Patents

Literature

48results about How to "Improve surface toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary polymer layered impregnated tile

InactiveUS6955853B1High mechanical strengthImprove thermal efficiencySynthetic resin layered productsCeramic shaping apparatusFiberInter layer

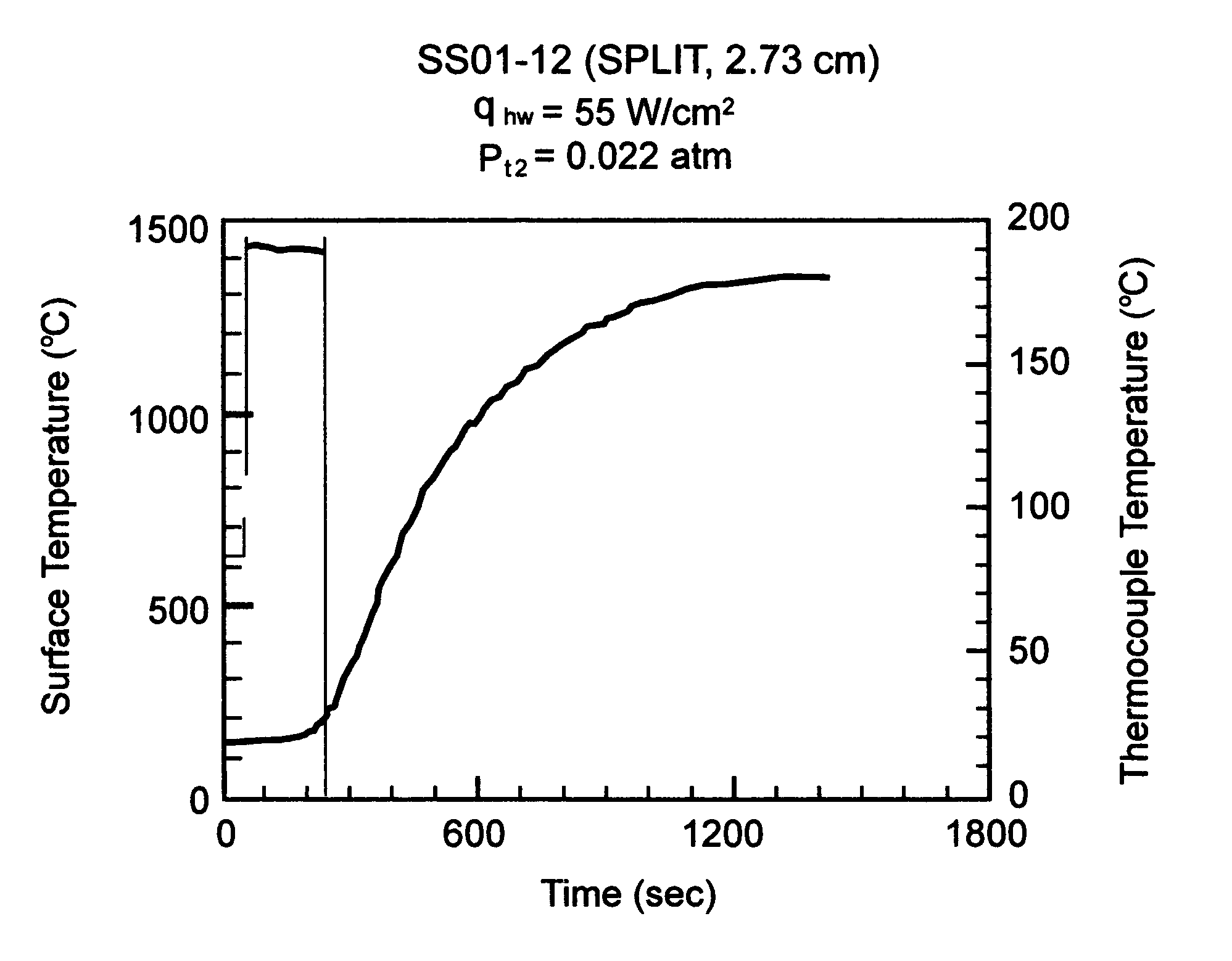

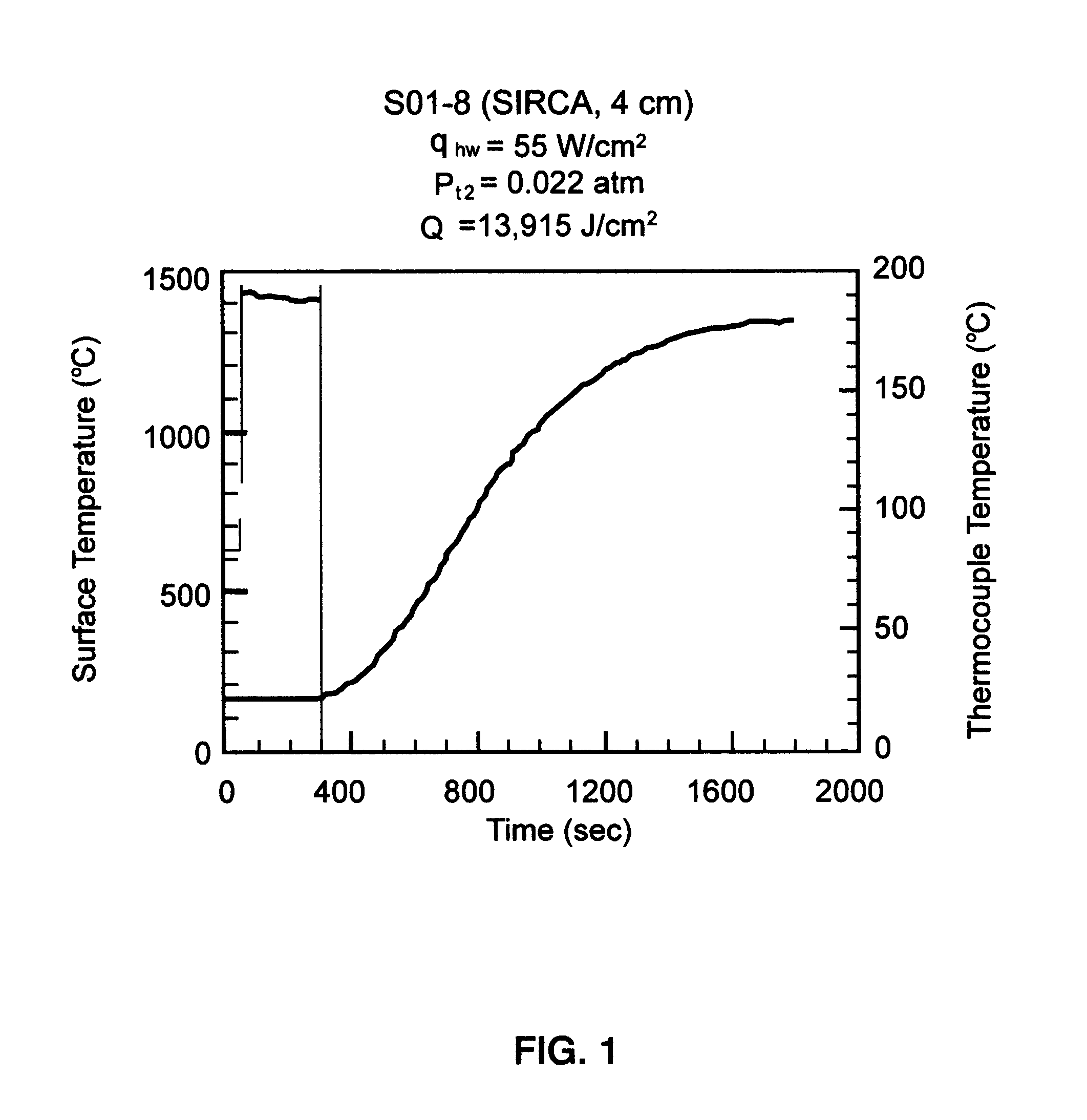

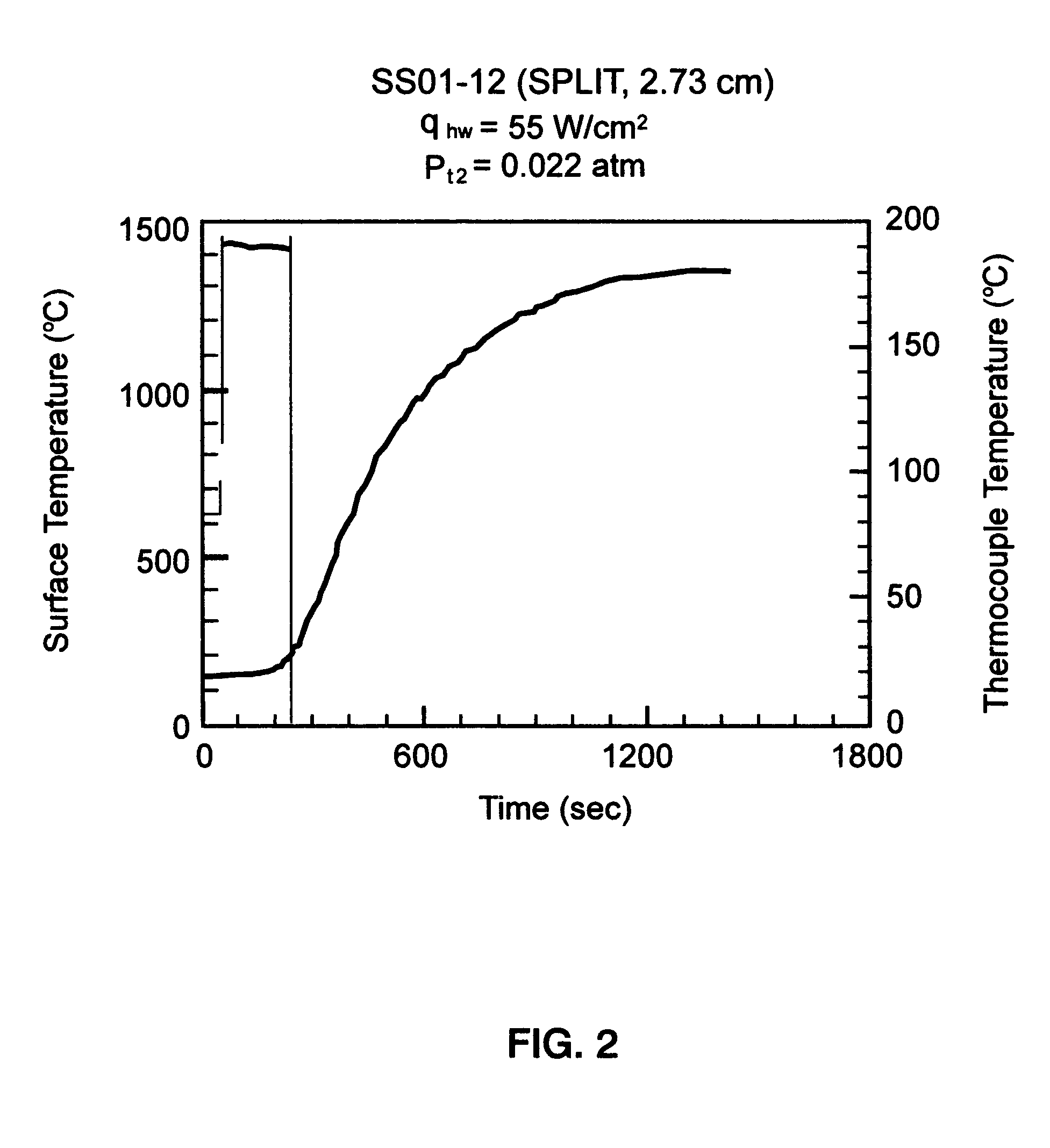

A low density organic polymer impregnated preformed fibrous ceramic article includes a plurality of layers. A front layer includes ceramic fibers or carbon fibers or combinations of ceramic fibers and carbon fibers, and is impregnated with an effective amount of at least one organic polymer. A middle layer includes polymer impregnated ceramic fibers. A back layer includes ceramic fibers or carbon fibers or combinations of ceramic fibers and carbon fibers, and is impregnated with an effective amount of at least one low temperature pyrolyzing organic polymer capable of decomposing without depositing residues.

Owner:NASA +1

Polyurethane transparent matt topcoat, preparation method and use method thereof

ActiveCN101381581AFeel smoothGood flexibilityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxLow speed

