Continuous cast-rolling forming method and continuous cast-rolling forming device for bicontinuous-phase composite board

A dual-continuous-phase, composite plate technology, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of high cost, incomplete impregnation of metal solution, long forming time, etc., to achieve easy operation and large-scale The effect of production and improvement of surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

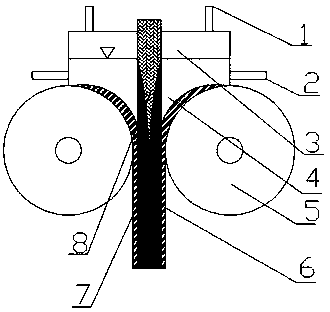

[0019] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the specific implementation of the present invention for preparing SiC-Al bicontinuous phase composite materials will be described in detail below in conjunction with the accompanying drawings, so that the above-mentioned and other purposes of the present invention, Features and benefits will be clearer. The drawings have not been drawn to scale, emphasis instead being placed upon illustrating the gist of the invention.

[0020] figure 1 It is a schematic diagram of the device for implementing the process of the present invention. like figure 1 Shown, method of the present invention comprises the following steps:

[0021] Feeding step: Feed the prefabricated porous ceramic plate 8 from the upper seal of the impregnation box 3 through a feeder.

[0022] Impregnation step: After the porous ceramic 8 is immersed in the metal solution 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com