Ultra-fine gradient hard alloy with WC grains in surface rich binding-phase layer arrayed in regular shape and preparation method of ultra-fine gradient hard alloy

A cemented carbide and binder phase technology, which is applied in the field of ultra-fine grain gradient cemented carbide and its preparation, can solve the problems of difficult control, poor rigidity and resistance to plastic deformation, and low hardness, so as to improve performance and surface Toughness, enhanced impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

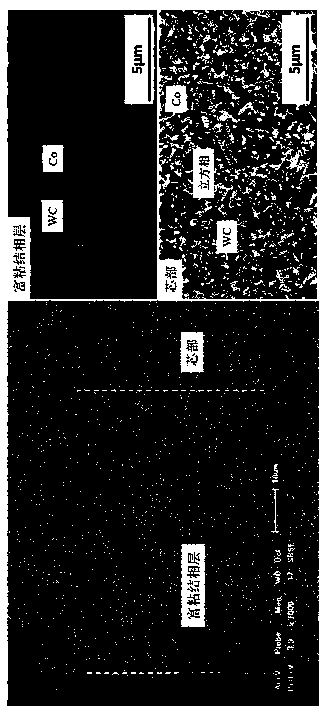

[0035] The present invention is an ultra-fine-grain gradient cemented carbide with regularly arranged WC crystal grains in the surface rich binder phase layer, and its composition is 80%WC, 3%Ti(C,N), 7% by mass percentage. (W,Ti)C, 10%Co, its metallographic structure is based on WC and cubic carbonitride as the core hard phase, and cobalt as the binder phase to form a 60μm thick binder phase layer on the outside. WC The average size of the crystal grains is 0.6μm, the surface rich binder phase gradient layer does not contain cubic carbonitrides, the cobalt content is 1-2 times the nominal cobalt content of the cemented carbide, and the surface rich binder phase gradient layer contains Most of the WC crystal grains are rectangular plates and arranged regularly, and the WC crystal grains in the core are randomly distributed.

[0036] The method for preparing an ultra-fine-grain gradient cemented carbide with regularly arranged WC crystal grains in the surface of the binder-rich la...

Embodiment 2

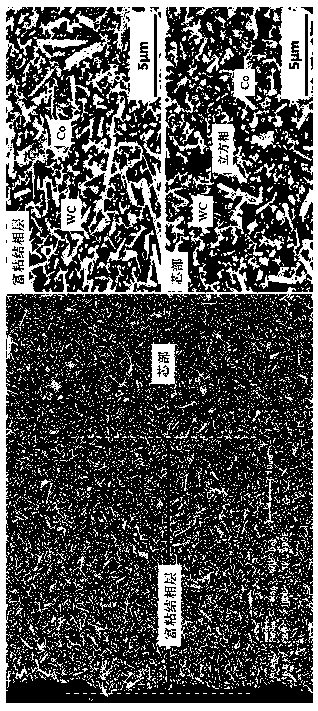

[0042] The present invention is an ultra-fine-grain gradient cemented carbide with regular arrangement of WC crystal grains in the surface rich binder phase layer, and its composition is 78%WC, 5%Ti(C,N), 8% by mass percentage. (W,Ti)C, 9%Co, its metallographic structure is based on WC and cubic carbonitride as the core hard phase, and cobalt as the binder phase to form a 50μm thick binder phase layer on the outside, WC The average grain size is 0.5μm, the outer binder-rich gradient layer does not contain cubic carbonitrides, the cobalt content is 1-2 times the nominal cobalt content of the cemented carbide, and the surface is rich in WC in the binder phase layer The shape is a rectangular plate and is arranged regularly, and the core WC crystal grains vary in size and are randomly distributed.

[0043] The method for preparing an ultra-fine-grain gradient cemented carbide with regularly arranged WC crystal grains in the surface of the binder-rich layer of the present invention i...

Embodiment 3

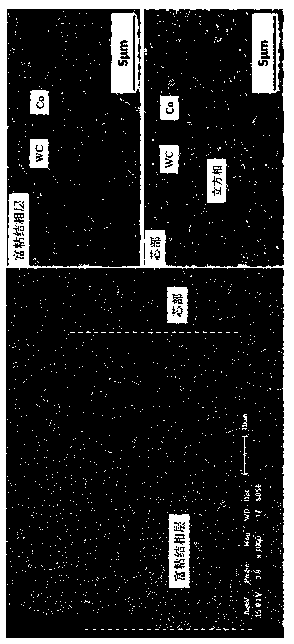

[0049] The present invention is an ultra-fine-grained graded cemented carbide with regularly arranged WC crystal grains in the binder-rich layer on the surface, and its composition is 82%WC, 4%Ti(C,N), 6% by mass percentage. (W,Ti)C, 8%Co. Its metallographic structure is based on WC and cubic carbonitride as the core hard phase, and cobalt as the binder phase to form a 70μm thick binder phase layer on the outside. WC The average grain size is 0.55μm, the outer binder-rich gradient layer does not contain cubic carbonitrides, the cobalt content is 1-2 times the nominal cobalt content of the cemented carbide, and the surface is rich in WC in the binder phase layer The shape is a rectangular plate and is arranged regularly, and the core WC crystal grains vary in size and are randomly distributed.

[0050] The method for preparing an ultra-fine-grain gradient cemented carbide with regularly arranged WC crystal grains in the surface of the binder-rich layer of the present invention is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com