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

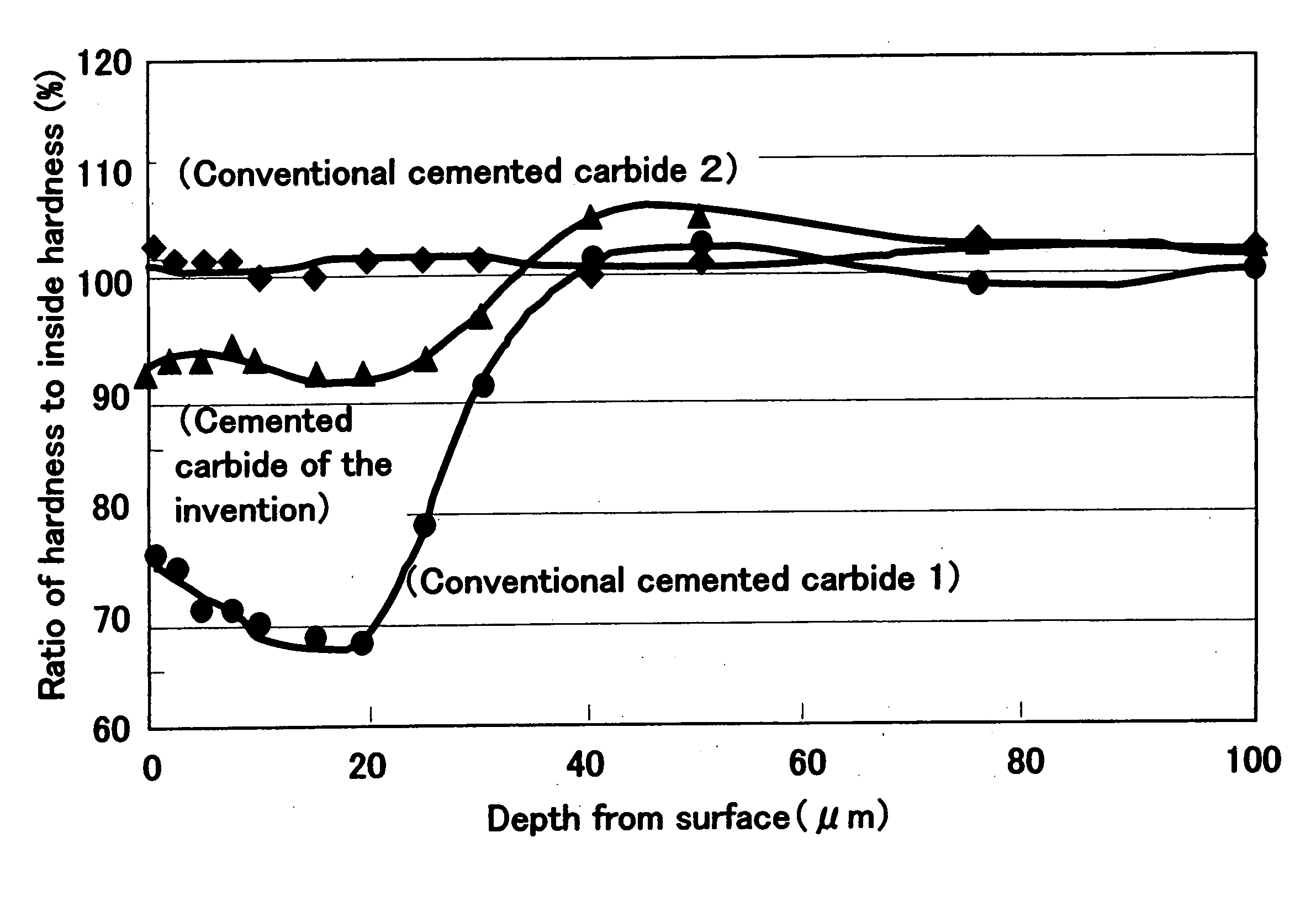

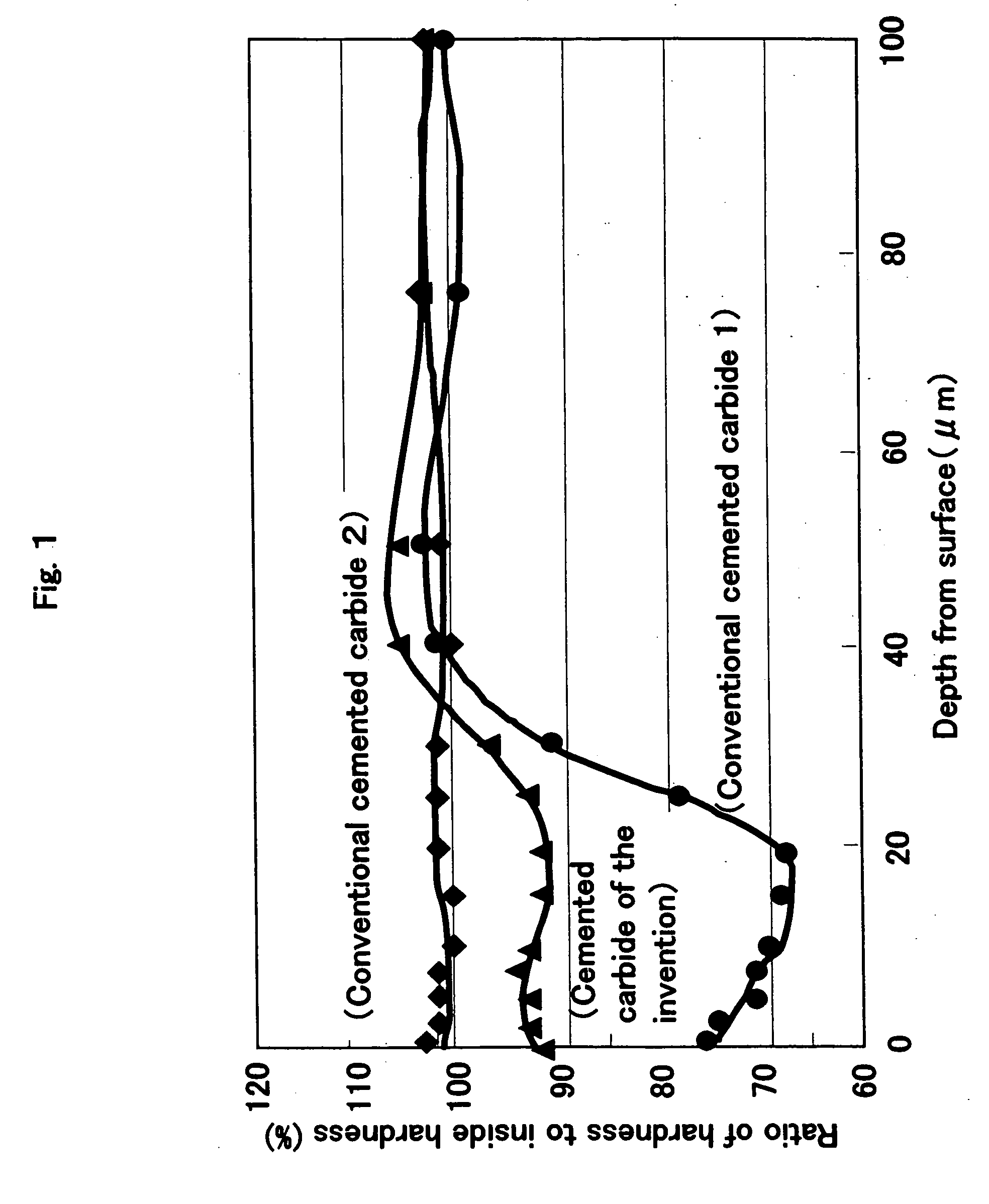

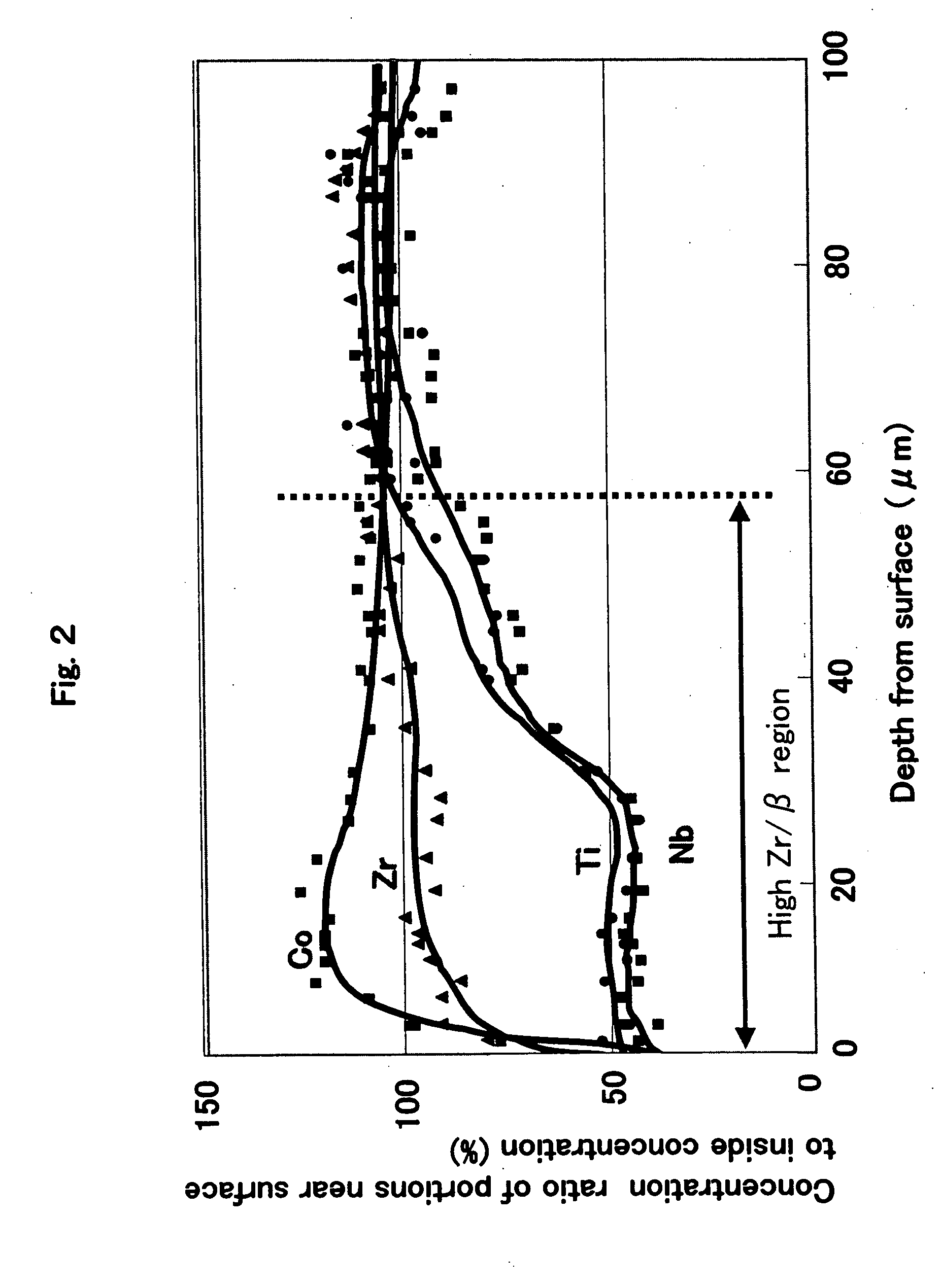

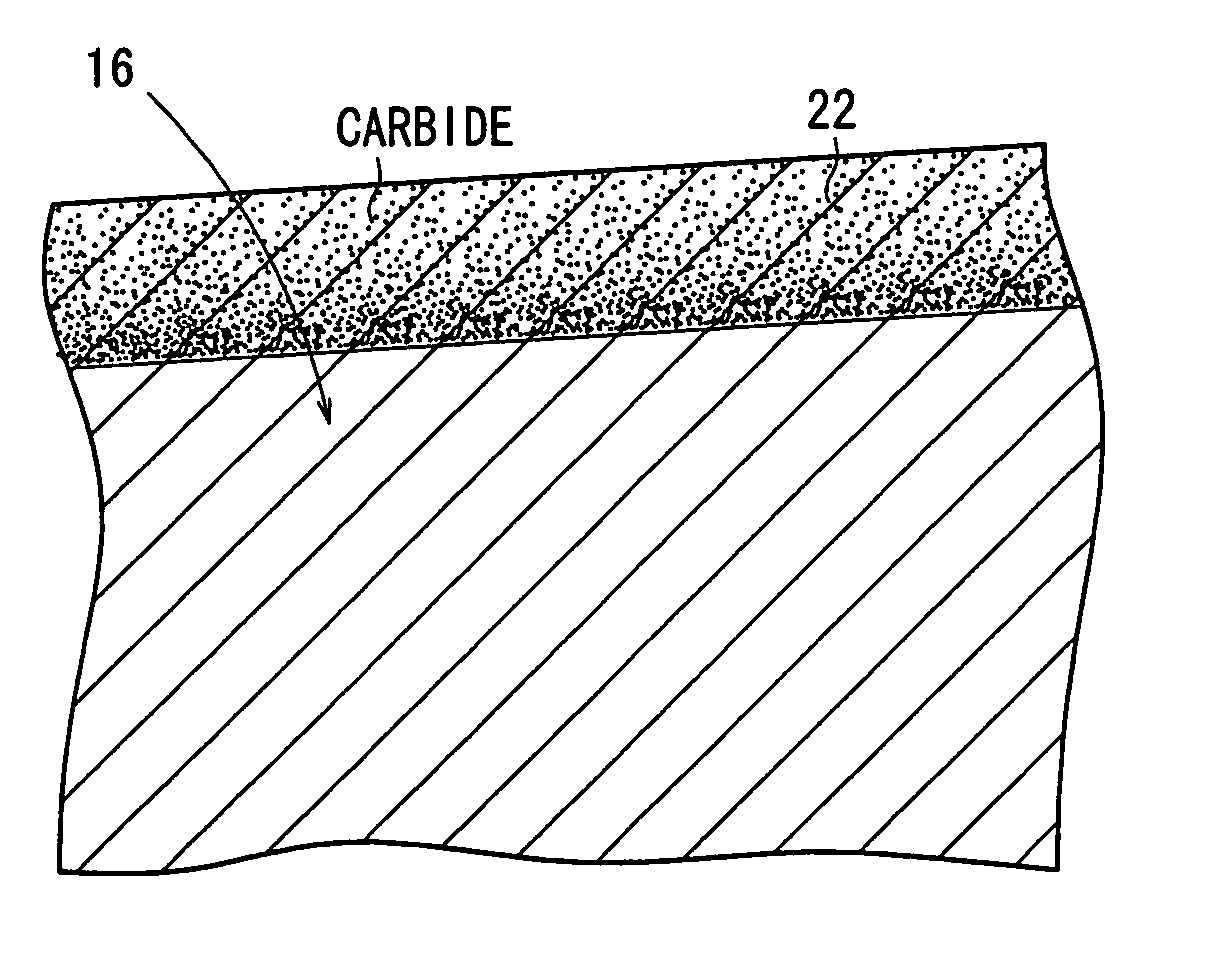

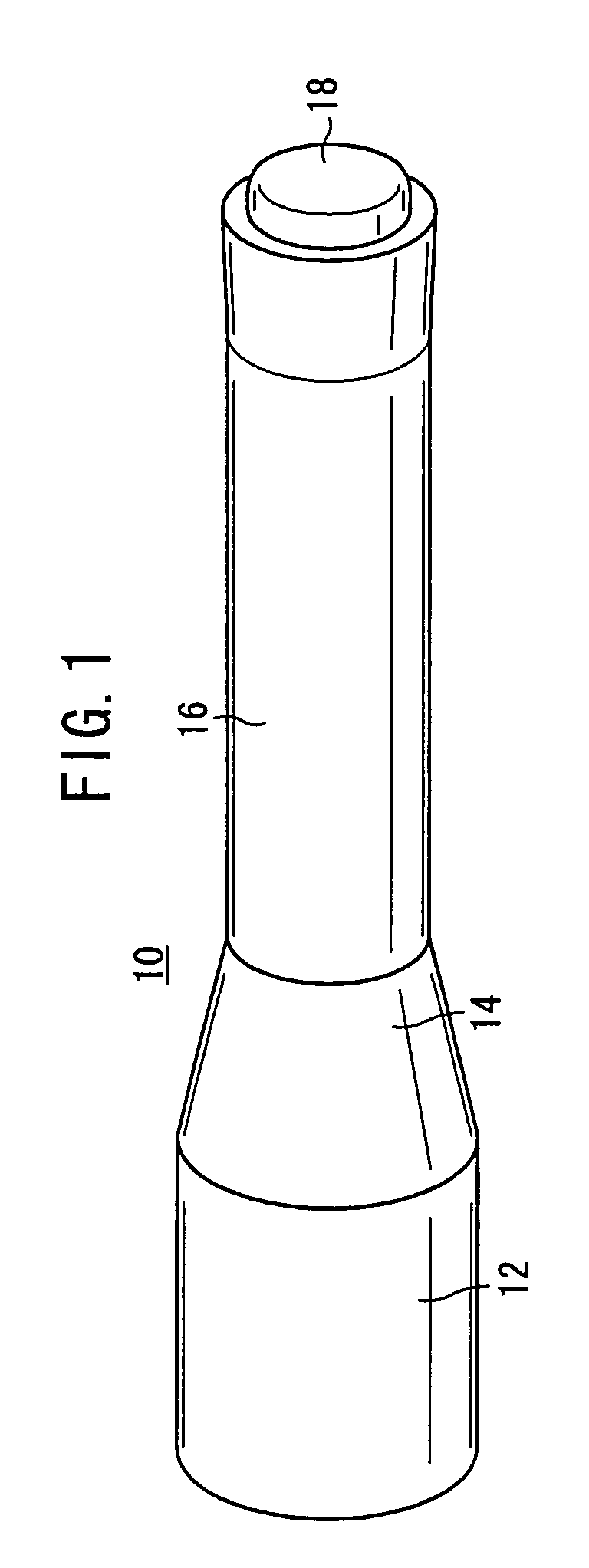

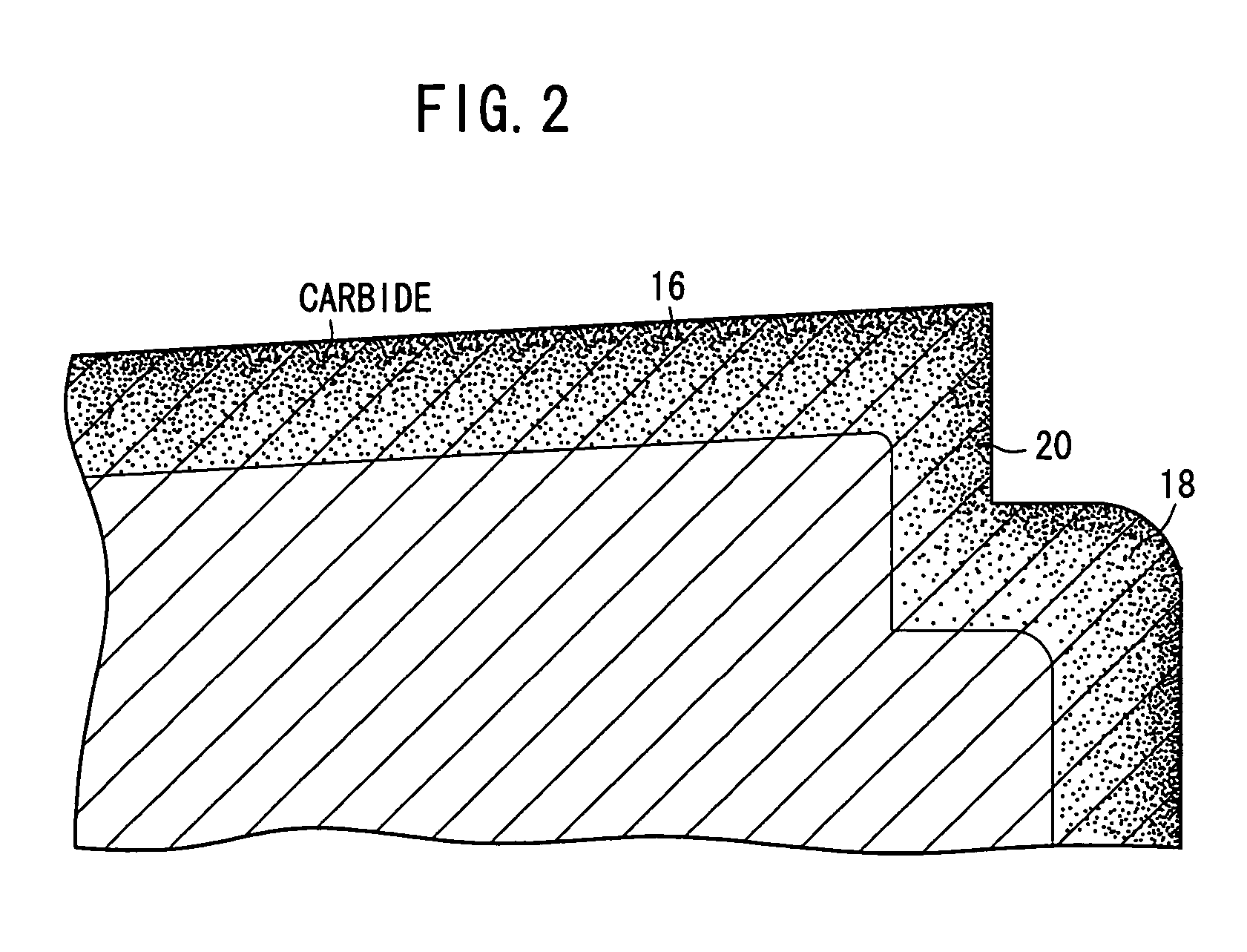

Cemented carbide and cutting tool

InactiveUS20050014030A1High hardnessImprove toughnessRecord information storageBonded abrasive wheelsCemented carbideHardness

There is provided a cemented carbide comprising a hard phase component which comprises a tungsten carbide (WC) and at least one selected from carbides, nitrides and carbonitrides of metals of the groups 4a, 5a and 6a in the periodic table; and a binder phase component comprising at least one of iron-group metals, wherein the surface region of the cemented carbide has 90-98% of the minimum hardness as compared with internal hardness, thereby having high hardness and toughness which is suitable to using as a cutting tool.

Owner:KYOCERA CORP

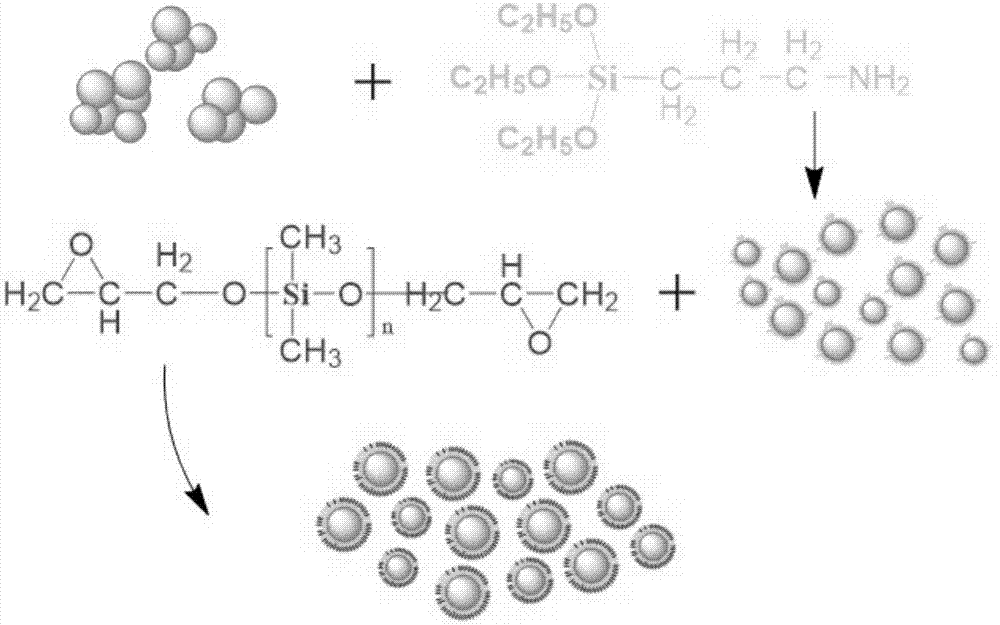

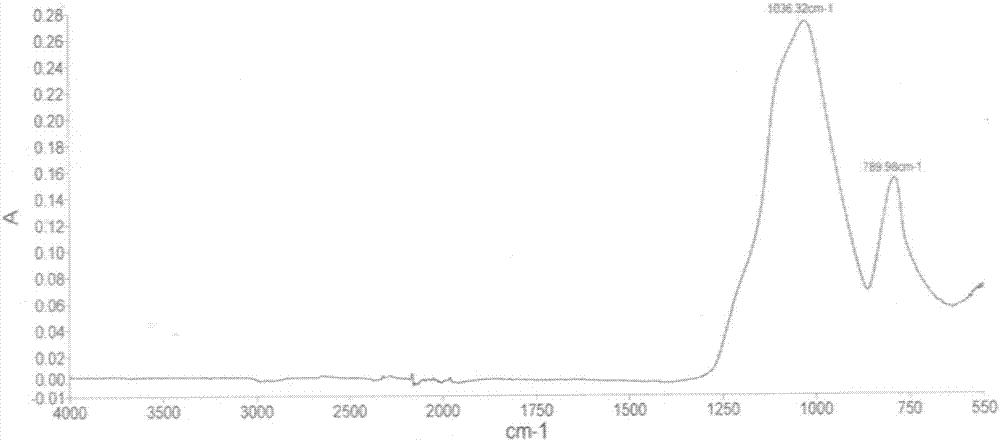

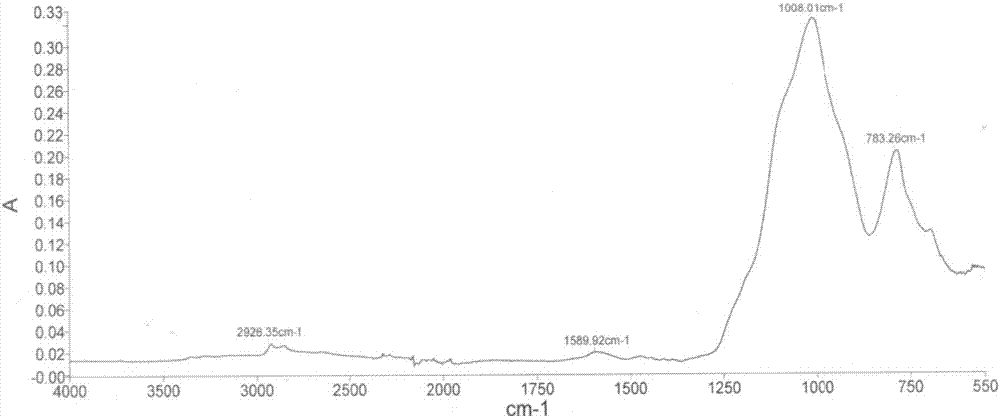

Silicon micro-powder with surface chemical modification, preparation method and application of same

ActiveCN107502000AImprove surface toughnessGood compatibilityNon-macromolecular adhesive additivesSilicon compoundsEpoxyAdhesive

The invention provides a silicon micro-powder with surface chemical modification, and a preparation method and an application of same, and belongs to the field of surface modification for non-metal-based materials. The preparation method includes the following steps: treating the surface of surface-hydroxylated silicon micro-powder with a silane coupling agent; and performing chemical grafting to the surface with epoxy group-terminated organosilane to form filler which has high surface toughness and has high compatibility and dispersibility in epoxy glue. Compared with silicon micro-powder without surface chemical modification, the preparation method enables the filler to have high dispersibility in epoxy glue, can effectively improve the toughness of the epoxy glue, and is very suitable for the fields of anti-low-temperature epoxy pouring sealants, sealing adhesives and bonding adhesives.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

