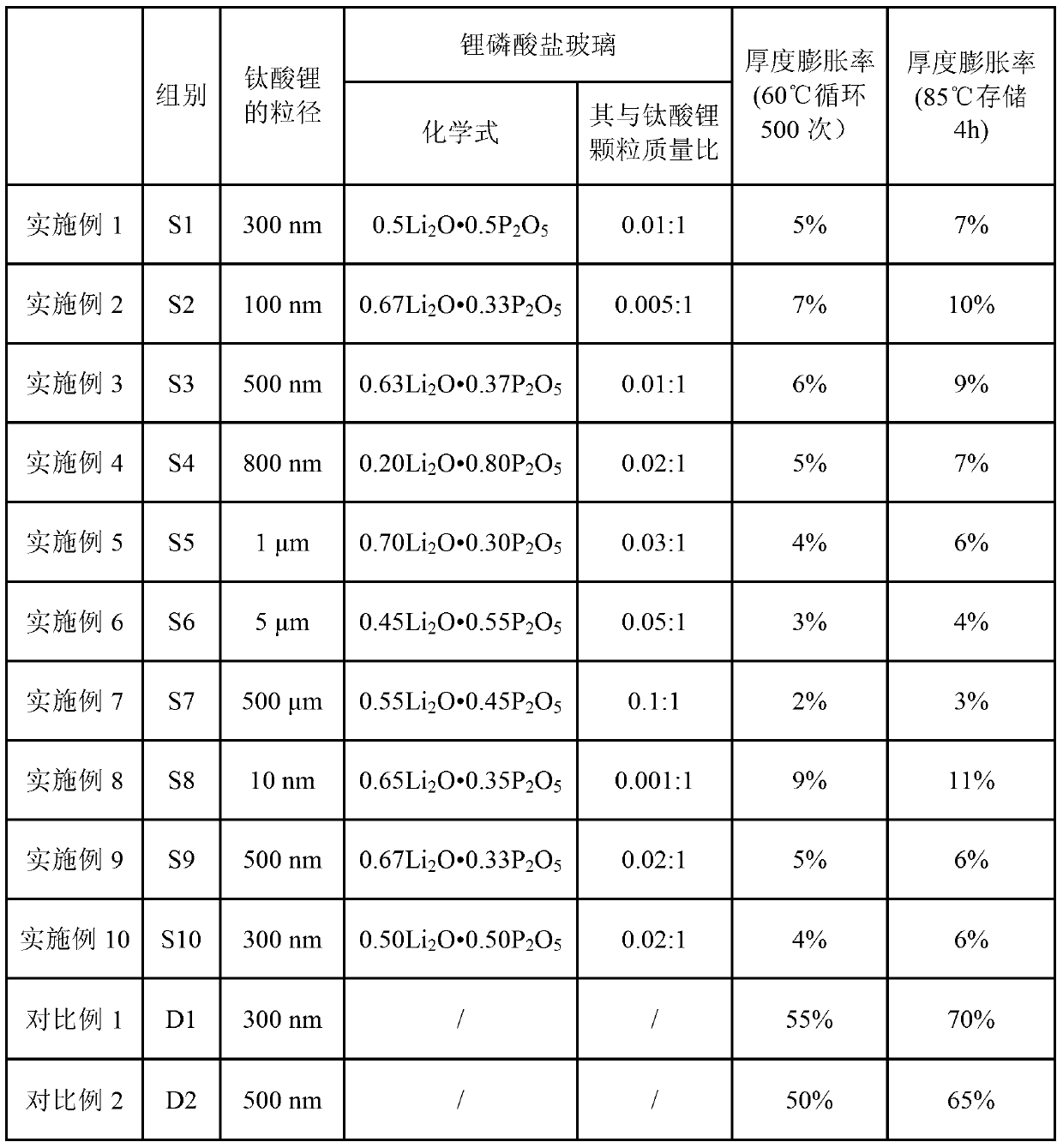

Embodiment 1

[0035] 500g particle size is 300nm lithium titanate particles, and the mixture of 2.150g lithium carbonate and 7.627g diammonium hydrogen phosphate (wherein the molar ratio of lithium element and phosphorus element is 0.5:0.5, wherein lithium carbonate and diammonium hydrogen phosphate Element and phosphorus corresponding to Li respectively 2 O and P 2 o 5 The mass ratio of the sum of the mass and the lithium titanate particles is 0.01:1) mixed in deionized water; after mixing evenly, ball milled on a ball mill for 6 hours to obtain a slurry; then the slurry was dried to obtain the precursor of lithium titanate composite material powder;

[0036] Put the precursor powder of lithium titanate composite material in a crucible, and then place it in a tube furnace for calcination at a constant temperature of 1000°C for 24 hours, and pulverize it after cooling to obtain lithium titanate particles coated with 0.5Li 2 O 0.5P 2 o 5 Lithium titanate composite material of lithium phos...

Embodiment 2

[0038] A mixture of 500g of lithium titanate particles with a particle size of 100nm, 1.200g of lithium hydroxide and 2.839g of ammonium dihydrogen phosphate (wherein the molar ratio of lithium to phosphorus is 0.67:0.33, wherein lithium hydroxide and ammonium dihydrogen phosphate Lithium element and phosphorus element respectively correspond to Li 2 O and P 2 o 5 The mass ratio of the sum of the mass of the lithium titanate particles to the lithium titanate particles is 0.005:1) and mixed in absolute ethanol; after mixing evenly, ball mill on a ball mill for 8 hours to obtain a slurry, and then dry the slurry to obtain the precursor of the lithium titanate composite material body powder;

[0039] Put the precursor powder of lithium titanate composite material in a crucible, and then place it in a tube furnace for calcination at a constant temperature of 1500°C for 2 hours, and then pulverize it after cooling to obtain lithium titanate particles coated with 0.67Li 2 O 0.33P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com