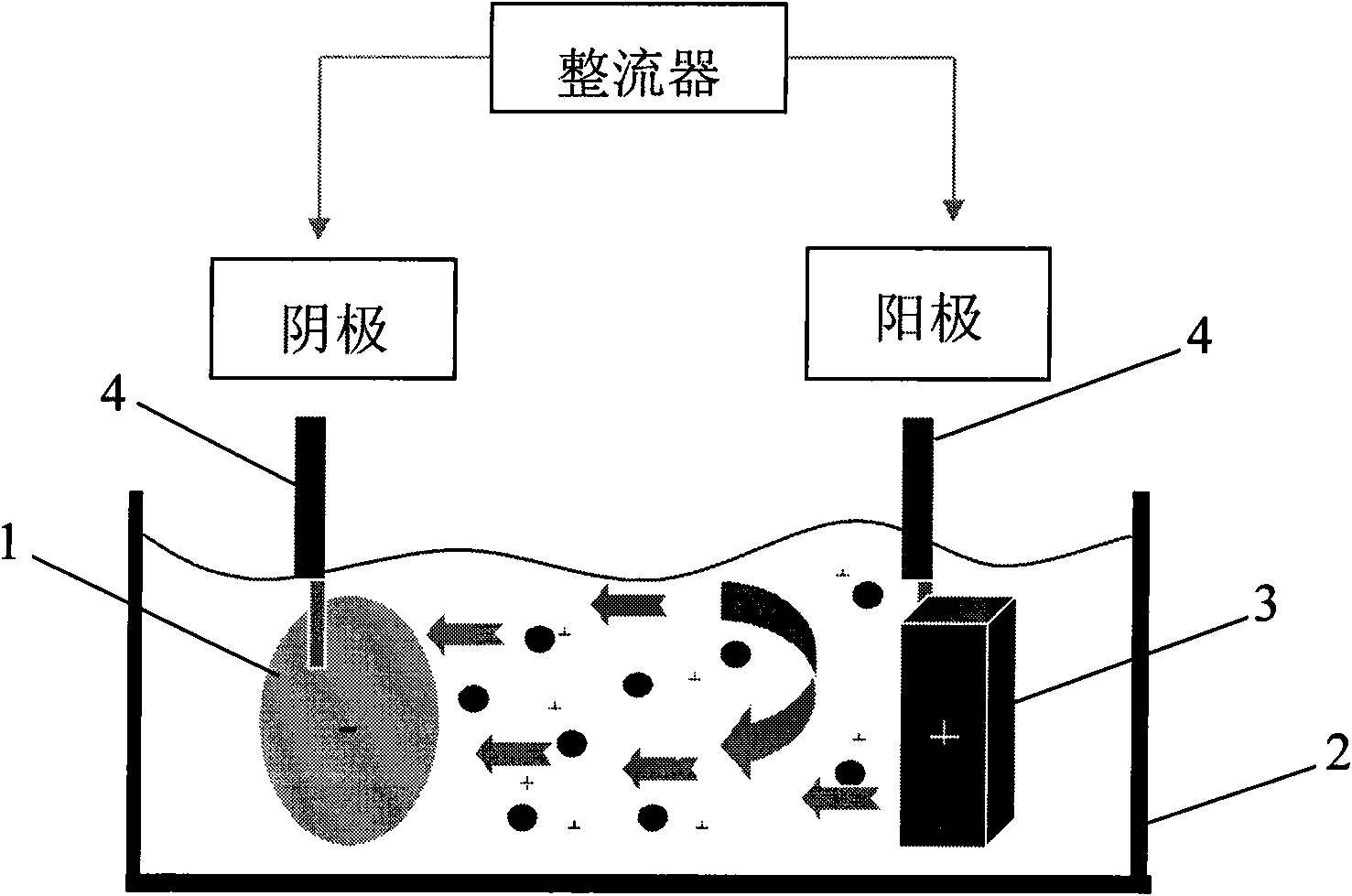

Method for plating nano nickel layer on metal workpiece

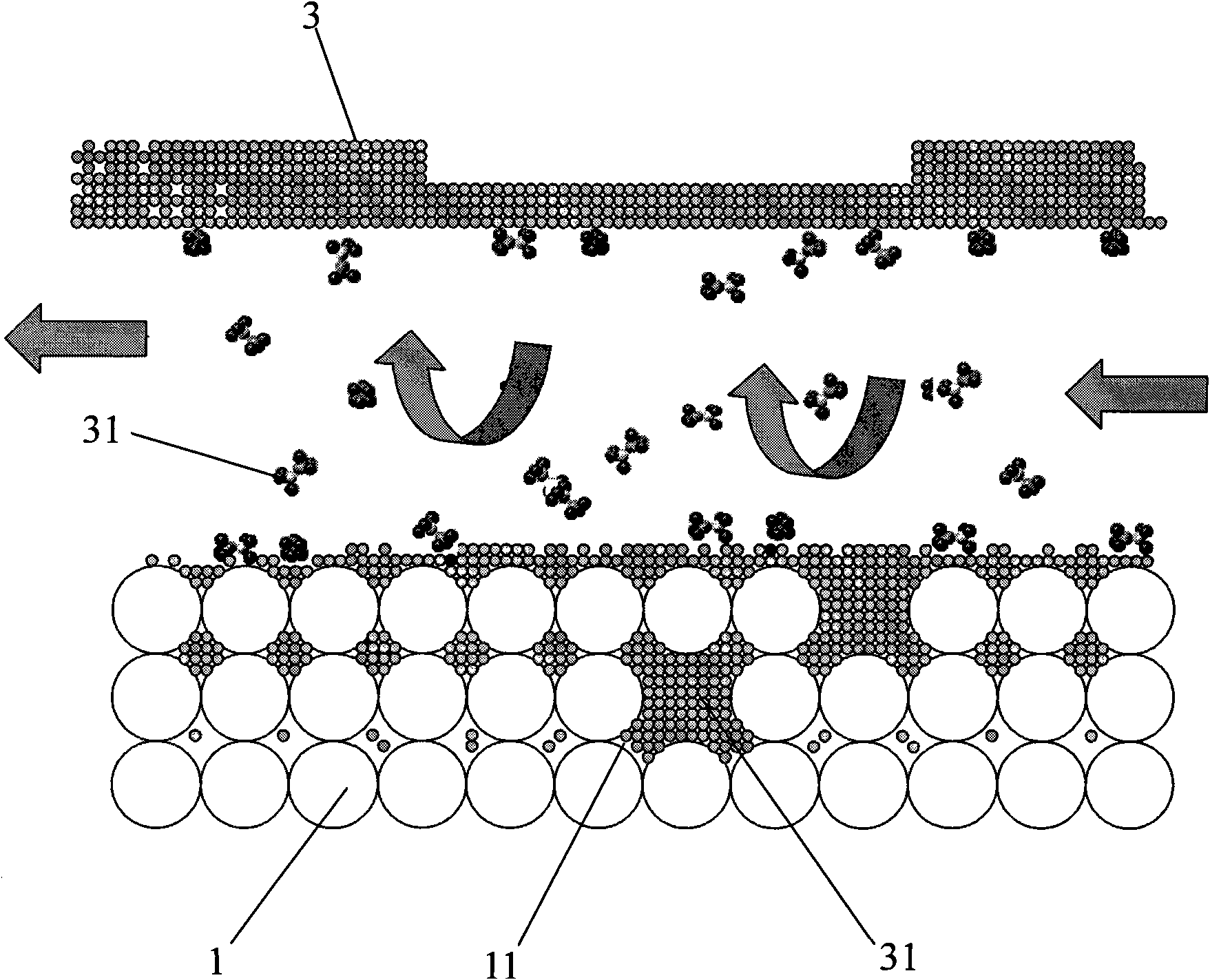

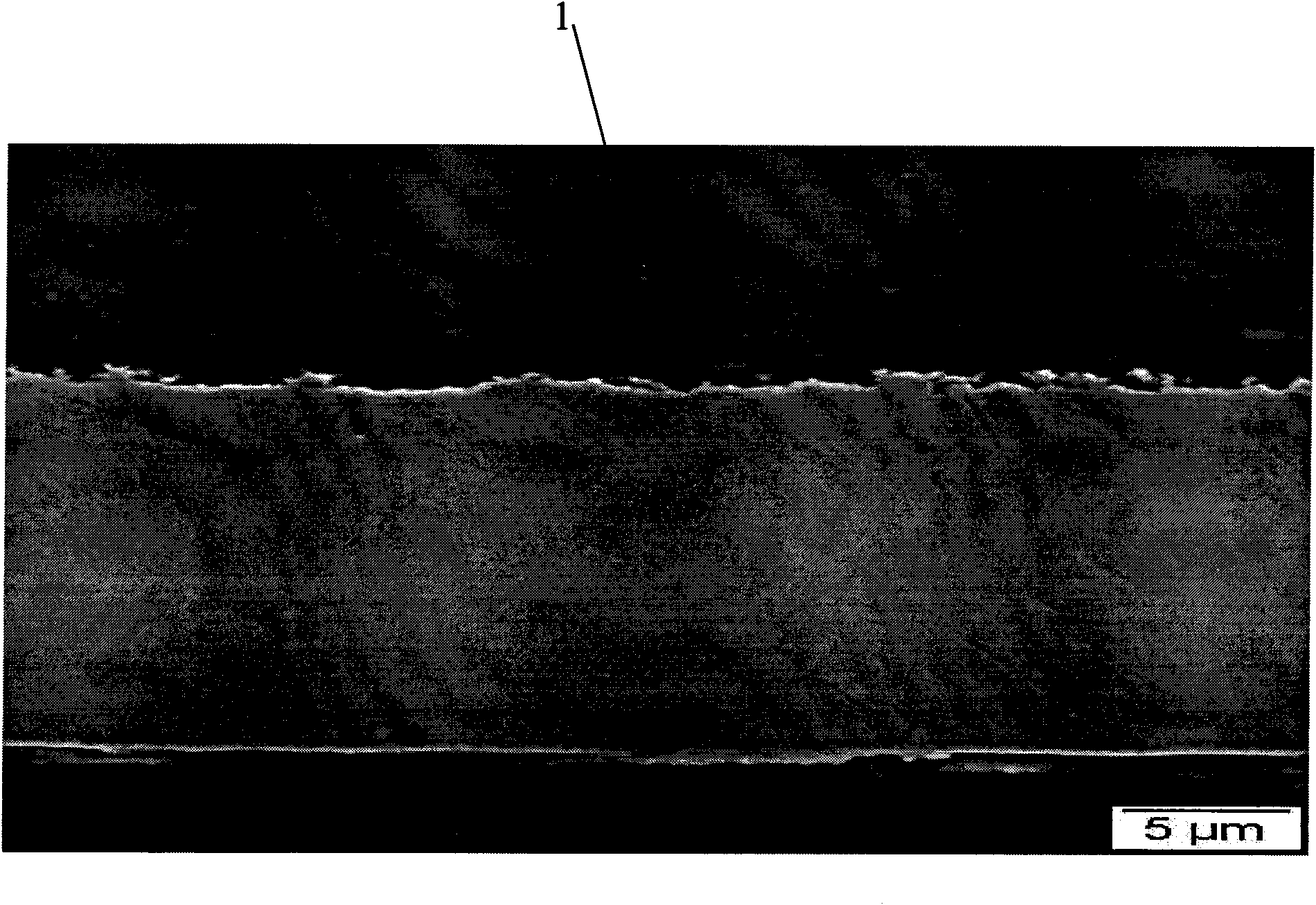

The invention relates to a method for plating a nano nickel layer on a metal workpiece. The method comprises the following steps of: baking, carbonizing and cleaning the metal workpiece, thoroughly burning off capillary impurities on the surface of the metal workpiece, carbonizing and cleaning the obtained metal workpiece; then putting the metal workpiece into an electroplating bath with bath solution for electroplating; wherein the metal workpiece is used as the cathode of the electroplating bath, the pure nickel target is used as the anode of the electroplating bath, and the bath solution in the electroplating bath is nickel aminosulfonate solution and flows in the electroplating bath; in the electroplating process, the pure nickel target of the anode is electrolyzed into nanometer nickel ions which are deposited in the capillary of the surface of the metal workpiece of the cathode and are regularly arranged into layered nano nickel film in sequence; and finally the metal workpiece is taken out from the electroplating bath and cleaned; wherein the electroplating technique is adopted to fill the nanometer nickel ions in the capillaries of the surface of the metal workpiece in a drilling manner; then the nanometer nickel ions can also be arranged and laminated on the surface of the metal workpiece in sequence, thus being capable of greatly increasing the surface toughness of the metal workpiece so as to strengthening the fragility of the metal workpiece.

Owner:陈仲禾

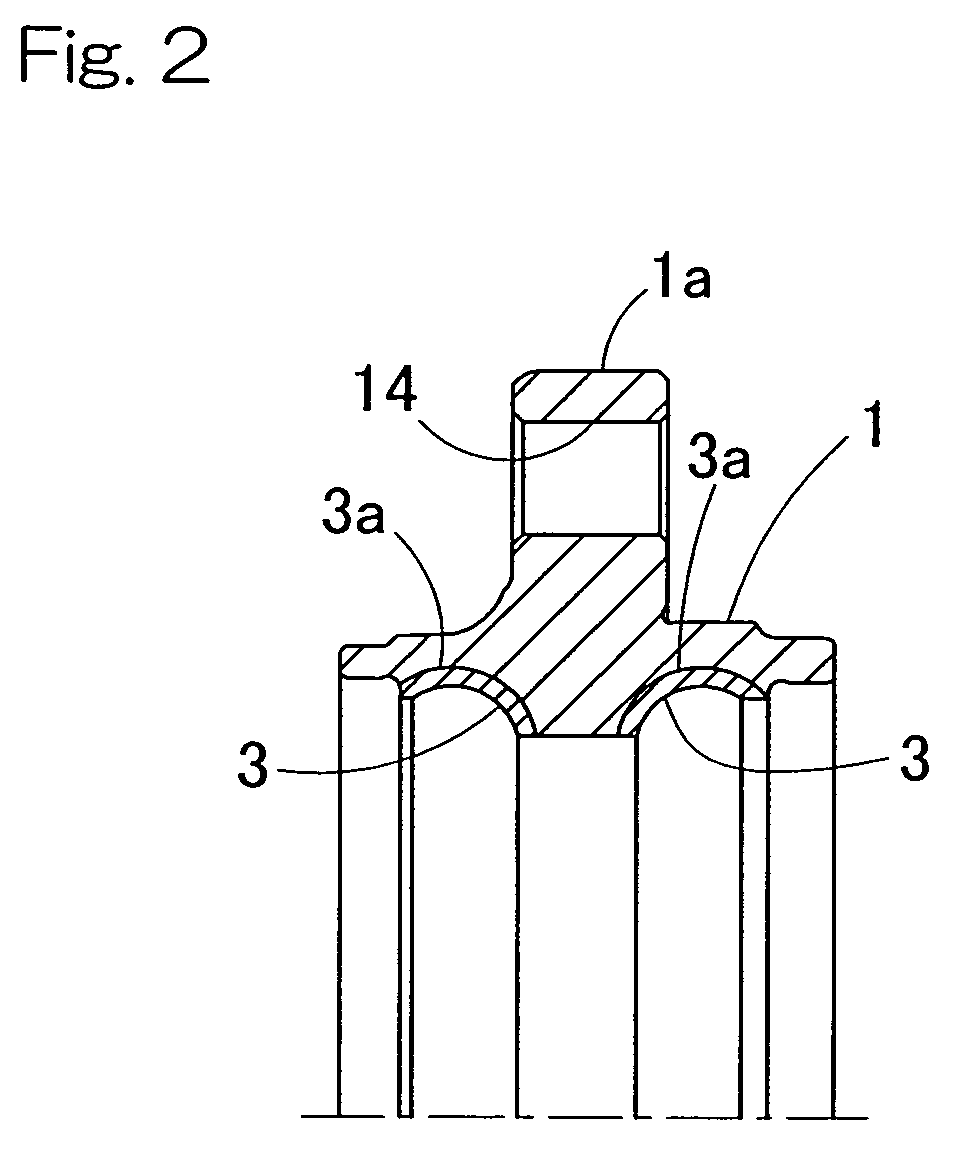

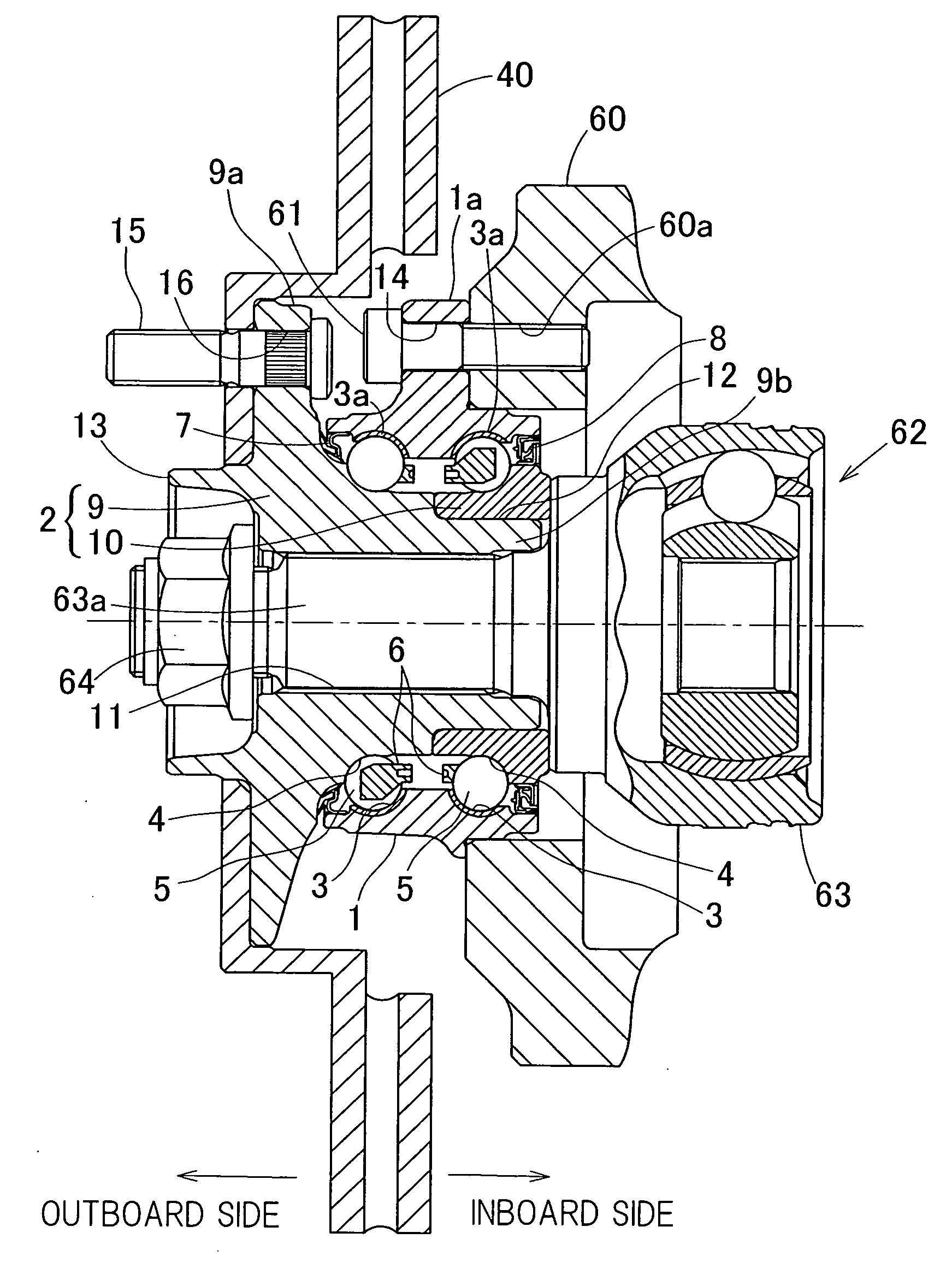

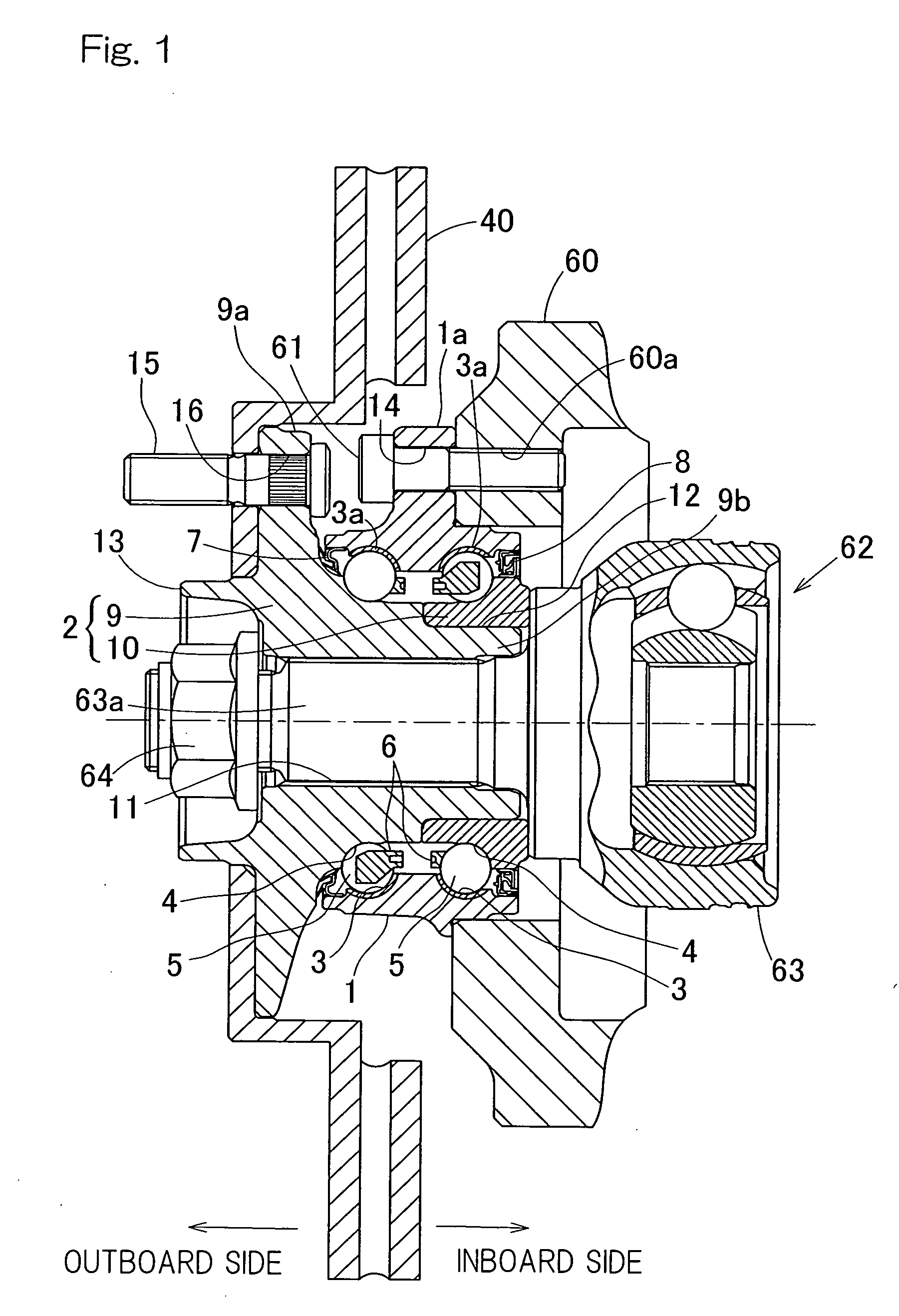

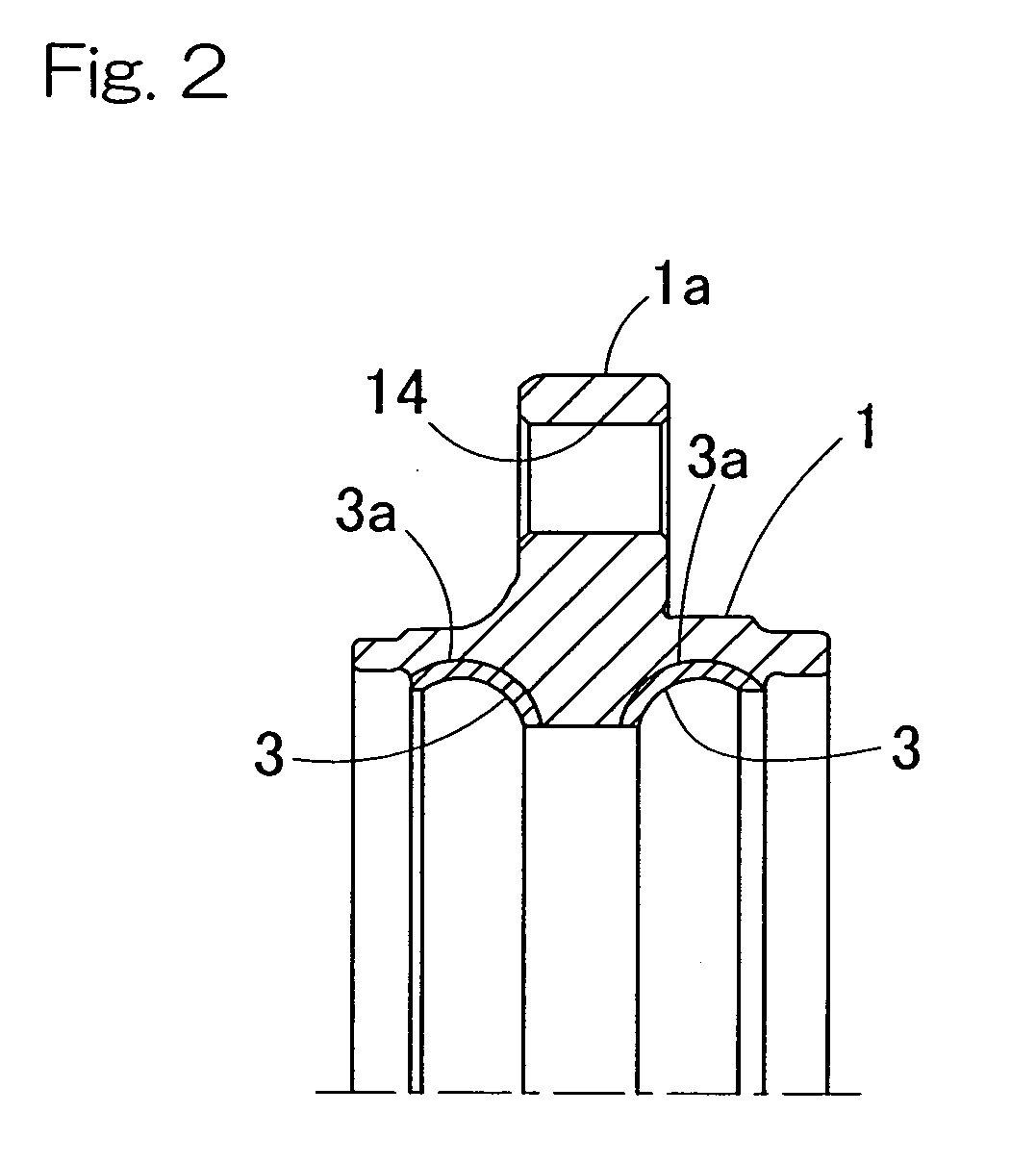

Wheel support bearing assembly

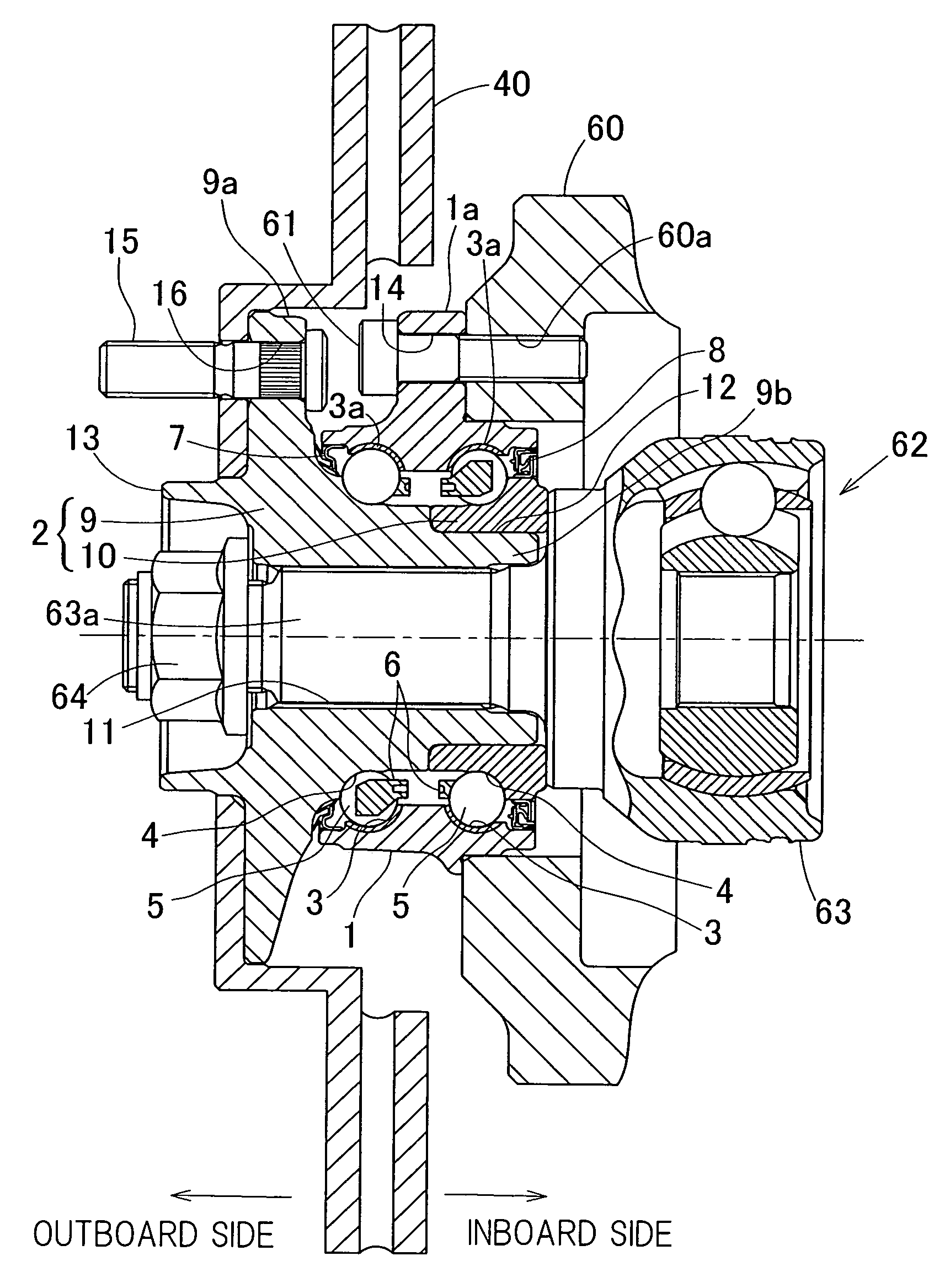

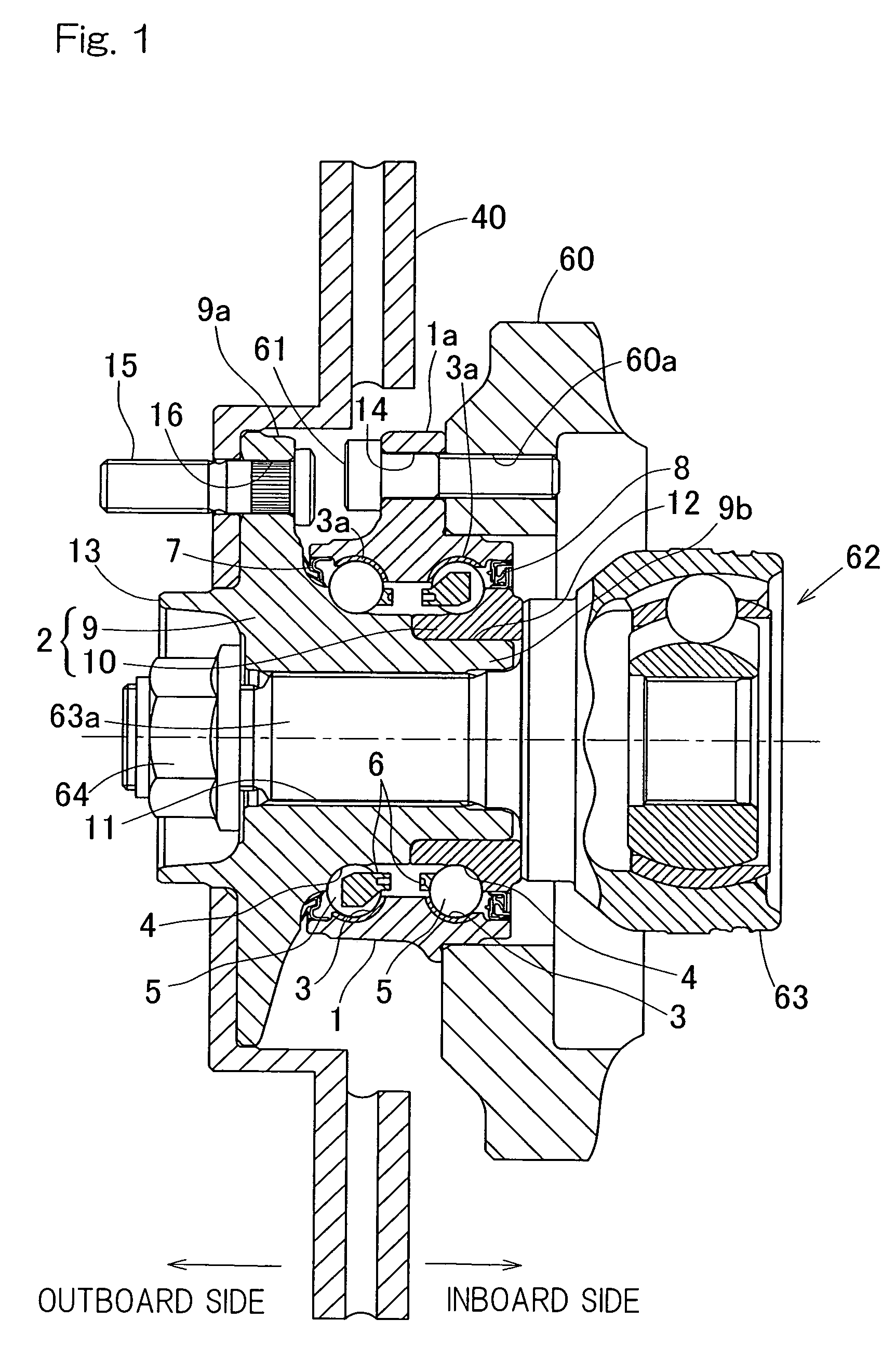

A wheel support bearing assembly includes an outer member (1), which serves as a stationary member and has an inner periphery formed with a plurality of rows of raceway surfaces (3), an inner member (2), which serves as a rotatable member and has an outer periphery formed with respective raceway surfaces (4) opposed to the previously described raceway surfaces (3), and a plurality of rows of rolling elements (5) interposed between the respective opposed raceway surfaces (3, 4). The outer member (1) is thermally refined by means of a quenching and a high temperature tempering process so that a layer of at least 2 mm in depth from a surface of the outer member is rendered to have a micro-pearlite structure.

Owner:NTN CORP

Wheel support bearing assemble

A wheel support bearing assembly includes an outer member (1), which serves as a stationary member and has an inner periphery formed with a plurality of rows of raceway surfaces (3), an inner member (2), which serves as a rotatable member and has an outer periphery formed with respective raceway surfaces (4) opposed to the previously described raceway surfaces (3), and a plurality of rows of rolling elements (5) interposed between the respective opposed raceway surfaces (3, 4). The outer member (1) is thermally refined by means of a quenching and a high temperature tempering process so that a layer of at least 2 mm in depth from a surface of the outer member is rendered to have a micro-pearlite structure.

Owner:NTN CORP

Preparation method of modified rubber particles and application thereof, frost-resistant water-permeable concrete and application thereof, frost-resistant water-permeable brick and preparation method thereof

ActiveCN111233381AHigh compressive strengthImprove flexural strengthSolid waste managementSingle unit pavingsHydroxypropylmethyl celluloseBuilding material

The invention provides a preparation method of modified rubber particles and an application thereof, anti-freezing pervious concrete and an application thereof as well as an anti-freezing pervious brick and a preparation method thereof, which belong to the technical field of pervious building materials. The preparation method comprises the following steps: mixing rubber particles with a surface treating agent, and carrying out surface coating treatment to obtain rubber particles with surfaces coated with the surface treating agent; wherein the surface treating agent comprises the following components in parts by weight: 15-35 parts of water glass, 2-6 parts of silicon phosphate, 50-75 parts of silica powder, 0.1-1 part of urea and 0.1-2 parts of hydroxypropyl methyl cellulose; and carryingout a curing reaction on the rubber particles coated with the surface treating agent at 40-60 DEG C for 1-3 hours to obtain the modified rubber particles. When the obtained modified rubber particlesare used for preparing the frost-resistant water-permeable concrete, the modified rubber particles are high in binding force with other components of the concrete, and the prepared frost-resistant water permeable brick is good in water permeability, high in strength and excellent in frost resistance.

Owner:JILIN UNIV

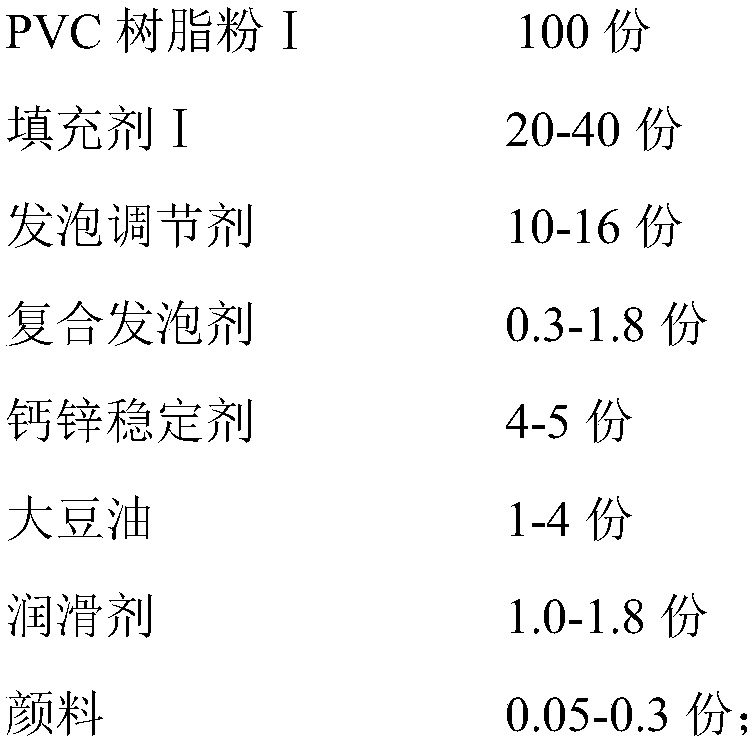

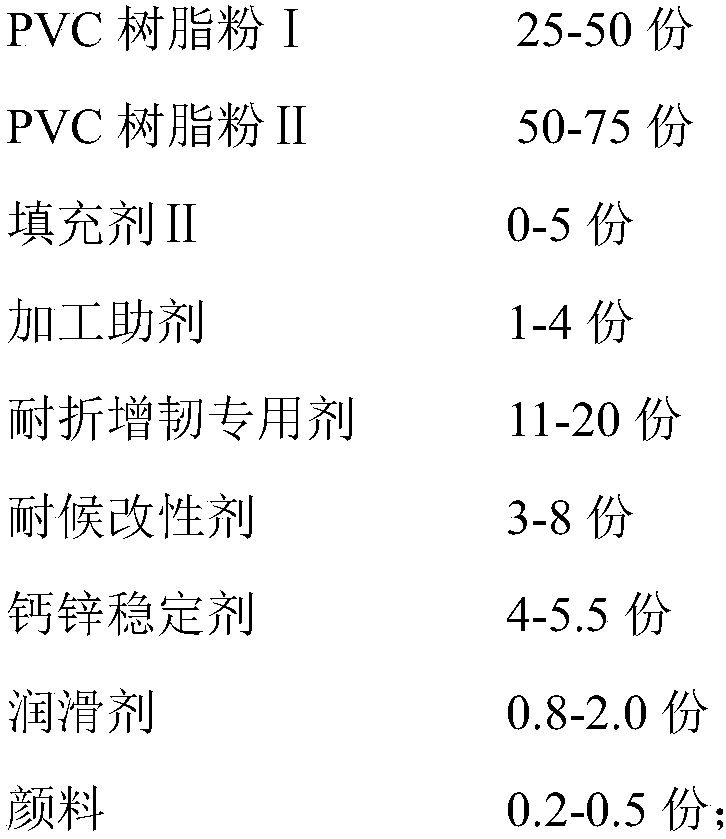

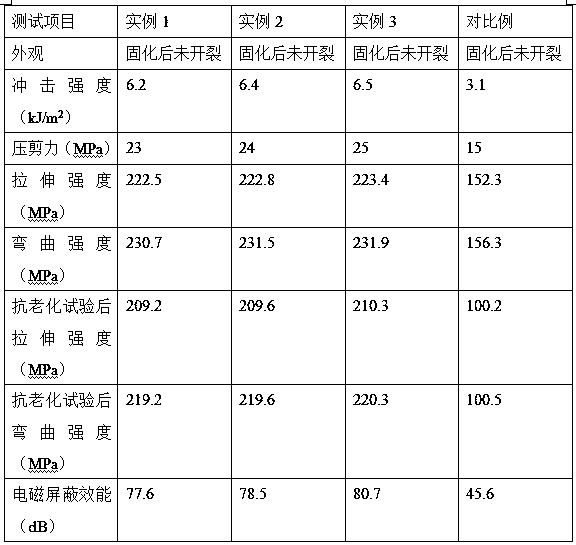

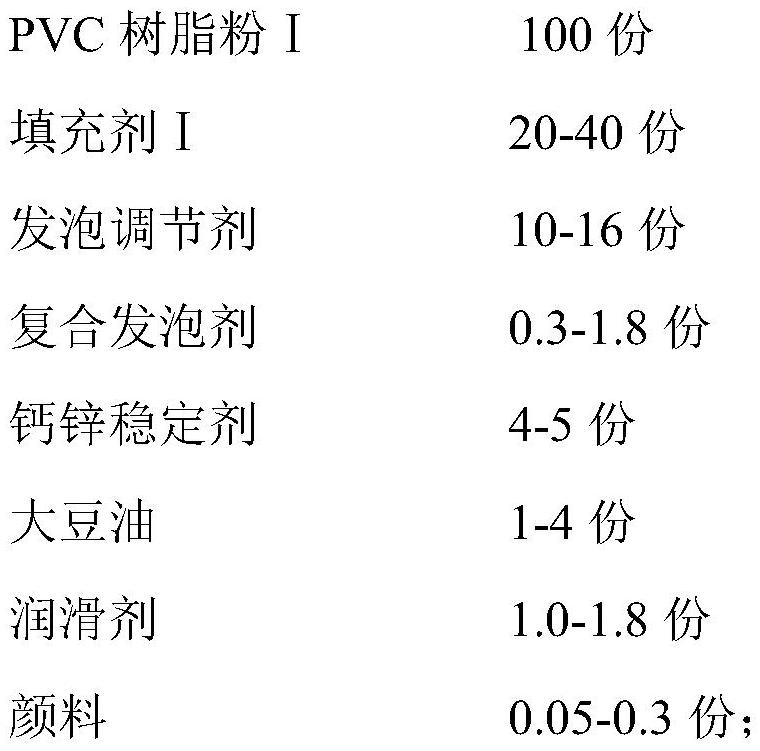

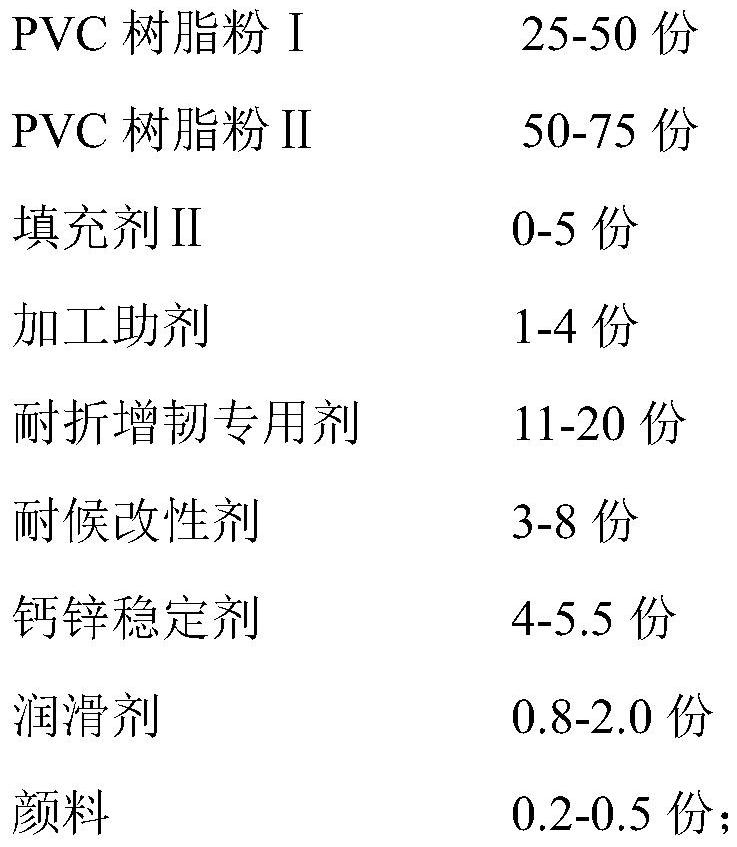

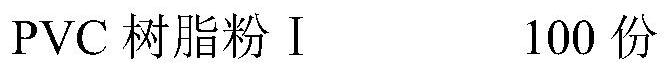

PVC foamed fold-proof plate and preparation method thereof

ActiveCN109591419AImprove liquidityFine foamSynthetic resin layered productsPolymer sciencePolyvinyl chloride

The invention belongs to the technical field of polyvinyl chloride plates, and particularly relates to a PVC foamed fold-proof plate and a preparation method thereof. The PVC foamed fold-proof plate comprises a core layer and surface layers, wherein the core layer is made from a foamed PVC material, and is prepared from PVC resin powder I, filler I, foaming regulator, compound foaming agent, calcium-zinc stabilizer, soybean oil, a lubricating agent and pigment; the upper surface layer and the lower surface layer are made of same raw materials; the surface layer is prepared from PVC resin powder I, PVC resin powder II, filler II, a processing aid, a fold-proof toughening specific agent, a weather-resistant modifying agent, calium-zinc stabilizer, a lubricating agent and pigment; and the fold-proof toughening specific agent is high-molecular-weight chlorinated polyethylene acrylate grafted polymer. The PVC foamed fold-proof plate has the advantages of high strength, pulling and folding resistance, surface cracking prevention, large-angle fold use availability and no mark, few combined joint and joint surface of the composition, environmental friendliness, sanitation, convenience in cleaning, high cost performance and wide application range.

Owner:SHANDONG BODO PLASTICS CO LTD

Preparation method of toughened and anti-aging unsaturated polyester resin

InactiveCN108948705AHigh bonding strengthImprove adhesionBuilding insulationsUltraviolet lightsCarbon nanotube

The invention discloses a preparation method of toughened and anti-aging unsaturated polyester resin which belongs to the technical field of resin preparation. In the preparation method, a hydroxyl condensation dehydration reaction is produced on epoxidized soybean oil and acrylate ester to form a network interpenetrating cross-linking structure; the epoxidized soybean oil contains a polar group and an active group such as an epoxy group, an ether bond and a hydroxyl group to make an acrylate glue solution exhibit excellent bonding strength; the epoxidized soybean oil in an acrylate emulsion has strong anti-oxidation performance, and can promote curing cross-linking of polyester resin, and at the same time, the phenomenon of aging and yellowing of the polyester resin can be reduced; carbonnanotubes are utilized as electron acceptors, and easily accept photogenerated electrons produced by titanium dioxide, thereby effectively suppressing recombination of the photogenerated electrons and holes, the absorption of ultraviolet light by titanium dioxide is increased; and the photocatalysis of the titanium dioxide can reinforces degradation and volatilization of organic solvents in polyester resin to accelerate curing of polyester resin. The toughened and anti-aging unsaturated polyester resin has a wide application prospect.

Owner:翟琳

Fe base alloy having layer and method for production thereof

InactiveUS20070172693A1High hardnessHigh strengthSolid state diffusion coatingNatural mineral layered productsHardnessToughness

On respective surfaces of the work pressing site and the body part of the portion having a less diameter of a preliminary formed article comprising SKH51 (a Fe base alloy), a powder of a material containing an element enhancing the hardness of SKH51 and a powder of a material containing an element being contained in SKH51 and not enhancing the hardness of SKH51 are applied respectively. By the heat treatment of the preliminary formed article after the above application, W and the like having been contained in an application agent is diffused into the surface side in the work pressing site, whereas, in the body part of the portion having a less diameter, W and the like having been contained in SKH51 is diffused into the surface side. As a result, a diffusion layer, wherein hardness increases as the distance from the surface decreases, is formed inside the work pressing site, and simultaneously, a concentration change portion, wherein toughness improves as the distance from the surface decreases, is formed in the body part of the portion having a less diameter.

Owner:HONDA MOTOR CO LTD

High-strength-and-ductility gray pig iron surface tissue form heating power reconstruction method

The invention discloses a high-strength-and-ductility gray pig iron surface tissue form heating power reconstruction method, and relates to metal material surface modification. The method mainly comprises the steps of gray pig iron surface magnetic control forced cooling laser fusion, laser shock and follow-up graphitization annealing treatment. Firstly, laser radiation is carried out to enable the gray pig iron surface to generate quick fusion under the action of a magnetic field, forced cooling solidification is carried out, and the wee surface white tissue is formed; secondly, laser shock is adopted for treating the gray pig iron surface obtained after laser fusion, the stress state of a fusion layer is changed, the white tissue on the surface layer is further refined, the tissue defectis increased, and tissue preparation is made of graphitization annealing; and finally, graphitization annealing is carried out to enable cementite in the surface refined whit tissue to be converted into wee spheroidal graphite, and the high-strength-and-ductility surface tissue form is prepared. By means of the method, the gray pig iron surface tissue form can be effectively improved, the graphitization time is shortened, and the surface obdurability is obviously improved. The high-strength-and-ductility gray pig iron surface tissue form heating power reconstruction method is simple in process procedure, easy to operate and suitable for large-scale batched production.

Owner:JIANGSU UNIV

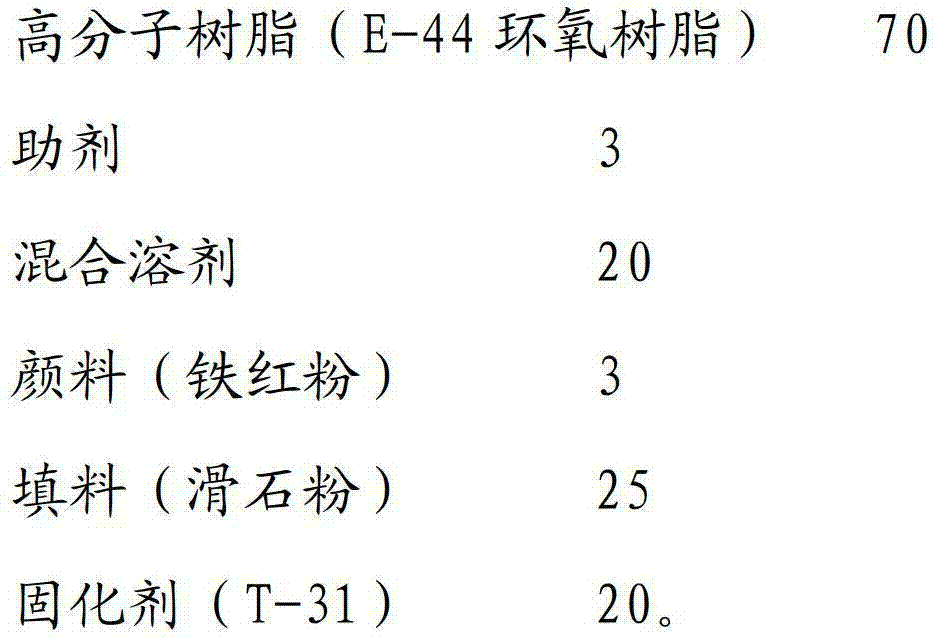

Metal anticorrosive material, and preparation method thereof

InactiveCN107099222AGood leveling performanceGood surface toughnessAnti-corrosive paintsEpoxy resin coatingsSolventMetal

The invention provides a metal anticorrosive material, and a preparation method thereof, and belongs to the field of anticorrosive material. The metal anticorrosive material comprises following raw materials, by weight, 70 to 80 parts of epoxy resin, 20 to 30 parts of a mixed solvent, 0.5 to 3 parts of a flexibilizer, 0.2 to 0.5 part of an antifoaming agent, 4 to 16 parts of a phenolic amine epoxy hardener, 1.2 to 3.2 parts of an anti-aging agent, 0.1 to 1.5 parts of an anti-oxidant, 0.1 to 0.8 part of a lubricant, 0.5 to 1.3 parts of a thixotropic agent, 1 to 3 parts of a pigment, and 15 to 25 parts of a filling material. The preparation method comprises following steps: 1, raw material weighing; 2, dissolving; 3, blending; 4, defoaming; and 5, impurity removing. The metal anticorrosive material is excellent in levelability, thixotropy, and impervious performance, high in surface toughness and adhesive force, is more friendly to the environment, is longer in service life; and no pin hole is formed.

Owner:合肥市晨雷思建筑材料科技有限公司

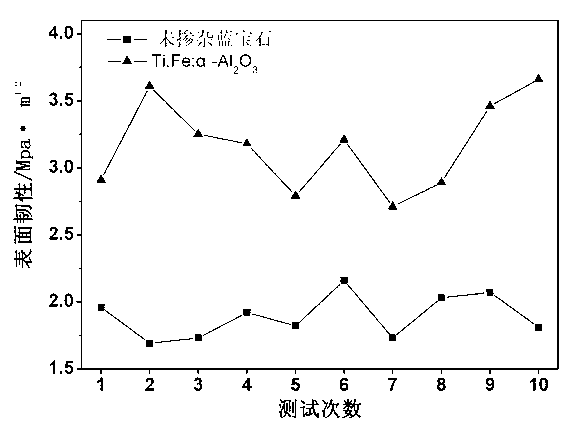

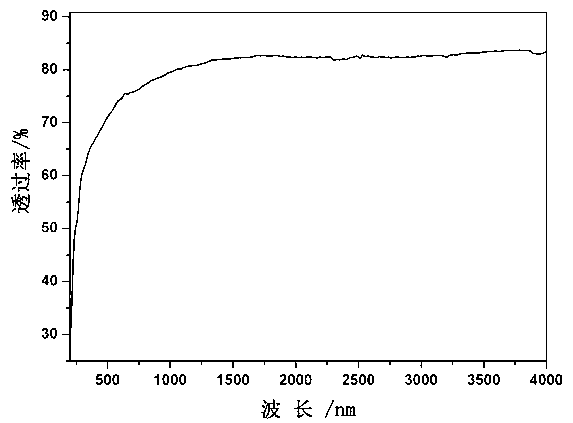

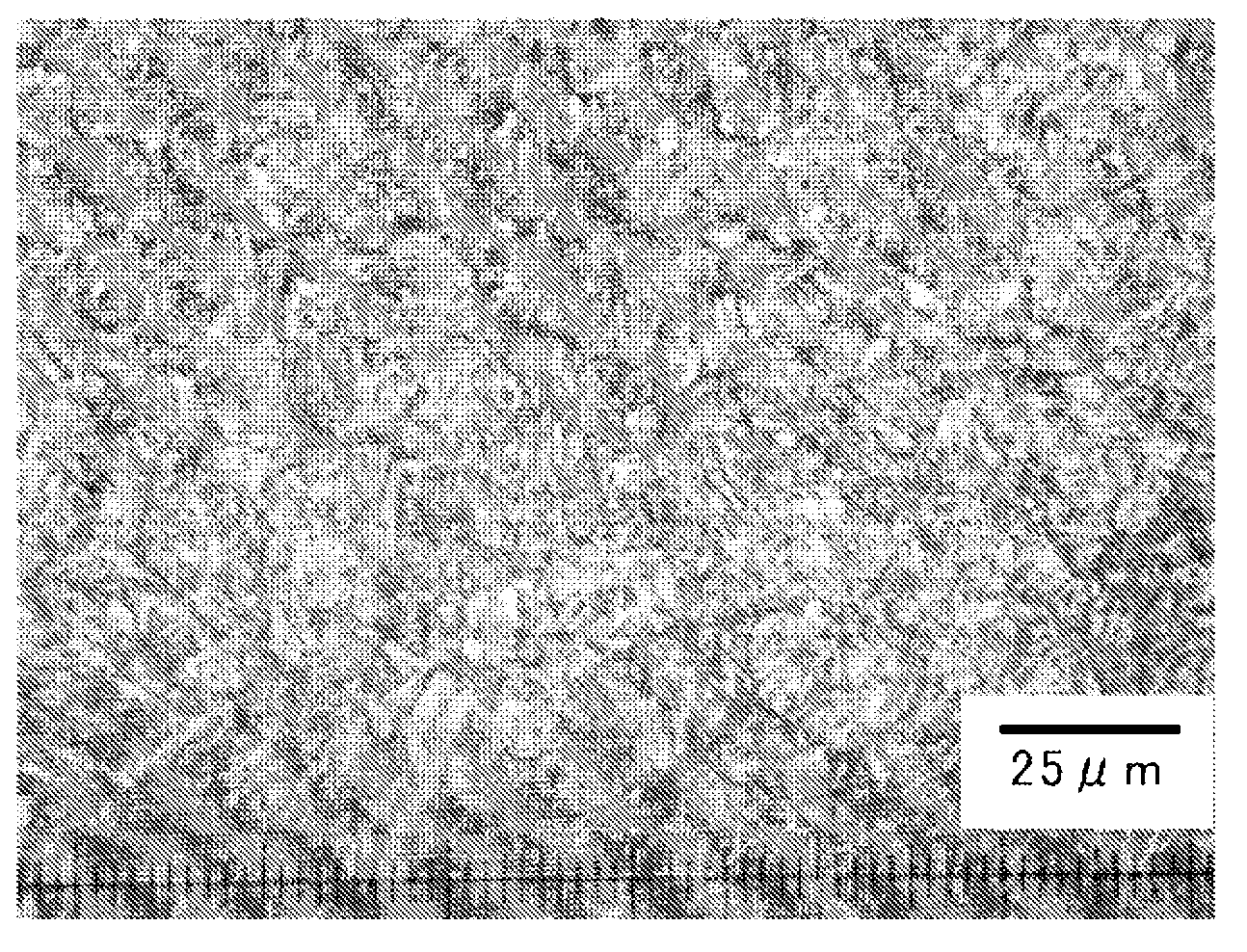

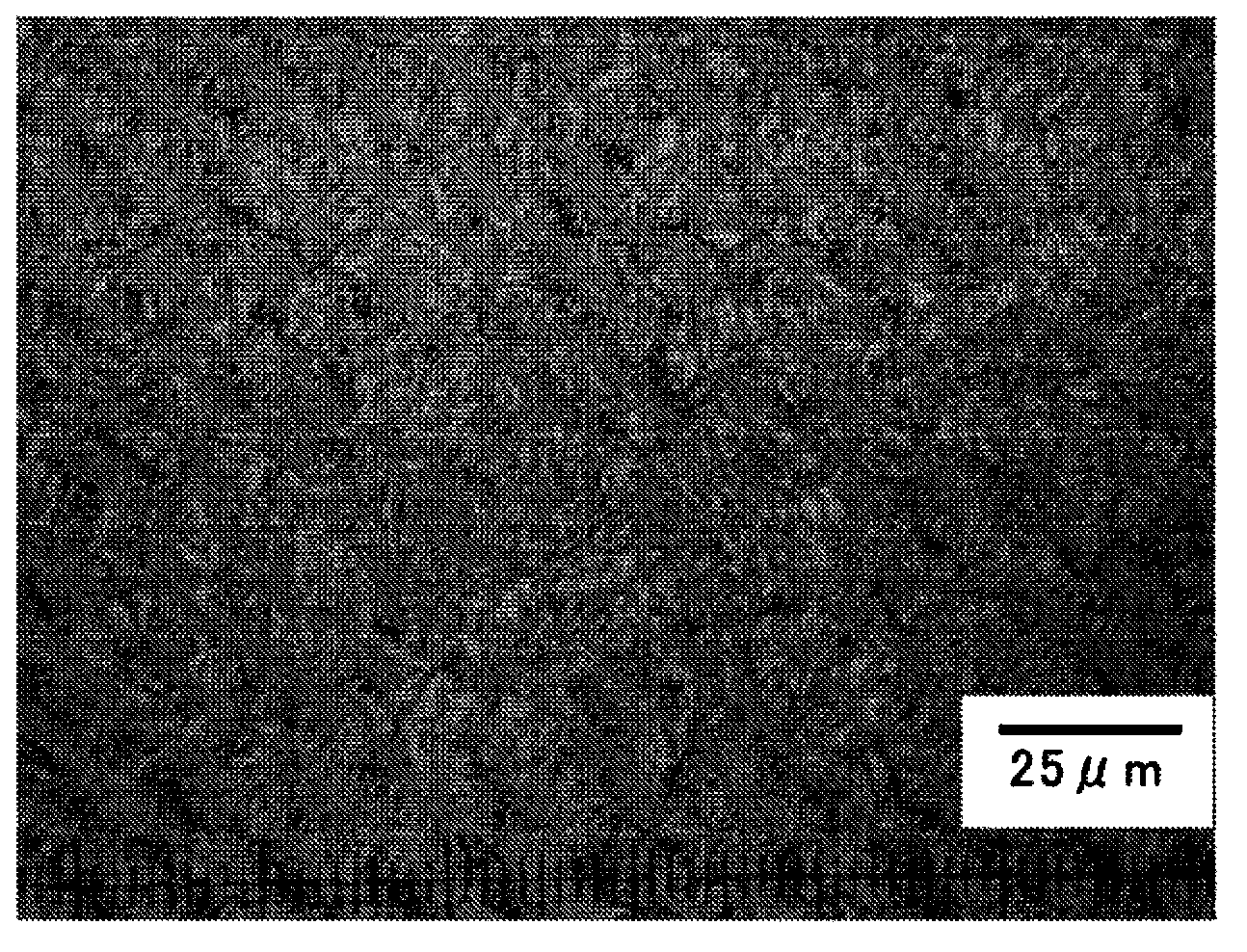

Star sapphire wafer and preparation method thereof

InactiveCN103014857AImprove surface toughnessStrong damage to spectral transmission performancePolycrystalline material growthBy pulling from meltWaferingTitanium ion

The invention discloses a star sapphire wafer and a preparation method of the star sapphire wafer. Second phase sediment is formed as a star on a surface of a mode guiding method titanium-doped sapphire wafer after the mode guiding method titanium-doped sapphire wafer is thermally treated, so that needle-shaped sediment can be found under an optical microscope. The preparation method comprises the following steps of: firstly, using the mode guiding method to grow and obtain the titanium-doped sapphire wafer, subsequently treating the wafer by using a series of aerobic thermal treatment methods to obtain the star sapphire wafer in the following sub steps of firstly aerobically annealing at a high temperature and uniformly oxidizing titanium ions to tetravalent colorless titanium ions, then cooling to a low temperature near at 1000 DEG C, insulating and nucleating the sediment phase in the wafer, subsequently heating to a sediment phase development temperature, insulating and forming as a star to prepare the star sapphire wafer. The star sapphire wafer disclosed by the invention is even and transparent, so that the flashing needle-shaped sediment can be founded under the optical microscope; and the wafer has the advantages of higher surface breaking tenacity and stable mechanical property.

Owner:苏州巍迩光电科技有限公司

Heat-resisting and anti-corrosion material and preparation method thereof

InactiveCN105001761AImprove the level ofImprove surface toughnessAnti-corrosive paintsEpoxy resin coatingsBenzoic acidPropionate

The invention provides a heat-resisting and anti-corrosion material. The heat-resisting and anti-corrosion material is composed of, by weight, 50-60 parts of high-molecular resin, 3-5 parts of auxiliaries, 10-15 parts of mixed solvent, 3-5 parts of benzoic acid, 4-6 parts of chitosan, 8-12 parts of sodium diacetate, 10-12 parts of calcium propionate, 2-4 parts of pigment, 10-15 parts of filler, 10-20 parts of curing agent and 6-8 parts of water. The heat-resisting and anti-corrosion material is high in adhesive force, high in solidification, environmentally friendly and economical and has a good heat-resisting effect.

Owner:HEFEI ZHONGHAO NEW MATERIAL CO LTD

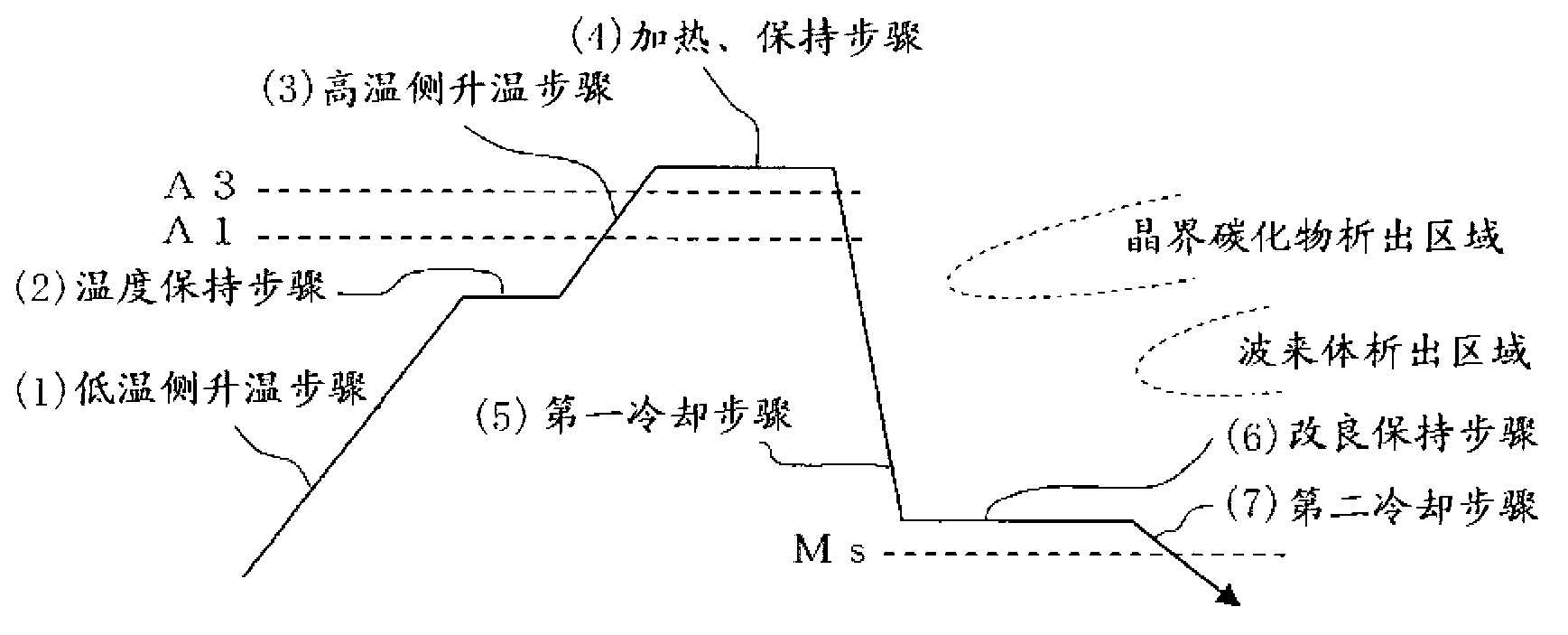

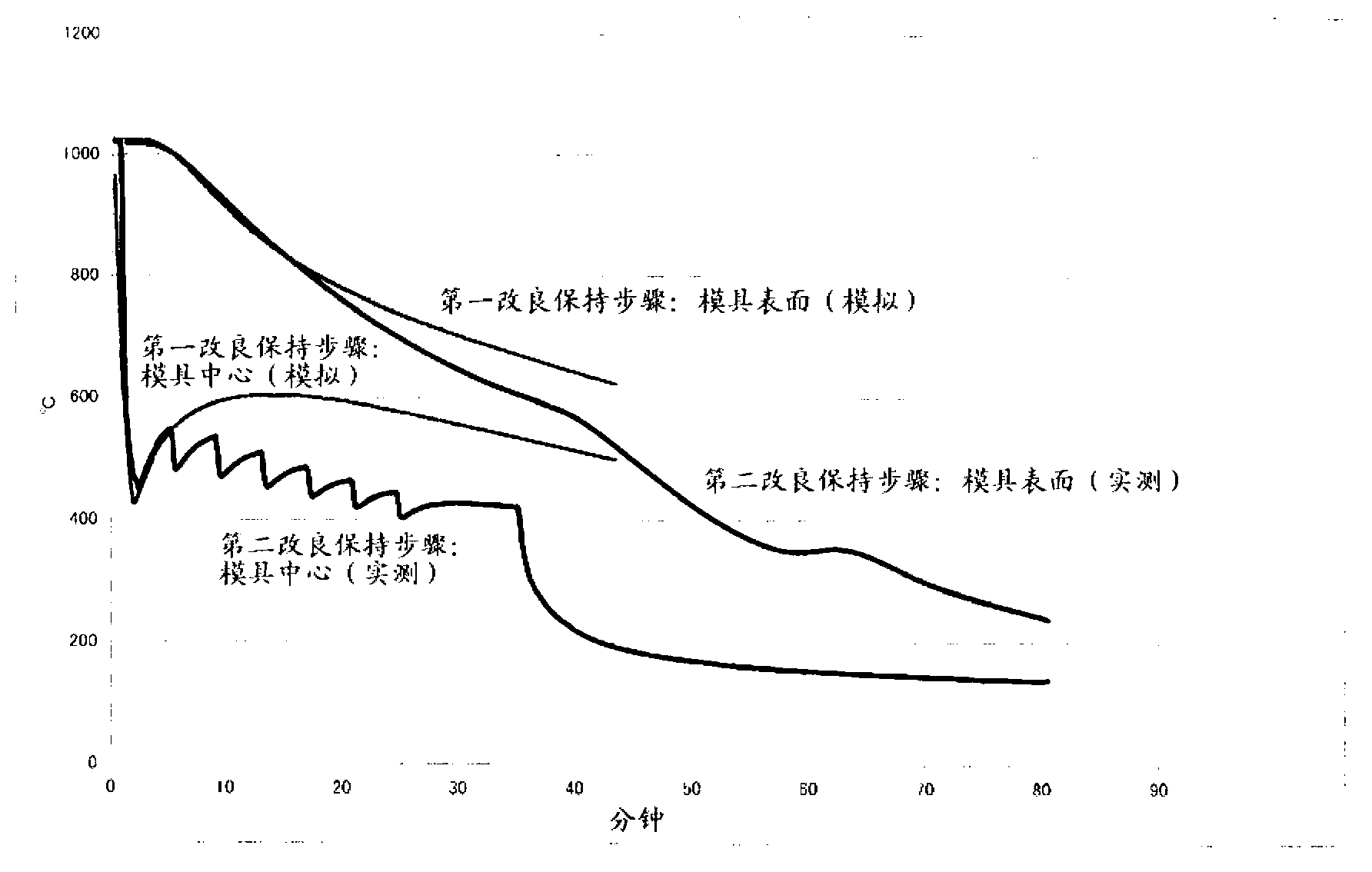

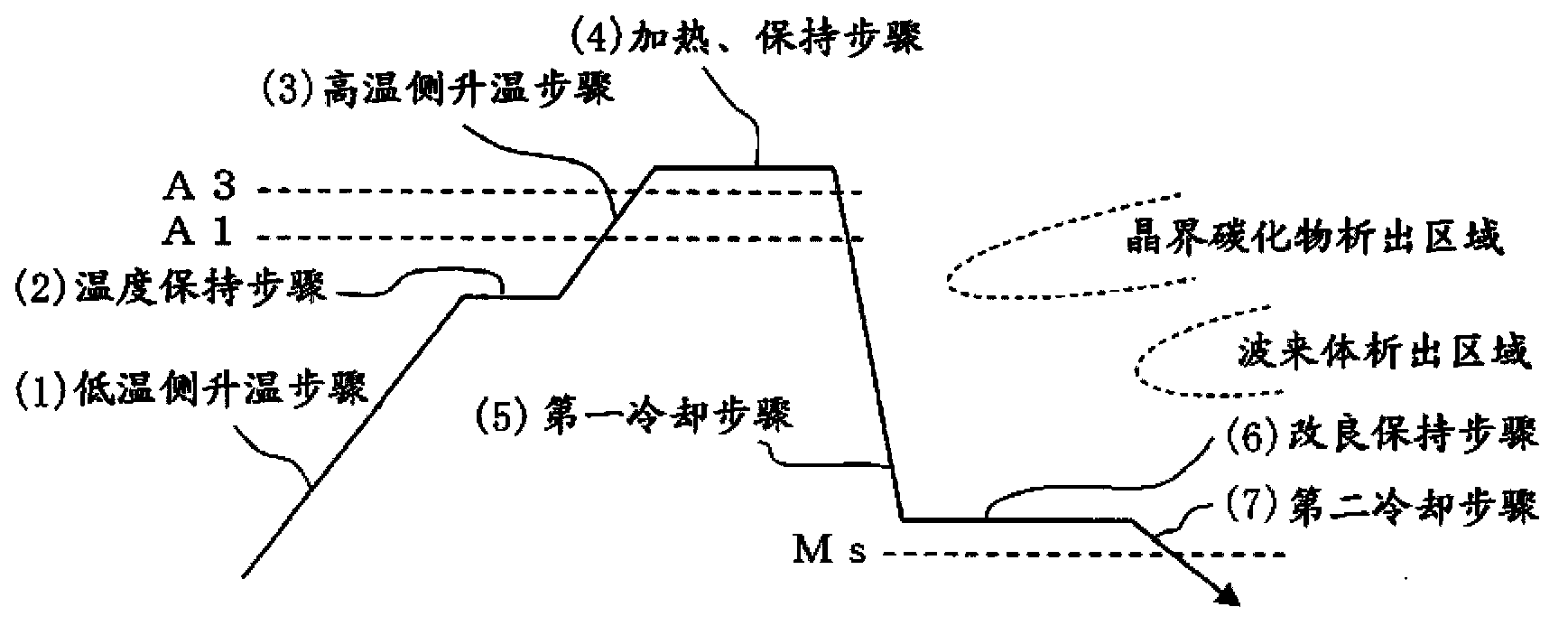

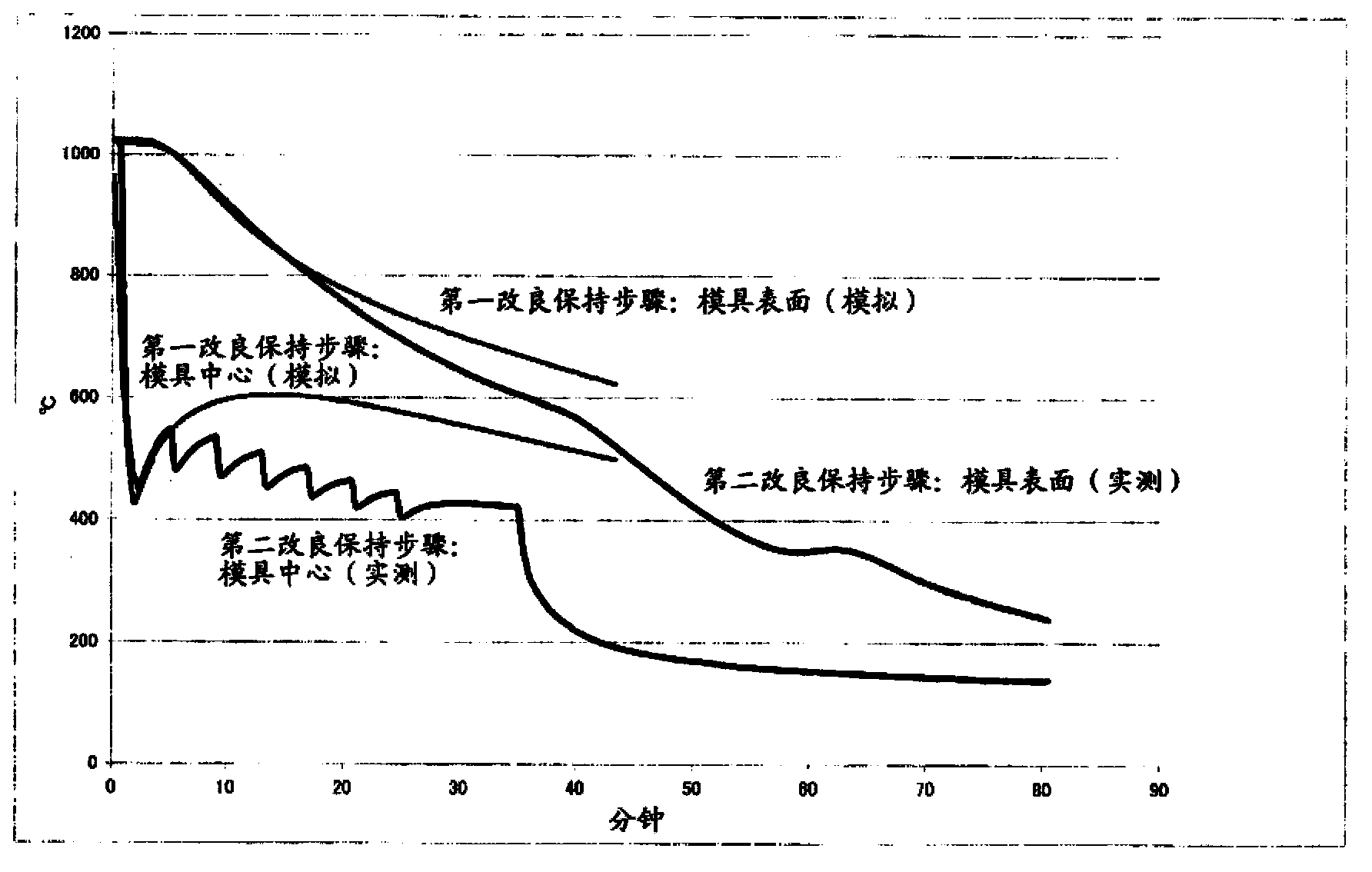

Method for quenching mold

ActiveCN103228802AImprove surface toughnessExtend your lifeFurnace typesQuenching agentsOil coolingMaterials science

A method for quenching a mold, comprising: a heating / retention step of heating the mold and retaining the mold at a temperature which is equal to or higher than an A3 transformation point and lower than 1150 DEG C; a first cooling step of, subsequent to the heating / retention step, immersing the mold in an oil vessel to cool the mold by oil cooling until the surface of the mold has a temperature which is equal to or lower than 700 DEG C and higher than an Ms point; an improved retention step of, subsequent to the first cooling step, pulling the mold out of the oil vessel to interrupt the oil cooling and retaining the mold until the surface of the mold has a temperature range which is higher than the Ms point and lower than the temperature at which the difference between the temperature of the surface of the mold and the temperature of the inside of the mold falls within 200 DEG C; and a second cooling step of, subsequent to the improved retention step, cooling the mold at a cooling rate of 1-50 DEG C / min until the surface of the mold has a temperature of 200 DEG C.

Owner:HITACHI METALS LTD +1

Fiber marble paint and preparation method thereof

The invention discloses fiber marble paint which is composed of the following raw materials by weight: 110-120 parts of silicone-acrylic emulsion, 4-6 parts of hydroxyethyl cellulose, 2-3 parts of dodecyl mercaptan, 0.1-0.3 part of tributyltin trichloride, 0.8-1 part of diacetone acrylamide, 5-7 parts of glass fiber, 0.4-1 part of 2-mercaptobenzimidazole, 2-4 parts of octyl epoxy stearate, 10-13 parts of bentonite and 2-3 parts of aluminum stearate, the bentonite is treated by cellulose, the surface toughness of the bentonite is effectively improved, then by surface treatment, the surface activity of the bentonite is improved, dispersion compatibility between the bentonite and the silicone-acrylic emulsion can be enhanced, and the uniform stability of a finished paint film can be improved.

Owner:张庆

High-brightness surface mirror resin for medium-hardness synthetic leather as well as preparation method and application of high-brightness surface mirror resin

InactiveCN109763349AImprove surface toughnessIncrease elasticitySynthetic resin layered productsTextiles and paperSolventChemistry

The invention relates to the technical field of leather, and discloses high-brightness surface mirror resin for medium-hardness synthetic leather. The resin is prepared from the following raw materials in parts by weight: 160-200 parts of resin, 3-5 parts of a curing agent, 5-9 parts of a solvent, 10-20 parts of a chain extender, 2-4 parts of a catalyst, 1-3 parts of aluminum powder and 2 5-10 parts of polymer diol. According to the high-brightness surface mirror resin for the medium-hardness synthetic leather, as well as a preparation method and an application of the high-brightness surface mirror resin, 160-200 parts of resin is put in a reactor, heated to 150-200 DEG C and stirred for 3-10 minutes, 1-3 parts of aluminum powder, 2-4 parts of catalyst and 5-10 parts of polymer diol are added, the high-brightness surface mirror resin prepared in claim 1 for the medium-hardness synthetic leather is heated to 60-70 DEG C, adhered to a PU resin layer and insulated for 10 minutes. A high-brightness layer prepared from the high-brightness surface mirror resin prepared in claim 1 for the medium-hardness synthetic leather has excellent elasticity and surface toughness and cannot be easilyscratched, and permanent indentation cannot be left during extrusion.

Owner:华大化学(安徽)有限公司

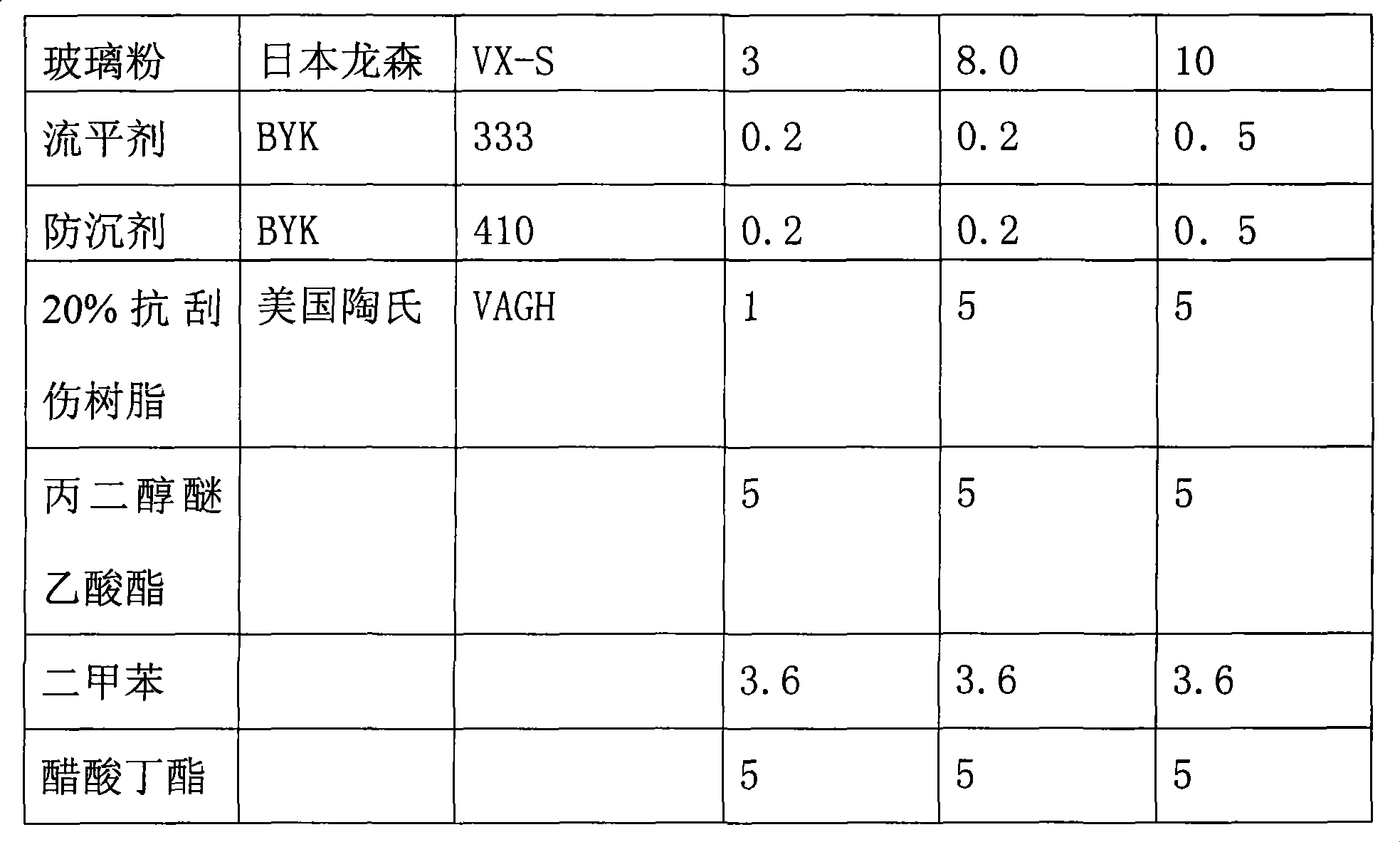

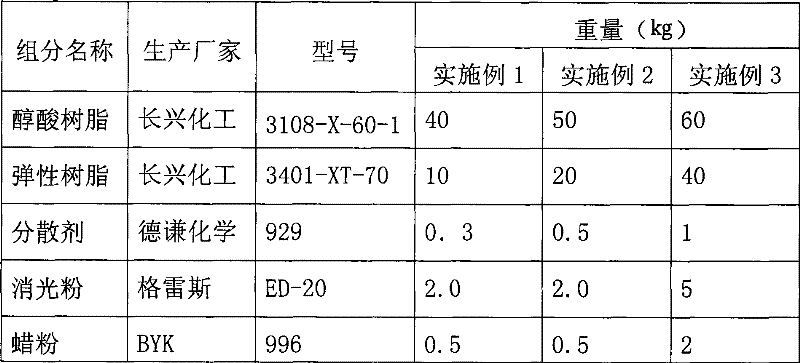

Polyurethane transparent matt topcoat, preparation method and use method thereof

ActiveCN101381581BFeel smoothGood flexibilityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxPolymer science

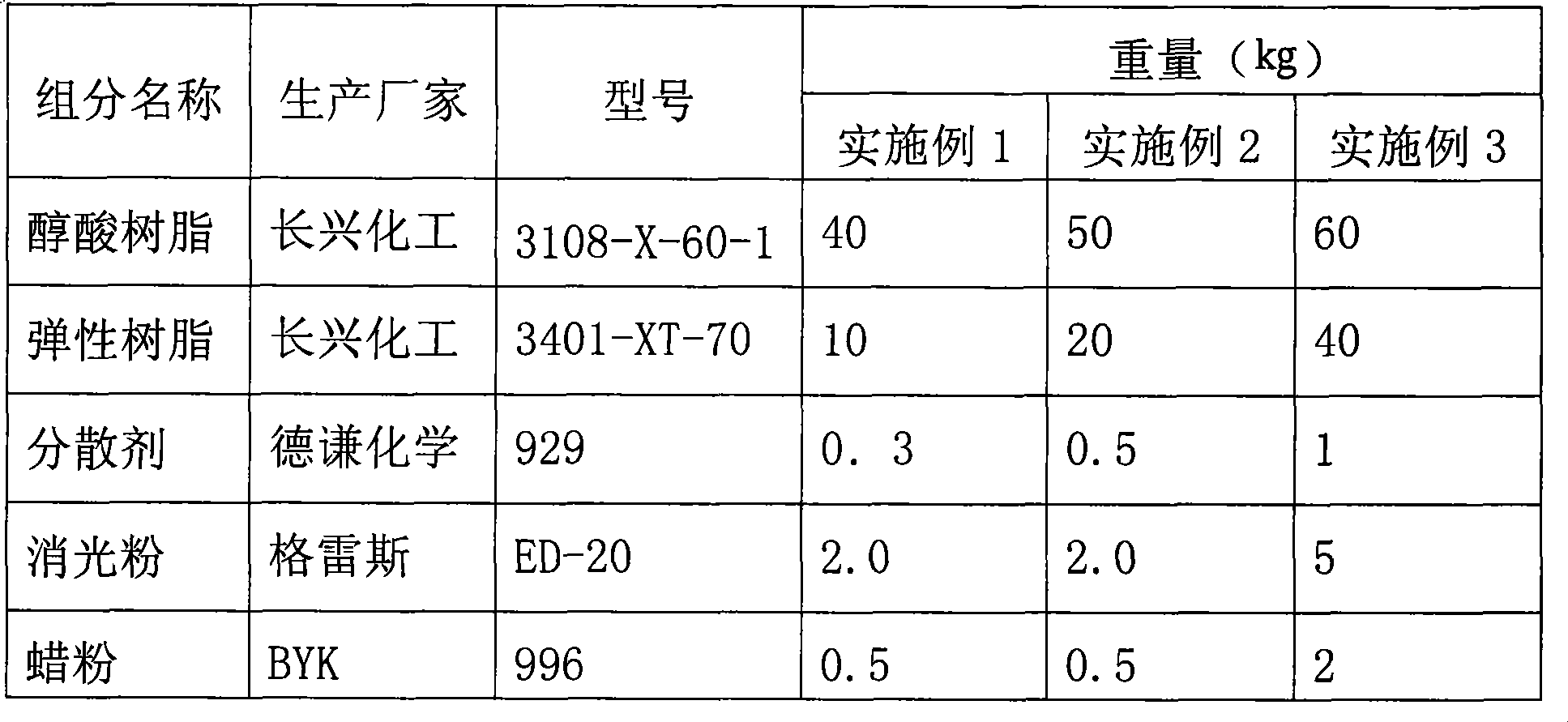

The invention relates to transparent matt polyurethane varnish. The preparation method of the varnish comprises the following steps: according to weight percentage, 40 to 60 percent of alkyd, 10 to 40 percent of elastic resin and 0.3 to 1.0 percent of a dispersant are sequentially added and are dispersed at the speed of 500 revolutions per minute for 3 to 5 minutes to evenness; while stirring, 2.0 to 5.0 percent of flatting powder, 3.0 to 10 percent of glass powder and 0.5 to 2.0 percent of wax powder are added and are dispersed for 15 minutes at the speed of 1,000 revolutions per minute tillthe fineness is less than or equal to 25 mu m; 0.2 to 0.5 percent of a leveling agent, 0.2 to 0.5 percent of an antisettling agent and 13.6 percent of a mixed solvent are sequentially added and are dispersed for 10 minutes at the speed of 800 revolutions per minute; 1.0 to 5.0 percent against 20 percent scratch resistant resin which is pre-dispersed is added into a varnish material obtained by the steps under the low-speed stirring; and after adding, the varnish material is dispersed for 10 to 15 minutes at the speed of 500 revolutions per minute to evenness and is filtered to obtain the transparent matt anti-scratch polyurethane varnish. The crosslinking density NCO / OH of the varnish and a curing agent is between 1.0 and 1.1; and the curing agent is mixed by the following compositions inweight percentage: 25 percent of aliphatic poly-isocyanate, 45 percent of aromatic poly-isocyanate and 30 percent of anhydrous butyl acetate. The varnish has good scratch resistance and high hardness; and a varnish film has smooth hand feeling, good transparence, does not blanch basically, has good storage stability and can be recoated.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

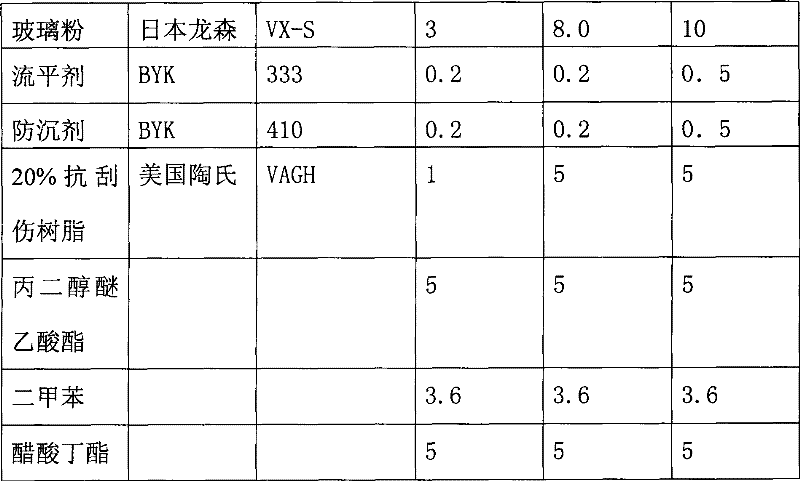

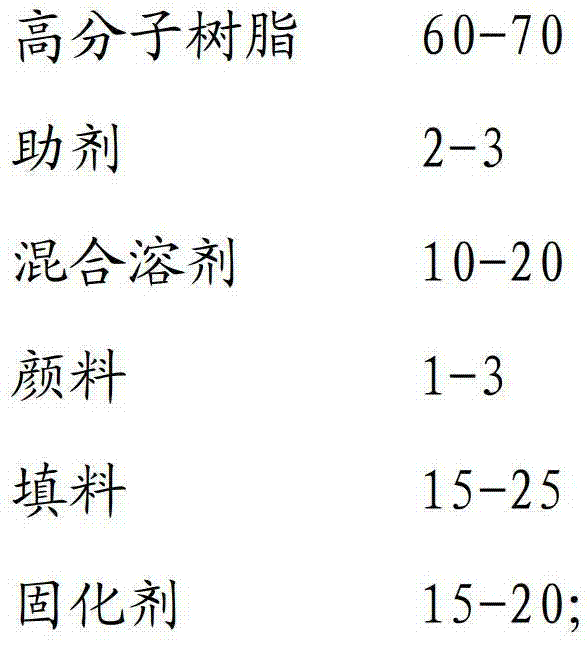

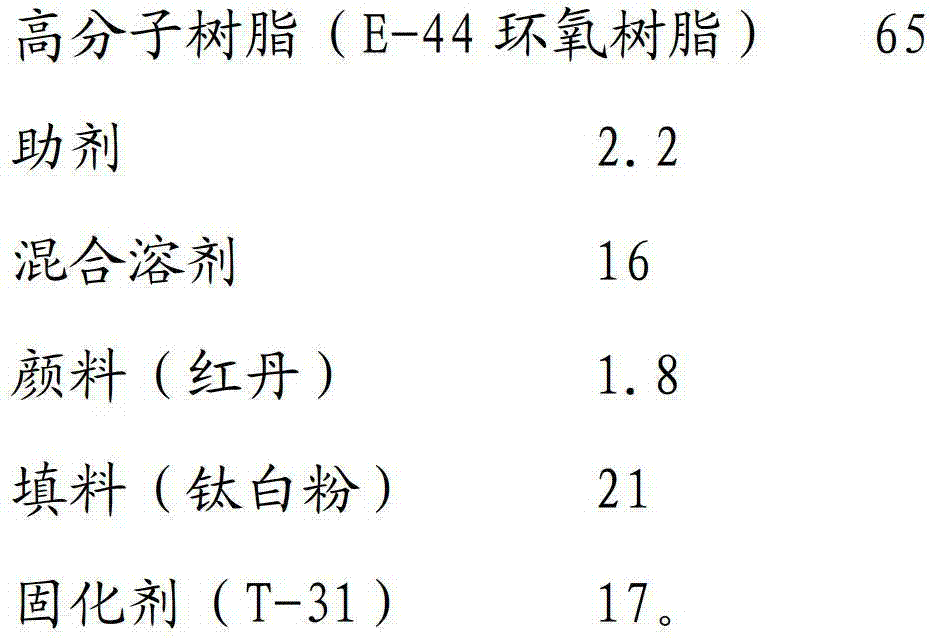

Anti-corrosion material and preparation method thereof

ActiveCN103184001BImprove the level ofImprove surface toughnessAnti-corrosive paintsEpoxy resin coatingsCross-linkMicrocrystalline wax

The invention discloses a corrosion-resistant material and a preparation method thereof. The corrosion-resistant material comprises raw materials in parts by weight as follows: 60 to 70 of a high molecule resin, 2 to 3 of an auxiliary, 10 to 20 of a mixed solvent, 1 to 3 of a pigment and 15 to 20 of a curing agent. The auxiliary is formed by mixing castor oil, dibutyl phthalate, a cross-linking agent CN-01 and petroleum microcrystalline wax in a weight ratio of 1: (0.8-1.2): (0.4-0.6): (0.4-0.6); and the mixed solvent is formed by ethanol, butanone and a dibasic ester (DBE) in a weight ratio of 1: (1.8-2.2): (6.5-7.5). According to the corrosion-resistant material and the preparation method thereof, the DBE and the petroleum microcrystalline wax which have unique characteristics are used, so that the corrosion-resistant material has the advantages of good leveling performance, pinhole freeness, good surface toughness, high adhesive force and curing degree, environmental protection and the like.

Owner:SHENZHEN CHENGGONG CHEM

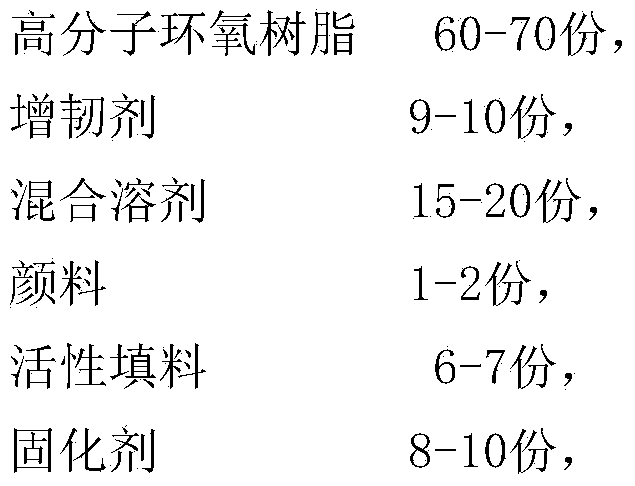

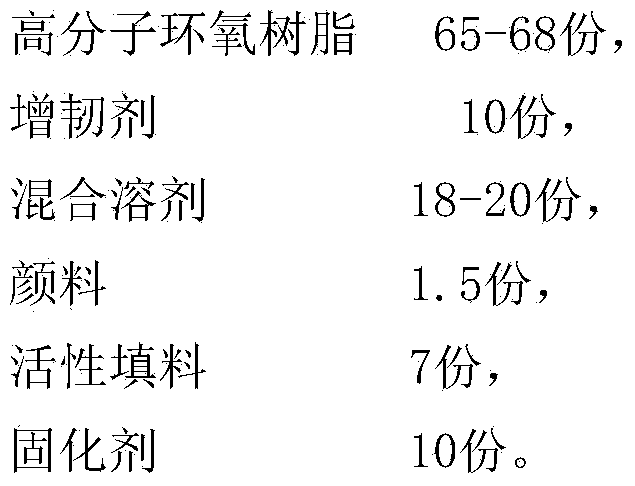

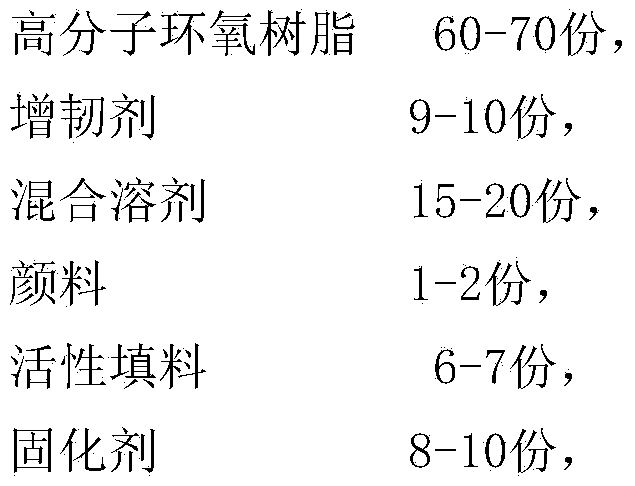

Concrete base wet-curing anticorrosive adhesive material and preparation method thereof

InactiveCN104178072AImprove the level ofImprove surface toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesSalt resistanceEpoxy

The invention relates to a concrete base wet-curing anticorrosive adhesive material and a preparation method thereof. The concrete base wet-curing anticorrosive adhesive material is prepared from a high-polymer epoxy resin, a toughener, a mixed solvent, a pigment, an active filler and a curing agent. The preparation method comprises the following steps: dissolving the high-polymer epoxy resin in the mixed solvent to obtain a mixture, sequentially adding the toughener, pigment and active filler into the mixture, carrying out ball milling to obtain a mixed slurry, carrying out vacuum degassing on the mixed slurry, and removing impurities to obtain the concrete base wet-curing anticorrosive adhesive material. The concrete base wet-curing anticorrosive adhesive material has the advantages of favorable leveling property, no pinhole, high adhesive force and high acid / alkali / salt resistance, and can still be brushed when the surface humidity of the concrete base is up to higher than 85%; when the adhesive material is brushed, the concrete component does not need to be completely dry; on the wet concrete surface, the adhesive material can be coated immediately after removal of shuttering; the adhesive material can also be brushed immediately after the underground water is pumped off or in light rain; and thus, the adhesive material saves time and labor, shortens the construction period, and is especially suitable for the concrete base in need of anticorrosive treatment, which does not allow long-term drying due to the construction period or when the underground water can easily upsurge.

Owner:SHANDONG HUALIN ANTI CORROSION TECH

Method for preparing photocatalyst dried polyester paint

InactiveCN108441091AHigh bonding strengthImprove adsorption capacityAntifouling/underwater paintsSiccativesPolyesterCarbon nanotube

The invention discloses a method for preparing photocatalyst dried polyester paint and belongs to the technical field of coating preparation. Epoxidized soybean oil in acrylate emulsion has strong oxidation resistance and can achieve an effect of promoting cured crosslinking of the polyester paint. A hydroxyl condensation dehydration reaction between the epoxidized soybean oil and acrylate is carried out so as to form a network interpenetrating crosslinked structure, the epoxidized soybean oil contains epoxy groups, ether bonds, hydroxyl and other polar groups and active groups and is combinedwith titanium dioxide to prepare photocatalyst dried powder, synergistic effects and photosensitization are achieved between carbon nano tubes and titanium dioxide molecules, the photocatalytic activity of the nano titanium dioxide can be improved, the photocatalytic efficiency is improved, degradation and volatilization of the titanium dioxide on polluting solvents can be enhanced, and a dryingeffect is achieved. Moreover, toxic and harmful gases in air such as formaldehyde can be effectively degraded, multiple types of bacteria can be effectively killed, and the polyester paint has deodorization property and anti-fouling performance and is wide in application prospects.

Owner:吴刚

Friction part having wear resistant coating and coating method therefor

ActiveUS20190177827A1Improve surface roughnessMinimizing frictional wearMolten spray coatingWear resistantWear resistance

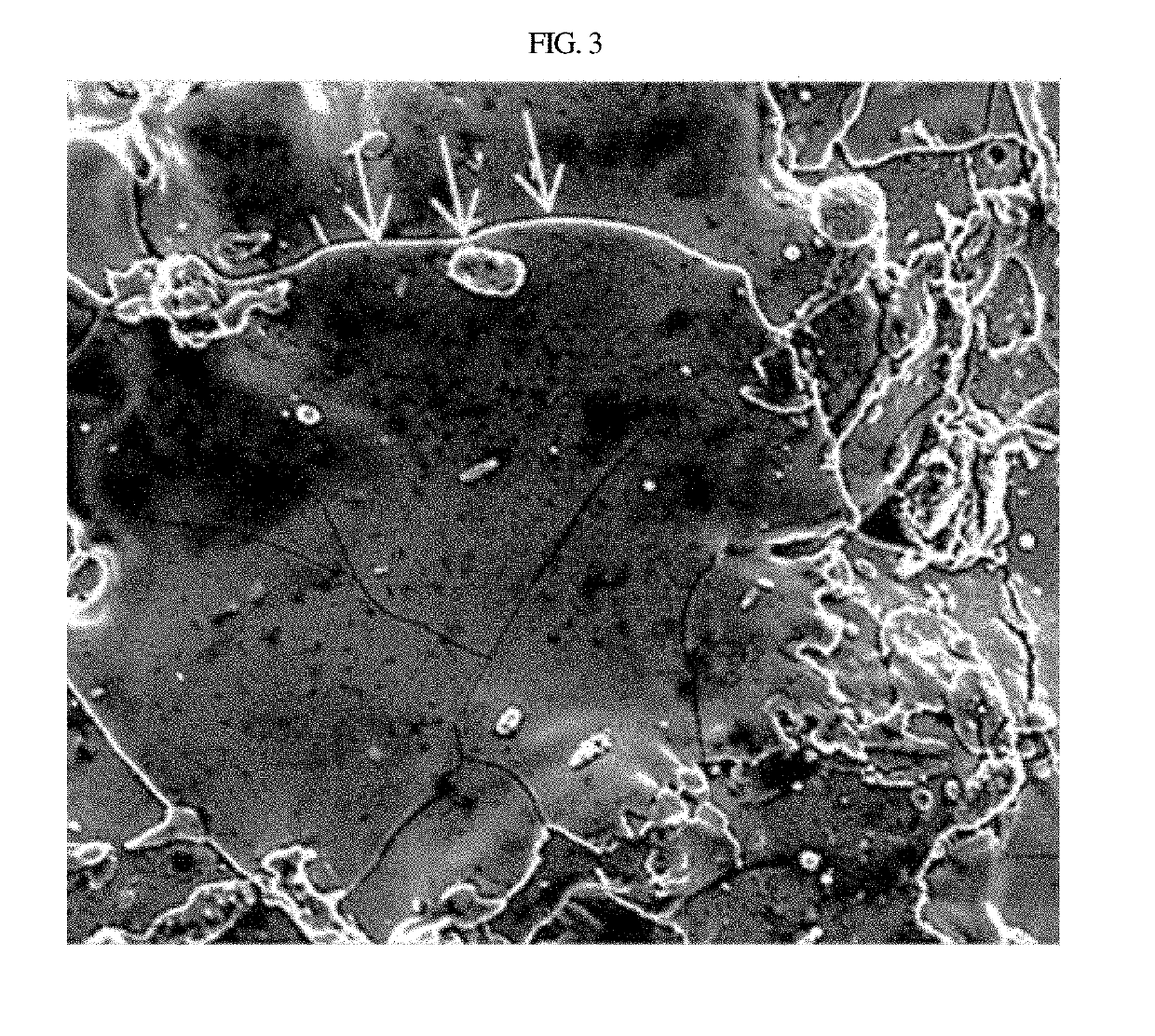

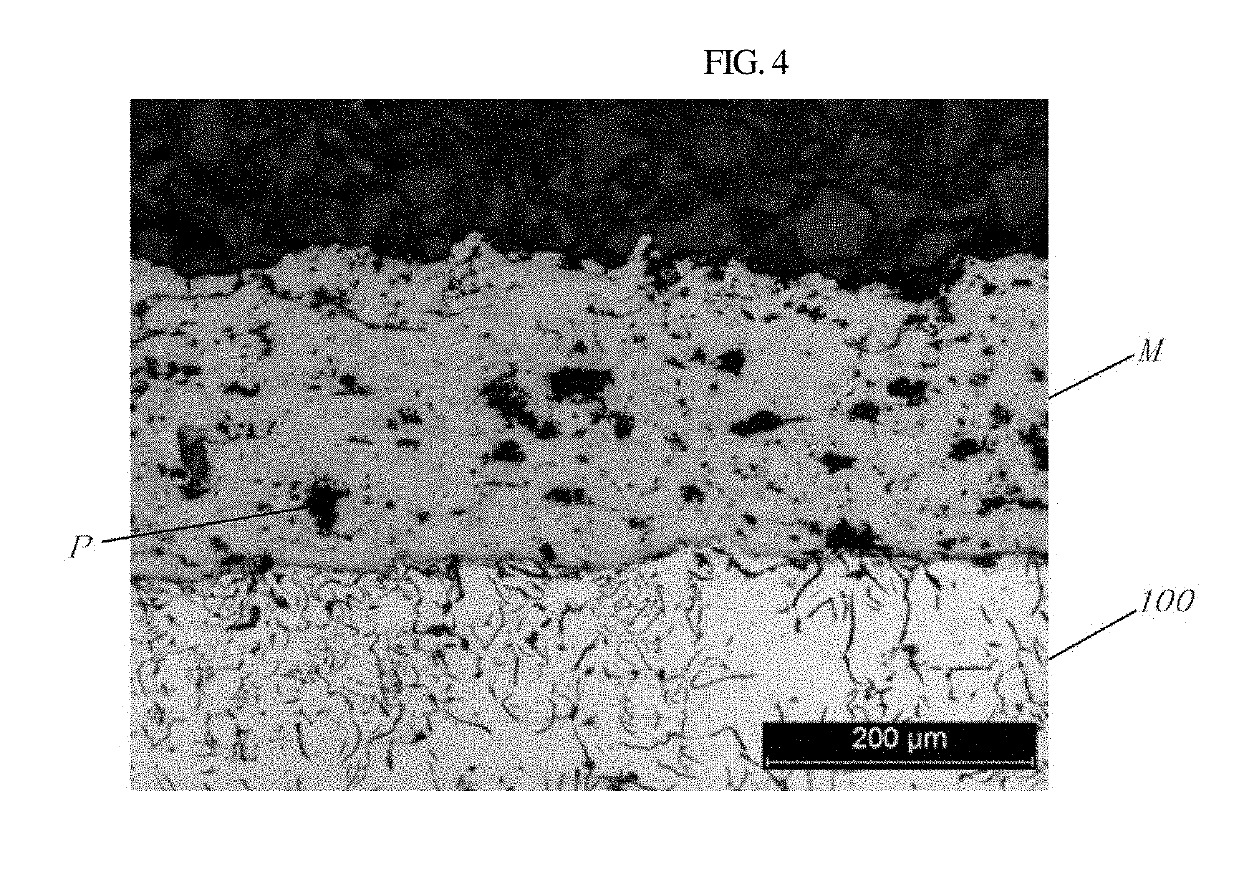

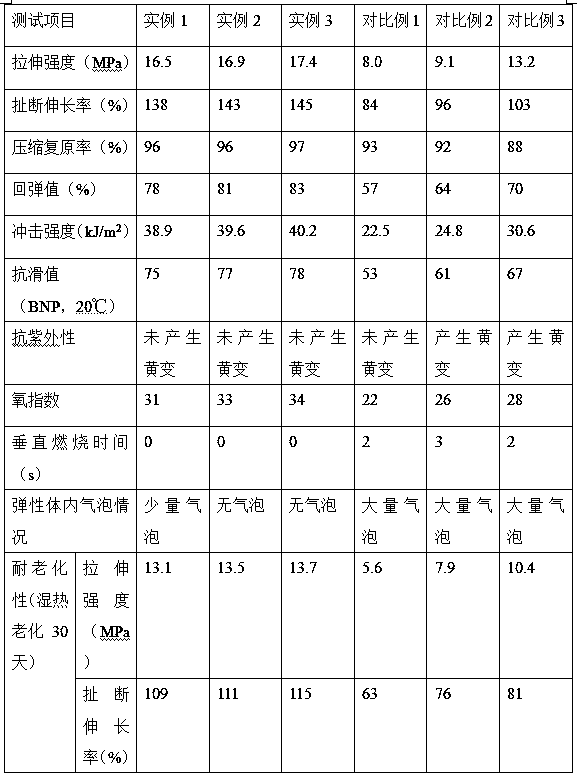

A coating method for a friction part according to the present disclosure includes the steps of: fabricating a wire comprising, by weight, 0.1% to 1.0% of La2O3 and a balance of Mo; and applying, by flame spraying, the fabricated wire to a surface of the friction part, whereby the friction part has improved wear resistance.

Owner:HYUNDAI MOTOR CO LTD +1

Preparation method of anti-aging water-permeable plastic runway

InactiveCN109988492AImprove hydrophilicitySuperhydrophilicGround pavingsRadiation-absorbing paintsPlastic materialsUltraviolet lights

The invention belongs to the technical field of plastic material preparation, and particularly relates to a preparation method of an anti-aging water-permeable plastic runway. The preparation method comprises the following steps: mixing and dispersing mixed monomers, a pre-emulsifier and water to obtain water-permeable paint; mixing isophthalic acid, neopentyl glycol and trimethylolpropane, and adding cyclohexanedicarboxylic acid, carboxylated asphalt, an anti-aging modification filler and the like to obtain anti-aging toughened polyester paint; and firstly spraying the anti-aging toughened polyester paint on a plastic runway base layer, then spraying a silicon dioxide / titanium dioxide composite hydrosol for impregnation and modification, and finally smearing the water-permeable paint to obtain the anti-aging water-permeable plastic runway. According to the invention, carboxylated asphalt and polyester resin are subjected to decarboxylation polymerization for improving the surface toughness of cured polyester resin, meanwhile, the carboxylated asphalt can serve as an electron acceptor for improving absorption of ultraviolet light by titanium dioxide, the photoinduced hydrophilicityof the whole plastic runway polyester coating can be improved through doping of silicon dioxide, water accumulation is not likely to happen, and the application prospect is wide.

Owner:常州瑞坦商贸有限公司

Mold quenching method

ActiveCN103228802BImprove surface toughnessExtend your lifeFurnace typesQuenching agentsOil coolingQuenching

A method for quenching a mold, comprising: a heating / retention step of heating the mold and retaining the mold at a temperature which is equal to or higher than an A3 transformation point and lower than 1150°C; a first cooling step of, subsequent to the heating / retention step, immersing the mold in an oil vessel to cool the mold by oil cooling until the surface of the mold has a temperature which is equal to or lower than 700°C and higher than an Ms point; an improved retention step of, subsequent to the first cooling step, pulling the mold out of the oil vessel to interrupt the oil cooling and retaining the mold until the surface of the mold has a temperature which is higher than the Ms point and at which the difference between the temperature of the surface of the mold and the temperature of the inside of the mold falls within 200°C; and a second cooling step of, subsequent to the improved retention step, cooling the mold at a cooling rate of 1-50°C / min until the surface of the mold has a temperature of 200°C.

Owner:HITACHI METALS LTD +1

PVC foamed fold-resistant board and preparation method thereof

ActiveCN109591419BImprove folding resistanceStretch lightly enhancedSynthetic resin layered productsPolymer sciencePolyvinyl chloride

The invention belongs to the technical field of polyvinyl chloride boards, and in particular relates to a PVC foamed fold-resistant board and a preparation method thereof. The PVC foam fold-resistant board includes a core layer and a skin layer. The core layer is made of foamed polyvinyl chloride material. The raw materials are PVC resin powder Ⅰ, filler Ⅰ, foam regulator, composite foaming agent, calcium zinc stabilizer, large Composed of soybean oil, lubricant and pigment; the upper skin layer and the lower skin layer have the same raw materials, and the skin layer material is composed of PVC resin powder Ⅰ, PVC resin powder Ⅱ, filler Ⅱ, processing aids, special agent for folding and toughening, and weather resistance modifier , Calcium zinc stabilizer, lubricant and pigment; special agent for folding and toughening is high molecular weight acrylate chlorinated polyethylene graft polymer. The PVC foam folding board has high strength, tensile resistance and folding resistance, the skin does not break, can be bent at a large angle, has no creases, reduces the combined interface and joint surface of the composition, is more environmentally friendly and hygienic, easy to clean, and cost-effective , The advantages of a wide range of use.

Owner:SHANDONG BODO PLASTICS CO LTD

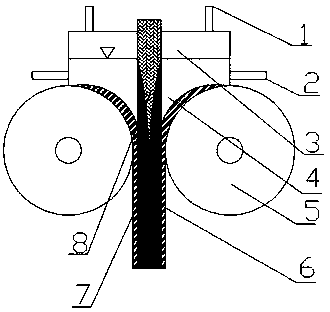

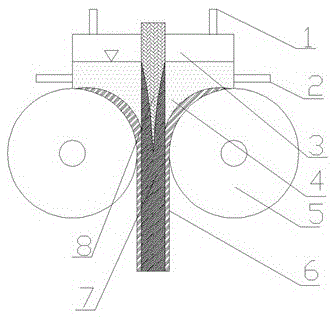

Continuous cast-rolling forming method and continuous cast-rolling forming device for bicontinuous-phase composite board

ActiveCN103894414AStrengthen and improve penetration abilityImprove surface propertiesRollsMetal rolling arrangementsHeat resistanceRoll forming

The invention provides a continuous cast-rolling forming method and a continuous cast-rolling forming device for a bicontinuous-phase composite board. The method includes that a prefabricated and formed porous ceramic board is fed into a metallic solution; the metallic solution infiltrates into porous ceramic under the action of pressure to form a bicontinuous-phase composite material; the surface of the composite material formed in the infiltration step is rolled, and a metal board layer is formed on the surface of the composite material through cooling. By the method, one-step continuous forming of the bicontinuous-phase composite material can be realized, metal phase mechanical property is improved, and wear, heat and corrosion resistance performance of the material is enhanced.

Owner:兴化市兴东铸钢有限公司

Preparation method and application of modified rubber particles, frost-resistant permeable concrete and its application, and frost-resistant permeable brick and its preparation method

ActiveCN111233381BHigh compressive strengthImprove flexural strengthSolid waste managementSingle unit pavingsCelluloseBrick

The invention provides a preparation method of modified rubber particles and an application thereof, anti-freezing pervious concrete and an application thereof as well as an anti-freezing pervious brick and a preparation method thereof, which belong to the technical field of pervious building materials. The preparation method comprises the following steps: mixing rubber particles with a surface treating agent, and carrying out surface coating treatment to obtain rubber particles with surfaces coated with the surface treating agent; wherein the surface treating agent comprises the following components in parts by weight: 15-35 parts of water glass, 2-6 parts of silicon phosphate, 50-75 parts of silica powder, 0.1-1 part of urea and 0.1-2 parts of hydroxypropyl methyl cellulose; and carryingout a curing reaction on the rubber particles coated with the surface treating agent at 40-60 DEG C for 1-3 hours to obtain the modified rubber particles. When the obtained modified rubber particlesare used for preparing the frost-resistant water-permeable concrete, the modified rubber particles are high in binding force with other components of the concrete, and the prepared frost-resistant water permeable brick is good in water permeability, high in strength and excellent in frost resistance.

Owner:JILIN UNIV

Method and device for continuous casting and rolling forming of double continuous phase composite plate

ActiveCN103894414BStrengthen and improve penetration abilityImprove surface propertiesRollsMetal rolling arrangementsHeat resistanceRoll forming

The invention provides a continuous cast-rolling forming method and a continuous cast-rolling forming device for a bicontinuous-phase composite board. The method includes that a prefabricated and formed porous ceramic board is fed into a metallic solution; the metallic solution infiltrates into porous ceramic under the action of pressure to form a bicontinuous-phase composite material; the surface of the composite material formed in the infiltration step is rolled, and a metal board layer is formed on the surface of the composite material through cooling. By the method, one-step continuous forming of the bicontinuous-phase composite material can be realized, metal phase mechanical property is improved, and wear, heat and corrosion resistance performance of the material is enhanced.

Owner:兴化市兴东铸钢有限公司

Concrete compression-resistant modifier

InactiveCN103601406AGood low temperature stabilityGuaranteed low temperature stabilityDehydroacetic acidEthylic acid

The invention discloses a concrete anti-cracking modifier, which is made by the following raw materials in parts by weight: 2.5-5 parts of periodate ligin, 1.2-1.8 parts of 4-isooctyl phenol, 1.5-2.8 parts of tributyl citrate, 0.8-1.5 parts of dehydroacetic acid, 2.3-2.8 parts of acacia gum, 5-10 parts of corn protein powder, 1.5-2.6 parts of tri-benzyl phenol polyoxyethylene ether and 0.5-1.1 parts of formaldehyde. Compared with the existing concrete modifier, the concrete anti-cracking modifier has features of high surface toughness, low brittleness and improved low-temperature stability of concrete. By adopting the anti-cracking modifier, the concrete has features of reduced thermal conductivity, reduced heat absorption value, increased thermal resistance and cold resistance, reduced temperature susceptibility and better high / low temperature stability of the asphalt concrete. The anti-cracking performance of roads of the concrete is improved, and furthermore the service life of the roads is prolonged and the maintenance cost is reduced.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com